3003 h14 aluminum sheet

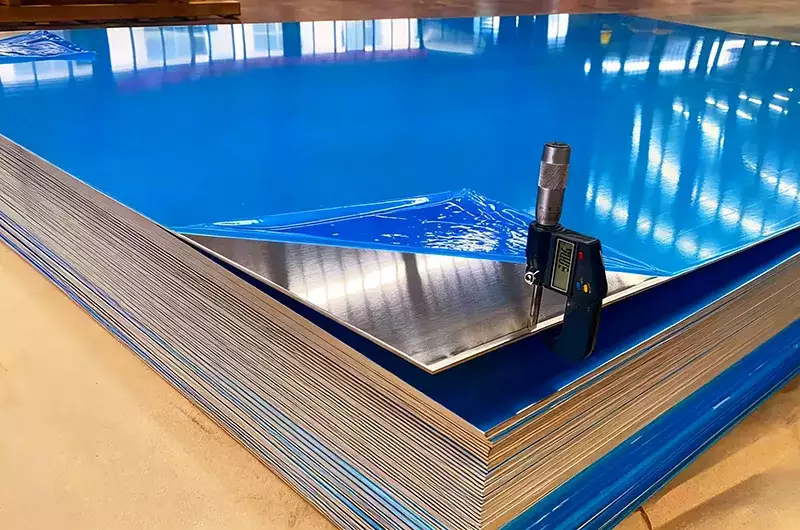

3003 H14 aluminum sheet is a widely used alloy, known for its excellent corrosion resistance, medium strength, and good workability. It is especially favored in applications where formability and durability are crucial.

3003 H14 is a medium-strength aluminum alloy, renowned for its versatility, corrosion resistance, and excellent formability. It primarily contains manganese (1.0-1.5%), offering about 20% higher strength than 1100 series aluminum alloys while maintaining good machinability and weldability.

Haomei Aluminum offers 3003 H14 aluminum sheets in various thicknesses and sizes to meet specific application needs. For example, the thickness range is from 0.2 mm to 450 mm, with lengths up to 12, 000 mm.

What is 3003 H14 aluminum?

3003 H14 aluminum alloy is a heat-treated state of the 3003 series aluminum alloy. The H14 state is achieved through strain hardening, which makes the alloy's strength fall between the fully annealed state (O) and the fully hardened state (H18).

- Main Composition: 3003 H14 aluminum mainly consists of aluminum with approximately 1.0% manganese added.

- Role of Manganese: Increases strength, making it about 20% stronger than 1000 series pure aluminum alloys.

3003 aluminum alloy cannot be further enhanced through heat treatment. The H14 state: Achieved through strain hardening, making the alloy's strength fall between the annealed state (O) and the fully hardened state (H18).

3003 H14 Aluminum Sheet Specifications

| Specifications | Details |

| Manufacturing Process | Cold-rolled, annealed to control hardness, H14 temper requires precise regulation of work-hardening. |

| Thickness | 0.5-25.0mm (Common specifications: Curtain wall 1.0-4.0mm, Battery shell 0.8~2.0mm) |

| Dimensions | Thickness range: 0.016 inches to 0.250 inches, width up to 60 inches, length customizable |

| Standards | ASTM B209, AMS 4008, AMS-QQ-A-250/2 |

| Forms | Available in sheet, coil, and embossed plate (with anti-slip pattern). |

Popular Thickness Options of 3003 H14 Aluminum Sheet

-

0.025" 3003 H14 Aluminum Sheet

-

0.032" 3003 H14 Aluminum Sheet

-

0.040" 3003 H14 Aluminum Sheet

-

0.050" 3003 H14 Aluminum Sheet

-

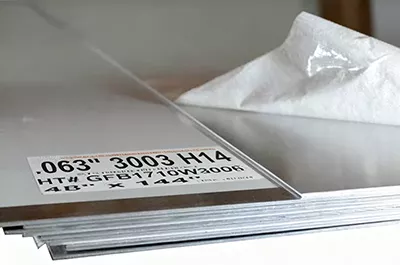

0.063" 3003 H14 Aluminum Sheet

-

0.080" 3003 H14 Aluminum Sheet

-

0.090" 3003 H14 Aluminum Sheet

-

0.100" 3003 H14 Aluminum Sheet

-

1/8" 3003 H14 Aluminum Sheet

-

0.190" 3003 H14 Aluminum Sheet

-

0.249" 3003 H14 Aluminum Sheet

Popular Size Options of 3003 H14 Aluminum Sheet

1' x 1' (12 x 12) 3003 H14 Aluminum Sheet

- Size: 12 x 12 inches (30.48 x 30.48 cm), small sheet easy to handle.

