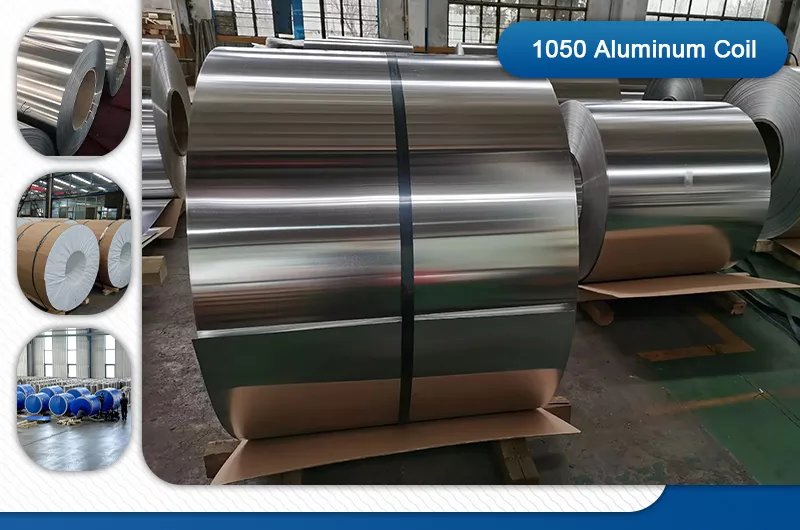

1050 Aluminum Coil

1050 Aluminum Coil is an industrial basic material made of high-purity aluminum, with an aluminum content of no less than 99.5%, belonging to the 1000 series commercial pure aluminum products. Its high purity provides excellent corrosion resistance, outstanding ductility, and superior thermal and electrical conductivity, making it play an important role in multiple industries.

As a soft and easily formable commercial pure aluminum alloy, 1050 Aluminum Coil is widely used in fields that require high processing performance and corrosion resistance. Although its mechanical strength is relatively low, it remains an ideal choice in the electrical, chemical, and construction industries due to its good electrical conductivity, thermal conductivity, and high reflectivity. In addition, it also has advantages in the manufacturing of radiators and industrial electrical components.

Due to its high purity, low cost, and easy processing, 1050 Aluminum Coil is widely used in printing, electronics, and transportation industries. Multiple tempers (such as H18 and H24) can meet diverse requirements, ranging from high strength needs to complex forming processes. Since it contains no strengthening elements, this alloy cannot increase strength through heat treatment, but it can be processed through methods such as contact welding or gas welding.

Haomei Aluminum specializes in the production of 1050 Aluminum Coil, sheets, and strips, with stable product performance and electrical conductivity up to 99%, meeting the needs of industrial electrical, architectural decoration, and transportation equipment applications. The company has sufficient inventory and can provide customized processing services, flexibly adjusting thickness and width, offering a one-stop aluminum solution for domestic and international customers.

Haomei 1050 Aluminum Coil Product Specifications

| Item | Parameter |

| Thickness Range | 0.10–8.0mm (Common thickness: 0.2–8.0mm; Ultra-thin specification 0.10–0.5mm suitable for precision fields such as printing plate making) |

| Width Range | 20–2650mm |

| Temper Types | H18 (High strength hardened), H24 (Medium strength hardened), O (Annealed) etc. |

| Coil Weight | Customizable |

| Surface Treatment | Bright finish, PE film, or polished surface |

| Standard Compliance | ASTM B209, EN 573, EN 485 |

| Packaging | Wooden pallets, moisture-proof paper, customizable inner/outer diameter options (e.g., inner diameter 75–505 mm) |

| Global Export Support | O, H14, H18 states available, with EN 10204 3.1 certification and logistics support |

Popular Tempers for 1050 Aluminum Coils

1050 H18 Aluminum Coil

The H18 temper is heavily cold-worked to deliver high tensile strength, making it an excellent choice for decorative applications that also demand structural reliability or for small industrial components. Due to its limited machinability, it is most suitable for straightforward stamping, bending, or forming operations rather than complex machining.

