3003 aluminum, as an aluminum-manganese alloy material, is widely used due to its good formability, weldability, corrosion resistance, and moderate strength.

3003 aluminum plates can be adapted to various scenarios through different processing tempers (such as H24 semi-hard temper), and they perform particularly well in humid or corrosive environments with high rust-resistance requirements.

3003 aluminum is a widely used wrought aluminum-manganese alloy (3xxx series), renowned for its excellent formability, weldability, and corrosion resistance. This alloy cannot be strengthened by heat treatment but can achieve various tempers through cold working. It is available in the forms of sheets, plates, foils, extrusions, and tubes, and is widely used in cooking, construction, chemical, decorative, and industrial fields.

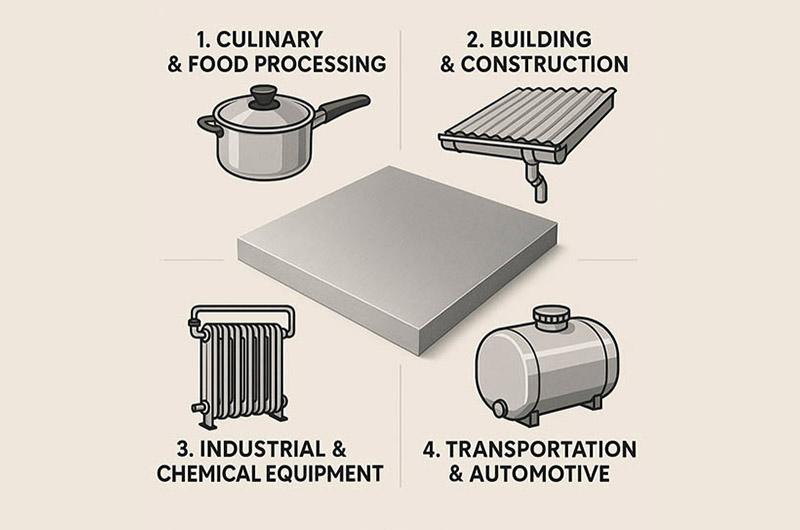

3003 aluminum used for Applications

3003 aluminum used for Cooking and Food Processing

- Cookware and tableware: pots, pans, trays, ice cube molds — utilizing high thermal conductivity and corrosion resistance

- Food containers and storage tanks: storage barrels, pressure vessels for edible oils and beverages

- Cooking utensils and baking tools: non-toxic and corrosion-resistant, ideal for pots, bowls, and food containers

- Beverage storage and transportation: suitable for water, milk, and other liquids due to hygienic properties

- Packaging: lightweight cans, closures, and aluminum foil for food preservation

3003 aluminum used for Construction

- Roofs, wall panels, and cladding: corrugated sheets, gutters, downspouts — lightweight and weather-resistant

- Piping systems and HVAC components: air conditioning evaporators, heat exchanger fins

- Architectural decorative elements: eaves, awnings, shutters

- Decorative items: easy to form into ornate architectural or home décor patterns

- Used for decorative panels in curtain walls, ceilings, and suspended ceilings, combining corrosion resistance and lightness

- For metal protective layers in pipeline insulation and construction hardware fittings, meeting moderate strength requirements

3003 aluminum used for Architectural Decoration

| Application Field | Product Name | Description |

| Roof and Wall Structures | Roofs and Wall Panels | Roofs and wall panels use 3003 aluminum because of its excellent flexibility and corrosion resistance, enabling it to withstand various climatic conditions. It is especially suitable for buildings that need to handle heavy snow or strong wind pressure. Its good formability makes it easier to process and fix during the installation of flat and sloped roofs, while its anti-oxidation properties ensure that the roof and wall surfaces will not rust or fade even after long-term outdoor exposure, thereby greatly extending service life. |

| Drainage System | Gutters and Downspouts | Gutters and downspouts use 3003 aluminum primarily to prevent corrosion problems in rainy or humid climates. This alloy has excellent rust resistance, and even with prolonged water contact, it does not develop rust spots, making it particularly suitable for eaves drainage systems. At the same time, its lightweight nature facilitates installation at height, and its good weldability and ductility allow for customization of various shapes of gutters and joints. |

