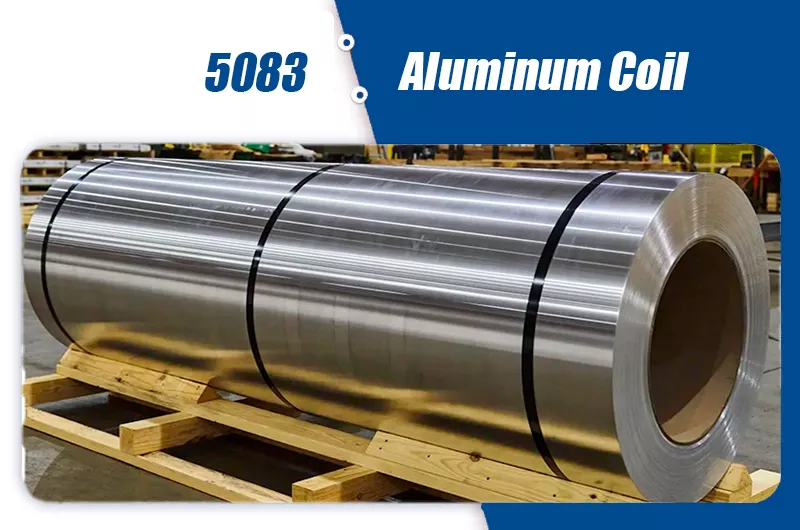

5083 Aluminum Coil

5083 aluminum coil is an aluminum–magnesium alloy material with magnesium (Mg) as the primary alloying element. It combines relatively high strength, excellent corrosion resistance, and good weldability, playing an important and irreplaceable role in fields such as shipbuilding and transportation.

As a non-heat-treatable aluminum alloy, 5083 aluminum coil cannot achieve strength enhancement through heat treatment. However, it inherently possesses medium-to-high strength and outstanding ductility, enabling it to meet the requirements of a wide range of demanding industrial applications.

Owing to its exceptional corrosion resistance, 5083 aluminum coil is particularly suitable for use in complex and harsh environments, and is widely applied in the manufacture of critical components in industries such as shipbuilding and automotive manufacturing. This alloy features low density and high tensile strength, which helps achieve structural lightweighting while ensuring excellent durability. In addition, 5083 aluminum coil exhibits good adaptability to various metal processing methods and welding processes, making subsequent fabrication and forming more convenient.

Compared with 5052 aluminum alloy, 5083 aluminum alloy offers superior strength and thermal conductivity, and can be strengthened through cold working, making it especially suitable for applications with high requirements for weldability. At the same time, it maintains stable mechanical properties even in low-temperature environments, and is therefore commonly used in dump truck bodies, ship structural components, and pressure vessels.

Technical Parameters of 5083 Aluminum Coil

| Feature | Detailed Description |

| Alloy Series | Al-Mg-Si series |

| Core Characteristics | High strength (excellent among non-heat-treatable alloys), outstanding corrosion resistance (especially against marine environments), excellent weldability, good cold workability, medium strength |

| Common Tempers | O, H111, H112, H116, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H321, etc. |

| Typical Applications | Shipbuilding (ship plates, decks), marine equipment, pressure vessels (tankers, refrigerated boxes), transportation (automobiles, subway/light rail), aerospace welded parts, missile components, armor, etc. |

| Thickness | 0.15mm - 8mm (common range) |

| Width | 100mm - 2650mm (common range) |

| Length | Customizable coil (C) or specific lengths |

Common 5083 Aluminum Coil Tempers

5083 H32 Aluminum Coil

- Features: Strain-hardened and partially annealed; excellent corrosion resistance, especially in marine environments; good weldability and moderate strength.

- Applications: Ideal for shipbuilding, marine structures, pressure vessels, fuel tanks, and chemical containers.

- Advantages: Combines durability and formability; resistant to seawater corrosion; suitable for structural applications requiring moderate strength.

5083 H111 Aluminum Coil

- Features: Slightly strain-hardened from annealed state; excellent corrosion resistance; maintains good mechanical properties after welding.

- Applications: Used in ship hulls, railway cars, cryogenic tanks, and chemical equipment.

- Advantages: Provides a balance between strength and ductility; good corrosion resistance in marine and chemical environments; easy to form and fabricate.

