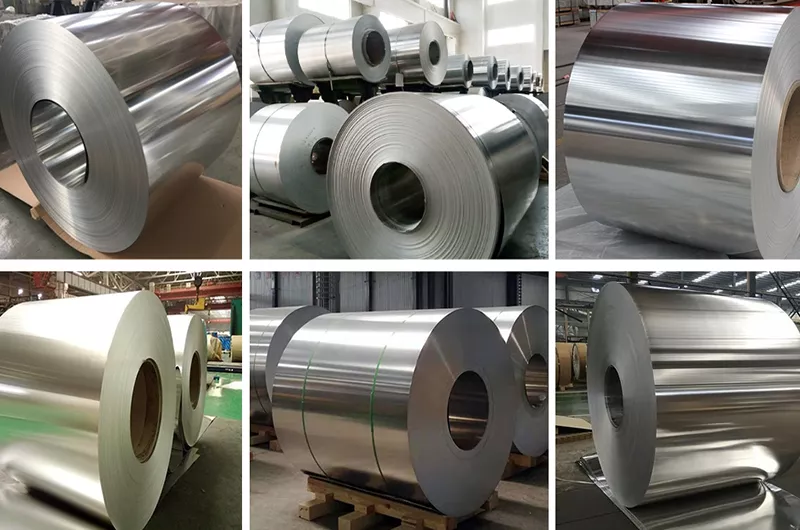

5005 Aluminum Coil

5005 aluminum coil is an aluminum-magnesium alloy material, widely used in construction, decoration, and industrial manufacturing.

5005 aluminum coil has good overall performance and a relatively moderate price. It not only has high strength and excellent forming performance, but also possesses good corrosion resistance and weldability. Notably, its anodizing effect is brighter than 3003 alloy and can achieve an aesthetically coordinated color tone consistent with 6063 alloy.

5005 aluminum coil belongs to the 5000 series aluminum alloys. It is a medium-strength aluminum alloy suitable for applications requiring bending, spinning, stretching, stamping, and rolling forming. It is commonly used in applications requiring anodizing treatment.

In addition to sheets, 5005 aluminum alloy is also available in coil form. It is resistant to atmospheric corrosion, can achieve high strength through cold working, and has good weldability.

5005 Aluminum Coil Common Specifications

The specifications of 5005 aluminum coil cover a wide range and can be customized according to requirements:

- Thickness: The common range is usually between 0.2mm and 10.0mm (some manufacturers can provide a thicker range).

- Width: The range is wide, commonly from 20mm to 2650mm.

- Length: Coils are usually non-standard in length. Sheet lengths can be customized according to requirements, for example, 500mm to 16, 000mm.

5005 Aluminum Coil Temper Standards

5005 O Aluminum Coil

O temper is the softest grade of 5005 aluminum alloy, with excellent formability and bending performance. It is very suitable for applications requiring high ductility and superior corrosion resistance, such as decorative panels, roofing, and interior building components.

5005 H32 Aluminum Coil

H32 temper is a 1/4 hard alloy that has undergone strain hardening and stabilization treatment, offering a balanced combination of strength and flexibility. It is very suitable for medium-strength structural applications, roofing, wall panels, and automotive interior applications that require additional mechanical strength without compromising workability.

5005 H34 Aluminum Coil

H34 temper is a 1/2 hard alloy that has undergone low-temperature stabilization treatment, optimized to achieve a precise balance between mechanical strength and ductility. It is suitable for exterior wall panels, architectural cladding, and applications requiring medium strength and excellent corrosion resistance.

5005 Aluminum Coil Surface Treatments and Finishes

- Mill Finish 5005 Aluminum Coil Natural rolled aluminum coil without surface treatment; offers excellent corrosion resistance, high formability, and good mechanical strength; widely used in industrial fabrication, construction, and HVAC components.

- Anodized 5005 Aluminum Coil Aluminum coil treated by electrochemical anodizing to form a durable oxide layer; enhances corrosion resistance, surface hardness, and aesthetic appeal; commonly used in architectural panels, roofing, curtain walls, and decorative applications.

