3003 Aluminum Foil

3003 aluminum foil belongs to the typical aluminum-manganese alloy (3xxx series) and is a mainstay product in the aluminum foil field due to its medium strength, excellent corrosion resistance, and good formability. Compared with 1000 series pure aluminum or 1100 aluminum foil, 3003 aluminum foil achieves approximately 20% higher strength through the addition of manganese, maintaining excellent ductility and tensile properties even in high-temperature environments, while also offering good weldability and machinability.

This aluminum foil cannot be strengthened by heat treatment; its strength is mainly achieved through cold working processes. Common temper conditions include H18, H22, and H24, and other hardness levels can be customized according to customer requirements.

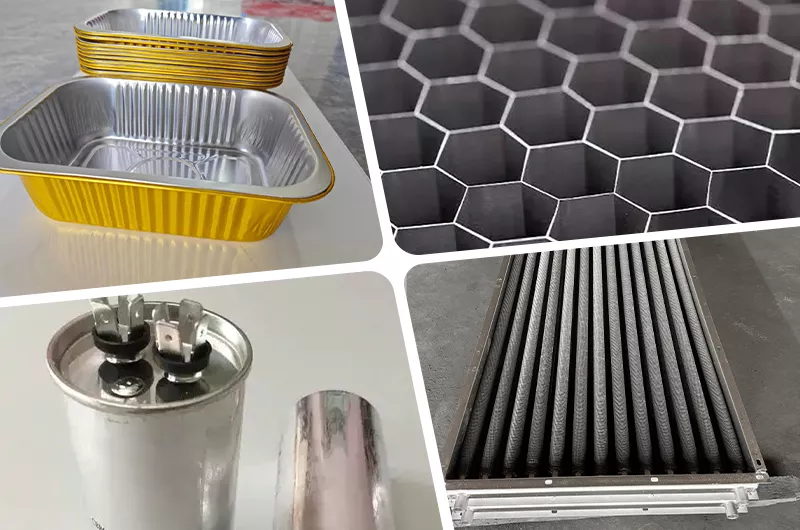

3003 aluminum foil is widely used in electronic foils, electrolytic capacitors, packaging materials, honeycomb cores, architectural sound insulation materials, and food containers. It is especially suitable for manufacturing components that require high formability, corrosion resistance, and stable mechanical properties. In addition, 3003 aluminum foil is often used for power battery casings, where its lightweight and high-strength characteristics help increase battery energy density, reduce vehicle weight, and ensure impact resistance and reliability during transportation and use.

Haomei Aluminum has been focusing on producing high-quality 3003 aluminum foil products since 1997, including household aluminum foil, container aluminum foil, packaging aluminum foil, and electronic aluminum foil. With stable mechanical properties and excellent corrosion resistance, our products meet diverse industrial and consumer needs.

3003 Aluminum Foil Specifications

| Item | Specification |

| Alloy Type | 3003 Aluminum-Manganese Alloy (Al-Mn) |

| Standard | QQA-1876, ASTM B479 |

| Thickness Range | 0.006 mm – 0.2 mm (customizable) |

| Ultra-thin foil (<0.02 mm): composite flexible packaging | |

| Medium-thick foil (0.02–0.1 mm): household, container, industrial materials | |

| Thick foil (>0.1 mm): high-rigidity container lids, industrial components | |

| Width Range | Approximately 10 mm – 1524 mm (can be slit to requirement) |

| Supply Form | Rolls (large/small), sheets, cut-to-size pieces |

| Temper / Hardness | O (Annealed): Softest, best formability |

| H14/H16/H18/H24 (strain-hardened): hardness and strength gradually increase, suitable for semi-hard to hard structural applications | |

| Surface | Single-sided/double-sided glossy finish, lubricated (oil-treated). |

| Typical Applications | Packaging materials, household aluminum foil, containers, electrolytic capacitors, honeycomb materials, industrial parts, power battery casings, etc. |

3003 Aluminum Foil Features and Advantages

3003 aluminum foil is a typical aluminum-manganese alloy (Al-Mn), containing approximately 1.0%–1.5% manganese, combining excellent strength and ductility, making it an ideal material for food packaging, liquid storage, and industrial applications. Its medium strength, higher than 1100 aluminum foil, meets most applications with general strength requirements while losing minimal ductility.