5083 O Aluminum Coil

- Features: Fully annealed (soft) temper; excellent corrosion resistance; high ductility; easy to form and shape.

- Applications: Suitable for marine applications, tanks, roofing, siding, and decorative architectural panels.

- Advantages: Maximum formability and workability; highly resistant to seawater corrosion; ideal for applications requiring bending, drawing, or shaping.

Types of 5083 Aluminum Coil and Surface Options

Surface treated through anodization to enhance corrosion resistance, wear resistance, and surface hardness; ideal for marine structures, architectural panels, and outdoor applications requiring long-term durability and aesthetic finish.

5083 Color Coated Aluminum Coil

Coated with a decorative color layer, combining corrosion protection with vibrant aesthetics; suitable for building facades, decorative panels, signage, and indoor/outdoor architectural applications.

5083 Mirror Aluminum Coil

Highly polished to a mirror finish for reflective surfaces; widely used in interior decoration, signage, elevators, and decorative facades where aesthetics are critical.

5083 Brushed Aluminum Coil

Brushed texture enhances visual appeal and wear resistance; perfect for kitchen appliances, elevator panels, furniture, and architectural decorative elements.

Embossed surface adds texture and strength, reducing glare and improving rigidity; suitable for interior decoration, ceilings, walls, and protective panels.

5083 Corrugated Aluminum Coil

Corrugated pattern increases structural strength and rigidity; commonly applied in roofing, siding, industrial sheds, and temporary structures.

5083 Coated Aluminum Coil

General coated surface provides additional protection against corrosion and wear; widely used in construction, transportation, and decorative applications.

5083 Laminated Aluminum Coil

Laminated with plastic, paper, or color film for moisture resistance, durability, and decorative effect; commonly used in packaging, appliance exteriors, and interior building materials.

5083 Mill Finish Aluminum Coil

Standard uncoated surface with natural aluminum finish; suitable for general fabrication, industrial applications, and further surface treatment or coating.

5083 Painted Aluminum Coil

Pre-painted with protective and decorative coating; ideal for architectural panels, transportation vehicles, signage, and decorative projects requiring aesthetic surfaces.

5083 Pre-Coated Aluminum Coil

Surface pre-coated with corrosion-resistant paint; ready-to-use for roofing, siding, cladding, and industrial applications.

5083 Pre-Painted Aluminum Coil

Pre-applied durable paint layer for both aesthetic and protective purposes; commonly used in construction, decoration, and industrial equipment.

5083 PVC Coated Aluminum Coil

Surface laminated with PVC film for excellent moisture resistance, scratch protection, and durability; used in roofing, cladding, and appliance protection.

5083 PVDF Coated Aluminum Coil

Coated with PVDF for superior UV, weather, and corrosion resistance; ideal for exterior facades, architectural panels, and high-performance decorative applications.

5083 PE Coated Aluminum Coil

Polyester coated for corrosion resistance and vibrant color retention; widely applied in decorative panels, signage, and building exteriors.

5083 Stucco Embossed Aluminum Coil

Stucco pattern embossing enhances rigidity, hides scratches, and improves aesthetics; ideal for roofing, siding, ceilings, and decorative construction applications.

5083 Textured Aluminum Coil

Textured surface increases slip resistance, hides scratches, and enhances decorative appeal; used in interior/exterior panels, furniture, and industrial protective coverings.

5083 Wood Aluminum Coil

Wood-grain textured aluminum provides natural wood appearance with aluminum durability; suitable for exterior and interior decoration, doors, windows, and wall panels.

5083 Perforated Aluminum Coil

Perforated surface allows ventilation, sound absorption, and aesthetic design; widely used in ceilings, facades, partitions, and acoustic panels.

5083 Checkered Aluminum Coil

Raised checkered pattern enhances slip resistance and structural strength; commonly applied in flooring, stair treads, ramps, and vehicle platforms.

5083 Ultra-wide Aluminum Coil

Extra-wide aluminum coil suitable for large-scale fabrication and industrial applications; reduces welding seams, ideal for shipbuilding, aerospace, and construction panels.

