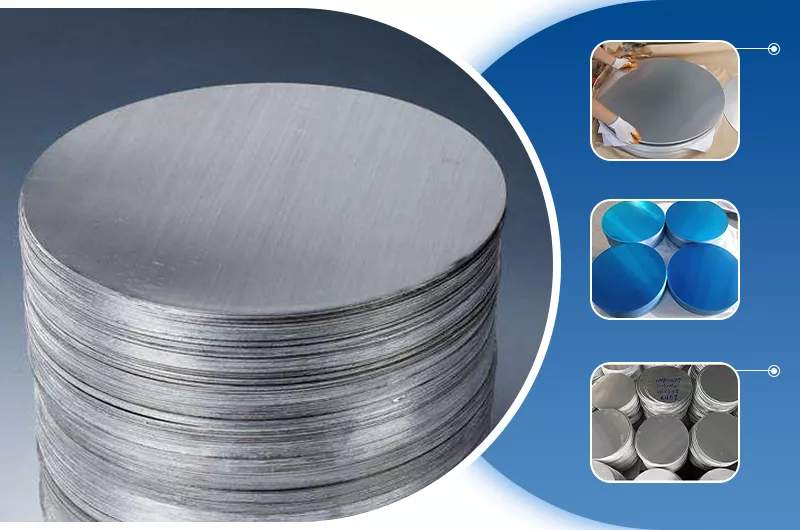

3003 Aluminum Disc Circle

3003 aluminum circles are round aluminum blanks made from 3003 aluminum alloy (Al-Mn series). They are well known for their excellent corrosion resistance, good formability, and smooth surface quality. They are one of the most commonly used aluminum circle materials for deep drawing and spinning applications.

3003 aluminum circles (also known as aluminum discs) are among the most widely used products in the aluminum processing industry. Because the 3003 alloy contains manganese, its strength is significantly higher than that of the 1xxx series (pure aluminum), while still maintaining excellent processing performance.

3003 aluminum circles belong to the 3xxx series aluminum alloys and are one of the most widely used rust-resistant aluminum materials. By adding approximately 1.0%–1.5% manganese to pure aluminum, the alloy significantly improves strength and corrosion resistance while retaining good workability.

3003 aluminum circles can be easily stamped, drawn, and bent into various complex shapes, and are widely used in cookware, pressure cookers, lighting equipment, electronics, construction, automotive components, and other industries. When selecting products, the appropriate temper and specifications should be chosen according to the specific application, and attention should be paid to material certification and surface quality.

As a professional 3003 aluminum circle manufacturer, Haomei Aluminum provides precision-cut circles with high dimensional accuracy and tight tolerances, along with factory-direct pricing and fast global delivery. Custom sizes and specifications are available upon request.

3003 Aluminum Disc Circle Specifications

| Property | Standard Range |

| Alloy | 3003 |

| Temper | O (Annealed), H12, H14, H16, H18, H24 |

| Thickness | 0.3mm – 10.0mm |

| Diameter | 100mm – 1200mm |

| Surface Finish | Bright, Mill Finish, Anodized, or Coated |

| Special Customization | Oversized dimensions or special shapes can be produced according to requirements |

Common Tempers and Performance Applications of 3003 Aluminum Circles

O Temper (Annealed)

Process: Full annealing

Characteristics: Softest condition with extremely high ductility; easy for deep drawing, stretching, and bending

Applications: Cookware, electronic device housings, components requiring complex forming

H Temper

H12/H22 (1/4 Hard):

- Tensile strength: 130–160 MPa, elongation ≥12%

- Suitable for light forming, such as lighting reflectors and signage

H14/H24 (1/2 Hard):

- Tensile strength: 170–200 MPa, elongation ≥5%

- Suitable for structural parts requiring a certain level of rigidity, such as electronic equipment frames

H18/H38 (Full Hard):

