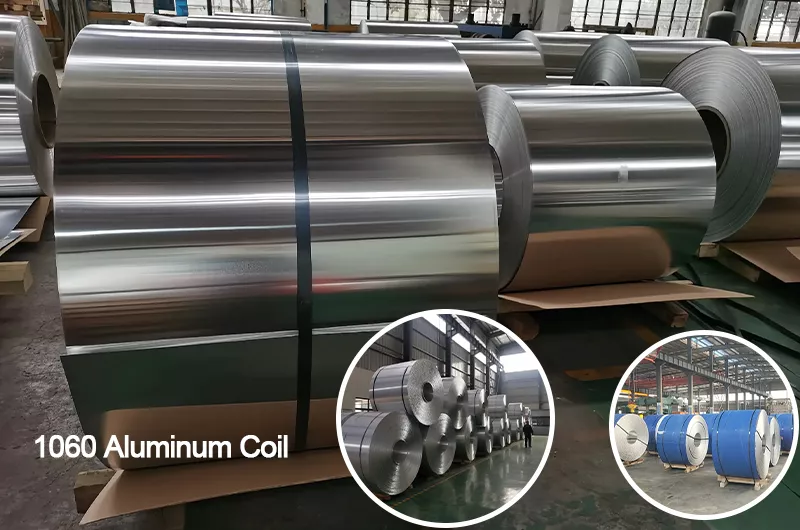

1060 Aluminum Coil

1060 aluminum belongs to the 1000 series aluminum alloys, which means it is a high-purity aluminum (≥99.6% Al). It cannot be strengthened through heat treatment and mainly relies on cold working (such as rolling) to improve its strength. Therefore, it is a typical "soft aluminum, " extremely easy to form, and possesses excellent electrical conductivity, thermal conductivity, plasticity, and elongation.

Due to its high electrical conductivity, corrosion resistance, and excellent processing performance, 1060 aluminum alloy is widely used in the electrical and chemical industries. Compared to higher-alloyed metals, 1060 aluminum alloy has relatively low mechanical strength, but its strength can be enhanced through cold working, though it still cannot be strengthened by heat treatment.

As one of the "highest purity" commonly used materials in the aluminum field, the value of 1060 aluminum coil is mainly reflected in its physical properties such as conductivity and flexibility, rather than raw strength. It is similar to 1050 aluminum alloy but has slightly higher aluminum content, thus performing better in terms of ductility, formability, and tensile strength. It is suitable for applications such as aluminum spacers, battery tabs, aluminum-plastic composite panels, lampshades, soft connections in power batteries, capacitor casings, road signs, and building walls.

With a simple production process, mature technology, and relatively low cost, 1060 aluminum coil has strong market competitiveness. Its surface is smooth, highly clean, and has excellent formability, fully meeting general processing requirements such as stamping and drawing. Overall, 1060 aluminum coil is one of the most widely used industrial aluminum materials, with main advantages including high aluminum content, good ductility, and excellent cost performance.

1060 Aluminum Coil Specifications

| Aluminum alloy | 1060 Aluminum coil |

| Temper | O, H18, H22, H24 |

| Thickness (mm) | 0.10-0.3 |

| Width (mm) | 100-2500 |

| Length (mm) | C |

| Application examples | Aluminum composite panels, oxidized lamp housing and holder, capacitor cases, etc. |

1060 Aluminum Coil Standards and Certifications

- ASTM: B209 (sheet/plate), B210 (tube), B211 (rod/wire).

- ISO: 6361 (wrought plates).

- EN: 573 (chemical composition).

Common 1060 Aluminum Coil Metal Tempers

- O

- H14

- H18

- H24

Equivalents of AA 1060

A1060 aluminum coil, 1060a aluminum coil, aa1060 aluminum coil, 1060aa aluminum coil,

Al1060 aluminum coil, a 1060 aluminum coil, aa 1060 aluminum coil, en1060 grade aluminum coil, etc

Surface Treatment of 1060 Aluminum Coil

PE pre-painted, PVDF prepainted, Embossed stucco, Color coated, etc

- 1060 Anodized Aluminum Coil Surface anodized to form a dense oxide layer, enhancing corrosion resistance, wear resistance, and decorative effect; widely used in curtain walls, roofing, appliances, and lighting.