- Features: Lightweight, easy to cut and bend.

- Applications: Small decorative items, model making, handicrafts, small structural components.

1' x 2' (12 x 24) 3003 H14 Aluminum Sheet

- Size: 12 x 24 inches (30.48 x 60.96 cm), medium-small sheet.

- Features: Versatile, easy to fabricate.

- Applications: Furniture panels, signage, lightweight structural panels.

1' x 3' (12 x 36) 3003 H14 Aluminum Sheet

- Size: 12 x 36 inches (30.48 x 91.44 cm), long sheet.

- Features: Suitable for covering larger surfaces.

- Applications: Architectural decoration, kitchen panels, small industrial equipment covers.

1' x 4' (12 x 48) 3003 H14 Aluminum Sheet

- Size: 12 x 48 inches (30.48 x 121.92 cm), medium-length sheet.

- Features: Easy to bend and punch.

- Applications: Signage, cabinet panels, lightweight protective covers.

2' x 2' (24 x 24) 3003 H14 Aluminum Sheet

- Size: 24 x 24 inches (60.96 x 60.96 cm), square sheet.

- Features: Suitable for modular applications.

- Applications: Wall decoration panels, small machinery covers, display shelves.

2' x 3' (24 x 36) 3003 H14 Aluminum Sheet

- Size: 24 x 36 inches (60.96 x 91.44 cm), medium sheet.

- Features: Easy to process and transport.

- Applications: Architectural decoration, signage, industrial equipment panels.

2' x 4' (24 x 48) 3003 H14 Aluminum Sheet

- Size: 24 x 48 inches (60.96 x 121.92 cm), standard industrial size.

- Features: Suitable for batch use.

- Applications: Cabinet panels, wall decoration, kitchen equipment covers.

3' x 3' (36 x 36) 3003 H14 Aluminum Sheet

- Size: 36 x 36 inches (91.44 x 91.44 cm), large sheet.

- Features: Moderate strength, ideal for bigger applications.

- Applications: Architectural panels, large signage, lightweight machinery covers.

3' x 4' (36 x 48) 3003 H14 Aluminum Sheet

- Size: 36 x 48 inches (91.44 x 121.92 cm), large sheet.

- Features: Suitable for covering wide surfaces.

- Applications: Exterior wall panels, machinery covers, furniture decorative panels.

4' x 4' (48 x 48) 3003 H14 Aluminum Sheet

- Size: 48 x 48 inches (121.92 x 121.92 cm), square large sheet.

- Features: Ideal for large-scale applications.

- Applications: Industrial machinery protection panels, large signage, building exterior panels.

4' x 10' (48 x 120) 3003 H14 Aluminum Sheet

- Size: 48 x 120 inches (121.92 x 304.8 cm), long sheet with large coverage.

- Features: Covers extensive surfaces efficiently.

- Applications: Curtain walls, ship panels, large machinery covers.

4' x 12' (48 x 144) 3003 H14 Aluminum Sheet

- Size: 48 x 144 inches (121.92 x 365.76 cm), extra-large sheet.

- Features: Suitable for extensive surface coverage.

- Applications: Large building exterior walls, industrial panels, ship or vehicle exteriors.

3003 H14 Aluminum Sheet: Available Surface Treatments

-

3003-H14 Stucco Embossed Aluminum Sheet

Stucco embossed aluminum sheet with an attractive textured surface that enhances aesthetics, hides fingerprints, and increases rigidity. Commonly used for decorative panels, wall cladding, and insulation jacketing.