- Tensile strength: ≥200 MPa, elongation ≥3%

- Suitable for components with high hardness requirements, such as lithium battery housings

| Alloy (Temper) | Processing Description | Performance Characteristics | Key Application Areas |

| 3003 O | Fully annealed condition (Soft) | Softest condition; highest elongation; excellent ductility; extremely easy to draw. | Deep drawing/deep forming products, such as deep pots, pressure cookers, special-shaped containers, and lampshades. |

| 3003 H12 | 1/4 hard | Slightly higher strength than O temper; retains good ductility with moderate springback. | Shallow stamped parts, general utensils, and standard spinning products. |

| 3003 H14 | Half-hard condition | Most widely used; best balance of strength, hardness, and ductility; resistant to deformation and easy to process. | Standard cookware such as non-stick pan bases, frying pans, traffic signs, and rice cooker inner pots. |

| 3003 H16 | 3/4 hard | Higher strength with reduced ductility; suitable for simple bending but not for stretching. | Architectural decorative materials, electronic components, and rigid signage. |

| 3003 H18 | Full hard condition | Highest strength; low elongation; very brittle; high hardness and excellent wear resistance. | Heat sink substrates, battery housings, and industrial support parts that do not require stamping. |

| 3003 H24 | Half-hard (partially annealed) | Performance close to H14; higher tensile strength with slightly better elongation than H14. | High-end composite cookware bases and parts requiring high flatness after forming. |

3003 Aluminum Circle Surface Treatment

3003 Mill Finish Aluminum Circle

- Mill finish / rolled surface: the original surface without any subsequent treatment, featuring slight rolling marks.

- Applications: industrial substrates, simple drawn parts, internal components that do not require decorative appearance.

3003 Brushed Aluminum Circle

- Brushed surface: continuous linear textures formed on the surface through mechanical abrasive belts or brush wheels.

- Applications: high-end cookware outer walls, electronic product housings, interior decorative panels.

3003 Polished/Mirror Finish Aluminum Circle

- Polished / mirror finish: multiple mechanical polishing processes create a highly reflective mirror-like surface.

- Applications: lighting reflectors, high-brightness decorative rings, laboratory utensils.

3003 Anodized Aluminum Circle

- Anodizing: a hard, transparent, or colored oxide film is formed on the surface through electrolysis.

- Applications: sports water bottles, hard-anodized cookware, corrosion-resistant architectural accessories.

3003 Non-stick Coated Aluminum Circle

- Non-stick coating: the surface is coated with polytetrafluoroethylene (PTFE) or ceramic materials and cured at high temperature.

- Applications: rice cooker inner pots, frying pans, baking trays.

3003 Powder Coated Aluminum Circle

- Powder coating: colored powder is electrostatically sprayed and baked to form a thick, durable colored protective layer.

- Applications: colored lampshades, traffic signage, outdoor metal artworks.

3003 PE/PVDF Coated Aluminum Circle

- Fluorocarbon / polyester coating: typically applied on coils before punching, offering excellent weather resistance.

- Applications: architectural exterior wall decoration, roofing panels, high-end signage.

3003 Sandblasted Aluminum Circle

- Sandblasted surface: abrasives impact the surface to create a uniform fine matte texture.

- Applications: modern-style lighting fixtures, electronic equipment bases, anti-slip components.

3003 Aluminum Circle Processing Methods

Stamping

- Principle: pressure is applied to the aluminum circle using a press and die to cause separation or shallow deformation, mainly used for flat processing.

- Advantages of 3003: H14/H16 tempers provide moderate strength, fast processing speed, high dimensional accuracy, and flat surfaces.

- Applications: bottle caps, traffic signs, gaskets, automobile license plates.

Deep Drawing (Stretch Forming)

- Principle: a punch presses the aluminum circle into a die, causing radial stretching and circumferential compression.

- Advantages of 3003: 3003-O temper is the preferred choice for deep drawing, offering extremely high elongation and uniform wall thickness in formed products.

- Applications: pressure cookers, deep soup pots, rice cooker inner pots.