1050 H24 Aluminum Coil

H24 features moderate work hardening, offering a well-rounded mix of strength, corrosion resistance, and outstanding electrical conductivity. Compared to H18, it is easier to machine and can be shaped into more intricate designs, such as decorative trims, enclosures, and other precision-formed parts.

1050 Aluminum Coil Surface Treatment Options

Ideal for building facades, appliance panels, and decorative applications, the anodized surface enhances corrosion and wear resistance. Optional color finishes allow for versatile aesthetic effects while maintaining durability.

1050 Coated Aluminum Coil

Widely used in outdoor decoration, roofing, and wall panels, this coil is coated with PE or PVDF to deliver vibrant colors, excellent weather resistance, and long-lasting visual appeal.

1050 Laminated Aluminum Coil

Designed for safe transportation and handling, the PE protective film prevents scratches and damage, keeping the coil in pristine condition until it is ready for use.

1050 Brushed Aluminum Coil

Perfect for appliance panels, interior decoration, and furniture surfaces, the brushed texture enhances both tactile feel and decorative appeal, while improving wear resistance.

Commonly applied to decorative panels and interior surfaces, embossed patterns add depth and visual interest, elevating the overall aesthetic.

1050 Mill Finish Aluminum Coil

Featuring a natural, uncoated surface, this coil is suitable for further processing, painting, or various industrial applications.

1050 Painted Aluminum Coil

Ideal for roofing, wall panels, and decorative surfaces, the pre-painted finish provides a wide color selection and reliable weather resistance.

1050 Pre-Coated Aluminum Coil

Factory-applied coatings improve durability and reduce the need for on-site painting, making it a practical choice for construction and building projects.

1050 Pre-Painted Aluminum Coil

Ready-to-use with a uniform painted surface, this coil ensures consistent color, long-term corrosion protection, and aesthetic quality for both interior and exterior decoration.

1050 PVC Coated Aluminum Coil

Commonly used in roofing, siding, and decorative panels, the PVC coating adds extra protection while offering flexible finishing options.

1050 Stucco Embossed Aluminum Coil

Perfect for decorative facades and wall panels, the stucco pattern creates a textured, three-dimensional effect that enhances architectural interest.

1050 Textured Aluminum Coil

Designed for both interior and exterior decoration, the textured surface improves grip, reduces glare, and adds visual character.

1050 Wood Aluminum Coil

Ideal for interior decoration, furniture, and building facades, the wood grain finish combines the natural look of wood with the strength and durability of aluminum.

1050 Aluminum Coil Color Options

1050 Aluminum Coil Characteristics

- Excellent Formability: 1050 aluminum alloy is soft and easy to stamp, bend, deep draw, and roll, allowing for easy processing of complex shapes or small-radius bent parts.

- Outstanding Electrical and Thermal Conductivity: Compared to most aluminum alloys, 1050 aluminum has superior electrical and thermal conductivity, commonly used in busbars, heat sinks, electrical connectors, and other applications requiring high energy transfer efficiency.

- Strong Corrosion Resistance: Its surface naturally forms a protective oxide layer, effectively preventing corrosion in humid environments and various chemical media, making it suitable for long-term outdoor or chemical environment use.

- Convenient Welding: Supports contact welding, gas welding, and spot welding, facilitating industrial assembly. However, since it is not suitable for strength enhancement via heat treatment, mechanical processing methods should be used to meet strength requirements.

- Diverse Surface Treatments: Can undergo polishing, anodizing, or coating, enhancing both decorative appearance and surface durability.

- High Ductility and Moderate Strength: Although its strength is lower than some aluminum alloys, its ductility and softness provide advantages in complex structures and precision processing.

- Cannot Be Strengthened by Heat Treatment: 1050 aluminum alloy relies on its high purity and physical properties rather than heat treatment processes to meet usage requirements.