- 1060 Coated Aluminum Coil Coated with protective paint for improved weather resistance and aesthetic appearance; commonly applied in roofing, wall cladding, billboards, and interiors.

- 1060 Laminated Aluminum Coil Surface laminated with plastic film or color film for moisture resistance, abrasion resistance, and decorative performance; suitable for packaging, appliance exteriors, and interior decoration.

- 1060 Brushed Aluminum Coil Brushed surface creates a linear texture with metallic luster; ideal for appliance panels, electronic housings, decorative trims, and furniture.

- 1060 Embossed Aluminum Coil Embossed with patterns such as diamond or five-bar for anti-slip and decorative effect; widely used in flooring, roofing, packaging, and refrigeration equipment.

- 1060 Mill Finish Aluminum Coil Supplied in natural mill finish without surface treatment; commonly used as raw material for further processing, stamping, or coating.

- 1060 Painted Aluminum Coil Painted surface provides durable protection and decorative color; used for building facades, roofing, advertising panels, and home appliances.

- 1060 Pre-Coated Aluminum Coil Pre-coated during production with strong adhesion and high durability; applied in ceilings, wall panels, roofing, and decorative cladding.

- 1060 Pre-Painted Aluminum Coil Pre-painted surface ensures uniform color and long-lasting finish; widely used in construction, windows, doors, and signage.

- 1060 PVC Coated Aluminum Coil Surface covered with PVC film for enhanced wear resistance, waterproofing, and chemical resistance; used in kitchen panels, furniture, and decorative boards.

- 1060 PE Coated Aluminum Coil Coated with polyester (PE) paint for bright colors and medium weather resistance at lower cost; ideal for interior decoration, billboards, and wall cladding.

- 1060 PVDF Coated Aluminum Coil Coated with polyvinylidene fluoride (PVDF) for superior weather resistance, UV protection, and long service life; commonly used in curtain walls, roofing, and high-end architecture.

- 1060 Stucco Embossed Aluminum Coil Stucco embossed surface provides unique decorative texture and anti-glare properties; applied in insulation, refrigeration panels, and building decoration.

- 1060 Textured Aluminum Coil Special surface textures such as grain or leather finish enhance decorative appeal and anti-slip performance; used in furniture, appliances, and interior design.

- 1060 Wood Aluminum Coil Wood grain surface finish by transfer printing or lamination, combining natural wood appearance with durability of aluminum; used for furniture, doors, windows, and decorative panels.

1060 Aluminum Coil Color Options

Color coated: red, blue, white, black, etc

Characteristics of 1060 Aluminum Coil

1060 aluminum coil, with its high purity, high ductility, excellent electrical conductivity, and corrosion resistance, is an ideal choice for industrial aluminum materials, electronic components, construction materials, and deep processing manufacturing. Its outstanding forming performance and high cost-effectiveness give it irreplaceable advantages in many application scenarios.

Excellent Corrosion Resistance

1060 aluminum coil exhibits outstanding corrosion resistance in the atmosphere, water (including salt water), and various chemical media, making it suitable for outdoor environments, chemical processing, and electrical applications.

High Electrical and Thermal Conductivity

Its electrical and thermal conductivity is close to that of copper. With the same weight, aluminum's conductivity is almost twice that of copper. This makes 1060 aluminum coil an ideal material for soft connections in power batteries, electrical components, and electronic products.

Excellent Formability

Soft in texture, extremely easy to roll, bend, deep draw, or spin, and not prone to cracking, it can meet the requirements for manufacturing complex parts and deep drawing.

High Reflectivity

1060 aluminum coil effectively reflects visible light, radiant heat, and radio waves. After anodizing or dark anodizing, it can possess both reflective and absorptive properties, making it very suitable for building curtain walls, lighting, and insulation applications.

