1100 embossed aluminum sheet is a type of aluminum alloy sheet made of industrial pure aluminum (aluminum content ≥99.00%), with specific patterns formed on the surface through the embossing process.

1100 embossed aluminum sheet not only has the excellent properties of aluminum but also features decorative patterns, making it commonly used in applications that require both practicality and aesthetics.

1100 Embossed Aluminum Sheet Informations

| Feature Item | Description or Parameter | Remarks/Notes |

| Main Material | 1100 alloy | Aluminum content ≥99.0%, belongs to pure aluminum series |

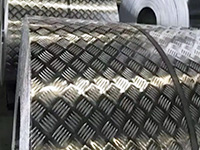

| Common Pattern Types | Diamond, five-bar, pointer type, rhombus pattern, etc. | Commonly used to enhance anti-slip property and decoration |

| Common Specifications | Thickness: 0.1mm - 120mm (common range 0.3mm-6.0mm) | Special specifications can be customized |

| Width: 20mm - 2000mm | ||

| Length: customizable, usually 1000mm - 12000mm | ||

| Common Tempers | O temper (annealed), H14, H18, H24, H112, etc. | Different tempers vary in hardness and strength |

| Main Application Fields | Architectural decoration (ceiling, curtain wall), transportation (car body panel, anti-slip floor plate), household items (tableware, furniture surface), electronic and electrical shells, etc. |

Advantages of 1100 Embossed Aluminum Sheet

- Lightweight: Aluminum alloy material is inherently light, making it easy to handle and install.

- Easy to process: Aluminum sheets are easy to cut, bend, and shape.

Limitations of 1100 Embossed Aluminum Sheet

- Lower strength: Compared to other aluminum alloys, 1100 aluminum alloy has lower strength.

- Prone to scratching: The surface texture may be easily scratched during use.

1100 Embossed Aluminum Sheet Coil Pattern Type

-

Stucco Embossed Aluminum Coil 1100

A Stucco Embossed Aluminum Coil 1100 is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco Embossed Aluminum Coil 1100s are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil 1100

Orange peel Embossed Aluminum Coil 1100 has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel Embossed Aluminum Coil 1100s are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

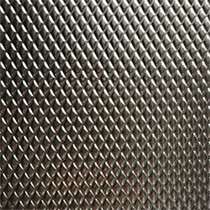

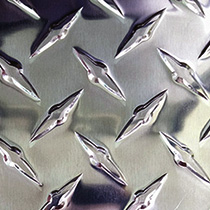

Diamond Embossed Aluminum Sheet Coil

Diamond Embossed Aluminum Coil 1100s are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond Embossed Aluminum Coil 1100s can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer Embossed Aluminum Coil 1100

Hammer Embossed Aluminum Coil 1100s have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean Embossed Aluminum Coil 1100

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil 1100

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop Embossed Aluminum Coil 1100s are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil 1100

A Hemispherical Embossed Aluminum Coil 1100 refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

Rhombus embossed aluminum coil

Rhombus-Embossed Aluminum Coil 1100 features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of Embossed Aluminum Coil 1100s and offers a variety of materials for Embossed Aluminum Coil 1100s.

1100 Embossed Aluminum Sheet Surface Treatment

1100 Anodized Stucco Embossed Aluminum Sheet Coil

- Features: Forms a dense aluminum oxide layer, strong corrosion resistance

1100 Mirror Embossed Aluminum Sheet Coil

- Features: Extremely high gloss and reflectivity

1100 Color-Coated Embossed Aluminum Sheet Coil

- Features: Rich surface coating colors

1100 Brushed Embossed Aluminum Sheet Coil

- Features: Uniform surface texture and high scratch resistance

1100 Fluorocarbon Coated Embossed Aluminum Sheet Coil

- Features: Excellent weather resistance, corrosion resistance, and chemical resistance, color remains stable and durable