-

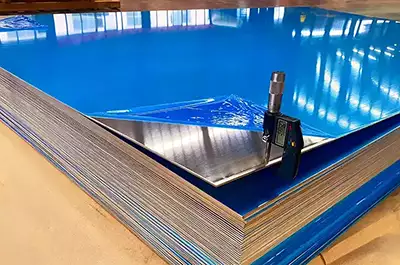

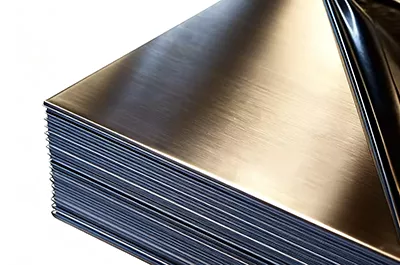

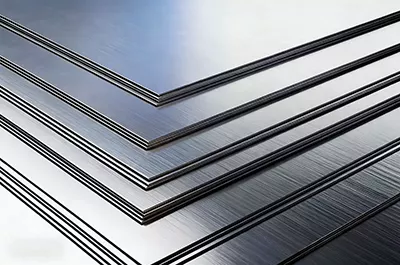

3003 H14 Mill Finish Aluminum Sheet

Plain aluminum sheet with natural mill finish, offering good corrosion resistance and excellent formability. Suitable for general sheet metal works, roofing, siding, and packaging applications.

-

3003-H14 Painted Aluminum Plate

Pre-painted aluminum plate with a durable coating for enhanced surface protection and decorative appeal. Widely used in building facades, signage, and interior/exterior decorative projects.

-

3003 H14 Anodized Aluminum Sheet

Anodized sheet with an oxide layer that improves corrosion resistance, wear resistance, and surface hardness. Ideal for architectural applications, appliances, and decorative trim.

-

3003 H14 Color-Coated Aluminum Sheet

Aluminum sheet coated with a variety of colors for aesthetic and protective purposes. Frequently used in roofing panels, ceilings, curtain walls, and advertising boards.

-

3003 H14 Perforated Aluminum Sheet

Aluminum sheet with custom perforations for ventilation, filtration, or decoration. Commonly used in screens, ceilings, facades, and soundproofing panels.

-

3003 H14 Corrugated Aluminum Sheet

Corrugated aluminum sheet with wave-like patterns that increase strength while keeping the material lightweight. Suitable for roofing, siding, wall panels, and temporary structures.

-

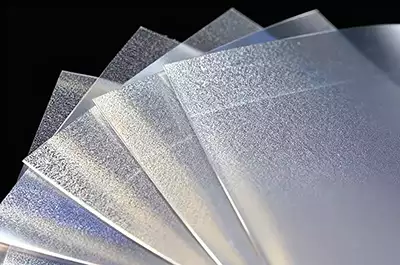

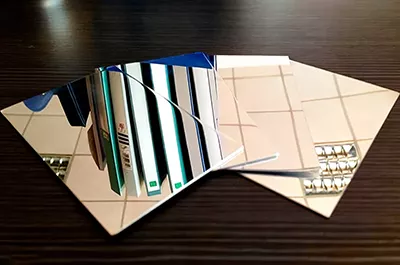

3003-H14 Mirror Polished Aluminum Sheet

Highly reflective polished surface that provides a mirror-like finish. Used in decorative applications, lighting reflectors, and interior design elements.

-

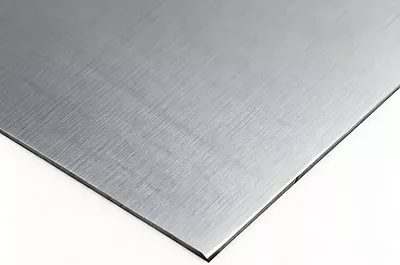

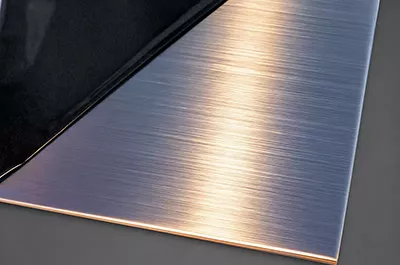

3003-H14 Brushed Aluminum Sheet

Brushed surface finish with linear texture that offers a modern, elegant appearance. Widely applied in household appliances, interior decoration, and signage.