| Architectural Decoration and Curtain Wall Systems | Architectural Panels and Decorative Strips | Architectural panels and decorative strips widely use 3003 aluminum due to its excellent ductility, allowing it to be used in the manufacture of complex curves and shapes to meet diverse and personalized aesthetic design requirements for building facades. After anodizing or coating treatment, the surface of this alloy becomes not only colorful and visually appealing but also further enhanced in corrosion and weather resistance, meeting the high standards for appearance and performance in modern architecture. |

| Interior Facilities and Energy-saving Structures | Garage Doors and Acoustic Ceilings | Garage doors and acoustic ceilings often use 3003 aluminum, mainly due to its light yet strong properties, which effectively reduce building load and improve structural stability. In garage door applications, this aluminum also exhibits good impact resistance, able to withstand mechanical wear caused by daily opening and closing. For acoustic ceilings, the aluminum is easy to perforate and process, making it an ideal structural support for acoustic materials, while also being easy to install and maintain, thereby improving indoor energy efficiency and comfort. |

3003 aluminum used for Industrial and Chemical Equipment

- Heat exchangers and radiators: Automotive radiators, engine cooling fins — thanks to its lightweight and high thermal conductivity.

- Pressure tanks and storage tanks: Used for chemicals, petroleum, and compressed gases.

- Manufacturing of chemical instruments, pressure vessels, and pipelines to meet corrosion resistance and weldability requirements.

- Applied in the power industry for anti-corrosion insulation equipment and mechanical processing components.

- Chemical storage tanks: Resistant to corrosion by acids, alkalis, and other active substances, with stable performance.

3003 aluminum used for HVAC and Duct Systems

| Application Field | Product Name | Description |

| Air distribution systems | Duct systems | Duct systems use 3003 aluminum because of its lightweight and easy formability, making it an ideal material for heating, ventilation, and air conditioning (HVAC) air distribution systems. This aluminum alloy can be easily bent, pressed, and welded during processing, adapting to various complex layouts and size requirements. At the same time, its excellent corrosion resistance prevents oxidation reactions in humid or temperature-fluctuating environments, ensuring long-term stable operation and reducing maintenance costs. |

| Thermal conduction systems | Heat exchangers and radiators | Heat exchangers and radiators widely use 3003 aluminum because its high thermal conductivity (193 W/m·K) significantly improves heat transfer efficiency. This aluminum alloy is commonly found in automotive radiators, air conditioning units, and various industrial cooling systems, rapidly transferring heat from the heat source to the cooling medium, thereby enhancing the overall thermal management performance of the equipment. In addition, its good corrosion resistance ensures that heat exchange components maintain stable performance during long-term operation. |

| Refrigeration systems | Evaporators | Evaporators are usually made of 3003 aluminum alloy, primarily because the material exhibits excellent corrosion resistance and resistance to thermal stress in humid and thermally cycling environments. In refrigeration systems, evaporators must withstand repeated temperature fluctuations and water vapor condensation. The oxidation resistance of 3003 aluminum prevents component failure due to corrosion. Additionally, its good formability helps create efficient and complex evaporator structures, enhancing the system’s heat exchange capacity and reliability. |

3003 aluminum used for General Sheet Metal Fabrication

- Sheet metal fabrication: Due to its ease of cutting and forming, it can be used for cabinets, architectural hardware, and brackets.

- Architectural hardware: Hinges, locks, brackets, panels.

- Signage and decorative foil: Billboards, decorative strips.

3003 aluminum used for Transportation and Automotive

- Applied in body structural parts, doors and windows, shelves, engine parts, and radiators of automobiles, subways, and railway passenger cars to meet lightweight requirements.

- Used in hull materials and naval components in shipbuilding to meet anti-rust requirements in humid environments.

- Fuel tanks and gasoline tanks: Corrosion resistant and lightweight, suitable for automobiles and small engines.

- Body panels and trailer panels: Non-structural exterior panels.

- Fuel tanks and structural panels: Lightweight properties improve fuel efficiency while maintaining durability.