1100 Polyester Coated Embossed Aluminum Sheet Coil

- Features: Strong coating adhesion and high cost-effectiveness

Chemical composition of 1100 embossed aluminum sheet

| Element | Composition % |

| Si | 0.95 |

| Fe | |

| Cu | 0.05-0.20 |

| Mn | 0.05 |

| Mg | - |

| Cr | - |

| Ni | - |

| Zn | 0.10 |

| Ti | - |

| Al | Remainder |

Thickness deviation of 1100 embossed aluminum sheet

| Thickness mm | Thickness tolerances within the following width ranges | ||

| 800.0-1600.0 | >1600.0-1800.0 | >1800-2400.00 | |

| 0.70-1.00 | ±0.03 | ±0.05 | ±0.08 |

| >1.00-1.20 | ±0.04 | ±0.06 | ±0.09 |

| >1.20-1.50 | ±0.05 | ±0.07 | ±0.10 |

The performance of 1100 embossed aluminum sheet

| Material | Temper | Tensile strength ksi | Yield strength (ksi min) | Elongation % in 2''0.064'' sheet |

| 1100 | 1100-0 | 11-15.5 | 3.5 | 30 |

| 1100 | 1100-H12 | 14-19 | 11 | 8 |

| 1100 | 1100-H14 | 16-21 | 14 | 5 |

| 1100 | 1100-H16 | 19-24 | 17 | 4 |

| 1100 | 1100-H18 | 22 (min) | - | 4 |

Width deviation of 1100 embossed aluminum sheet

| Thickness mm | Width tolerances within the following width ranges | |||||||

| <100.0 | >100.0 -300.0 | >300.0-500.0 | >500.0-800.0 | >800.0-1 250.0 | >1 250.0-1 800.0 | >1 800.0-2 000.0 | >2 000.0-2 400.0 | |

| 0.30—1.60 | + 0, 3 0 | + 0, 4 0 | + 1.0 0 | + 1.5 0 | + 2, 0 0 | + 3.0 0 | — | — |

| >1.60—3.50 | — | — | — | + 2.0 0 | 4-3.0 0 | + 4.0 0 | + 5.0 0 | + 6.0 0 |

1100 Embossed Aluminum Sheet Applications

Architectural Decoration

- Curtain wall decoration (hollow carving design), ceiling panels (orange peel pattern enhances three-dimensional effect)

- Anti-slip stair treads (five-bar pattern), balcony guardrails

Industrial Equipment

- Refrigerated truck interior wall (diamond pattern enhances adhesion), chemical storage tank liner (corrosion resistance)

- New energy charging pile shell (lightweight + weather resistance)

Home Appliances and Daily Necessities

- Refrigerator liner (orange peel pattern improves condensation water drainage), microwave oven cavity

- Kitchenware (baking pans, stew pots), furniture handles (anodized treatment)

Transportation

- High-speed train interior panels (lightweight requirement), container truck flooring (anti-slip and wear-resistant)

- Ship decks (resistant to seawater corrosion)

Advantages of 1100 Aluminum Sheet Embossing Process

- Enhance aesthetics: embossed patterns improve visual appeal and can be customized.

- Improve grip/anti-slip property: certain embossed patterns, such as checkered plates, provide better traction.

- Increase surface area: this can improve the heat dissipation performance of insulation panels.

- Lightweight: aluminum is inherently light, suitable for various applications.

1100 Embossed Aluminum Sheet Alternative Material Comparison

Recommendation based on specific usage environment:

- If high corrosion resistance is required, choose 1100

- If high strength is required, consider 3003

- For marine environments, 5052 is recommended

| Material | Advantages | Disadvantages | Applicable Scenarios |

| 3003 Embossed Aluminum Sheet | Higher strength | Slightly weaker corrosion resistance | Heavy-duty structural parts, outdoor billboards |

| 5052 Embossed Aluminum Sheet | Excellent seawater corrosion resistance | Higher price (about 30% more expensive) | Shipbuilding, marine engineering |

| Embossed Stainless Steel Plate | Excellent corrosion resistance | Heavy weight (density 7.9g/cm³) | Food processing equipment, medical field |

1100 Embossed Aluminum Sheet Procurement Technical Points

As a manufacturer with a complete industrial chain, Haomei Aluminum is very pleased to provide you with professional technical advice to ensure that the products you purchase fully meet the requirements of your project.

Purpose and Environment (the basis for all selection)

- Indoor Use: such as interior decorative ceilings, furniture panels, electrical appliance shells, etc. Haomei Recommendation: Requirements for corrosion resistance and wear resistance are relatively low. Normally, oxidation resistance treatment or ordinary protective film is sufficient to meet transportation and installation needs. The focus is on surface aesthetics and clarity of embossing patterns.

