The 1060 embossed aluminum plate is a decorative and functional aluminum plate made from 1060 aluminum alloy through an embossing process. The 1060 aluminum alloy belongs to the 1000 series and is known for its high aluminum content, making it highly pure and suitable for various applications due to its excellent performance.

The 1060 aluminum alloy contains at least 99.6% aluminum, which is higher than the 1050 series. This high aluminum content ensures outstanding corrosion resistance, thermal conductivity, and machinability.

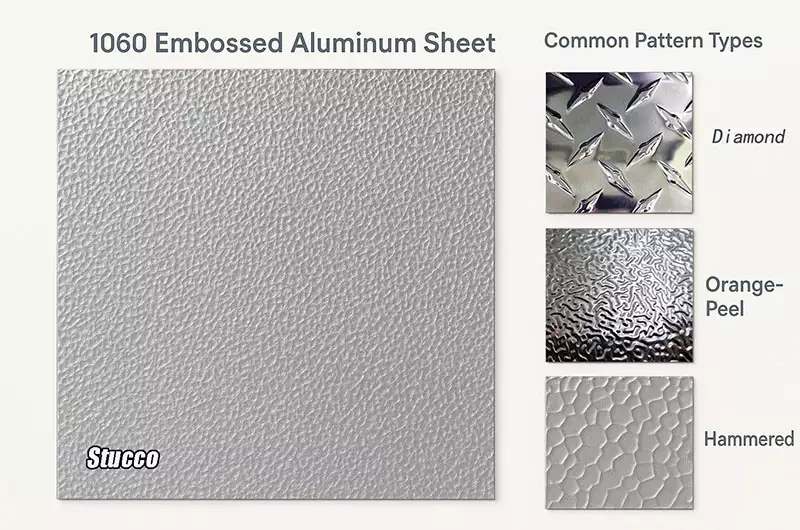

1060 Embossed Aluminum Sheet is a pure aluminum alloy with a patterned surface created by a rolling embossing process (e.g., stucco, orange peel, diamond, or hammered patterns). It combines lightweight, corrosion resistance, and increased mechanical strength due to work hardening. The embossing process uses cold rolling to form the surface texture, improving slip resistance, stiffness, and thermal reflectivity.

1060 Embossed Aluminum Sheet combines the excellent corrosion resistance, formability, and electrical conductivity of pure aluminum with the enhanced structural rigidity and decorative appeal of an embossed surface. With customizable thickness, coating, and pattern options, it is ideal for applications in refrigeration, construction, HVAC, transportation, and industrial sectors.

The embossed designs of 1060 Embossed Aluminum Sheet (such as five-bar tread, orange peel, and diamond patterns) significantly enhance anti-slip properties, with a surface roughness Ra value of 1.6–3.2 μm. It forms a dense aluminum oxide film that resists atmospheric and water corrosion, but contact with alkaline or chloride-containing environments should be avoided. When treated with anodizing or fluorocarbon coating, its weather resistance can last over 20 years.

The Specifications of 1060 Embossed Aluminum Sheet

| Parameter | Range/Details |

| Thickness | 0.09–3.5 mm (common: 0.2–2 mm for sheets; ≤3.5 mm for coils) |

| Width | 100–2650 mm (standard: 1000–1300 mm) |

| Length | to clients’ requirement |

| Temper | O (annealed), H12, H14, H24, H26 (H24 semi-hard most common) |

| Surface Finish | Plain mill, anodized, or pre-painted stucco |

| Embossing Patterns | Stucco, orange peel, rhombus, hemisphere, cobblestone |

| Coating | Polyester, Fluorocarbon, polyurethane and epoxy coating |

1060 Embossed Aluminum Sheet Surface Textures

Through embossing, the 1060 aluminum plate can achieve various textures and patterns, such as diamond and orange peel. These textures not only enhance aesthetics but also provide functional advantages, such as improved grip and slip resistance.

-

Stucco Embossed Aluminum Coil 1060

A Stucco Embossed Aluminum Coil 1060 is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco Embossed Aluminum Coil 1060s are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil 1060

Orange peel Embossed Aluminum Coil 1060 has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel Embossed Aluminum Coil 1060s are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

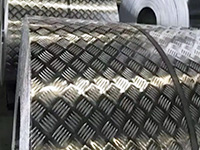

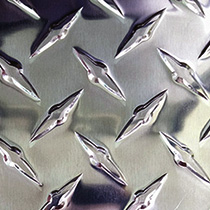

Diamond Embossed Aluminum Sheet Coil

Diamond Embossed Aluminum Coil 1060s are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond Embossed Aluminum Coil 1060s can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer Embossed Aluminum Coil 1060

Hammer Embossed Aluminum Coil 1060s have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean Embossed Aluminum Coil 1060

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil 1060

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop Embossed Aluminum Coil 1060s are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil 1060

A Hemispherical Embossed Aluminum Coil 1060 refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

Rhombus embossed aluminum coil

Rhombus-Embossed Aluminum Coil 1060 features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of Embossed Aluminum Coil 1060s and offers a variety of materials for Embossed Aluminum Coil 1060s.

Features of 1060 Embossed Aluminum Sheet

High Purity Aluminum

The aluminum purity of 1060 aluminum plate is 99.6%, offering excellent corrosion and oxidation resistance. This makes it highly suitable for use in environments exposed to moisture and chemicals.

Good Thermal Conductivity

The high thermal conductivity of 1060 aluminum plate makes it very effective in applications requiring efficient heat dissipation. It helps maintain stable temperatures in various industrial and commercial applications.