Safe and Environmentally Friendly

Non-magnetic and non-toxic, it can be safely used in food packaging, medical devices, and electrical equipment.

Good Weldability

1060 aluminum coil can be processed using various welding methods. However, due to its soft material, slight "galling" may occur during machining, so attention is needed during mechanical cutting.

1060 Aluminum Coil Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni | Others | Al |

| 1060 | ≤ 0.25 | ≤ 0.35 | ≤ 0.05 | ≤ 0.03 | ≤ 0.03 | / | ≤ 0.05 | ≤ 0.03 | / | ≤0.05 | Remainder |

1060 Aluminum Coil Mechanical Properties

| Alloy Temper | Thickness(in.) | Tensile strength(ksi) | Yield strength(ksi) | Elongation(%) |

| 1060-O | 0.006-0.019 | 8.0-14.0 | 2.5 | Min15 |

| 1060-O | 0.020-0.050 | Min22 | ||

| 1060-O | 0.051-3.000 | Min25 | ||

| 1060-H12 | 0.017-0.050 | 11.0-16.0 | 9 | Min6 |

| 1060-H22 | 0.051-2.000 | Min12 | ||

| 1060-H14 | 0.006-0.019 | 12.0-17.0 | 10 | Min1 |

| 1060-H24 | 0.020-0.050 | Min5 | ||

| 1060-H24 | 0.051-1.000 | Min10 | ||

| 1060-H16 | 0.006-0.019 | 14.0-19.0 | 11 | Min1 |

| 1060-H26 | 0.020-0.050 | Min4 | ||

| 1060-H26 | 0.051-0.162 | Min5 | ||

| 1060-H18 | 0.006-0.019 | Min16.0 | Min12.0 | Min1 |

| 1060-H28 | 0.020-0.050 | Min3 | ||

| 1060-H28 | 0.051-0.128 | Min4 | ||

| 1060-H112 | 0.250-0.499 | Min11.0 | Min7.0 | Min10 |

| 1060-H112 | 0.500-1.000 | Min10.0 | Min5.0 | Min20 |

| 1060-H112 | 1.001-3.000 | Min9.0 | Min4.0 | Min25 |

1060 Aluminum Coil Physical Properties

- Electrical Conductivity: Equivalent to 55% of copper, very suitable for manufacturing electrical components.

- Thermal Conductivity: Efficient heat transfer, suitable for heat exchangers and radiators.

- Corrosion Resistance: Excellent resistance to atmospheric and chemical corrosion.

- Low Mechanical Strength: Not heat-treatable, but can be strengthened by cold working (e.g., H12, H14, H18 temper).

- Formability: Good plasticity, suitable for stamping, drawing, and deep drawing.

1060 Aluminum Coil Applications

1060 aluminum coil has good ductility, formability and high tensile strength, making it widely used in power batteries, aluminum-plastic panels, lamps, capacitor housings, road signs, building walls, aluminum spacers, battery busbars, aluminum composite panels, lampshades and brackets, exterior walls, etc.

Hot-rolled 1060 aluminum coil uses battery soft connections, aluminum-plastic panels, road signs, lamps, capacitor housings, building curtain walls, etc.

1060 aluminum coil can also be used for aluminum busbars, car radiators, new energy vehicle charging piles, molds, etc.

| Application Field | Specific Use |

| Construction Field | Exterior walls, signage, roof insulation, cladding, curtain walls, etc., improving building energy efficiency |

| Orange peel aluminum coil (with anti-slip texture) used for stair treads, decorative panels | |

| Industrial Field | High-efficiency heat dissipation components such as heat exchangers and transformer windings |

| Insulation of pipes and equipment, reducing heat energy loss | |

| Chemical instruments, heat sinks, heat exchanger manufacturing | |

| Electrical and Chemical Industries | Used in applications requiring high conductivity and corrosion resistance |

| Electrical wires, circuit boards, transformer coils, and other components | |

| Consumer Goods Industry | Manufacturing of kitchenware and electronic device components |

| Used in kitchen utensils, reflectors, decorative panels, etc. | |

| Daily Life Field | Food packaging, kitchenware, decorations, and other daily necessities |

| Automotive body insulation, engine heat shielding, improving fuel economy | |

| Special Scenarios | Insulation layers in refrigeration equipment, ensuring stability in low-temperature environments |

1060 Insulation Aluminum Coil

The 1060 aluminum coil is used for insulation and soundproofing in various industries. Its high thermal conductivity makes it an ideal choice for insulation purposes.