- Outdoor Use: such as building exterior walls, canopies, vehicle body panels, etc. Haomei Recommendation: Weather resistance must be emphasized. We strongly recommend anodizing treatment (can generate dense oxide film, UV resistant, corrosion resistant) or PVDF coating (fluorocarbon coating, excellent weather resistance, no discoloration for 20 years). Ordinary protective films will age and crack under long-term sunlight outdoors and are only suitable for transportation protection, not for final use.

Specifications and Tolerances (precise dimensions are the guarantee of assembly)

- Thickness (common range: 0.3mm - 6.0mm). Curtain wall panels commonly use 1.5mm-3.0mm; decorative ceilings commonly use 0.5mm-1.0mm; industrial anti-slip plates commonly use 2.0mm-6.0mm.

- Width & Length: Conventional sizes: Haomei’s base coil widths are usually 1000mm, 1250mm, 1500mm, etc. It is best if your required sizes can be integer cuts from our base coil width, which minimizes waste and reduces costs.

- Tolerance Requirements: The ±0.01mm-±0.05mm you mentioned belongs to high-precision tolerance, usually used in precision occasions where thickness requirements are strict. General commercial tolerance is about ±0.05mm. Please specify your tolerance standard, as it directly affects cost and rolling process.

Special Sizes: Non-standard sizes can be customized, but may require mold or cutting fees.

Pattern Types (combination of functionality and aesthetics)

Common Patterns: Haomei has a large stock of conventional embossing rolls, such as:

- Diamond: Most common, anti-slip, wear-resistant, aesthetic.

- Five-bar: Excellent anti-slip performance, commonly used for treads and flooring.

- Pearl / Orange Peel: Delicate and beautiful, strong decorative effect, commonly used in home appliances and interior decoration.

- Small Checker: Anti-slip, refined visual effect.

Pattern Height:

This is a key parameter! It directly affects anti-slip performance and wear resistance. For example, for heavy-duty tread plates, pattern height is recommended >0.8mm; for decorative façades, 0.3-0.5mm is sufficient.

Please be sure to provide the required pattern model or samples. If the existing patterns do not meet your needs, Haomei can customize embossing rolls for you, but you will need to bear the corresponding mold costs and minimum order requirements.

Temper (O temper, H temper, etc. – determines the "softness/hardness" of the material)

O Temper (annealed):

- Features: Soft, excellent ductility, suitable for bending, deep drawing, stretching, and other deep forming processes.

- Haomei Tip: If you need to stamp complex shapes (such as cookware, lampshades), be sure to choose O temper.

H Temper (strain-hardened):

- H14: Half-hard temper. A commonly used temper that balances certain formability and strength. Suitable for general bending and applications not requiring deep drawing.

- H18 / H38: Full-hard temper. High hardness, high strength, but poor ductility. Only suitable for flat plate use or applications requiring simple bending.

- Haomei Tip: Incorrect temper selection will lead to cracking and wrinkling during processing. Please specify your subsequent processing method.

Surface Treatment

Protective Film

- Purpose: Purely protective, prevents surface scratches during transportation, processing, and installation.

- Choice: Single-sided film or double-sided film? Ordinary film (may leave glue over time) or high-quality weather-resistant film?

Anodizing

- Purpose: Improves surface hardness, wear resistance, corrosion resistance, and can be dyed into various colors (such as champagne gold, black, bronze, etc.). A common choice for high-end applications.

- Haomei Tip: Please specify oxide film thickness (e.g., 10μm, 15μm) and color code.

Coating

Purpose: Decoration and protection. For example, spray painting, fluorocarbon coating (PVDF), etc.

For a quick quotation, you can provide the following information:

- Product Purpose: e.g., exterior building curtain wall

- Alloy Temper: e.g., 1100-H14

- Pattern Type: e.g., diamond pattern, provide samples or photos

- Specific Specifications: thickness (tolerance requirements), width, length

- Surface Treatment: e.g., anodized, champagne color, 10μm film thickness; single-sided protective film

- Purchase Quantity: tons or square meters

- Packaging Method: e.g., wooden pallet + steel strip packaging

- Delivery Time Requirement: approximately how many days

As a manufacturer, Haomei promises: Upon receiving your clear requirements, we will provide you with the most competitive price in the market, stable product quality, and reliable delivery time. We have full-process production capability from casting, hot rolling, cold rolling to finishing, embossing, and surface treatment, enabling us to provide you with one-stop solutions.

Other Alloy Embossed Aluminum Sheet Coil

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.