5052 embossed aluminum sheet is an industrial functional material made from 5052 aluminum alloy as the base material, with concave and convex patterns formed on the surface through rolling process. It combines practicality and decorative properties.

The core advantage of 5052 embossed aluminum sheet lies in combining the corrosion resistance of 5052 alloy with the functionality of embossing process, making it widely used in construction, transportation, household, and other fields.

With its comprehensive performance and flexible customization capability, 5052 embossed aluminum sheet has become an ideal material for both industrial and civil applications. Whether it is the corrosion resistance requirement of ship decks or the aesthetic pursuit of building curtain walls, the optimal solution can be achieved through the reasonable selection of alloy temper and pattern design.

| Characteristic Item | Parameter Range / Description |

| Common Alloy Tempers | H32, H34, H112, etc. |

| Thickness (mm) | 1.2 - 8.0 (can be thicker for specific uses) |

| Width (mm) | 100 - 1850 (customizable, ultra-wide plates up to 2650mm available) |

| Length (mm) | 500 - 16000 (customizable) |

| Surface Patterns | Five-bar, three-bar, two-bar, one-bar, pointer pattern, diamond pattern, etc. |

| Typical Characteristics | Excellent corrosion resistance and rust resistance; high fatigue strength; good forming processability and weldability; good anti-slip performance |

5052 Embossed Aluminum Sheet Material Properties

- Corrosion Resistance: Performs excellently in humid and marine environments, suitable for ships, carriage floors, etc.

- Medium Strength: Balances load-bearing capacity with processing flexibility.

- Processing Performance: Can be formed through bending, stamping, welding (ER5356 welding wire recommended), etc.; surface can undergo anodizing, painting, and other treatments to meet decorative needs.

5052 Embossed Aluminum Coil & Sheet Pattern Types

The 5052 embossed finish provides a textured surface that enhances grip and reduces glare. This finish is achieved through a pressing process that creates a raised pattern of dimples or bumps on the surface.

-

Stucco Embossed Aluminum Coil 5052

A Stucco Embossed Aluminum Coil 5052 is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco Embossed Aluminum Coil 5052s are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil 5052

Orange peel Embossed Aluminum Coil 5052 has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel Embossed Aluminum Coil 5052s are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

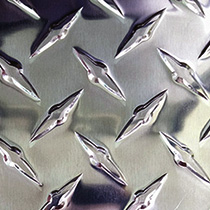

Diamond Embossed Aluminum Sheet Coil

Diamond Embossed Aluminum Coil 5052s are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond Embossed Aluminum Coil 5052s can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer Embossed Aluminum Coil 5052

Hammer Embossed Aluminum Coil 5052s have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean Embossed Aluminum Coil 5052

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil 5052

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop Embossed Aluminum Coil 5052s are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil 5052

A Hemispherical Embossed Aluminum Coil 5052 refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

Rhombus embossed aluminum coil

Rhombus-Embossed Aluminum Coil 5052 features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of Embossed Aluminum Coil 5052s and offers a variety of materials for Embossed Aluminum Coil 5052s.

5052 Stucco Embossed Aluminum Sheet Surface Finish

5052 Anodized Stucco Embossed Aluminum Sheet Coil

- Features: Forms a dense aluminum oxide layer, strong corrosion resistance

5052 Mirror Embossed Aluminum Sheet Coil

- Features: Extremely high gloss and reflectivity

5052 Color-Coated Embossed Aluminum Sheet Coil

- Features: Rich surface coating colors

5052 Brushed Embossed Aluminum Sheet Coil

- Features: Uniform surface texture and high scratch resistance

5052 Fluorocarbon Coated Embossed Aluminum Sheet Coil

- Features: Excellent weather resistance, corrosion resistance, and chemical resistance, color remains stable and durable

5052 Polyester Coated Embossed Aluminum Sheet Coil

- Features: Strong coating adhesion and high cost-effectiveness

5052 Stucco Embossed Aluminum Sheet Advantages

- Corrosion resistance: 5052 aluminum is highly resistant to corrosion, making it an ideal choice for outdoor and marine environments.

- Lightweight: Aluminum is much lighter than steel, making it easier to handle and install.

- Sustainability: Aluminum is recyclable, contributing to environmentally friendly practices.

