6061 Aluminum Coil

6061 aluminum coil is a very common and widely used form of aluminum alloy product. It is a rolled material made from 6061 aluminum alloy through hot rolling or cold rolling processes.

6061 aluminum coil is a rolled product based on 6061 aluminum alloy, featuring high strength, good corrosion resistance, and excellent machinability. It is widely used in industrial manufacturing and construction fields.

6061 aluminum coil is achieved by combining aluminum with magnesium and silicon. This heat-treatable alloy has multiple temper states (such as -O or -T6) and is widely applied in structural components, marine applications, transportation, and other engineering fields.

- Temper (O or T6) - depends on your forming process.

- Thickness and width - depends on your product design.

- Surface requirements - whether pre-oxidation or protective film is needed.

What is 6061 Aluminum Alloy?

6061 aluminum alloy is the most classic and representative grade among the 6-series aluminum alloys (Al-Mg-Si system). Its main alloying elements are magnesium (Mg) and silicon (Si), allowing it to achieve high strength through heat treatment (T6 temper).

Main characteristics:

- Medium to high strength: Especially in the T6 heat-treated condition, its strength performance is outstanding, approaching that of some mild steels.

- Good machinability: Easy to perform turning, milling, drilling, planing, etc., with a smooth surface finish after machining.

- Excellent corrosion resistance: Especially after anodizing, it forms a hard, corrosion-resistant surface layer.

- Good weldability: Can be welded using various methods, with good welding performance.

- Anodizable: Very suitable for surface treatments such as anodizing and painting, which can improve corrosion resistance while achieving an attractive appearance.

6061 Aluminum Coil Specifications

| Specification | Details |

| Alloy / Temper | 6061, available in O, T4, T6, T651, etc. |

| Surface Treatment | Mill finish, anodized, coated, or polished for enhanced appearance and protection |

| Thickness | 0.016" – 0.25" (0.4 mm – 6.35 mm) |

| Width | 36" – 72" (900 mm – 1800 mm) |

| Length | Coil form, cut-to-length available |

6061 Aluminum Coil Features

- Medium Strength: Stronger than 6063 alloy, suitable for structural component manufacturing.

- Excellent Corrosion Resistance: The synergistic effect of magnesium and silicon forms a dense oxide layer, especially suitable for outdoor or humid environments, such as automotive wheels and interior/exterior panels of rail vehicles.

- Good Machinability: Can be formed through rolling, extrusion, welding, and other processes. The T651 temper eliminates internal stress through pre-stretching, ensuring machining accuracy.

- Welding and Surface Treatment: Supports multiple welding methods. After anodizing, it achieves a uniform and aesthetically pleasing surface, commonly used in 3C product casings and architectural decoration.

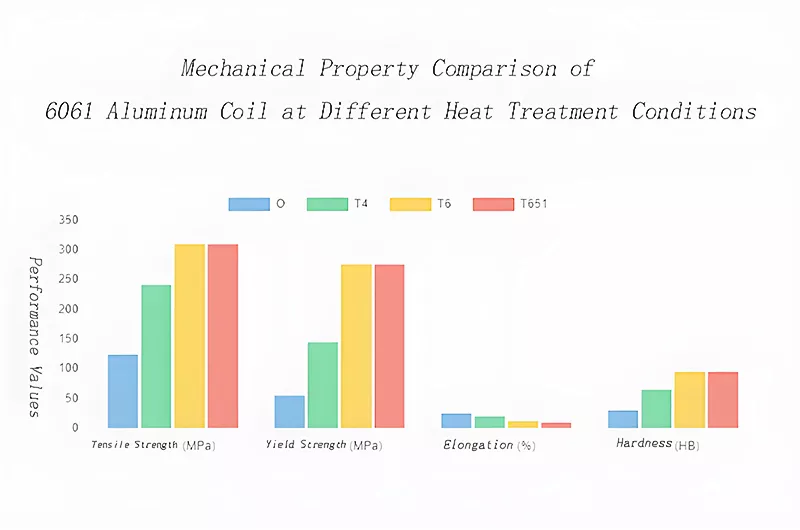

6061 Aluminum Coil Temper Types

- O Temper (Annealed): This is the softest temper with excellent plasticity, very suitable for deep drawing, stretching, and other severe deformation forming processes. However, it has the lowest strength.