Spinning

- Principle: the aluminum circle is fixed on a rotating mandrel, and pressure from spinning rollers gradually forces the sheet to conform to the mold shape.

- Advantages of 3003: suitable for manufacturing complex curved shapes with rotational symmetry.

- Applications: lampshades, reflectors, woks, decorative containers with special shapes, funnels.

| Processing Method | Temper | Standard Description (Product Name/Description) | Typical End Applications |

| Stamping | H14 / H16 | 3003 H14 Stamping Aluminum Circle | Bottle caps, traffic signs, gaskets |

| Deep Drawing | O (Hot Rolled) | 3003 DC Deep Drawing Aluminum Circle | Pressure cookers, rice cooker inner pots, deep pots |

| Spinning | O / H12 | 3003 Spinning Quality Aluminum Circle | Lampshades, reflectors, woks |

- General stamping: H14 is the most cost-effective choice, ensuring sufficient hardness while maintaining stable formability.

- Deep drawing: O temper must be used. If the drawing depth is extremely large, intermediate annealing may be required during processing.

- Spinning: O temper or H12 is recommended to prevent cracking during processing.

Stamping Processed 3003 Aluminum Circles

Common tempers: H14 / H16

- 3003 Aluminum Bottle Caps

- 3003 Aluminum Traffic Signs

- 3003 Aluminum Gaskets / Washers

- 3003 Aluminum License Plates

Deep Drawn 3003 Aluminum Circles

Common temper: O temper

- 3003 Aluminum Pressure Cooker Bodies

- 3003 Aluminum Rice Cooker Inner Pots

- 3003 Aluminum Deep Soup Pots

- 3003 Aluminum Aerosol Cans

Spinning Processed 3003 Aluminum Circles

Common tempers: O temper / H12

- 3003 Aluminum Lamp Shades

- 3003 Aluminum Reflectors

- 3003 Aluminum Cooking Woks

- 3003 Aluminum Artware / Vases

- Hot Rolled (DC): If you require deep drawing, it is recommended to clearly specify Hot Rolled or DC Quality, as hot rolled blanks have finer grain structures and will not produce “orange peel” surface defects during high-depth cookware forming.

- Cold Rolled (CC): If you only need flat traffic signs or shallow stamping, Cold Rolled (CC) is sufficient and more cost-effective.

3003 Aluminum Disc Circle Features

- Strength: Moderate strength; not heat-treatable, but strength can be increased through cold working.

- Formability: Highly suitable for deep drawing, spinning, bending, and stamping, allowing complex shapes to be formed.

- Corrosion resistance: Excellent; suitable for outdoor and humid environments.

- Weldability: Good; easy to weld using conventional methods.

- Non-heat-treatable alloy: Strength can only be increased through cold working and cannot be hardened by heat treatment.

- Electrical conductivity: Good (approximately 60% of pure aluminum), suitable for electrical applications.

- Machinability: Weldable and machinable.

- Thermal conductivity: Suitable for heat transfer applications.

- Smooth and clean surface with low earing rate.

3003 Aluminum Disc Circle Chemical Composition Limits

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al Min |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | – | – | – | – | 0.05 | 0.15 | Remainder |

Typical Mechanical Properties Data Of Aluminum 3003

| Alloy-Temper | Tensile Strength | Yield Strength | Elongation |

| (ksi) | (ksi) | (%) | |

| 3003-O | 16 | 6 | 30 |

| 3003-H14 | 22 | 21 | 3 |

| 3003-H18 | 29 | 27 | 3 |

3003 Aluminium Circle Diameter Tolerance

| Nominal Diameter | Tolerance |

| Multiple of 5mm | +/- 0.5mm |

| Not multiple of 5mm | +/- 3.0mm |

3003 Aluminum Disc Circle Applications

- Cookware: pots, frying pans, lids, pressure cookers (due to excellent formability and corrosion resistance).

- Tanks and containers: storage tanks, fuel tanks, chemical equipment.

- Signage and decoration: road signs, vehicle decorative parts, architectural components.