- 5005 Color Coated Aluminum Coil Coil coated with decorative paint layer in various colors and finishes; provides excellent weather resistance, UV protection, and aesthetic versatility; ideal for exterior building facades, ceiling panels, and decorative purposes.

- Painted / Pre-Painted 5005 Aluminum Coil Factory-applied paint coating ensuring uniform color, excellent adhesion, and long-term corrosion protection; suitable for construction, signage, transportation, and industrial equipment requiring functional and decorative surfaces.

- 5005 Polished Mirror Aluminum Coil Mechanically polished to a highly reflective mirror-like surface; combines corrosion resistance with visual appeal; used in interior decoration, elevator panels, furniture, signage, and high-end architectural applications.

- Brushed 5005 Aluminum Coil Textured linear finish achieved by abrasive polishing; provides modern aesthetic, reduces visible fingerprints, and maintains good corrosion resistance; commonly used in kitchen appliances, furniture, interior decoration, and elevator panels.

- Embossed / Stucco Embossed 5005 Aluminum Coil Aluminum coil with patterned embossed surface to enhance rigidity, visual appeal, and anti-slip properties; ideal for roofing, siding, decorative panels, and transportation interiors.

- PVC Coated 5005 Aluminum Coil Coil covered with protective PVC film to prevent scratches, stains, and corrosion during fabrication, transport, and installation; perfect for curtain walls, signage, furniture, and decorative panels.

5005 Aluminum Coil Color Options

5005 Aluminum Coil Chemical Composition Limits

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al Min | |

| 5005 | 0.30 | 0.7 | 0.20 | 0.20 | 0.5-1.1 | 0.10 | 0.25 | – | 0.05 | 0.15 | Remainder |

Ttypical Mechanical Properties Data Of Aluminum 5005

| Alloy-Temper | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

| 5005-O | 18 | 6 | 22 |

| 5005-H14 | 23 | 22 | 4 |

| 5005-H18 | 29 | 28 | 2 |

5005 Aluminum Alloy Material Properties

5005 Aluminum Coil Machinability

- Easy to cut, shear, and punch.

- Can be processed by bending, rolling, stamping, or deep drawing.

- Best performance is achieved in softer tempers like O or H32.

5005 Aluminum Coil Weldability

- Excellent weldability using TIG, MIG, or resistance welding.

- No preheating is required for most welding operations.

- Minimal risk of cracking, making it suitable for fabrication and assembly.

5005 Aluminum Coil Heat Treatment

- 5005 is a non-heat-treatable alloy; mechanical properties are developed through work hardening (H32, H34 tempers).

- Can be annealed to O temper for maximum softness and formability.

- Thermal processes mainly serve to relieve stresses or improve ductility, not to increase strength.

5005 Aluminum Coil Advantages and Disadvantages

Advantages:

- Excellent corrosion resistance, especially against atmospheric and marine environments.

- High formability, easy to bend, roll, and shape.

- Lightweight yet maintains moderate strength.

- Suitable for architectural, roofing, and decorative applications.

Disadvantages:

- Lower strength compared to other high-strength aluminum alloys (such as 5005 H34 vs 5052 H32).

- Not suitable for applications requiring very high mechanical load or structural stress.

5005 Aluminum Coil Applications

Piping Applications

- Features: Corrosion-resistant, lightweight, easy to process, aesthetically pleasing.

- Uses: Ventilation and exhaust ducts, protective sleeves, and other functional and structural pipes.

- Advantages: Balances performance, cost, and practicality, serving as an essential material for modern industry and construction.

Architectural and Decorative Applications

- Features: Strong weather resistance, oxidation resistance, attractive appearance, excellent anodizing effect.

- Uses: High-end wide façade panels, interior and exterior decorative components (decorative strips, trims), roofing coils.

- Advantages: Combines aesthetics and durability, enhancing building appearance and service life.

Facade and Door & Window Applications

- Features: Beautiful and durable after anodizing.

- Uses: Architectural exterior facade decoration.

- Advantages: Enhances facade aesthetics, corrosion-resistant, and weather-resistant.

Ceiling and Partition Applications

- Features: Lightweight, corrosion-resistant.

- Uses: Indoor ceilings, partition materials.

