3003-H14 aluminum alloy is one of the most widely used general-purpose aluminum materials in the industrial field, often regarded as the "mainstay material" of the 3xxx series. This alloy is based on commercial pure aluminum with an appropriate amount of manganese added to form a typical Al-Mn series corrosion-resistant aluminum alloy, which increases the strength by about 20% compared with the 1000 series pure aluminum while maintaining good plasticity and workability, achieving an excellent balance between performance and cost.

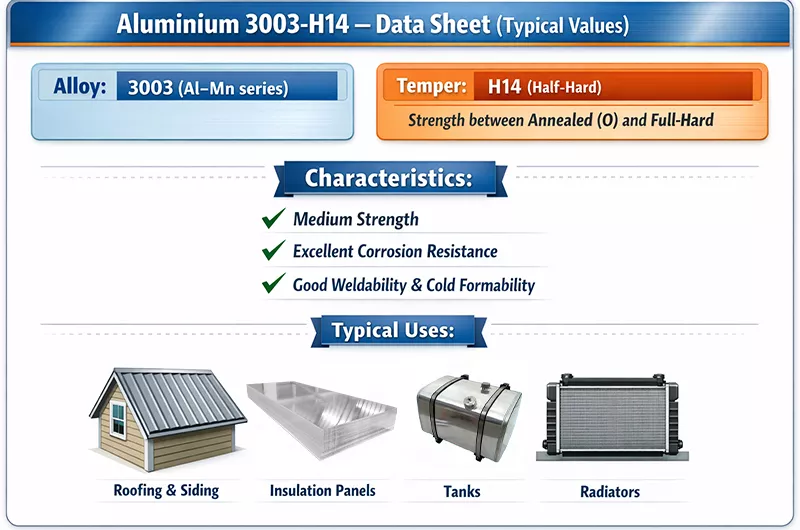

- Alloy: 3003 (Al–Mn series alloy)

- Temper: H14 (strain-hardened half-hard) — strength lies between annealed (O) and full-hard tempers.

- Characteristics: medium strength, excellent corrosion resistance, good weldability, and cold formability.

- Typical applications: roofing, siding, insulation panels, tanks, radiators, etc.

As a non-heat-treatable aluminum alloy, the mechanical properties of 3003 are primarily enhanced through cold working. The H14 temper indicates that the material has reached a half-hard state through strain hardening (work hardening), typically corresponding to about 20%–30% cold rolling deformation without further annealing. This temper achieves a balance between strength, rigidity, and formability, making the material capable of higher load-bearing while maintaining excellent formability, weldability, and corrosion resistance.

Thanks to these characteristics, 3003 H14 aluminum alloy is widely used in architectural decoration, equipment manufacturing, packaging containers, and general structural components, making it a standardized engineering material that combines reliability and cost-effectiveness.

Aluminium 3003 H14 Mechanical Properties

| Property | Value |

| Temper Condition | Work-hardened (H14) |

| Tensile Strength | 140 – 180 MPa |

| Proof Stress | ≥ 50 MPa |

| Elongation (at 50 mm) | ≥ 5 % |

| Hardness (Brinell) | 28 HB |

Aluminium 3003 H14 Physical Properties

| Property | Value |

| Density | 2.73 g/cm³ |

| Melting Point | 655 °C |

| Thermal Expansion | 23.1 × 10⁻⁶ /K |

| Modulus of Elasticity | 69.5 GPa |

| Thermal Conductivity | 190 W/m·K |

| Electrical Resistivity | 0.034 × 10⁻⁶ Ω·m |

3003 H14 Aluminium Chemical Composition

The addition of Manganese is the defining characteristic of this alloy.

| Element | Content (%) |

| Aluminum (Al) | 96.8 - 99.0% |

| Manganese (Mn) | 1.0 - 1.5% |

| Copper (Cu) | 0.05 - 0.20% |

| Iron (Fe) | 0.7% Max |

| Silicon (Si) | 0.6% Max |

| Zinc (Zn) | 0.1% Max |

Product Forms Available for 3003-H14 Aluminum

| Product form | Description | Typical thickness range | Common applications |

| Sheet | Flat-rolled product cut to size | ~0.2 – 6 mm | Roofing panels, cladding, appliances, tanks |

| Coil | Continuous rolled strip wound in coils | ~0.2 – 6 mm | Roll forming, stamping, HVAC parts |

| Plate | Thick flat product | > 6 mm | Structural components, tooling bases |

| Foil | Very thin rolled material | ~0.006 – 0.2 mm | Packaging, insulation, heat exchangers |