Reason for Choice: 1060 aluminum has good thermal conductivity, making it highly effective in insulation applications. Its excellent corrosion resistance and formability also contribute to the manufacture of insulation materials.

1060 Transformer Aluminum Coil

Due to its good electrical conductivity and ability to handle high currents, the 1060 aluminum coil can be used for transformer windings and other electrical components.

Reason for Choice: This alloy has good electrical conductivity, which is crucial for transformer windings and other electrical components. Its high purity and low resistance ensure efficient performance in electrical applications.

1060 Battery Soft Connection Aluminum Coil

Due to its flexibility and excellent electrical conductivity, it can be used for connecting terminals in batteries (especially lithium batteries).

Reason for Choice: The flexibility and high conductivity of 1060 aluminum make it an ideal choice for battery soft connections. It can withstand repeated bending while maintaining good electrical performance.

1060 Lighting Fixture Aluminum Coil

The 1060 aluminum coil is used in lighting fixtures due to its reflective properties and lightweight characteristics.

Reason for Choice: The reflective properties of 1060 aluminum enhance the light distribution and efficiency of lighting fixtures. Its lightweight and corrosion-resistant features make it suitable for various lighting applications.

1060 Signage Aluminum Coil

Due to its durability, corrosion resistance, and ability to retain paint and other finishes, it is used for signage.

Reason for Choice: 1060 aluminum has excellent surface finish, weather resistance, and ease of manufacturing, making it an ideal choice for signage. It retains paint and other finishes well, maintaining the appearance of signs over time.

1060 Automotive Heat Insulation Plate Aluminum Coil

Due to its thermal conductivity and lightweight properties, it can be used for heat shields and insulation in automotive applications.

Reason for Choice: In automotive applications, 1060 aluminum is chosen for its thermal conductivity and lightweight characteristics. It provides effective insulation while being easy to form and install.

1060 Radiator Aluminum Coil

The 1060 aluminum coil is used in cooling systems for radiators due to its excellent thermal conductivity and effective heat dissipation capabilities.

Reason for Choice: 1060 aluminum is favored for radiators because of its high thermal conductivity, which helps with effective heat dissipation. It can be formed into thin and efficient fins, enhancing the radiator's performance.

1060 Lithium Battery Soft Connection Aluminum Coil

Similar to the previously mentioned battery soft connections, it is specifically used for lithium battery connections, featuring flexibility and conductivity.

Reason for Choice: Like other battery connections, 1060 aluminum is used for its flexibility, good conductivity, and ability to handle repeated stress. Its properties ensure reliable performance in lithium battery applications.

More Informations about Aluminum Coil 1060 Application

- Lighting, printing, packaging, decoration, electronic surface, hot-rolled thick plate, PS substrate, aluminum-plastic substrate, aluminum curtain wall substrate, aluminum-plastic board substrate, aluminum spacer, aluminum embossed plate

- Indoor: wall decoration, ceiling, room, kitchen and balcony, shutters, doors, curtain wall

- Outdoor: wall covering, exterior wall, roof, awning, tunnel, column cover, renovation

- Advertising: display stand, signboard, signboard, storefront

Advantages and Limitations of 1060 Aluminum Coil

Advantages: excellent plasticity, corrosion resistance, electrical and thermal conductivity, easy processing (stamping, drawing), mature technology, and economical price.

Limitations: low strength, cannot be strengthened by heat treatment, and average machinability.