- HVAC: refrigerator panels, gas pipelines.

- Lighting: reflective lampshades and recessed lighting components.

- Industrial: pressure vessels, tanks, and fuel tank end caps.

- Electronics: heat sinks, housings.

- Automotive: heat exchangers, fuel tanks, piping systems.

- Construction: garage doors, refrigerator panels.

| Application Scenario | Common Thickness Range (mm) | Recommended Temper | Processing Method |

| Deep drawn cookware | 1.0 - 5.0 | O | Deep drawing, stretching, spinning |

| Lighting fixtures / reflectors | 0.5 - 1.5 | O | Spinning, stamping |

| Electronic enclosures | 0.8 - 2.0 | H14 / H24 | Bending, shallow stamping |

| Pressure vessel heads | 3.0 - 10.0 | O / H112 | Spinning, heavy stamping |

| Food packaging containers | 0.2 - 1.0 | H14 / H24 | Stamping |

3003 Aluminum Disc Circle for the Cookware Industry

Inner bodies and bases of non-stick pans, frying pans, and pressure cookers

Advantages: uniform heat conduction, resistance to deformation, corrosion resistance, lightweight

- Common thickness: 1.0mm - 6.0mm (high-end pressure cookers or cookware bases may be thicker).

- Common temper: O temper (fully annealed, most suitable for deep drawing and resistant to cracking).

- Common diameter: 100mm - 1200mm.

- Feature description: Compared with 1050 pure aluminum, 3003 has higher hardness, making cookware less prone to deformation.

3003 Aluminum Disc Circle for Electronics and Electrical Applications

Heat sinks, electronic equipment housings, lithium battery casings (H14 temper)

Advantages: good electrical conductivity and heat dissipation performance, electromagnetic shielding properties

- Common thickness: 0.5mm - 3.0mm.

- Common temper: H14 (half-hard) or H24 (strain-hardened and partially annealed).

- Specification features: battery casings usually choose H14 temper, which provides adequate strength and good bending performance to protect internal components.

3003 Aluminum Disc Circle for Architectural Decoration

Roofing and wall decorative panels, ceilings, curtain walls

Advantages: lightweight, rust-resistant, easy to process and form, long service life

- Common thickness: 1.2mm - 3.0mm.

- Common temper: H14, H16, H24.

- Specification features: the construction industry does not require high elongation, but demands high flatness and surface coating performance. H tempers provide better wind pressure resistance.

3003 Aluminum Disc Circle for Industrial Equipment

Chemical storage tanks, pressure vessels, refrigeration equipment

Advantages: excellent chemical corrosion resistance, suitable for long-term use in humid environments

- Common thickness: 3.0mm - 8.0mm (relatively thick specifications).

- Common temper: O temper or H112.

- Specification features: end caps for industrial storage tanks usually require thicker 3003 aluminum circles formed by spinning or stamping.

3003 Aluminum Disc Circle for Daily Consumer Products

Lighting reflectors, water heater inner tanks, food packaging containers

Advantages: attractive appearance, durable, non-toxic (food-grade applications)

- Common thickness: 0.3mm - 1.5mm.

- Common temper: O temper (for spun lampshades) or H14 (for flat structural parts).

- Specification features: lighting reflectors usually require extremely high surface finish, sometimes even mirror-finish aluminum.

Why choose 3003 aluminum alloy to make aluminum discs

- Excellent Formability: 3003 aluminum alloy is renowned for its exceptional formability. This alloy can be easily stamped, spun, or deep drawn into various shapes without cracking or deforming, allowing for complex geometric designs during manufacturing.

- Food Safety: 3003 aluminum alloy has a high aluminum content, which makes it less likely to produce undesirable flavors or reactions when in contact with food. Therefore, it is very suitable for use in food packaging and utensils.

- Moderate Strength: While 3003 aluminum alloy does not have the highest strength on the market, it provides a good balance between strength and formability. This alloy is strong enough for general applications while maintaining good processing performance.