1050 Aluminum Coil Chemical Composition

The main component is aluminum (above 99.5%), with trace amounts of iron (≤0.4%), silicon (≤0.25%), and copper (≤0.05%).

| Element | Composition |

| Aluminium | 99.5% min |

| Copper | 0.05% max |

| Iron | 0.4% max |

| Magnesium | 0.05% max |

| Manganese | 0.05% max |

| Silicon | 0.25% max |

| Titanium | 0.03% max |

| Vanadium | 0.05% max |

| Zinc | 0.05% max |

1050 Aluminum Coil Mechanical Properties

| Alloy-Temper | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

| 1050-O | 11 | 4 | 40 |

| 1050-H14 | 16 | 15 | 7 |

| 1050-H18 | 23 | 22 | 4 |

1050 Aluminum Coil Physical Properties

- Low density (~2.71 g/cm³), excellent electrical and thermal conductivity;

- High plasticity, good corrosion resistance (naturally forms an aluminum oxide protective layer on the surface);

- Low strength, cannot be strengthened by heat treatment, moderate machinability, but supports contact welding and gas welding.

- Thermal conductivity: 222 W/m·K

- Electrical conductivity: ~61% IACS (International Annealed Copper Standard).

Popular 1050 Aluminum Coil Sizes and Specifications

| Item | Thickness (inch) | Thickness (mm) | Width (inch) | Width (mm) | Temper | Surface Finish | Notes |

| 0.019" 1050 Aluminum Coil | 0.019 | 0.48 | 12–48 | 300–1200 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Thin decorative or industrial coil |

| 0.024" 1050 Aluminum Coil | 0.024 | 0.61 | 12–48 | 300–1200 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Widely used in signage & panels |

| 0.027" 1050 Aluminum Coil | 0.027 | 0.69 | 12–48 | 300–1200 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | General fabrication applications |

| 0.032" 1050 Aluminum Coil | 0.032 | 0.81 | 12–60 | 300–1500 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Panels, roofing, decorative purposes |

| 0.04" 1050 Aluminum Coil | 0.04 | 1.02 | 12–60 | 300–1500 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Structural or industrial coil |

| 0.05" 1050 Aluminum Coil | 0.05 | 1.27 | 24–60 | 600–1500 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Heavy-duty industrial applications |

| 0.063" 1050 Aluminum Coil | 0.063 | 1.6 | 24–72 | 600–1800 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | OEM & construction projects |

| 0.08" 1050 Aluminum Coil | 0.08 | 2.03 | 24–72 | 600–1800 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Machinery & fabrication |

| 0.1" 1050 Aluminum Coil | 0.1 | 2.54 | 24–72 | 600–1800 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Industrial & structural use |

| 0.125" 1050 Aluminum Coil | 0.125 | 3.18 | 24–72 | 600–1800 | O, H14, H24 | Mill Finish, Pre-painted, Embossed, Anodized | Heavy industrial & fabrication |

1050 Aluminum Coil Typical Applications

| Industry | Description |

| Printing Industry | 1050 Aluminum Coil is widely used in the printing industry, especially in the production of CTP plates and PS plates. Due to its high flatness and good surface smoothness, it provides precise printing results. Its ultra-thin specifications (such as 0.10–0.5mm) make it ideal for precision plate making, meeting the high-quality printing requirements. |

| Electronics & Electrical | In the electronics and electrical industry, 1050 Aluminum Coil is widely used in the manufacture of capacitor housings and conductive connectors. This is due to the high conductivity of aluminum alloy, which helps improve the performance of electrical products. Its lightweight and corrosion-resistant properties also make electronic products more durable, suitable for external protection of various electrical equipment. |

| Building Decoration | 1050 Aluminum Coil is widely used in building decoration for aluminum-plastic panels, lighting materials, and outdoor advertising frames. Due to its excellent corrosion resistance, it is suitable for outdoor environments, able to withstand various harsh weather conditions while maintaining aesthetics and durability, especially in areas with high air pollution, showing its advantages. |

| Industrial Parts | 1050 Aluminum Coil is also widely used in the industrial sector, especially in the manufacture of heat sinks, nameplates, and chemical containers. The good formability and corrosion resistance of the aluminum alloy make it perform excellently in these applications. Especially in chemical containers, it effectively prevents corrosion, extending the product's service life. |

| Electrical Industry | In the electrical industry, 1050 Aluminum Coil is used to manufacture radiators and cable sheaths. Its excellent conductivity and good heat dissipation performance make it an ideal choice for radiators and cable sheaths. Especially in high-power electrical equipment, it provides efficient heat dissipation and electrical protection, ensuring stable operation of the equipment. |