- Advantages: Easy to install, suitable for humid indoor environments, durable and aesthetically pleasing.

Transportation Applications

- Features: Lightweight, corrosion-resistant, easy to process.

- Uses: Automotive interior panels (dashboard, decorative strips), license plate materials, vehicle interior components, new energy vehicle parts.

- Advantages: Reduces vehicle weight, improves fuel efficiency, and allows complex shaping.

Body Structural Components Applications

- Uses: Car doors, hoods, and other body structural parts.

- Advantages: Improves vehicle performance, reduces weight, and increases fuel efficiency.

Electronics and Electrical Applications

- Features: Good protection, aesthetically pleasing, with some heat dissipation capability.

- Uses: Conductor materials, instrument housings, electrical panels.

- Advantages: Provides protection and aesthetics while supporting heat dissipation needs.

Daily Necessities and Hardware Applications

- Features: Lightweight, corrosion-resistant, easy to process.

- Uses: Cookware (pots, kettles), kitchen utensils, lighting parts, and other hardware products.

- Advantages: Durable, attractive, and easy to process.

Industrial and Packaging Applications

- Features: Corrosion-resistant, good sealing.

- Uses: Food and beverage cans, chemical storage tanks, wires and cables (O temper annealed material).

- Advantages: Ensures storage safety while combining corrosion resistance and workability.

Haomei 5005 Aluminum Coil Stock and Availability

| Item | Thickness | Size | Color | Form |

| 5005 H34 Aluminum Coil – .032" x 36" x Coil | .032 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .032" x 48" x Coil | .032 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .040" x 36" x Coil | .040 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .040" x 48" x Coil | .040 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .050" x 48" x Coil | .050 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .063" x 36" x Coil | .063 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .063" x 48" x Coil | .063 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .063" x 60" x Coil | .063 inches | 60" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .080" x 48" x Coil | .080 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .090" x 36" x Coil | .090 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .090" x 48" x Coil | .090 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .125" x 36" x Coil | .125 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .125" x 48" x Coil | .125 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .125" x 60" x Coil | .125 inches | 60" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .190" x 48" x Coil | .190 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 H34 Aluminum Coil – .250" x 48" x Coil | .250 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .032" x 36" x Coil | .032 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .032" x 48" x Coil | .032 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .040" x 36" x Coil | .040 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .040" x 48" x Coil | .040 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .050" x 48" x Coil | .050 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .063" x 36" x Coil | .063 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .063" x 48" x Coil | .063 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .063" x 60" x Coil | .063 inches | 60" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .080" x 48" x Coil | .080 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .090" x 36" x Coil | .090 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .090" x 48" x Coil | .090 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .125" x 36" x Coil | .125 inches | 36" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .125" x 48" x Coil | .125 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .125" x 60" x Coil | .125 inches | 60" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .190" x 48" x Coil | .190 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

| 5005 Anodized Aluminum Coil – .250" x 48" x Coil | .250 inches | 48" x Coil | Black/Bronze/Clear/Gold | Coil |

5005 Aluminum Coil Selection Recommendations

- If your product requires good formability (e.g., deep drawing, bending), O temper (annealed) is recommended.

- If the product requires a combination of strength and formability, H2X (e.g., H24) or H3X (e.g., H34) tempers may be suitable.

- If higher strength and hardness are required, H1X (e.g., H18) temper can be considered.

- For exterior parts requiring anodizing, 5005 aluminum coil is a highly recommended option.

5005 Aluminum Coil Comparison with Other Alloys

5005 vs 5052

- Strength: 5052 has a higher magnesium content (2.2%-2.8%) with tensile strength up to 260MPa, suitable for high-load scenarios.

- Corrosion resistance: 5005 performs better in atmospheric environments, while 5052 is more suitable for marine or chemical environments.

- Cost: 5005 is generally lower in price than 5052, suitable for budget-sensitive projects.

5005 vs 6061

- Heat treatment: 6061 can be strengthened by heat treatment, achieving higher strength, but has poorer weldability.

- Application differences: 5005 is mostly used for decorative and structural components, while 6061 is more suitable for mechanical parts or high-strength frames.

Explore Different Aluminum Coil Grades

Further reading