-

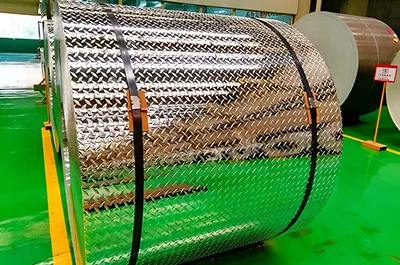

3003 H14 Aluminum Diamond Plate

Aluminum sheet with raised diamond patterns that provide anti-slip properties and durability. Commonly used in flooring, stair treads, truck beds, and industrial walkways.

-

3003 H14 Aluminum Tread Plate

Similar to diamond plate but available in various raised tread patterns for slip resistance. Ideal for flooring, loading ramps, vehicle steps, and protective wall panels.

3003 H14 Aluminum Plate Sheet Color Options

3003 H14 Aluminum Properties

- Alloy Composition: Primarily aluminum with about 1.2% manganese, providing around 20% higher strength compared to 1100 series.

- Temper Name (H14): Indicates the material has undergone strain hardening and partial annealing, achieving a semi-hard state with balanced strength and formability.

- Corrosion Resistance: Due to the manganese content, it performs excellently in atmospheric and marine environments.

- Formability: Easy to bend, deep draw, spin, or weld using standard methods.

- Lightweight: Density is approximately 2.73 g/cm³ (0.099 lb/in³), making it ideal for transportation and construction applications.

- Not Heat-Treatable: Strength can only be enhanced through cold working.

- Good Formability: Easy to carry out deep drawing, spinning, and other processes.

- Excellent Weldability: Can be joined by welding or brazing.

3003 H14 Aluminum Sheet Applications

3003 H14 aluminum is commonly used to manufacture metal sheet parts, including panels, pipes, and cabinets. It is also widely used in the packaging industry for producing food and beverage cans and in the construction industry for producing roofing and wall panel materials. Due to its excellent corrosion resistance, it is frequently used in marine and chemical processing applications.

| Application Field | Description |

| Construction | 3003 H14 aluminum sheet is widely used in the construction industry, especially for roofing, wall panels, and decorative elements. Its excellent weather resistance makes it an ideal choice for curtain walls and exterior cladding, particularly for external decoration of buildings. 3003 H14 aluminum sheet is typically available in thicknesses of 1.0 to 4.0mm, offering both aesthetic and durable building appearances, while its oxidation and corrosion resistance enables it to withstand various weather conditions. |

| Food and Chemical Equipment | 3003 H14 aluminum sheet is widely used in food and chemical equipment due to its low reactivity and corrosion resistance. It is commonly used to manufacture storage tanks, cookware, and processing equipment, especially for storing and processing chemically active substances. Its excellent corrosion resistance ensures that the aluminum sheet does not release harmful substances when handling food or chemicals, meeting sanitary standards, and is suitable for long-term contact with food or chemicals in equipment manufacturing. |

| Automotive | 3003 H14 aluminum sheet also plays an important role in the automotive industry, particularly in the manufacture of fuel tanks and heat exchangers. Due to its lightweight and good formability, 3003 H14 aluminum sheet helps reduce the overall weight of vehicles, improving fuel efficiency. Meanwhile, the corrosion resistance of aluminum ensures the durability of these components, especially when vehicles are exposed to humid and harsh environments for extended periods. |

| HVAC Systems | 3003 H14 aluminum sheet is widely used in HVAC (Heating, Ventilation, and Air Conditioning) systems, especially in piping systems and other components requiring lightweight and corrosion-resistant materials. Its excellent workability and corrosion resistance make it an ideal material for transporting air and fluids in HVAC systems, especially for equipment exposed to moisture or corrosive environments over time. |

| Packaging | 3003 H14 aluminum sheet is mainly used for the production of containers and closures in the packaging industry. Its processability and corrosion resistance make 3003 H14 aluminum sheet very suitable for packaging food and beverages, particularly for products that need long-term storage. The lightweight characteristics of aluminum make packaging more convenient while effectively maintaining the safety and hygiene of the packaged contents. |