- Truck and trailer components: Due to its high strength-to-weight ratio, it can be used for commercial vehicle roofs and side panels.

- Heat exchangers: Crucial in automotive cooling systems for controlling engine temperature.

3003 aluminum used for Packaging and Container Manufacturing

- Used to produce low-load containers for liquids or gases, such as fuel tanks, lubrication oil conduits, and chemical liquid storage tanks.

- Widely used in all-aluminum easy-open cans, packaging foils, and deep-drawn stamped containers for food, beverages, and chemical products.

3003 aluminum used forElectronics, Home Appliances, and Daily Products

- Used in refrigerators, air conditioner ventilation ducts, heat sinks, and appliance housings, balancing formability and strength.

- Used to manufacture cookware, clock dials, nameplates, and decorative items for consumer products.

3003 Aluminum Forms

| Product Form | Description |

| Sheet & Plate | Sheet & Plate is one of the most common forms of 3003 aluminum alloy, available in a wide range of thicknesses, from ultra-thin foil (a few microns) to medium-thick plates of several millimeters. Thanks to its excellent formability, moderate strength, and superior corrosion resistance, it is widely used in roofing, wall panels, cookware, decorative panels, and industrial equipment casings. 3003 sheet is easy to cut, stamp, bend, and weld, making it ideal for structural applications requiring a combination of strength and lightweight properties. |

| Foil | Foil made from 3003 aluminum alloy offers excellent flexibility and ductility, and is widely used in packaging, insulation materials, and interior decoration. Its superior moisture resistance, oxidation resistance, and printability make it an ideal material for food packaging, pharmaceutical packaging, cosmetic outer packaging, and reflective building interior layers. Additionally, embossed or colored 3003 aluminum foil is also used in decorative panels, providing both aesthetic and protective functions. |

| Extruded Profiles | Extruded Profiles include structural shapes such as angles, channels, and tubes. Made from 3003 aluminum alloy, these profiles offer good ductility and extrudability and can be formed into various complex cross-sectional shapes. They are widely used in building structures, decorative frames, mechanical supports, and furniture components. These profiles are not only lightweight but also provide excellent corrosion resistance, making them suitable for long-term use in both indoor and outdoor environments. |

| Tubes & Ducting | Tubes & Ducting are important application forms of 3003 aluminum, commonly found in circular, rectangular, oval, and spiral-wound duct shapes. These products are extensively used in HVAC systems, ventilation equipment, automotive piping, and lightweight structural engineering. 3003 aluminum tubes are lightweight, highly formable, and corrosion-resistant, significantly enhancing airflow efficiency and system longevity, making them key materials in modern energy-efficient buildings and industrial piping systems. |

3003 Aluminum Tempers

Tempers range from O (annealed) to H14/H24 (work‐hardened) to meet different strength/formability requirements.

| Temper | Description |

| O (Annealed) | The O temper of 3003 aluminum is fully annealed, offering the softest material characteristics and exhibiting excellent formability and ductility. It is suitable for applications requiring deep drawing, bending, or complex forming, such as cookware, roofing panels, and decorative components. Although its strength is low, it provides great processing flexibility, making it ideal for applications with high forming demands but low mechanical strength requirements. |

| H14 (Half-Hard) | 3003 aluminum in H14 temper is a half-hard material achieved through work hardening. It has higher strength than O temper while still maintaining good formability. It is widely used in architectural decorative panels, ceilings, louvers, and automotive panels, excelling in applications that require moderate complexity processing with a certain level of strength. |

| H24 (Partially Annealed after Cold Working) | The H24 temper of 3003 aluminum is produced by cold working followed by partial annealing. It combines moderate strength with good formability. Its mechanical properties lie between those of H14 and O tempers, making it an ideal choice for gutters, downspouts, packaging containers, and heat exchange components where both strength and ductility are required. |

3003 Aluminum Chemical Composition

- Aluminum (Al): 96.8–99%

- Manganese (Mn): 1.0–1.5%

- Copper (Cu): 0.05–0.20%

- Iron (Fe): ≤ 0.7%

- Silicon (Si): ≤ 0.6%

- Zinc (Zn): ≤ 0.1%

- Residuals: ≤ 0.15%

3003 conforms to ISO 6361 and ASTM standards B209/B210/B211/B221/B483/B491/B547. As a wrought alloy, it is produced by rolling or extrusion processes, but it is typically not strengthened by casting or forging.