| Chemical Industry | 1050 Aluminum Coil is commonly used in the manufacture of storage tanks and containers in the chemical industry. This is due to the outstanding corrosion resistance of aluminum alloy, which remains stable in chemically corrosive environments, making it suitable for storing various chemicals and preventing external damage to container materials, thereby extending the lifespan of the equipment. |

| Construction | In the construction industry, 1050 Aluminum Coil is widely used in materials such as waterproof boards, roofs, and decorative finishes. It is compatible with anodizing treatment, providing additional corrosion resistance and surface aesthetics, making it suitable for various external building environments, especially performing excellently in humid or extreme weather conditions. |

| Consumer Goods | 1050 Aluminum Coil is used in the consumer goods sector for applications such as battery foils, food packaging, and light reflectors. Due to its lightweight, high conductivity, and good corrosion resistance, it is widely used in the production of battery foils, improving the performance and efficiency of batteries. At the same time, it is used in food packaging and light reflectors, meeting the requirements for material lightness and durability. |

Application Characteristics of Different Specifications of 1050 Aluminum Coil

The application areas of 1050 aluminum coils are closely related to their specifications. Different thicknesses of 1050 coils show distinct performance in applications:

Ultra-thin 1050 aluminum coil (thickness < 0.3 mm):

- Mainly used in electronics, such as CTP and PS plate substrates, applications that demand extremely high flatness and surface quality of the coil.

- Also used to manufacture battery explosion valves and tab material, utilizing its excellent conductivity and corrosion resistance.

- Used for capacitors, EMI shielding materials, etc.

Thin coil (0.3–1.0 mm):

- This coil is widely used in packaging—food and pharmaceutical—leveraging its good corrosion resistance and formability.

- Used in architectural decoration such as ceilings, wall panels, often requiring painting or anodizing.

- In home appliances like fridge and air‑conditioner heat sinks and interiors.

- Used in automotive for insulation materials and decorative parts.

Medium‑thick coil (1.0–6.0 mm):

- Used in curtain walls and roofing, often color‑coated for good weather resistance and esthetics.

- Automotive body and structural parts piggybacking on its light weight and strength.

- Interior decoration and structural parts in ships and trains.

- Chemical equipment and containers, utilizing its corrosion resistance.

- Signage and advertising boards, often anodized or painted.

Thick coil (> 6.0 mm):

- Mainly used in special industrial equipment and structural parts like pressure vessels and piping systems.

- Also used where high strength and wear resistance are needed, like machinery parts and molds.

It is worth noting that coil width also influences application. Wide coils are typically used in large construction and industrial applications, while narrow coils fit smaller products and precision parts.

Application Scenarios of 1050 Aluminum Coil with Different Surface Treatments

The surface treatment of 1050 coil directly determines its final use and performance characteristics:

1050 Anodized Aluminum Coil

Electronic industry: used for PCBs, electronic components, and shielding materials.

Architectural decoration: curtain walls, window/door frames, ceilings, offering good weather resistance and aesthetics.

Household goods: furniture, kitchen and bathroom devices, with high surface hardness and easy to clean.

Automotive industry: interior trims and decorative strips, with wear and corrosion resistance.

1050 Painted Aluminum Coil

Construction: roofs, walls, ceilings, providing a richness of color choices and long-term weather resistance.

Home appliances: fridge, air‑con, washer shells and decorative panels.

Transport: interior and exterior decoration of cars, trains, ships.

Signage: signs, lightboxes, display racks, with decorative and weather-resistant properties.

1050 Color-Coated Aluminum Coil

Architectural decoration: curtain walls, roofs, wall panels, providing a variety of colors and textures.

Home appliances: for manufacturing external housings and decorative parts.

Packaging: aluminum‑plastic composite panels and decorative materials.

Special uses: fire‑resistant materials, insulation materials, etc.

1050 Brushed Aluminum Coil

Architectural decoration: elevator interiors, door handles, decorative trims, with a premium metallic texture.

Electronics: housings and trims for phones, computers, TVs.