Advantages of 1060 Aluminum Coil

- High cost-effectiveness compared to alloyed aluminum

- Good processing performance and strong ductility

- Corrosion resistant

- Lightweight and durable

Limitations of 1060 Aluminum Coil

- Lower strength compared to alloy series (not suitable for applications requiring high mechanical strength)

- Easily scratched or dented if not surface-treated

Comparison of 1060 Aluminum Coil with Similar Alloys

- Compared to 1050: Slightly higher aluminum content (99.6% vs. 99.5%), better conductivity.

- Compared to 3003: Lower strength, but better formability and corrosion resistance.

| Comparison Target | Comparison Dimension | Description |

| 1050 Aluminum | Aluminum Content | 1060 aluminum has a higher aluminum content, reaching 99.6%, slightly higher than the 99.5% of 1050 aluminum. This small compositional difference gives 1060 aluminum slightly better electrical conductivity, making it particularly suitable for electrical and conductor fields requiring high conductivity. |

| Electrical Conductivity | Due to its higher purity, 1060 aluminum slightly outperforms in conductivity. Its excellent conductivity gives it an advantage in cable sheaths, wires, electrical busbars, etc. Although both alloys have similar mechanical properties, 1060 aluminum is more suitable in environments requiring high conductivity and corrosion resistance. | |

| 3003 Aluminum | Strength | 1060 aluminum is weaker than 3003 aluminum, which contains manganese. 3003 belongs to the aluminum-manganese alloy series and has higher mechanical strength, suitable for structural parts with certain load-bearing requirements. In contrast, 1060 aluminum is more suitable for light-load structures and non-load-bearing components. |

| Formability | 1060 aluminum has excellent ductility and flexibility, and better formability than 3003 aluminum. Its high purity provides good plasticity, making it highly suitable for deep drawing, spinning, bending, and other processes, performing better in complex shape processing. | |

| Corrosion Resistance | 1060 aluminum exhibits excellent oxidation resistance and corrosion resistance at normal temperature and in general environments. Compared to 3003 aluminum, which contains other alloy elements, 1060 aluminum has more stable chemical corrosion resistance, especially in humid or mildly acidic environments. It is suitable for use in decorative panels, signs, reflectors, and other applications requiring high surface stability. |

1060 aluminum coil is a fundamental material in industries emphasizing conductivity, formability, and corrosion resistance. It adapts to various temper states and applications, and its cost-effectiveness makes it a preferred choice for manufacturers worldwide.

1060 Aluminum Coil Production Process

- Processing Flow: Raw material refining → smelting and casting → hot rolling → cold rolling → stretching and leveling → surface treatment.

- Annealing Process: Includes rapid annealing (350~410℃), high-temperature annealing (350~500℃), and low-temperature annealing (150~250℃) to optimize material properties.

1060 aluminum coil combines high purity, excellent formability, and outstanding corrosion resistance, making it a widely used material suitable for a broad range of applications across industries.

Is 1060 Aluminum Coil Suitable for Your Project?

When selecting aluminum materials, balancing performance and cost is crucial. Haomei Aluminum's 1060 aluminum coil is known for its high purity, high conductivity, and excellent ductility, making it an ideal choice for projects requiring economical and easily formable materials. Whether for stamping, bending, or deep processing, 1060 aluminum coil can easily handle the tasks while maintaining stable quality and excellent surface flatness.

If your project requires higher tensile strength or hardness, we recommend considering our 3000 series (manganese alloy) or 5000 series (magnesium alloy) to meet more demanding mechanical performance requirements. Haomei Aluminum always provides comprehensive aluminum solutions, ensuring each project uses the most suitable material.

1060 Aluminum Coil Purchasing and Application Recommendations

When purchasing and using 1060 aluminum coil, Haomei Aluminum recommends referring to the following points to ensure material performance matches project requirements:

State Selection

For deep drawing or complex forming, it is recommended to choose O temper soft aluminum coil;

For general stamping processing, H22 or H24 temper can be selected to balance strength and ductility.

Surface Requirements

For mirror or anodized applications, high-cleanliness aluminum coil is required to ensure no roll marks or scratches on the surface;

Haomei Aluminum can provide finely processed aluminum coils to meet different processing needs.