3003 H14 Aluminium Sheet (Thin Sheet)

In the actual market, one of the most common supply forms of 3003-H14 is the thin sheet. This temper material, after strain hardening, possesses moderate rigidity, not as soft as the annealed state, while still retaining good bending and stamping adaptability, making it widely used in general manufacturing.

Thin sheets are usually delivered as cut-to-size flat plates, covering a wide range of thicknesses to meet various needs, from decorative panels to structural coverings. Due to their good surface flatness and dimensional stability, users can often proceed directly to cutting or forming processes without complex pre-treatment.

In terms of applications, these products are commonly used for architectural decorative panels, roofing materials, appliance casings, tank components, and various general metal components. For scenarios requiring both corrosion resistance and a certain level of strength, H14 thin sheets are usually a reliable choice.

3003 H14 Aluminium Coil

Coil form also accounts for a large proportion, especially advantageous in continuous processing production. The material is supplied in full coils, convenient for subsequent flattening, slitting, or roll forming, not only improving processing efficiency but also better controlling material utilization.

Compared with sheets, coils offer greater flexibility in specifications, covering a wider range of thicknesses and widths, and can also be provided with oiling, coating, or other surface treatments as needed. This allows adaptation to different manufacturing processes, rather than being limited to a single use.

In practical applications, 3003-H14 coils are widely used for architectural profiled panels, heat exchanger components, transportation panels, and container manufacturing. For customers requiring stable batch supply, coils are usually a more economical choice that aligns with production rhythms.

3003 H14 Aluminium Foil

Although 3003 alloy can be processed into foil, the H14 temper is not the most common configuration in the industry. Foil applications often emphasize softness or extremely high hardness, so annealed or full-hard products are more prevalent in the market.

In individual cases, if an application requires a compromise between stiffness and formability, thinner H14 materials may be selected, but overall this is a niche demand. More typical foil applications remain in food containers, heat exchanger fins, and insulation fields, often using other annealed tempers.

Therefore, from a supply perspective, 3003-H14 foil is not a mainstream circulating form.

3003 H14 Aluminium Plate (Thick Plate)

Thick plates can theoretically be produced, but in actual market demand, they occupy a small proportion. This is related to the positioning of the 3003 alloy — it emphasizes corrosion resistance and workability rather than load-bearing strength, so thick plate applications often shift to other higher-strength alloy systems.

However, in scenarios where strength requirements are not high but stable corrosion resistance is needed, thick plates of this material may still be used, such as linings for chemical equipment, tank components, or some industrial structural panels. Such orders are usually customized rather than standard stock products.

Overall, thick plates are more of a supplementary supply form rather than a mainstream market category.

3003 H14 Aluminium Processing and Performance Characteristics

3003 H14 aluminium alloy is a typical Al–Mn series corrosion-resistant aluminum, achieving a good balance between workability and environmental stability, and is widely used in construction, chemical equipment, and food processing component manufacturing. The material is in a strain-hardened state (half-hard temper), with strength mainly derived from cold working rather than heat treatment.

Corrosion Resistance

3003 H14 has outstanding corrosion resistance and is one of the common rust-proof aluminum alloys. It remains stable in air, humid environments, and various industrial or chemical media, effectively resisting oxidation and surface degradation, suitable for tanks, heat exchangers, and outdoor structures.

Formability

The material exhibits excellent cold working performance, capable of bending, stamping, and deep drawing, suitable for manufacturing complex geometries. In the H14 temper, approximately 90° bends can usually be achieved without cracking, with a recommended bend radius of about 1–2 times the sheet thickness, demonstrating good fabrication flexibility.

Weldability

This alloy is highly compatible with conventional welding processes; both TIG (GTAW) and MIG (GMAW) welding can achieve reliable joints, and it is also suitable for brazing and soft soldering. Overall, the welding performance is stable, making it a common choice for lightweight structural components requiring joining.