- T4/T6 Temper (Solution Heat-Treated + Artificial Aging): This is the most commonly used high-strength temper. The T6 temper is the peak hardness condition, offering the highest strength but relatively lower plasticity. It is more suitable for bending, shearing, and similar processing, rather than deep drawing.

6061 O Aluminum Coil

- Characteristics: O temper is fully annealed, the softest condition with excellent plasticity and formability.

- Properties: Good corrosion resistance and weldability, ideal for deep drawing, stretching, and severe deformation forming.

- Processing: Can undergo extensive cold working, stamping, rolling, or deep drawing.

- Applications: Suitable for structural components after post-heat treatment, aerospace prototypes, and other deep-formed parts.

6061 T4 Aluminum Coil

- Characteristics: Solution heat-treated and naturally aged, offering medium strength and good toughness.

- Properties: Balanced formability and strength, suitable for bending and light structural applications.

- Processing: Can be formed before final aging; moderate machining difficulty.

- Applications: Structural components, automotive panels, light machinery, and parts that may be later T6 treated.

6061 T6 Aluminum Coil

- Characteristics: Solution heat-treated and artificially aged to peak strength, with high strength and moderate ductility.

- Properties: Excellent corrosion resistance, good machinability with sharp tools, suitable for structural and load-bearing applications.

- Processing: More difficult to form than O or T4 tempers; bending and shearing possible with proper tooling.

- Applications: Structural components, automotive parts, transportation equipment, aerospace components, and high-strength applications.

6061 T651 Aluminum Coil

- Characteristics: T6 temper with stress-relief stretching, offering high strength and excellent dimensional stability.

- Properties: Maintains strength while minimizing residual stresses and distortion.

- Processing: Suitable for precision machining and forming; excellent stability during fabrication.

- Applications: Aerospace components, precision structural parts, and other applications requiring high dimensional accuracy.

6061 T42 Aluminum Coil

- Characteristics: Solution heat-treated and partially stress-relieved by stretching, balancing strength and formability.

- Properties: Moderate peak strength with improved ductility compared to T6.

- Processing: Can be bent or lightly formed after heat treatment; machining is moderate.

- Applications: Structural components requiring controlled strength with some flexibility.

6061 T62 Aluminum Coil

- Characteristics: Solution heat-treated and artificially aged to slightly below T6 peak, offering high strength with improved ductility.

- Properties: Good corrosion resistance and moderate machinability; balances strength and flexibility.

- Processing: Suitable for forming and bending; easier than T6 for some fabrication processes.

- Applications: Structural parts needing high strength but with some tolerance for flexibility, automotive and industrial components.

Selection Recommendations:

If deep drawing or stretch forming is required, O temper aluminum coil should be chosen, and then heat-treated to T6 temper after forming to achieve the required strength. If it is mainly used for bending, riveting, or shearing and then used directly, choosing T6 temper aluminum coil is more economical and efficient.

6061 Aluminum Coil Surface Finishes and Specialty Types

- Characteristics: Surface treated through anodizing to form a protective oxide layer.

- Properties: Enhanced corrosion resistance, improved surface hardness, and aesthetic appeal.

- Applications: Architectural panels, electronic housings, and outdoor structures.

6061 Color Coated Aluminum Coil

- Characteristics: Coated with a colored paint or PVDF layer for decorative and protective purposes.

- Properties: Resistant to corrosion, UV light, and fading.

- Applications: Building facades, signage, interior decoration, and roofing panels.

- Characteristics: Patterned surface achieved through embossing for texture and aesthetics.

- Properties: Non-slip, decorative, and corrosion-resistant.

- Applications: Decorative panels, wall cladding, ceilings, and signage.

6061 Mirror Polished Aluminum Coil

- Characteristics: Highly reflective, smooth surface polished to a mirror finish.

- Properties: Excellent appearance and corrosion resistance.

- Applications: Decorative surfaces, signage, elevator panels, and interior trim.

6061 Punching Aluminum Coil

- Characteristics: Pre-perforated with patterns or holes through punching.

- Properties: Lightweight, ventilated, and corrosion-resistant.

- Applications: Acoustic panels, filters, ventilation panels, and decorative screens.

Mill Finish 6061 Aluminum Coil

- Characteristics: Natural finish directly from rolling mill without additional surface treatment.

- Properties: Smooth, plain surface, ready for further processing or coating.