- Low maintenance: The embossed surface can hide scratches and dents better than a smooth surface, reducing the need for maintenance.

Chemical Composition of 5052 Embossed Aluminum Sheet

| Element | Composition % |

| Al | REM |

| Si | ≤0.25 |

| Cu | ≤0.10 |

| Mg | 2.2 - 2.8 |

| Zn | ≤0.10 |

| Mn | ≤0.10 |

| Cr | 0.15 - 0.35 |

| Fe | ≤0.40 |

| Single | ≤0.05 |

| Total | ≤0.15 |

Mechanical Properties of 5052 Embossed Aluminum Sheet

| Properties/Alloy | 5052-O | 5052-H111 | 5052-H112 | 5052-H24 | 5052-H32 | 5052-H34 |

| Tensile Strength | 79-190 MPa | 75-190 MPa | 89-200 MPa | 190-250 MPa | 180-230 MPa | 200-260 MPa |

| Shear Strength | 130 MPa | 120 MPa | 120 MPa | 150 MPa | 140 MPa | 150 MPa |

| Fatigue Strength | 26 MPa | 66 MPa | 73 MPa | 110 MPa | 120 MPa | 130 MPa |

| Elastic Modulus | 68 GPa | 68 GPa | 68 GPa | 68 GPa | 68 GPa | 68 GPa |

| Brinell Hardness | 47 | 46 | 55 | 67 | 60 | 68 |

| Elongation at Break | 22% | 19% | 10% | 8% | 12% | 10% |

5052 Stucco Embossed Aluminum is a versatile and practical choice for a wide range of applications, combining strength, aesthetics and excellent weather resistance. Whether used in construction, transportation or decorative applications, this material provides a reliable solution for functional and aesthetic needs.

Core Application Fields of 5052 Embossed Aluminum Sheet

Transportation

- Shipbuilding: Decks, cabin floors; seawater corrosion resistance is superior to ordinary steel.

- Automobiles: Body panels (thickness 1.5-2.0mm), fuel tanks, pedals; weight reduction of more than 40% while enhancing corrosion resistance.

Architectural Decoration

- Curtain walls, ceilings, partitions: After anodizing, colors such as champagne gold and matte black can be achieved, enhancing modern architectural aesthetics.

- Anti-slip stair treads: Five-bar aluminum sheet performs stably in humid environments, reducing the risk of slipping.

Industry & Household

- Machinery housings: 5052B aluminum plate (improved type) is suitable for mold making, can be milled and carved into complex shapes.

- Furniture decoration: Cabinet panels, screens; embossing achieves a balance between anti-slip function and aesthetics.

Comparison of 5052 Embossed Aluminum with Other Alloys

| Characteristic | 5052 Embossed Aluminum Sheet | 6061 Embossed Aluminum Sheet | 5083 Embossed Aluminum Sheet |

| Main Alloying Elements | Magnesium (2.2-2.8%) | Magnesium + Silicon (0.8-1.2%) | Magnesium (4.0-4.9%) |

| Corrosion Resistance | Excellent (suitable for marine environment) | Good (requires coating protection) | Outstanding (high magnesium content resists salt spray) |

| Strength | Medium (H32 tensile strength 210-260MPa) | High (T6 tensile strength above 310MPa) | Relatively High (H32 tensile strength 275MPa) |

| Typical Applications | Architectural decoration, automobile pedals | Structural parts, mechanical components | Ship decks, pressure vessels |

Purchasing Considerations for 5052 Embossed Aluminum

Clarify Requirements

- If high corrosion resistance is required, choose 5052; if high strength is required, consider 6061; for extreme marine environments, 5083 is recommended.

- Choose embossing type according to application scenario, e.g., five-bar for anti-slip, orange peel pattern for decoration.

Pay Attention to Material and Temper

Confirm the brand, origin, and whether the aluminum coil meets your required quality certification. The performance of different tempers (such as O temper, H32, H34, etc.) varies greatly, so choose based on processing needs.

Samples and Inspection

Before bulk purchasing, be sure to ask the supplier to provide samples, so that you can visually check the clarity of the embossing, surface quality, and basic dimensions.

Other Alloy Embossed Aluminum Sheet Coil

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.