5083 Aluminum Coil Color Options

5083 Aluminum Coil for Sale

| Product | Thickness (mm) | Width (mm) | Inner Dia. (mm) | Unit Weight (MT) |

| 5083 O Aluminum Coil | 1 | 1000 | 508 | 2.5 |

| 5083 O Aluminum Coil | 1.2 | 1220 | 508 | 2.8 |

| 5083 O Aluminum Coil | 1.5 | 1250 | 508 | 3 |

| 5083 H111 Aluminum Coil | 1.8 | 1250 | 508 | 3.5 |

| 5083 H111 Aluminum Coil | 2 | 1500 | 508 | 4 |

| 5083 H32 Aluminum Coil | 2.5 | 1500 | 508 | 4.8 |

| 5083 H32 Aluminum Coil | 3 | 1500 | 508 | 5.5 |

| 5083 H116 Aluminum Coil | 3 | 2000 | 610 | 6 |

| 5083 H116 Aluminum Coil | 3.5 | 2000 | 610 | 6.8 |

| 5083 H321 Aluminum Coil | 4 | 2000 | 610 | 7.5 |

| 5083 H321 Aluminum Coil | 4.5 | 2000 | 610 | 8 |

| 5083 H321 Aluminum Coil | 5 | 2000 | 610 | 8.5 |

| 5083 H321 Aluminum Coil | 6 | 2000 | 610 | 9.5 |

| 5083 H321 Aluminum Coil | 8 | 2200 | 610 | 11 |

| 5083 H321 Aluminum Coil | 10 | 2200 | 610 | 13 |

Performance Characteristics of 5083 Aluminum Coil

- Excellent Corrosion Resistance These coils have outstanding corrosion resistance, ensuring robust performance under various conditions.

- High Strength The high-strength aluminum used in these coils ensures excellent mechanical performance.

- High Fatigue Strength Our 5083 aluminum coils feature high fatigue strength, suitable for applications requiring repeated loading.

5083 Aluminum Coil Chemical Properties

| SI | CU | FE | MG | MN | TI | ZI | Other |

| 0.40% | 0.10% | 0.40% | 4.0-4.9% | 0.40-1.0% | 0.15% | 0.25% | 0.05-0.10% |

5083 Aluminum Coil Applications

The numerous advantages of 5083 aluminum coil make it an excellent choice for industries such as shipbuilding, automotive, and armor. Specific industrial applications include:

- Shipbuilding

- Rail Vehicles

- Pressure Vessels

- Automotive Body

- Mining Equipment

- Storage Tanks

- Bulletproof Armor

| Application Area | Specific Components | Core Advantages |

| Shipbuilding | Hull sides, bottom plates, decks, etc. | Resistant to seawater corrosion, reduces vessel weight (up to over 20%), provides classification society certification (e.g., CCS China, SGS Switzerland) |

| Transportation | Automotive body panels, subway/light rail vehicles, tanker trucks, refrigerated vehicle bodies | Excellent weldability, lightweight and energy-saving, corrosion resistance, good low-temperature performance |

| Aerospace | Aircraft fuel tanks, fuel pipes, welded structural parts (e.g., aircraft panel weldments) | Medium strength, excellent weldability and fatigue resistance |

| Pressure Vessels & Special Equipment | Refrigerated containers, refrigeration units, drilling equipment, TV towers, missile parts, armor | Meets strict fire-resistant pressure vessel requirements, high safety, corrosion resistant |

| Other Industrial Fields | Chemical tanks, curtain wall materials, instrument brackets, electrical housings | Surface can be anodized for aesthetic appearance, good formability, high corrosion resistance |

Shipbuilding

- Hull Structure: Hull plates, decks, bulkheads, etc., with excellent seawater corrosion resistance and fatigue performance.

- Special Ships: Low-temperature storage tanks for LNG carriers (stable performance at -163℃).

- Certification Requirements: Must pass ABS, DNV GL, and other classification society certifications. For example, Baowu Aluminum's 5083-O/H111 plates have obtained ABS certification.

Automotive & Rail Transportation

- Body Components: Truck frames, tanker truck bodies (corrosion resistance superior to carbon steel).

- Lightweight Design: Fuel tanks, crash beams, reducing weight while improving fuel efficiency.

Chemical & Pressure Vessels

- Tanks & Pipelines: Used for storing corrosive liquids (e.g., chemicals, seawater), excellent weldability reduces leakage risk.

- Industry Standards: Must comply with ASTM B209 (Aluminum and Aluminum Alloy Sheet & Plate) and ASME BPVC (Pressure Vessel Standards).