- Applications: Fabrication, construction, and general industrial uses.

Brushed 6061 Aluminum Coil

- Characteristics: Fine linear texture achieved through brushing for an elegant finish.

- Properties: Attractive appearance, corrosion-resistant, hides fingerprints.

- Applications: Interior decoration, appliances, elevator panels, and signage.

PVDF Coated 6061 Aluminum Coil

- Characteristics: Coated with PVDF (polyvinylidene fluoride) for long-term durability and color retention.

- Properties: Excellent UV, weather, and corrosion resistance.

- Applications: Exterior cladding, roofing, and architectural decoration.

PVC Laminated 6061 Aluminum Coil

- Characteristics: Laminated with PVC film for protection and aesthetics.

- Properties: Scratch-resistant, corrosion-resistant, and lightweight.

- Applications: Interior panels, ceilings, furniture, and decorative surfaces.

Corrugated 6061 Aluminum Coil

- Characteristics: Formed with wave-like corrugations for rigidity and strength.

- Properties: Lightweight, strong, and corrosion-resistant.

- Applications: Roofing, siding, and structural panels.

Perforated 6061 Aluminum Coil

- Characteristics: Evenly punched with holes for airflow or decoration.

- Properties: Lightweight, ventilated, and aesthetically pleasing.

- Applications: Acoustic panels, decorative screens, filters, and ventilation systems.

- Characteristics: Smooth, shiny surface achieved through mechanical polishing.

- Properties: Good corrosion resistance and reflective surface.

- Applications: Decorative panels, signage, appliances, and interior trim.

Hard Anodized 6061 Aluminum Coil

- Characteristics: Thick anodized layer for high surface hardness.

- Properties: Excellent wear resistance, corrosion resistance, and durability.

- Applications: Industrial parts, aerospace components, cookware, and structural applications.

Textured 6061 Aluminum Coil

- Characteristics: Surface treated to create textured patterns for aesthetics and grip.

- Properties: Anti-slip, decorative, and corrosion-resistant.

- Applications: Flooring, decorative panels, and industrial surfaces.

Color Anodized 6061 Aluminum Coil

- Characteristics: Anodized with colored oxide layer for decorative finish.

- Properties: Corrosion-resistant, UV-resistant, and durable.

- Applications: Architectural panels, furniture, and exterior decoration.

Insulated 6061 Aluminum Coil

- Characteristics: Combined with insulating layer for thermal or acoustic insulation.

- Properties: Reduces heat transfer, lightweight, and corrosion-resistant.

- Applications: Roofing, HVAC panels, and wall cladding.

Clad 6061 Aluminum Coil

- Characteristics: Laminated with other metals for enhanced properties.

- Properties: Combines corrosion resistance with strength or thermal conductivity.

- Applications: Marine structures, heat exchangers, and industrial applications.

Anti-slip 6061 Aluminum Coil

- Characteristics: Surface patterned to provide grip and prevent slipping.

- Properties: Durable, corrosion-resistant, and slip-resistant.

- Applications: Flooring, stair treads, walkways, and ramps.

- Characteristics: Raised checker pattern on the surface for anti-slip properties.

- Properties: Lightweight, corrosion-resistant, and provides traction.

- Applications: Flooring, industrial platforms, and truck beds.

- Characteristics: Diamond-shaped raised pattern for strong anti-slip performance.

- Properties: Corrosion-resistant, durable, and provides excellent traction.

- Applications: Walkways, vehicle flooring, industrial platforms, and ramps.