3003 Aluminum Mechanical Properties

- Tensile Strength: 110–140 MPa in O temper; up to approximately 200 MPa after cold working

- Yield Strength: 50–120 MPa (depending on temper)

- Elongation at Break: 11–29%

3003 Aluminum Physical and Thermal Properties

- Density: 2.73 g/cm³

- Thermal Conductivity: approx. 154 W/m·K

- Specific Heat Capacity: 0.893 J/g·°C

3003 Aluminum Key Characteristics

- Corrosion Resistance: The natural oxide layer effectively resists moisture and chemical erosion.

- Formability: Easily bent, spun, or deep drawn without cracking.

- Weldability: Compatible with standard welding processes such as TIG and MIG.

- Thermal Conductivity: Efficient heat dissipation, suitable for HVAC and automotive systems.

- Cost-Effectiveness: More economical than alloys like 5052, though with slightly higher density.

3003 Aluminum Formability and Weldability

- Formability: Excellent—can be cold or hot rolled, bent to small radii, deep drawn, and spun.

- Weldability: Good weldability with GTAW, GMAW, or SMAW processes; suitable for fabricating complex assemblies.

3003 Aluminum Corrosion Resistance

Naturally resistant to atmospheric and water corrosion, making it an ideal choice for outdoor and food-related environments.

3003 Aluminum Advantages and Limitations

Advantages of 3003 Aluminum

- Excellent formability and weldability

- Good corrosion resistance in most environments

- An affordable and versatile alloy

Limitations of 3003 Aluminum

- Only medium strength—not suitable for high-stress structural components

- Non-heat treatable—strength must be obtained through cold working

3003 Aluminum Standards and Specifications

- ASTM B209: Sheets and plates

- ASTM B221: Extruded bars, rods, and profiles

- ISO 6361: General wrought products

Products you may be interested in

- 3003 Aluminum Coil

- 3003 Aluminum Plate and Sheet

- 3003 h14 aluminum sheet

- 3003 h22 aluminum sheet

- 3003 o aluminum sheet

- 3003 Aluminum Disc Circle

Users viewing this material also viewed the following

- Aluminum Tread Plate 3003

- 3003 Embossed Aluminum Sheet

- 3003 Aluminum Diamond Plate

- 3003 Hot-rolled Aluminum Plate

- 3003 Honeycomb Aluminum

- 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell

- 3003+4343 Power Battery Cooling Plate

- 3003 Aluminum Plate for Brazing Water Cooling Plate

- Aluminum Brazing Composite Material 3003+4045 Aluminum Plate

- 3003 Aluminum Disc for Non-stick Pan

- 3003 Aluminum Plate for Mobile Phone Battery Shell

- 3003 Corrugated Aluminum Sheet

- 3003 Aluminum Plate for Automobile Fender

- 3003 Checker Aluminum Plate for Stair Anti-slip

- 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip

- 3003 Ultra-wide Curtain Wall Aluminum Plate

- 3003 Aluminum Plate for Building Decoration

- 3003 Roof Aluminum Plate for Decoration

- 3003 Aluminum Sheet Coil for Thermal Insulation Material

- 3003 Pre-painted Aluminum Coil

Recommended Content

- 3003 Aluminum Tubing

- 3003 Aluminum vs. 3005 Aluminum

- 3003-H18 Aluminum vs. 3005-H18 Aluminum

- What is the difference between 3003 H14 and 3105 H14?

- 3003 Aluminum vs. 3104 Aluminum

- 3003-H18 Aluminum vs. 3004-H18 Aluminum

- 3003-O Aluminum vs. 3004-O Aluminum

- What is the difference between 3003 and 3004 aluminum?

- 3003-H22 Aluminum vs. 3003-H24 Aluminum

- What is the difference between 3003 O and 3003 H14?

- What is the difference between 3003 H14 and H24?