Machinability

The overall machinability is moderate. Due to the relatively soft material, issues such as tool sticking or surface scoring may occur during cutting, requiring proper selection of tools and cutting parameters. For applications emphasizing high-speed machining, heat-treatable alloys like 6061-T6 are usually preferred.

Heat Treatment Response

3003 H14 aluminium is not a heat-treatable alloy, and its mechanical properties are primarily strengthened through cold working, without significant strength improvement achievable through T6 or other heat treatment processes. This characteristic should be considered carefully during material selection.

3003 H14 Aluminium Applications

With good corrosion resistance, medium strength, and excellent forming performance, 3003 H14 aluminium sheet is widely used in industrial and civil fields where both reliability and cost-effectiveness are required. Its typical applications include:

Food and Daily Equipment

Suitable for cookware, kitchen equipment, and food processing devices, as well as the manufacture of food packaging containers. The material offers good formability and stable safety, meeting long-term usage requirements.

Chemical and Storage/Transportation Equipment

Due to its excellent corrosion resistance, it is commonly used in chemical storage tanks, pipelines, pressure vessels, and related corrosion-resistant structural components, making it a common choice in chemical equipment manufacturing.

Transportation and Automotive Industry

Widely used in lightweight vehicle structures, such as truck and trailer roofs, side panels, as well as automotive trim and heat sink components, balancing strength and workability.

Construction and Decorative Panels

As a general-purpose sheet material, 3003 H14 is commonly used in roofing systems, exterior wall panels, gutters, louvers, and signage panels, providing both weather resistance and aesthetic appeal.

HVAC and Heat Exchange Systems

In the HVAC industry, it is used for manufacturing heat exchangers, evaporators, ducts, and fins, with good thermal conductivity and workability improving system efficiency and manufacturing convenience.

Sheet Metal and Industrial Container Manufacturing

Suitable for various sheet metal stamping and deep processing applications, such as tanks, instrument panels, decorative panels, and general industrial containers.

New Energy and Electronics

Recently, it has also been applied in lithium battery casings and packaging materials, performing well in fields that require high material stability and formability.

Products you may be interested in

- 3003 Aluminum Coil

- 3003 Aluminum Plate and Sheet

- 3003 h14 aluminum sheet

- 3003 h22 aluminum sheet

- 3003 o aluminum sheet

- 3003 Aluminum Disc Circle

- 3003 Aluminum Foil

Users viewing this material also viewed the following

- Aluminum Tread Plate 3003

- 3003 Embossed Aluminum Sheet

- 3003 Aluminum Diamond Plate

- 3003 Hot-rolled Aluminum Plate

- 3003 Honeycomb Aluminum

- 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell

- 3003+4343 Power Battery Cooling Plate

- 3003 Aluminum Plate for Brazing Water Cooling Plate

- Aluminum Brazing Composite Material 3003+4045 Aluminum Plate

- 3003 Aluminum Disc for Non-stick Pan

- 3003 Aluminum Plate for Mobile Phone Battery Shell

- 3003 Corrugated Aluminum Sheet

- 3003 Aluminum Plate for Automobile Fender

- 3003 Checker Aluminum Plate for Stair Anti-slip

- 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip

- 3003 Ultra-wide Curtain Wall Aluminum Plate

- 3003 Aluminum Plate for Building Decoration

- 3003 Roof Aluminum Plate for Decoration

- 3003 Aluminum Sheet Coil for Thermal Insulation Material

- 3003 Pre-painted Aluminum Coil

Recommended Content

- What is 3003 aluminum used for?

- 3003 Aluminum Tubing

- 3003 Aluminum vs. 3005 Aluminum

- 3003-H18 Aluminum vs. 3005-H18 Aluminum

- What is the difference between 3003 H14 and 3105 H14?

- 3003 Aluminum vs. 3104 Aluminum

- 3003-H18 Aluminum vs. 3004-H18 Aluminum

- 3003-O Aluminum vs. 3004-O Aluminum

- What is the difference between 3003 and 3004 aluminum?

- 3003-H22 Aluminum vs. 3003-H24 Aluminum

- What is the difference between 3003 O and 3003 H14?

- What is the difference between 3003 H14 and H24?