Household goods: furniture, kitchenware, bath ware, with fine texture and scratch resistance.

1050 Sand-Blasted Aluminum Coil

Architectural decoration: curtain walls, windows/doors, ceilings, offering good texture and slip resistance.

Industrial equipment: machine housings, instrument panels, with hard, scratch-resistant surfaces.

Decorative arts: artworks, displays, with unique visual texture.

1050 Film‑Covered Aluminum Coil

Temporary protection: protects coil surface during transport and processing.

Special application: for semi‑finished products needing subsequent processing; the protective film prevents scratches.

Typical Industry Use Cases of 1050 Aluminum Coil

Electronics & Electrical Industry

CTP and PS plate substrates: 0.1–0.3 mm thick 1050 coil, specially surface-treated, is a key material in printing. CTP plates demand extremely high flatness, surface roughness, and conductivity.

EMI shielding materials: 1050 coil combined with electrical steel can form EMI shielding for EMC designs in electronics.

Heat sinks: using 1050 coil's good thermal conductivity for manufacturing heat sinks in electronic equipment.

Battery materials: ~0.2 mm 1050 coil is widely used for battery tabs and explosion valves, leveraging its conductivity and corrosion resistance.

Construction Industry

Roofs and walls: 0.5–1.5 mm color‑coated or anodized 1050 coil is ideal for roof and wall decoration due to light weight, weather resistance, and aesthetics.

Curtain wall systems: 1.0–3.0 mm 1050 coil, surface-treated, used for curtain walls, offering both beauty and protection.

Ceilings and trims: 0.3–1.0 mm coil, often painted or anodized, for interior decoration.

Insulation materials: coil laminated with insulation for building thermal insulation and energy-saving applications.

Packaging Industry

Food and pharmaceutical packaging: 0.1–0.3 mm 1050 coil, with good corrosion resistance and hygiene, compliant with food/pharma standards.

Aluminum‑plastic composite panels: used as surface layer, offering decoration and mechanical performance.

Bottle caps and beverage cans: 0.2–0.5 mm coil stamped and drawn into various caps and can parts.

Transportation Industry

Automotive interiors: 0.3–1.0 mm anodized or painted coil used in dashboards, door trims, etc.

Ship and train decoration: 1.0–3.0 mm coil, surface-treated, used for internal decoration with good corrosion and esthetic performance.

Insulation and sound‑proofing materials: coil laminated with other materials for automotive, marine, and aircraft thermal/acoustic insulation systems.

Home Appliance Industry

Refrigerators and air‑cons: 0.3–1.0 mm 1050 coil for refrigerator liners, air‑con heat sinks and decorative panels.

Kitchen appliances: ovens, microwaves, dishwashers liners and trim, leveraging corrosion resistance and thermal conductivity.

Small appliances: kettles, coffee makers outer shells and trims, often anodized or painted.

Other Applications

Lighting industry: 0.2–0.5 mm 1050 coil for lamp reflectors and housings, using its reflectivity and thermal properties.

Chemical equipment: 1.0–6.0 mm coil for chemical vessels, piping, reactors, using corrosion resistance.

Signage and advertising: 0.5–2.0 mm coil, surface-treated, used for signs, billboards, display racks.

Daily necessities: furniture decoration, kitchenware, photo frames, etc., utilizing its formability and decorative appeal.

1050 Aluminum Coil Production Process Flow

The production process of 1050 aluminum coil is relatively simple and technically mature, which is one of the reasons for its high cost-effectiveness. The main production process flow is as follows:

- Raw Material Preparation: The main raw material is high-purity aluminum ingots with a required purity of over 99.5%.

- Smelting: Aluminum ingots are placed into the melting furnace and heated to 650-700°C until melted. Refining and Impurity Removal: The molten aluminum needs to be refined to remove impurities and gases.

- Casting: The refined molten aluminum is poured into a crystallization pool and cooled to form ingots or billets.

- Hot Rolling: After heating the ingots to the appropriate temperature, they are hot-rolled through a series of rollers.

- Cold Rolling (Optional): Depending on product requirements, the hot-rolled aluminum plates or strips may undergo further cold rolling.