- Good Heat Resistance: 3003 aluminum alloy has good heat resistance, making it suitable for applications where heat or thermal conductivity is a consideration. It is commonly used in manufacturing heat exchangers, cookware, and other products requiring good thermal performance.

- Excellent Weldability: 3003 aluminum alloy has high weldability, allowing it to be easily welded into more complex components. This increases its flexibility and diversity of applications in manufacturing various shapes and structures.

3003 Aluminum Disc Circle Manufacturing Process

- Melting and rolling: Aluminum ingots are melted and rolled into large coils.

- Stamping: High-speed stamping presses use circular molds to "punch" discs from the aluminum coil, optimizing layout to minimize waste.

- Annealing (optional): If these discs are used for deep drawing, they are usually heat-treated to achieve the "O" temper, making them as soft and ductile as possible.

- Melting: High-purity aluminum ingots are alloyed with manganese and other elements, then melted in a furnace.

- Casting: The molten alloy is cast into slabs or coils.

- Rolling: Cold rolling or hot rolling is used to achieve the required thickness.

- Annealing: Fully annealed (O temper) or partially annealed as needed.

- Cutting: Sheets are cut into circles using a press or laser cutter.

- Surface treatment: Optional film coating, painting, or anodizing (though 3003 is rarely anodized due to uneven results).

Comparison of 3003 Aluminum Disc Circle with Other Common Aluminum Alloys

| Property | 3003 Aluminum Disc | 1060 Aluminum Disc (Pure Aluminum) | 6061 Aluminum Disc |

| Alloy Series | Al-Mn | Pure Aluminum (99.6%+) | Al-Mg-Si |

| Tensile Strength | 120-200MPa | 60-95MPa | 205-290MPa |

| Hardness | Medium (about 10% harder than 1060) | Low | High (heat-treatable) |

| Corrosion Resistance | Excellent (rust-proof aluminum) | Good | Good (surface treatment required) |

| Weldability | Excellent | Good | Good |

| Machinability | Excellent (cold working) | Excellent | Excellent (cold or hot) |

| Typical Applications | Cookware, construction, chemical equipment | Cables, gaskets, reflective materials | Mechanical parts, aerospace components |

Comparison of 3003 Aluminum Discs and 1100 Aluminum Discs

| Comparison Item | 3003 Aluminum Discs | 1100 Aluminum Discs |

| Strength | Due to the presence of manganese, 3003 aluminum discs have slightly higher strength compared to 1100 aluminum discs, making them more suitable for applications requiring moderate strength. | 1100 aluminum discs are softer and have lower strength, making them unsuitable for high-strength applications. |

| Formability and Machinability | 3003 aluminum discs also exhibit good formability and machinability, easily processed by spinning, deep drawing, stamping, and other methods. | 1100 aluminum discs have excellent formability, easily bent, shaped, and manufactured into various products. |

| Corrosion Resistance | 3003 aluminum discs have better atmospheric corrosion resistance than 1100 aluminum discs, primarily due to the presence of manganese, providing stronger corrosion resistance. | 1100 aluminum discs have good corrosion resistance. |

| Typical Applications | Kitchenware: Due to its moderate strength and good corrosion resistance, it is widely used in cookware, baking pans, and other kitchen utensils. | Food Processing: Due to its high purity and excellent corrosion resistance, it is commonly used in food processing equipment and containers. |

| Building Decoration: Applied in building decoration and exterior wall panels. | Heat Exchangers: High thermal and electrical conductivity make it suitable for manufacturing heat exchangers. | |

| Automotive Parts: Suitable for automotive components requiring moderate strength and good corrosion resistance. | Chemical Equipment: Used in chemical processing equipment requiring high corrosion resistance. |

Key Points for Selecting 3003 Aluminum Disc Circle

Select temper according to application:

- Deep drawing: choose O temper (high ductility)

- Structural support: choose H14/H24 temper (medium strength)