| New Energy Vehicles | 3003 H14 aluminum sheet has received widespread attention in the new energy vehicle sector, especially in the power battery enclosures (such as square lithium batteries). Aluminum sheet has good deep drawing performance, which meets the complex structural needs of battery enclosures, while its lightweight characteristics help reduce the overall vehicle weight and improve battery efficiency. The use of 3003 H14 aluminum sheet not only enhances the impact resistance of the battery enclosure but also effectively improves overall safety and reliability. |

| Industrial Packaging | 3003 H14 aluminum sheet is also widely used in industrial packaging, particularly in the manufacture of electronic device enclosures, heat sinks, etc. Its excellent conductivity and ease of processing make 3003 H14 aluminum sheet ideal for electronic product enclosures and cooling systems, which can effectively improve heat dissipation and protect electronic components from external factors, ensuring the stable operation of the equipment over time. |

| General Parts | 3003 H14 aluminum sheet plays an important role in manufacturing general parts, particularly in the production of stamped parts and molds. Due to its medium strength and excellent plasticity, 3003 H14 aluminum sheet can be applied in various scenarios that require medium strength and high elongation, such as automotive parts, household appliance components, etc. Its excellent workability makes it an ideal material for processing complex shapes and high-precision components. |

What is Equivalent to 3003 H14?

UNS A93003; ISO AlMn1Cu; Aluminium 3003-H14; AA3003-H14; Al3003-H14

3003 H14 Aluminum Mechanical Properties

| Property | Value |

| Density g/cm^3 | 3 |

| Ultimate Tensile Strength KSI | 22 |

| Brinell Hardness 500 kg load | 40 |

| Yield Tensile Strength KSI | 21 |

| Elongation % in 2 in. | 8 |

| Shear Strength KSI | 14 |

| Melting Point °F | 1190 - 1210 |

| Machinability % | 30 |

| Electrical Conductivity % IACS | 44 |

3003 Aluminum Chemistry Information

| Element | Percentage |

| Al | 98.7 |

| Cu | 0.05 - 0.2 |

| Fe | 0.7 max |

| Mn | 1 - 1.5 |

| Si | 0.6 max |

| Zn | 0.1 max |

3003 H14 Aluminum Sheet Physical Properties

- Formability: High elongation rate, suitable for deep drawing processes, can be formed into complex shapes (such as new energy vehicle battery shells) through 5-7 passes.

- Corrosion Resistance: The surface oxide film is dense, suitable for humid or high-temperature environments.

- Lightweight: Density of about 2.73g/cm³, approximately one-third the weight of steel, contributing to weight reduction needs.

Haomei 3003 H14 Aluminum Alloy Products

3003 H14 Aluminum Sheet

Lightweight, corrosion-resistant aluminum sheet with good formability and weldability; commonly used for roofing, siding, decorative panels, and general sheet metal applications.

3003 H14 Aluminum Plate

Thicker, more robust form of 3003 H14 alloy offering moderate strength and excellent corrosion resistance for structural components, industrial equipment, marine parts, and storage tanks.

3003 H14 Aluminum Tubing

Formable and corrosion-resistant tubing suitable for lightweight structural frameworks, HVAC components, irrigation pipes, and other applications requiring good ductility and weldability.

3003 H14 Aluminum Coil

Rolled coil stock for continuous production — ideal for roofing panels, siding, curtain walls, and chemical equipment; easily cut, bent, and stamped to shape.

3003 H14 Aluminum Strip / Tape

Slit strip and tape offering flexibility and corrosion resistance, used for cable wrapping, heat exchangers, insulation cladding, and decorative trims.

3003 H14 Aluminum Circle / Disc

Blanked circles and discs with excellent ductility for cookware blanks, lighting reflectors, traffic signs, and stamped components requiring smooth formability.

Comparison of 3003 H14 Aluminum and Similar Alloys

- Compared to 5052 aluminum alloy: 5052 (magnesium alloy) offers higher strength and better saltwater resistance, while 3003 H14 is more cost-effective and easier to form, making it more suitable for general applications.