Standards and Specifications

Our 1060 aluminum coil strictly complies with GB/T 3880 and ASTM B209, ensuring stable and reliable material quality.

Application Notes

- 1060 aluminum coil is suitable for general stamping, bending, and deep processing applications, but not suitable for conditions requiring high load-bearing or strong impact resistance.

- If a project requires higher strength or corrosion resistance, alloys such as 3003 (rust-resistant aluminum) or 5052 can be selected to meet more stringent conditions.

Clarify Purchasing Requirements

- Before placing an order, clarify the aluminum coil thickness, temper (O or H18), and surface treatment (whether coating, embossing, etc.) according to project usage;

- Pay attention to the minimum order quantity. Haomei Aluminum usually requires a minimum order of 3 tons to ensure reasonable procurement planning.

Haomei Aluminum is committed to providing customers with high-quality aluminum coils and professional solutions, ensuring that every 1060 aluminum coil meets your actual application requirements.

1060 Aluminum Coil Related Questions

| Question | Answer |

| What is 1060 Aluminum equivalent to? | 1060 Aluminum is equivalent to ISO Al99.6 and UNS A91060. |

| What is the strength of aluminum 1060? | The tensile strength of Aluminum 1060 typically ranges between 70 to 130 MPa. |

| What is the difference between Aluminum 1050 and 1060? | The difference between Aluminum 1050 and 1060 is the aluminum content, with 1050 containing at least 99.50% aluminum and 1060 containing at least 99.60% aluminum. |

| What is the difference between 1060 and 6061 aluminum? | The difference between 1060 and 6061 aluminum is that 1060 is a high-purity aluminum with excellent corrosion resistance and workability, while 6061 is an alloy with added silicon and magnesium, offering higher strength and better machinability. |

Explore Different Aluminum Coil Grades

Further reading

- 1060 Aluminum Plate Sheet

- 1060 h12 aluminum sheet plate

- 1060 h24 aluminum sheet plate

- 1060 Aluminum Disc Circle

- 1060-O Aluminum

- 1060-H14 Aluminum

- 1060-H16 Aluminum

- 1060-H18 Aluminum

- 1060 H22 Aluminum

- 1060 H26 Aluminum

- 1060 H28 Aluminum

- 1060 Aluminum Strip

- 1060 Aluminum Foil

Users viewing this material also viewed the following

- 1060 Aluminum Sheet Coil for Pipeline Insulation

- 1060 O Aluminium Strips for Transformers Winding

- 1060 Aluminum Mirror Sheet Coil

- 1060 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1060 Aluminum Plate for Curtain Wall Panel

- 1060 Aluminum Plate for Stamping Parts

- 1060 Aluminum Plate for Automotive Parts

- 1060 H24 Stamping Aluminum Plate for Aluminum Bottle Cap

- 5 Bar 1060 Aluminum Checker Plate

- 1060 Decorative Aluminum Plate

- 1060 Aluminum Tread Plate for Carriage Floor

- 1060 Hot-rolled Aluminum Plate for Lamps

- 1060 Aluminum Circle Disc for Kitchenware

- 1060 O Aluminum Coil Strip for Mask Nose Clip

- 1060 Aluminum Strip for Vial Seals

- 1060 Embossed Aluminum Sheet for Automotive Heat Shields

- 1060 Aluminum Plate Strips for Capacitor Shells – High Purity & Durable

- 1060 Aluminum Plate for Outdoor Billboard

- 1060 Aluminum Plate for Printed Circuit Board (PCB) Substrates

- 1060 Aluminum Plate for Aluminum-based Copper-clad Plate

Recommended Content

- Key Differences Between 1050 and 1060 Aluminum What You Need to Know

- 1060-O Aluminum vs. 1100-H14 Aluminum: A Comparative Analysis

- 1060 Aluminum vs. 1100-H14 Aluminum: Key Differences

- Performance Comparison: 1060-H16 Aluminum vs. 1060-H24 Aluminum

- Differences Between 1060-H22 Aluminum and 1070-H22 Aluminum

- Comparison of 1060-H28 Aluminum vs. 1100-H28 Aluminum