Outstanding Corrosion Resistance

3003 aluminum foil exhibits excellent resistance to atmospheric, chemical, and aqueous corrosion, making it especially suitable for humid environments and food contact applications, effectively resisting various chemical media.

Excellent Formability

In the annealed state (O temper), this foil is soft and can easily undergo deep drawing, spinning, bending, and stamping without cracking, suitable for various customized shapes and industrial processing requirements.

Good Thermal and Electrical Conductivity

3003 aluminum foil has high thermal conductivity, suitable for heat exchangers, cookware, and electronic heat dissipation components, and also possesses certain electrical conductivity to meet some thermal and electrical requirements.

Machining and Welding Performance

Although its strength is mainly achieved through cold working (strain hardening) rather than heat treatment, its machinability is excellent, easy to shear, stamp, weld (with special welding wire), coat, and print, allowing for diversified processing and surface treatment.

Environmental and Safety

3003 aluminum foil is non-magnetic, non-toxic, recyclable, and complies with modern food safety and environmental protection requirements.

With medium strength, excellent corrosion resistance, superior formability, and good thermal and electrical conductivity, 3003 aluminum foil demonstrates high cost-effectiveness in food packaging, liquid storage, industrial manufacturing, and cookware applications, making it a reliable and versatile aluminum alloy material choice.

3003 Aluminum Foil Applications

Due to its excellent corrosion resistance, good formability, and medium strength, 3003 aluminum foil is widely used in multiple fields, including food packaging, industrial manufacturing, construction, and electronics.

Food and Pharmaceutical Packaging

In the field of food and pharmaceutical packaging, 3003 aluminum foil is one of the core materials, widely used for yogurt lids, jelly lids, meal boxes, pull tabs for cans, as well as snack bags, coffee bags, milk powder bags, and steam bags laminated with plastic or paper, providing good barrier properties and rigidity. In addition, rolled or sheet aluminum foil for household grilling, baking, and food wrapping is also an important application.

Industrial and Construction

In industrial and construction applications, 3003 aluminum foil is often used for lightweight high-strength honeycomb cores, outer insulation layers of air conditioning and hot water pipes, roof and wall decorative panels, acoustic ceilings, and shielding layers for communication cables, combining lightweight, corrosion resistance, and decorative effects.

Daily Use and Electronics

In daily use and electronics, it is used for sealed bottle caps for beverages and medicines, housings and heat sinks for electronic components (such as capacitors and LED substrates), labels for premium alcoholic beverages and cosmetics, meeting both functional and aesthetic requirements.

Heat Exchangers and Special Industrial Applications

3003 aluminum foil is also widely used in heat exchanger fins, radiators, thermal and moisture insulation layers, as well as chemical and industrial linings, demonstrating its balanced overall performance and high industrial adaptability.

With excellent corrosion resistance, formability, and thermal conductivity, 3003 aluminum foil permeates nearly every corner of modern life and industry, making it an indispensable high-performance aluminum alloy material across multiple industries.

3003 Aluminum Composition

| Element | 3003 |

| Silicon | 0.6 |

| Iron | 0.7 |

| Copper | 0.05-0.20 |

| Manganese | 1.0-1.5 |

| Zinc | 0.10 |

| Aluminum | balance |

| Other Elements (each) | 0.05 |

| Other Elements (total) | 0.15 |

Aluminium 3003 Mechanical Properties

| Property | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| 3003 O (Annealed) | 110–145 | 35–70 | 18–28 | 35–50 |

| 3003 H14 (Half-Hard) | 190–215 | 125–145 | 8–12 | 60–75 |

| 3003 H16 (3/4 Hard) | 215–235 | 150–170 | 6–10 | 70–85 |

| 3003 H18 (Full Hard) | 230–250 | 175–210 | 3–6 | 85–95 |

Why Choose 3003 Aluminum Foil?