6061 Aluminum Coil Color Options

6061 Aluminum Coil Mechanical Property Limits

| Temper | Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | |||||

| Min | Max | Min | Max | |||

| O | 0.006 - 0.007 | - | 22 | - | 12 | 10 |

| O | 0.008 - 0.009 | - | 22 | - | 12 | 12 |

| O | 0.010 - 0.020 | - | 22 | - | 12 | 14 |

| O | 0.021 - 0.128 | - | 22 | - | 12 | 16 |

| O | 0.129 - 0.250 | - | 22 | - | 12 | 18 |

| T4 | 0.006 - 0.007 | 30 | - | 16 | - | 10 |

| T4 | 0.008 - 0.009 | 30 | - | 16 | - | 12 |

| T4 | 0.010 - 0.020 | 30 | - | 16 | - | 14 |

| T4 | 0.021 - 0.249 | 30 | - | 16 | - | 16 |

| T42 | 0.006 - 0.007 | 30 | - | 14 | - | 10 |

| T42 | 0.008 - 0.009 | 30 | - | 14 | - | 12 |

| T42 | 0.010 - 0.020 | 30 | - | 14 | - | 14 |

| T42 | 0.021 - 0.250 | 30 | - | 14 | - | 16 |

| T6 and T62 | 0.006 - 0.007 | 42 | - | 35 | - | 4 |

| T6 and T62 | 0.008 - 0.009 | 42 | - | 35 | - | 6 |

| T6 and T62 | 0.010 - 0.020 | 42 | - | 35 | - | 8 |

| T6 and T62 | 0.021 - 0.250 | 42 | - | 35 | - | 10 |

6061 Aluminum Coil Chemical Composition Limits

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al | |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

6061 Aluminum Coil Processing, Heat Treatment and Welding Properties

6061 Aluminum Coil Machinability

Advantages

- Excellent machinability, suitable for precision machining.

- Good formability, suitable for bending, stamping, and other forming processes.

- Excellent surface quality, can be directly used for surface treatment without additional milling.

- Good dimensional stability, especially after T651 temper treatment.

Disadvantages

- Difficult cold working in T6 temper.

- Strict temperature control required for hot working.

- Work hardening may occur during cold working.

6061 Aluminum Coil Heat Treatment Properties

Advantages

- Significant strengthening effect, with a substantial increase in strength after T6 treatment.

- Multiple heat treatment tempers available (O, T4, T6, T651, etc.).

- Good dimensional stability after heat treatment, especially in T651 temper.

- Mature heat treatment process, ensuring stable and reliable product quality.

Disadvantages

- High heat treatment cost, requiring solution treatment and artificial aging.

- Increased machining difficulty after heat treatment, requiring sharper tools.

- Significant internal stress and deformation may occur during heat treatment.

- Risk of over-aging, requiring strict process control.

6061 Aluminum Coil Welding Properties

Advantages

- Suitable for multiple welding methods (TIG, MIG, etc.).

- Wide selection of filler materials (ER4043, ER5356, etc.).

- Good corrosion resistance in the welded area.

- Excellent brazing performance.

Disadvantages

- Softening in the heat-affected zone, with strength potentially dropping to 70% of the base metal.

- Significant welding deformation, requiring proper fixtures and tooling.

- Sensitivity to welding cracks, requiring strict process control.

- Post-weld heat treatment may be needed, increasing process complexity.