- Compared to 1100 series: 3003 H14 has 20% higher strength while maintaining similar corrosion resistance.

| Comparison Item | 3003 H14 Aluminum Alloy | 5052 Aluminum Alloy | 1100 Series Aluminum Alloy |

| Strength | 3003 H14 has lower strength, but is about 20% stronger than 5052. Suitable for light load-bearing applications. | 5052 has higher strength, especially in high-pressure or heavy-load applications. | 1100 Series aluminum alloys have the lowest strength, suitable for light-load and low-strength requirements. |

| Corrosion Resistance | 3003 H14 has good corrosion resistance, suitable for general environmental applications, but is less resistant to saltwater than 5052. | 5052 has better corrosion resistance in harsh environments like saltwater, making it suitable for marine or chemical applications. | 1100 Series aluminum alloys have excellent corrosion resistance, especially suitable for humid environments. |

| Formability | 3003 H14 is very easy to form, suitable for complex processing requirements, and has a low processing cost. | 5052, although it has good formability, is more difficult to process than 3003 H14 and is more expensive. | 1100 Series aluminum alloys have the best formability and are easy to process both cold and hot. |

| Cost-effectiveness | 3003 H14 is a more economical choice, suitable for large-scale general applications, especially in cost-sensitive fields. | 5052 is more expensive and is suitable for applications requiring higher strength and corrosion resistance, but it has a higher cost. | 1100 Series aluminum alloys are the least expensive and are suitable for low-load applications where strength is not critical. |

| Application Scenarios | Suitable for most general applications, such as home appliances, automotive parts, kitchen equipment, decorative parts, etc. | Widely used in environments requiring high strength and good corrosion resistance, such as marine equipment, the chemical industry, etc. | Mainly used in applications with low strength requirements, such as packaging, decoration, lightweight structural components, etc. |

3003 H14 Aluminum vs 6061

For applications requiring good formability and medium strength, 3003-H14 is preferred. In contrast, 6061 is chosen for its higher strength, heat treatability, and excellent corrosion resistance, making it suitable for applications with higher demands.

| Feature | 3003-H14 Aluminum | 6061 Aluminum |

| Heat Treatment | 3003 H14 cannot be heat treated. Strength is achieved through cold working. | Can be heat treated. It can be processed into various states, such as T6, to increase strength and hardness. |

| Applications | Common Uses: Kitchen utensils, food and chemical processing, storage tanks, and residential roofing. Suitable for places requiring good formability and medium strength. | Common Uses: Aerospace components, automotive parts, structural components, marine applications, and high-stress machinery. Suitable for places requiring high strength, good corrosion resistance, and heat treatability. |

| Cost and Availability | Cost: Typically lower due to simpler alloying elements and lower strength. | Cost: Typically higher due to its higher strength and more complex alloying and heat treatment processes. |

Aluminum 3003-H14 vs 5052-H32

3003-H14 Aluminum: Offers excellent formability, typically used in applications requiring medium strength and good corrosion resistance in less corrosive environments. It is cost-effective and ideal for manufacturing kitchen utensils, storage tanks, and residential roofing materials.

5052-H32 Aluminum: Provides significantly higher strength and superior corrosion resistance, making it an ideal choice for more demanding applications such as marine environments and pressure vessels. It is more expensive and suited for applications where high strength and durability are crucial.

| Feature | 3003-H14 Aluminum | 5052-H32 Aluminum |

| Workability | Excellent formability, deep drawing, and welding | Good formability and welding; more challenging to machine |

| Heat Treatment | Not heat-treatable; strength is achieved through cold working | Not heat-treatable; strength is achieved through cold working and strain hardening |

| Corrosion Resistance | Good in atmospheric conditions; less so in harsh environments | Excellent, particularly in marine environments; highly resistant to corrosion |

| Applications | Kitchen utensils, food and chemical handling, storage tanks, residential roofing | Marine environments, automotive parts, pressure vessels, fuel tanks |

| Cost and Availability | Generally less expensive due to simpler alloy and processing | Typically more expensive due to alloy complexity and higher strength |