- Annealing: Annealing is a crucial process to adjust the final properties of 1050 aluminum coils.

- Finishing: Includes processes such as shearing, slitting, straightening, and surface treatment.

- Packaging and Storage: Aluminum coils that pass inspection are packaged according to customer requirements.

Comparative Advantages of 1050 Aluminum Coil over the 1060 Series

- Similar electrical conductivity and corrosion resistance: The purity of 1050 makes its performance in these aspects almost identical to that of 1060.

- Lower cost and simpler production: Free of magnesium and other alloying elements, it simplifies the smelting/rolling process and reduces raw material costs.

Comparative Analysis with Other Aluminum Alloy Coils

Performance Comparison Between 1050 Coil and 3003 Coil

| Performance Index | 1050 Aluminum Coil | 3003 Aluminum Coil |

| Chemical Composition | Pure Aluminum (Al ≥ 99.5%) | Aluminum-Manganese Alloy (Mn 1.0–1.5%) |

| Density | 2.71 g/cm³ | Approx. 2.73 g/cm³ |

| Tensile Strength | 65–95 MPa (O temper) | 110–130 MPa (O temper) |

| Yield Strength | 35–85 MPa (O temper) | 45–60 MPa (O temper) |

| Elongation | 20–25% (O temper) | 15–20% (O temper) |

| Electrical Conductivity | 61% IACS | Approx. 30% IACS |

The performance comparison shows that 1050 and 3003 aluminum coils each have their own advantages:

- Strength: 3003 aluminum coil has significantly higher strength than 1050, especially in annealed (O) condition. Its tensile strength is about 40% higher than 1050, making it more suitable for applications requiring higher strength.

- Corrosion Resistance: 1050 pure aluminum coil has better corrosion resistance, especially in certain chemical environments. This is due to the more uniform and denser oxide film formed on the surface of pure aluminum.

- Electrical and Thermal Conductivity: 1050 aluminum coil offers significantly better electrical and thermal conductivity than 3003, making it more suitable for electrical and heat conduction applications.

- Formability: 1050 aluminum coil has slightly better formability than 3003, particularly in deep drawing and stretching processes.

- Weldability: 3003 aluminum coil has better weldability than 1050, which makes it more popular in applications requiring extensive welding.

Performance Comparison Between 1050 Aluminum Coil and 5052 Aluminum Coil

| Performance Index | 1050 Aluminum Coil | 5052 Aluminum Coil |

| Chemical Composition | Pure Aluminum (Al ≥ 99.5%) | Aluminum-Magnesium Alloy (Mg 2.2–2.8%) |

| Density | 2.71 g/cm³ | 2.68 g/cm³ |

| Tensile Strength | 65–95 MPa (O temper) | 170–210 MPa (O temper) |

| Yield Strength | 35–85 MPa (O temper) | 70–110 MPa (O temper) |

| Elongation | 20–25% (O temper) | 15–25% (O temper) |

| Electrical Conductivity | 61% IACS | Approx. 35% IACS |

Compared to 1050, 5052 aluminum coil has the following advantages:

- High Strength: 5052 aluminum coil has significantly higher strength than 1050, especially in H32 and H34 tempers, where its tensile strength can reach 230–280 MPa, far exceeding the 95–125 MPa range of 1050.

- Lower Density: 5052 has a slightly lower density than 1050, making it more advantageous in weight-sensitive applications.

- Corrosion Resistance: 5052 performs better than 1050 in marine and certain chemical environments, especially in salt spray conditions.

- Fatigue Resistance: 5052 has significantly better fatigue resistance, suitable for applications subjected to cyclic loading.

- Work-Hardening Capability: 5052 can achieve higher strength through cold working, whereas 1050 has relatively limited work-hardening effects.