Compared with ordinary pure aluminum foil, 3003 aluminum foil offers approximately 20% higher strength. While maintaining its lightweight characteristics, it is more durable, less prone to tearing or deformation, and can meet the strength requirements of various industrial and everyday applications.

In addition, 3003 aluminum foil has excellent corrosion resistance, capable of withstanding prolonged exposure to air, moisture, and various chemical media. This makes it particularly reliable in food packaging, pharmaceutical packaging, chemical packaging, and construction protection applications.

In terms of processing performance, 3003 aluminum foil has excellent ductility and can easily be processed through rolling, coiling, bending, stretching, or printing into different thicknesses and specifications to meet diverse production needs. Combined with its reasonable cost, 3003 aluminum foil becomes an economical choice that balances high strength, corrosion resistance, and ease of processing. Whether for industrial applications or food packaging, 3003 aluminum foil provides stable quality and reliable performance.

Is 3003 Aluminum Foil Suitable for Your Project?

At Haomei Aluminum, we recommend 3003 aluminum foil as an ideal choice for a wide range of applications. With excellent ductility and corrosion resistance, 3003 aluminum foil is especially suitable for deep drawing processes, such as producing deep food trays, pharmaceutical packaging, or other precision-formed products. Additionally, its moisture resistance is outstanding, ensuring it does not easily rust even in high-humidity environments, providing reliable assurance for your project.

Of course, if your project requires higher strength or high-temperature resistance, we can also provide 5xxx or 6xxx series aluminum foil to ensure optimal performance in different application scenarios. Haomei Aluminum is committed to providing each customer with precisely matched aluminum solutions, helping your projects be implemented efficiently and safely.

3003 Aluminum Foil vs 8011

8011-type materials focus on flexibility and safety, whereas 3003-type materials emphasize durability and strength.

| Feature | 3003 Aluminum Foil | 8011 Aluminum Foil |

| Main Alloy | Manganese ($Mn$) | Iron ($Fe$) & Silicon ($Si$) |

| Strength | Higher. Better for structural parts. | Lower. Optimized for flexibility. |

| Corrosion | Excellent (very high $Mn$ content). | Good, but slightly less than 3003. |

| Formability | Best for Deep Drawing (deep trays). | Best for Wrapping and sealing. |

| Primary Use | HVAC, industrial trays, heat shields. | Household foil, pharma blister packs. |

When to choose 8011 (The "Flexible" Choice)

Choose 8011 if your project involves:

- Food Packaging: It is the standard for "dead-fold" (wrapping a sandwich or lining a tray) because it stays in place perfectly.

- Lamination: It bonds exceptionally well to paper or plastic films for things like yogurt lids or candy wrappers.

- Medicine: It’s the go-to for blister packs because it’s easy to puncture but keeps out moisture.

When to choose 3003 (The "Rigid" Choice)

Choose 3003 if your project involves:

- Rigid Containers: If you are manufacturing deep-dish foil pans or heavy-duty food trays that shouldn't collapse when picked up.

- High Temperature/Pressure: Its higher tensile strength makes it better for automotive heat shields or radiator components.

- Extreme Moisture: The manganese gives it a slight edge in resisting "white rust" in humid environments.

Comparison of 3003 Aluminum Foil with Other Common Aluminum Foils

| Property | 3003 Aluminum Foil | 1050/1060 Pure Aluminum Foil | 5052 Aluminum Foil |

| Main Alloy | Al-Mn | Pure Aluminum (>99.5%) | Al-Mg |

| Strength | Medium | Low (softer) | High |

| Formability | Excellent | Very Good | Good (but harder than 3003) |

| Corrosion Resistance | Good | Excellent | Superior (especially resistant to seawater) |

| Typical Applications | Packaging containers, household foil, industrial materials | Electrolytic capacitors, high-reflectivity mirrors, labels | Ships, vehicle components, high-demand containers |

| Cost | Medium | Lower | Higher |

- If you need deep drawing (e.g., making complex containers), 3003 is the first choice.