Haomei 3003 Aluminum Plate Sheet Stock List

| Description | Surface Treatment | Temper | Thickness (In) | Width (In) | Length (In) | Form |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.249" x 48" x 120" | Mill Finish | H14 | 0.249" | 48" | 120" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.250" x 24" x 48" | Mill Finish | H14 | 0.250" | 24" | 48" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.250" x 48" x 144" | Mill Finish | H14 | 0.250" | 48" | 144" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.375" x 24" x 48" | Mill Finish | H14 | 0.375" | 24" | 48" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.375" x 48" x 144" | Mill Finish | H14 | 0.375" | 48" | 144" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.63" x 24" x 48" | Mill Finish | H14 | 0.65" | 24" | 48" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Plate 0.63" x 48" x 144" | Mill Finish | H14 | 0.68" | 48" | 144" | Plate |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.032" x 48" x 144" | Mill Finish | H14 | 0.032" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.032" x 48" x 144" | Mill Finish | H14 | 0.032" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.04" x 48" x 120" | Mill Finish | H14 | 0.04" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.05" x 48" x 120" | Mill Finish | H14 | 0.05" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.063" x 48" x 96" | Mill Finish | H14 | 0.063" | 48" | 96" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.08" x 36" x 96" | Mill Finish | H14 | 0.08" | 36" | 96" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.08" x 48" x 144" | Mill Finish | H14 | 0.08" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.09" x 48" x 120" | Mill Finish | H14 | 0.09" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.09" x 60" x 120" | Mill Finish | H14 | 0.09" | 60" | 120" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.1" x 48" x 144" | Mill Finish | H14 | 0.1" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.125" x 36" x 120" | Mill Finish | H14 | 0.125" | 36" | 120" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.125" x 48" x 96" | Mill Finish | H14 | 0.125" | 48" | 96" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.19" x 48" x 144" | Mill Finish | H14 | 0.19" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003 H14 Mill Finish Aluminum Sheet 0.19" x 48" x 96" | Mill Finish | H14 | 0.19" | 48" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.02" x 36" x 96" | Stucco Embossed | H14 | 0.02" | 36" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Plate 0.250" x 24" x 24" | Stucco Embossed | H14 | 0.250" | 24" | 24" | Plate |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Plate 0.250" x 36" x 36" | Stucco Embossed | H14 | 0.250" | 36" | 36" | Plate |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Plate 0.375" x 24" x 24" | Stucco Embossed | H14 | 0.375" | 24" | 24" | Plate |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Plate 0.375" x 36" x 36" | Stucco Embossed | H14 | 0.375" | 36" | 36" | Plate |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Plate 0.63" x 24" x 24" | Stucco Embossed | H14 | 0.63" | 24" | 24" | Plate |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Plate 0.63" x 36" x 36" | Stucco Embossed | H14 | 0.66" | 36" | 36" | Plate |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.025" x 48" x 120" | Stucco Embossed | H14 | 0.025" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.032" x 36" x 120" | Stucco Embossed | H14 | 0.032" | 36" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.04" x 48" x 120" | Stucco Embossed | H14 | 0.04" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.05" x 60" x 120" | Stucco Embossed | H14 | 0.05" | 60" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.05" x 60" x 144" | Stucco Embossed | H14 | 0.05" | 60" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.063" x 48" x 144" | Stucco Embossed | H14 | 0.063" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.08" x 48" x 120" | Stucco Embossed | H14 | 0.08" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.08" x 60" x 120" | Stucco Embossed | H14 | 0.08" | 60" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.09" x 48" x 144" | Stucco Embossed | H14 | 0.09" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.09" x 60" x 96" | Stucco Embossed | H14 | 0.09" | 60" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.1" x 48" x 120" | Stucco Embossed | H14 | 0.1" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.125" x 60" x 144" | Stucco Embossed | H14 | 0.125" | 60" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.125" x 60" x 120" | Stucco Embossed | H14 | 0.125" | 60" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 Stucco Embossed Aluminum Sheet 0.19" x 60" x 144" | Stucco Embossed | H14 | 0.19" | 60" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.249" x 48" x 144" | White Painted Sheet | H14 | 0.249" | 48" | 144" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.250" x 24" x 36" | White Painted Sheet | H14 | 0.250" | 24" | 36" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.250" x 48" x 48" | White Painted Sheet | H14 | 0.250" | 48" | 48" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.375" x 24" x 36" | White Painted Sheet | H14 | 0.375" | 24" | 36" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.375" x 48" x 48" | White Painted Sheet | H14 | 0.375" | 48" | 48" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.63" x 24" x 36" | White Painted Sheet | H14 | 0.64" | 24" | 36" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Plate 0.63" x 48" x 48" | White Painted Sheet | H14 | 0.67" | 48" | 48" | Plate |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.032" x 48" x 120" | White Painted Sheet | H14 | 0.032" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.032" x 48" x 120" | White Painted Sheet | H14 | 0.032" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.04" x 48" x 144" | White Painted Sheet | H14 | 0.04" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.05" x 48" x 96" | White Painted Sheet | H14 | 0.05" | 48" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.063" x 48" x 120" | White Painted Sheet | H14 | 0.063" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.063" x 60" x 120" | White Painted Sheet | H14 | 0.063" | 60" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.08" x 48" x 96" | White Painted Sheet | H14 | 0.08" | 48" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.08" x 60" x 96" | White Painted Sheet | H14 | 0.08" | 60" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.09" x 48" x 96" | White Painted Sheet | H14 | 0.09" | 48" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.1" x 36" x 96" | White Painted Sheet | H14 | 0.1" | 36" | 96" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.125" x 48" x 120" | White Painted Sheet | H14 | 0.125" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.125" x 48" x 144" | White Painted Sheet | H14 | 0.125" | 48" | 144" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.19" x 48" x 120" | White Painted Sheet | H14 | 0.19" | 48" | 120" | Sheet |