Comparison of Application Scenarios for Different Aluminum Alloy Coils

1050 Aluminum Coil

High requirements for electrical and thermal conductivity

Extremely high corrosion resistance needed

Excellent workability required

High surface treatment quality required

Low cost and low strength applications

3003 Aluminum Coil

Moderate strength and good corrosion resistance

Good weldability required

Food and chemical equipment

Beverage cans and packaging materials

Decorative applications with certain strength requirements

5052 Aluminum Coil

High strength and weight-sensitive applications

Marine and other harsh corrosive environments

High fatigue strength required

Pressure vessels and high-pressure pipelines

Good formability and surface quality required

Cost and Performance Comparison of Different Aluminum Alloy Coils

| Item | 1050 Aluminum Coil | 3003 Aluminum Coil | 5052 Aluminum Coil |

| Material Cost | Lowest cost due to simple composition and relatively simple production process (approx. 30% lower) | Moderate cost, about 10–15% higher than 1050 due to manganese addition and slightly more complex process (approx. 15–20% lower) | Highest cost, about 20–30% higher than 1050 due to magnesium content and more complex processing (approx. 20–30% higher) |

| Processing Cost | Lowest processing cost, excellent workability, suitable for simple processes | Moderate processing cost, close to 1050, slightly higher in some processes | Higher processing cost, especially in hot working due to lower hot workability |

| Lifecycle Cost | Long lifespan in general environments, but frequent maintenance/replacement in harsh environments | Similar lifespan to 1050, with slightly better corrosion resistance | Longest lifespan in harsh environments such as marine and high-strength applications, lowest long-term maintenance cost |

| Cost-Performance Analysis | Best suited for low-cost, low-strength applications, highest cost-effectiveness | Ideal for moderate strength and good corrosion resistance requirements, an economical and practical choice | Suitable for high strength, weight-sensitive, or corrosive environments. Though initial investment is high, it offers the best long-term value |

Usage Considerations for 1050 Aluminum Coil

To ensure optimal performance of 1050 aluminum coil in use, the following considerations should be taken into account:

Material Selection Notes:

Select the appropriate alloy temper based on application needs, e.g., O temper for deep drawing, H14 for general bending and stamping.

Consider environmental factors—special surface-treated products should be used in marine environments.

Choose appropriate alloys based on strength requirements. 1050 aluminum coil is not suitable for high-strength structural applications.

Consider the requirements of subsequent processing—avoid using H18 temper material before welding.

Processing Notes:

Check material hardness and ductility before cold working to ensure suitability for processing.

Control processing speed and deformation to avoid excessive stress concentration.

Use appropriate lubricants during processing to reduce friction and heat generation.

Apply proper post-treatment to processed parts, such as stress-relief annealing or surface treatment.

Surface Treatment Notes:

Thoroughly clean the material surface before surface treatment to remove oil, dust, and oxide layers.

Select the appropriate surface treatment method based on the application environment, e.g., fluorocarbon coating for outdoor use.

Strictly control treatment parameters such as temperature, duration, and solution concentration.

Avoid scratches and contamination after treatment to ensure surface quality.

1050 Aluminum Coil Advantages and Limitations

- Advantages: Cost-effective, lightweight, corrosion-resistant, high formability.

- Limitations: Lower strength compared to alloys like 3003 or 5052; not suitable for high-stress applications.

The most common temper states for 1050 aluminum include O (annealed), H12, H14, H18, and H24, each providing different balances of strength and ductility.

1050 aluminum coil is a versatile material highly regarded for its purity and functional characteristics. Although it is not suitable for high-stress applications, its electrical conductivity, formability, and corrosion resistance make it an indispensable material in the electronics, construction, and energy sectors.

1050 aluminum coil is a high-purity industrial pure aluminum product known for its excellent corrosion resistance, high ductility, and outstanding thermal and electrical conductivity. Although it has low mechanical strength and poor machinability, its excellent formability and weldability make it widely used across electrical, chemical, food processing, and construction industries. Additionally, it is available in various hardness levels and sizes, further enhancing its versatility and making it the preferred choice for applications where strength is not the primary requirement.

Explore Different Aluminum Coil Grades

Further reading

- 1050 Aluminum Plate Sheet

- 1050 Aluminum Strip

- 1050 h14 aluminium sheet plate

- Aluminium 1050 h24

- 1050 Aluminum Disc Circle

- 1050 H18 Aluminium

- 1050 O Aluminum

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

- 1050 Aluminum Foil

Users viewing this material also viewed the following

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

Recommended Content