Construction & Infrastructure

- Curtain Walls & Roofs: Strong weather resistance, can be anodized or painted to enhance aesthetics and durability.

- Offshore Platforms: Corrosion-resistant enclosure systems, long-term resistance to sea wind and salt spray.

5083 Aluminum Coil Selection and Usage Recommendations

When selecting and using 5083 aluminum coil, there are several points that need special attention:

Clarify Requirements: First, be clear about your product’s requirements for strength, corrosion resistance, forming methods (stamping, bending, stretching, etc.), and whether welding will be involved. Based on these factors, choose the most suitable alloy temper (e.g., O temper for deep drawing, H32/H34 temper for higher strength).

Pay Attention to Corrosion Resistance: Although 5083 offers excellent corrosion resistance, in harsh environments (e.g., high temperature and humidity, strong acidic or alkaline conditions) or when connected with other metals (especially copper, steel, etc.), additional protective measures such as coatings or insulation should be considered to prevent galvanic corrosion.

Key Processing Points:

- Welding: 5083 has excellent weldability and is suitable for various welding methods including arc welding. It is recommended to use 5-series aluminum welding wire (e.g., 5356).

- Forming: O temper materials have good plasticity, suitable for deep drawing and other severe forming processes; H temper materials require attention to work hardening tendencies and may need intermediate annealing steps.

- Supplier Qualification: For products used in critical fields such as shipbuilding and pressure vessels, always choose reliable suppliers who can provide classification society certifications (e.g., CCS, GL, DNV) or relevant industry certifications, and request material certificates.

Comparison of 5083 with Other Alloys

| Alloy | Main Advantages | Typical Applications | 5083 Differentiating Features |

| 5052 | Medium strength, lower cost | General containers, automotive parts | Higher magnesium content, superior corrosion resistance and strength |

| 6061 | Heat-treatable, higher strength | Mechanical parts, aerospace | Better corrosion resistance and low-temperature performance |

| 304 Stainless Steel | High strength, excellent corrosion resistance | Chemical equipment, construction | Only 1/3 the density of steel, significant weight reduction |

5083 Aluminum Coil Advantages and Disadvantages

| Feature Dimension | Advantages | Disadvantages |

| Corrosion Resistance | Excellent, especially resistant to seawater and industrial chemical corrosion, highly suitable for marine environments. | — |

| Weldability | Excellent weldability, stable welded joint performance. | — |

| Strength & Weight | Medium strength, low density (~2.66g/cm³), clear lightweight advantage. | Compared to 2xxx or 7xxx ultra-hard aluminum alloys, absolute strength is lower and not suitable for ultra-high strength applications. |

| Processing Performance | Good cold forming ability (e.g., bending), fatigue resistance. | Cannot be strengthened by heat treatment; work hardening is the main strengthening method. Bending performance is limited, especially in H112 temper which is prone to cracking, requiring large bending radii or annealing to O temper. |

| Other Properties | Good electrical and thermal conductivity, fire-resistant, environmentally friendly and recyclable. | Compared with pure aluminum or some other alloys, the price may be higher. High magnesium content under long-term high-temperature conditions (e.g., >65℃) may cause sensitization (β-phase precipitation), potentially reducing stress corrosion cracking resistance (careful selection of grade and control of usage conditions is required). |

5083 Aluminum Coil Frequently Asked Questions

5083 aluminum coil tends to crack during bending. How can this be avoided?

5083 aluminum sheet (especially in H112 temper) has a high magnesium content and relatively high hardness, which makes it prone to cracking during bending. Preventive measures include:

- Choose the appropriate temper: Prefer O temper (annealed state) materials, which have better plasticity and are easier to bend.

- Increase the bending radius: The larger the bending radius, the higher the success rate. Avoid sharp bends or 90-degree right-angle bends.

- Pay attention to bending direction: The bending direction should be perpendicular to the rolling direction of the aluminum sheet, not parallel, to reduce cracking risk.

- Arrange subsequent processes: If the product requires brushing or surface finishing, it is best to bend first and then perform the finishing process, otherwise the risk of cracking increases.

In what corrosive environments can 5083 aluminum coil be used?

5083 aluminum coil has excellent corrosion resistance and is especially suitable for:

- Marine atmosphere and seawater environments: Its seawater corrosion resistance makes it a common material for shipbuilding and offshore facilities.