| AMS 4008 ASTM B209 3003-H14 White Painted Aluminum Sheet 0.19" x 60" x 120" | White Painted Sheet | H14 | 0.19" | 60" | 120" | Sheet |

3003 H14 Aluminum Selection Recommendations

- 3003 H14 Aluminum Priority Scenarios: For deep drawing, lightweight, and high corrosion resistance requirements, such as in new energy vehicles, building curtain walls.

- 3003 H14 Aluminum Alternative: If higher strength is needed, consider 5052/H32 aluminum plates; if cost is a concern, choose 1-series pure aluminum.

Products you may be interested in

Further reading

Users viewing this material also viewed the following

- Aluminum Tread Plate 3003

- 3003 Embossed Aluminum Sheet

- 3003 Aluminum Diamond Plate

- 3003 Hot-rolled Aluminum Plate

- 3003 Honeycomb Aluminum

- 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell

- 3003+4343 Power Battery Cooling Plate

- 3003 Aluminum Plate for Brazing Water Cooling Plate

- Aluminum Brazing Composite Material 3003+4045 Aluminum Plate

- 3003 Aluminum Disc for Non-stick Pan

- 3003 Aluminum Plate for Mobile Phone Battery Shell

- 3003 Corrugated Aluminum Sheet

- 3003 Aluminum Plate for Automobile Fender

- 3003 Checker Aluminum Plate for Stair Anti-slip

- 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip

- 3003 Ultra-wide Curtain Wall Aluminum Plate

- 3003 Aluminum Plate for Building Decoration

- 3003 Roof Aluminum Plate for Decoration

- 3003 Aluminum Sheet Coil for Thermal Insulation Material

- 3003 Pre-painted Aluminum Coil

Recommended Content

- What is 3003 aluminum used for?

- 3003 Aluminum Tubing

- 3003 Aluminum vs. 3005 Aluminum

- 3003-H18 Aluminum vs. 3005-H18 Aluminum

- What is the difference between 3003 H14 and 3105 H14?

- 3003 Aluminum vs. 3104 Aluminum

- 3003-H18 Aluminum vs. 3004-H18 Aluminum

- 3003-O Aluminum vs. 3004-O Aluminum

- What is the difference between 3003 and 3004 aluminum?

- 3003-H22 Aluminum vs. 3003-H24 Aluminum

- What is the difference between 3003 O and 3003 H14?

- What is the difference between 3003 H14 and H24?