- If you require extremely high corrosion resistance (e.g., exposure to seawater or highly corrosive food), 5052 may be more suitable.

- If you need the softest foil (e.g., for wrapping very delicate items), 1060 pure aluminum foil is better.

- For blister packaging (e.g., pill packs), 8011 is more commonly used due to its better ductility and fold resistance.

3003 Aluminum Foil Selection Recommendations

At Haomei Aluminum, we recommend that customers consider the following key factors when selecting 3003 aluminum foil to ensure that the material performance perfectly matches the project requirements:

- Application: Clearly define what type of product or process the aluminum foil will be used for, as this directly determines the required strength, ductility, and corrosion resistance.

- Thickness: Choose the appropriate thickness based on product functionality and processing requirements. Thickness affects barrier performance, strength, and cost, and is an important reference for selection.

- Temper: Select the appropriate softness or hardness according to the processing method. O temper is the softest and suitable for deep drawing; H18 is the hardest and suitable for applications with high strength requirements.

- Surface Treatment: Confirm whether oiling, non-stick coating, printing, or choosing glossy/matte finishes is needed to meet functional or aesthetic requirements.

- Specifications: Determine the required roll width, roll weight, or sheet size according to equipment and production plans to ensure efficient and economical production.

Haomei Aluminum is dedicated to providing customers with customized 3003 aluminum foil solutions, offering professional guidance from material selection to processing, ensuring your project is successfully implemented.

Further reading

- 3003 Aluminum Coil

- 3003 Aluminum Plate and Sheet

- 3003 h14 aluminum sheet

- 3003 h22 aluminum sheet

- 3003 o aluminum sheet

- 3003 Aluminum Disc Circle

Users viewing this material also viewed the following

- Aluminum Tread Plate 3003

- 3003 Embossed Aluminum Sheet

- 3003 Aluminum Diamond Plate

- 3003 Hot-rolled Aluminum Plate

- 3003 Honeycomb Aluminum

- 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell

- 3003+4343 Power Battery Cooling Plate

- 3003 Aluminum Plate for Brazing Water Cooling Plate

- Aluminum Brazing Composite Material 3003+4045 Aluminum Plate

- 3003 Aluminum Disc for Non-stick Pan

- 3003 Aluminum Plate for Mobile Phone Battery Shell

- 3003 Corrugated Aluminum Sheet

- 3003 Aluminum Plate for Automobile Fender

- 3003 Checker Aluminum Plate for Stair Anti-slip

- 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip

- 3003 Ultra-wide Curtain Wall Aluminum Plate

- 3003 Aluminum Plate for Building Decoration

- 3003 Roof Aluminum Plate for Decoration

- 3003 Aluminum Sheet Coil for Thermal Insulation Material

- 3003 Pre-painted Aluminum Coil

Recommended Content

- Aluminium 3003 H14 Data Sheet

- What is 3003 aluminum used for?

- 3003 Aluminum Tubing

- 3003 Aluminum vs. 3005 Aluminum

- 3003-H18 Aluminum vs. 3005-H18 Aluminum

- What is the difference between 3003 H14 and 3105 H14?

- 3003 Aluminum vs. 3104 Aluminum

- 3003-H18 Aluminum vs. 3004-H18 Aluminum

- 3003-O Aluminum vs. 3004-O Aluminum

- What is the difference between 3003 and 3004 aluminum?

- 3003-H22 Aluminum vs. 3003-H24 Aluminum

- What is the difference between 3003 O and 3003 H14?

- What is the difference between 3003 H14 and H24?