- High hardness requirement: choose H18/H38 temper (high hardness)

Select thickness:

- Cookware bases: 2.0-6.0mm (ensures uniform heat conduction and strength)

- Electronic devices: 0.5-2.0mm (lightweight)

- Decorative materials: 0.3-1.0mm (balance of aesthetics and cost)

Surface treatment:

- Food contact: food-grade coating (anodizing not recommended)

- Outdoor applications: fluorocarbon coating (improves weather resistance)

- General use: optional single or double-sided film protection

Haomei 3003 Aluminum Disc Packaging

Use of Desiccants

Place desiccants on the sides of the aluminum discs to prevent moisture and keep the product dry. This step helps avoid oxidation or other damage to the aluminum discs caused by moisture during storage and transportation.

Plastic Wrap

Completely wrap the aluminum discs in clean plastic wrap. The primary function of this plastic wrap is to keep the aluminum discs clean, preventing the influence of dust, dirt, and other contaminants, while also providing a good sealing effect.

Kraft Paper Wrap

Wrap the plastic-covered aluminum discs in kraft paper. This paper material enhances the seal and provides an additional protective layer for the aluminum discs, effectively preventing damage or tearing of the plastic wrap, increasing the durability and stability of the packaging.

Packaging Methods

Wooden Pallet Packaging: Place the packaged aluminum discs on a wooden pallet and cover the pallet's surface with hard cardboard. The cardboard provides additional protection, preventing the aluminum discs from being compressed or impacted during transportation.

Wooden Box Packaging: Place the packaged aluminum discs in a wooden box, which provides a sturdy protective structure to prevent damage during transportation. The wooden box surface should also be reinforced with steel straps to enhance stability and safety.

Steel Strap Reinforcement

Apply steel straps to the surface of the wooden box to ensure its sturdiness and safety. These steel straps effectively prevent deformation or damage of the wooden box due to heavy pressure or vibration during transportation, ensuring the aluminum discs arrive in good condition.

Further reading

- 3003 Aluminum Coil

- 3003 Aluminum Plate and Sheet

- 3003 h14 aluminum sheet

- 3003 h22 aluminum sheet

- 3003 o aluminum sheet

Users viewing this material also viewed the following

- Aluminum Tread Plate 3003

- 3003 Embossed Aluminum Sheet

- 3003 Aluminum Diamond Plate

- 3003 Hot-rolled Aluminum Plate

- 3003 Honeycomb Aluminum

- 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell

- 3003+4343 Power Battery Cooling Plate

- 3003 Aluminum Plate for Brazing Water Cooling Plate

- Aluminum Brazing Composite Material 3003+4045 Aluminum Plate

- 3003 Aluminum Disc for Non-stick Pan

- 3003 Aluminum Plate for Mobile Phone Battery Shell

- 3003 Corrugated Aluminum Sheet

- 3003 Aluminum Plate for Automobile Fender

- 3003 Checker Aluminum Plate for Stair Anti-slip

- 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip

- 3003 Ultra-wide Curtain Wall Aluminum Plate

- 3003 Aluminum Plate for Building Decoration

- 3003 Roof Aluminum Plate for Decoration

- 3003 Aluminum Sheet Coil for Thermal Insulation Material

- 3003 Pre-painted Aluminum Coil

Recommended Content

- What is 3003 aluminum used for?

- 3003 Aluminum Tubing

- 3003 Aluminum vs. 3005 Aluminum

- 3003-H18 Aluminum vs. 3005-H18 Aluminum

- What is the difference between 3003 H14 and 3105 H14?

- 3003 Aluminum vs. 3104 Aluminum

- 3003-H18 Aluminum vs. 3004-H18 Aluminum

- 3003-O Aluminum vs. 3004-O Aluminum

- What is the difference between 3003 and 3004 aluminum?

- 3003-H22 Aluminum vs. 3003-H24 Aluminum

- What is the difference between 3003 O and 3003 H14?

- What is the difference between 3003 H14 and H24?