- Certain chemical environments: Can resist corrosion from a variety of chemicals.

- However, for strongly acidic or strongly alkaline specific chemical media, suitability must be verified case by case, or additional protective measures should be taken.

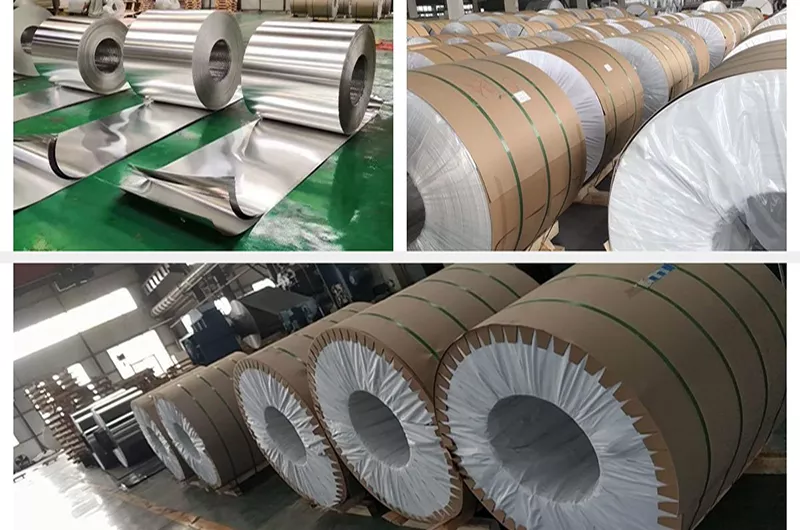

What should be noted during transportation and storage of 5083 aluminum coil?

Proper transportation and storage are critical for maintaining the quality of aluminum coils:

- Moisture-proof sealing: Aluminum coils should be wrapped with plastic sheets and sealed with transparent tape to prevent moisture ingress that could cause corrosion or discoloration (white spots).

- Secure packaging: Outer packaging should use thick cardboard, tightly packed. If possible, add a layer of kraft paper between the plastic sheet and cardboard for extra protection. Finally, place on a wooden pallet and reinforce with steel straps.

- Prevent collision: During transportation, coils should be secured to avoid severe impacts or jolts that could deform the coil or damage the surface.

- Storage environment: Store in a dry, ventilated, and clean warehouse. Avoid storing with chemicals or moist items.

What are the main differences between 5083 and 5052 aluminum coils?

Both are aluminum-magnesium alloys (5-series), but differ in composition and performance:

- Magnesium content: 5083 has a higher magnesium content than 5052. Generally, higher magnesium content leads to higher strength.

- Strength: 5083 has higher tensile and yield strength than 5052.

- Application focus: 5052 emphasizes good formability, fatigue strength, and moderate corrosion resistance, used for instruments, enclosures, sheet metal parts, etc. 5083 focuses on higher strength, excellent corrosion resistance (especially maritime), and weldability, used in shipbuilding, pressure vessels, and other demanding fields.

| Comparison Item | 5083 Aluminum Coil | 5052 Aluminum Coil |

| Magnesium Content | 4.0%-4.9% | 1.9%-2.5% |

| Tensile Strength | 270-350MPa | 170-230MPa |

| Corrosion Resistance | Excellent (seawater resistant) | Good (freshwater, atmospheric) |

| Cost | Higher | Lower |

| Formability | Moderate (thick plate forming may require heating) | Excellent (thin plate easy to bend and stamp) |

| Suitable Scenarios | Marine, low-temperature, load-bearing structures | Appliance housings, decorative parts, lightweight thin structures |

Selection Recommendation: For seawater resistance, load-bearing, or low-temperature environments, choose 5083; for appliances, decorative, lightweight parts with budget constraints, choose 5052.

Explore Different Aluminum Coil Grades

Further reading

- 5083 Aluminum Plate Sheet

- 5083 h321 aluminum plate sheet

- 5083 h116 aluminum plate sheet

- 5083 h111 aluminum plate sheet

- 5083 h112 aluminum plate sheet

- 5083 h22 aluminum plate sheet

- 5083 h34 aluminum plate sheet

- 5083 o aluminum plate sheet

- 5083 H131 Aluminum Plate

Users viewing this material also viewed the following