6061 Aluminum Coil Common Applications

Applications in Construction and Decoration

Structural Applications

- Curtain walls and roofing systems

- Door and window frames

- Architectural decorative trims

Decorative Applications

- Ceilings and suspended ceiling systems

- Interior decorative panels

- Building shading systems

Applications in Transportation

Automotive Applications

- Vehicle body structural components

- Automotive interior parts

- Automotive thermal management systems

Rail Transportation Applications

- Interior and exterior panels of rail vehicles

- Flooring and car body panels

- Vehicle structural frameworks

Applications in Electronics and Electrical Equipment

Electronics Applications

- 3C product casings

- Structural components of electronic devices

- Heat dissipation systems

Electrical System Applications

- Busbars and conductive strips

- Electrical equipment enclosures

- Wire and cable sheaths

6061 Aluminum Coil Size Options and Cut-to-Length Availability

| Product Description | Temper | Thickness (in) | Width (in) |

| COIL 6061 T6 .016 x 36 | T6 | 0.016 | 36 |

| COIL 6061 T6 .025 x 48 | T6 | 0.025 | 48 |

| COIL 6061 T6 .032 x 48 | T6 | 0.032 | 48 |

| COIL 6061 T6 .040 x 48 | T6 | 0.04 | 48 |

| COIL 6061 T6 .063 x 48 | T6 | 0.063 | 48 |

| COIL 6061 T6 .063 x 60 | T6 | 0.063 | 60 |

| COIL 6061 T6 .100 x 48 | T6 | 0.1 | 48 |

| COIL 6061 T6 .125 x 48 | T6 | 0.125 | 48 |

| COIL 6061 T6 .125 x 60 | T6 | 0.125 | 60 |

| COIL 6061 T6 .188 x 48 | T6 | 0.188 | 48 |

| COIL 6061 T6 .190 x 60 | T6 | 0.19 | 60 |

| COIL 6061 T6 .250 x 48 | T6 | 0.25 | 48 |

| COIL 6061 T6 .250 x 60 | T6 | 0.25 | 60 |

| COIL 6061 T651 .016 x 36 | T651 | 0.016 | 36 |

| COIL 6061 T651 .025 x 48 | T651 | 0.025 | 48 |

| COIL 6061 T651 .032 x 48 | T651 | 0.032 | 48 |

| COIL 6061 T651 .040 x 48 | T651 | 0.04 | 48 |

| COIL 6061 T651 .063 x 48 | T651 | 0.063 | 48 |

| COIL 6061 T651 .063 x 60 | T651 | 0.063 | 60 |

| COIL 6061 T651 .100 x 48 | T651 | 0.1 | 48 |

| COIL 6061 T651 .125 x 48 | T651 | 0.125 | 48 |

| COIL 6061 T651 .125 x 60 | T651 | 0.125 | 60 |

| COIL 6061 T651 .188 x 48 | T651 | 0.188 | 48 |

| COIL 6061 T651 .190 x 60 | T651 | 0.19 | 60 |

| COIL 6061 T651 .250 x 48 | T651 | 0.25 | 48 |

| COIL 6061 T651 .250 x 60 | T651 | 0.25 | 60 |

| COIL 6061 T42 .016 x 36 | T42 | 0.016 | 36 |

| COIL 6061 T42 .025 x 48 | T42 | 0.025 | 48 |

| COIL 6061 T42 .032 x 48 | T42 | 0.032 | 48 |

| COIL 6061 T42 .040 x 48 | T42 | 0.04 | 48 |

| COIL 6061 T42 .063 x 48 | T42 | 0.063 | 48 |

| COIL 6061 T42 .063 x 60 | T42 | 0.063 | 60 |

| COIL 6061 T42 .100 x 48 | T42 | 0.1 | 48 |

| COIL 6061 T42 .125 x 48 | T42 | 0.125 | 48 |

| COIL 6061 T42 .125 x 60 | T42 | 0.125 | 60 |

| COIL 6061 T42 .188 x 48 | T42 | 0.188 | 48 |

| COIL 6061 T42 .190 x 60 | T42 | 0.19 | 60 |

| COIL 6061 T42 .250 x 48 | T42 | 0.25 | 48 |

| COIL 6061 T42 .250 x 60 | T42 | 0.25 | 60 |

Comparison of 6061 Aluminum with Other Alloys

| Alloy | Strength | Corrosion Resistance | Machinability | Typical Applications |

| 6061 | High | Excellent | Good | Structural components, automotive parts |

| 6063 | Medium | Excellent | Excellent | Door and window frames, decorative profiles |

| 5052 | Medium | Excellent | Good | Pressure vessels, ship decks |

| 7075 | Very High | Medium | Poor | Aerospace critical components |

How to Choose 6061 Aluminum Coil

- O Temper (Annealed): Highest plasticity and lowest strength

- T4 Temper (Solution treated and naturally aged): Medium strength with good toughness

- T6 Temper (Solution treated and artificially aged): Highest strength and hardness

- T651 Temper (T6 with stress-relief stretching): High strength and good dimensional stability

As a widely used aluminum alloy material, 6061 aluminum coil offers medium strength, good machinability, excellent corrosion resistance, and an attractive appearance. It plays an important role in construction, transportation, electronics, and industrial fields. Its advantages lie in its well-balanced overall performance, mature processing technology, diverse surface treatment options, and relatively reasonable cost, making it an ideal choice for many applications.

From a performance perspective, 6061 aluminum coil achieves a good balance between strength, toughness, and corrosion resistance. Especially after T6 heat treatment, its strength can reach the level of medium steel, while its weight is only about one-third of steel, making it highly suitable for applications requiring lightweight materials.

However, 6061 aluminum coil also has some limitations, such as high heat treatment costs, softening in the weld heat-affected zone, and limited corrosion resistance in certain environments. Therefore, when selecting and using 6061 aluminum coil, it is necessary to weigh its advantages and disadvantages according to specific application requirements and choose the appropriate specifications, temper, and surface treatment to fully leverage its strengths while mitigating its weaknesses.

Explore Different Aluminum Coil Grades

Users viewing this material also viewed the following

Recommended Content