Lightweight

The lightweight nature of aluminum provides advantages in ease of handling, transportation, and installation. This is particularly beneficial in industries where weight reduction is crucial.

Excellent Formability

The 1060 aluminum plate is renowned for its excellent machinability and ductility. It can be easily formed into various shapes and patterns, making it suitable for a range of embossing designs and applications.

Durability and Longevity

The embossed surface of the 1060 aluminum plate enhances its durability and abrasion resistance. The surface patterns can withstand physical impacts and environmental factors, ensuring long-term performance.

Easy Maintenance

Due to its natural corrosion resistance and easy-to-clean aluminum surface, the 1060 embossed aluminum plate requires minimal maintenance. Its stain and dirt resistance ensures visual appeal with low maintenance costs.

1060 Embossed Aluminum Sheet chemical composition

1060 alloy is an industrial pure aluminum (Al content ≥ 99.6%) and contains trace elements such as silicon ≤ 0.25%, iron ≤ 0.35%, and copper ≤ 0.05%.

- Alloy: 1060 (UNS A91060, AA1060).

- Purity: Aluminum content 99.6%, with trace elements (Silicon ≤ 0.25%, Iron ≤ 0.4%, Copper ≤ 0.05%).

- Available tempers include: O (annealed) for optimal ductility; and H series (H12–H26) for varying degrees of work hardening and strength.

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.15 | Remain |

Physical properties of 1060 Embossed Aluminum Sheet

| Alloy Temper | Specified | Tensile | Yield | Elongation(%) |

| Thickness(in.) | strength(ksi) | strength(ksi) | ||

| 1060-O(annealed) | 0.006-0.019 | 8.0-14.0 | 2.5 | Min15 |

| 0.020-0.050 | Min22 | |||

| 0.051-3.000 | Min25 | |||

| 1060-H12/1060-H22 | 0.017-0.050 | 11.0-16.0 | 9 | Min6 |

| 0.051-2.000 | Min12 | |||

| 1060-H14/1060-H24 | 0.006-0.019 | 12.0-17.0 | 10 | Min1 |

| 0.020-0.050 | Min5 | |||

| 0.051-1.000 | Min10 | |||

| 1060-H16/1060-H26 | 0.006-0.019 | 14.0-19.0 | 11 | Min1 |

| 0.020-0.050 | Min4 | |||

| 0.051-0.162 | Min5 | |||

| 1060-H18/1060-H28 | 0.006-0.019 | Min16.0 | Min12.0 | Min1 |

| 0.020-0.050 | Min3 | |||

| 0.051-0.128 | Min4 | |||

| 1060-H112 | 0.250-0.499 | Min11.0 | Min7.0 | Min10 |

| 0.500-1.000 | Min10.0 | Min5.0 | Min20 | |

| 1.001-3.000 | Min9.0 | Min4.0 | Min25 |

Advantages of 1060 Aluminum

- High corrosion resistance and excellent formability — not heat-treatable, but can be strengthened through cold working.

- Good electrical and thermal conductivity, suitable for heat exchangers and reflector applications.

- Reflective surface enhances aesthetics and functional performance in HVAC, lighting, and solar applications.

- Excellent ductility, suitable for bending, deep drawing, and welding.

Applications of 1060 Embossed Aluminum Sheet

| Application Field | Specific Product Use | Description |

| Architectural Decoration | Building exterior walls, curtain walls, wall panels, ceilings, interior panels | 1060 embossed aluminum sheet is widely used in architectural decoration due to its unique surface texture and high reflectivity, providing an excellent decorative effect. It is applied to building exteriors, curtain walls, wall panels, ceilings, and interior panels, enhancing the texture of architectural appearance. Thanks to its good weather resistance, lightweight nature, and corrosion resistance, it maintains stable performance and long-lasting aesthetics in various climatic conditions. |

| Automotive Industry | Engine compartments, heat shields, thermal insulation covers, protective covers | In the automotive industry, 1060 embossed aluminum sheet is favored for its excellent thermal conductivity and corrosion resistance. It is widely used in engine compartments for heat shields, thermal insulation covers, and protective covers. These components are often exposed to high temperatures and corrosive environments. 1060 embossed aluminum effectively reflects heat and resists oxidation, ensuring operational safety and extending the service life of automotive parts. |

| Refrigeration Equipment | Refrigerator and freezer liners | 1060 embossed aluminum sheet is used as the liner in refrigerators and freezers to enhance heat exchange efficiency per unit area through its textured surface. The patterned structure promotes air circulation and improves heat exchange. Its aluminum base provides excellent oxidation and moisture resistance, effectively preventing corrosion caused by condensation and frost during long-term use. The material is cost-effective and suitable for mass production. |

| HVAC | Ductwork, thermal reflectors | In HVAC systems, 1060 embossed aluminum sheet is used in ductwork and thermal reflectors to optimize airflow distribution and thermal reflection. The embossed surface structure effectively guides air circulation within insulation layers and enhances the reflection of radiant heat, thereby improving overall system energy efficiency. Its lightweight and ease of processing make it ideal for complex duct systems and thermal components. |

| Transportation and Industrial Use | Flooring, stair treads, protective panels | In transportation and industrial settings, 1060 embossed aluminum sheet is widely used for vehicle flooring, stair treads, walkways, and equipment protection panels. Its embossed patterns (such as orange peel, hammered, five-bar tread) provide excellent anti-slip properties, enhancing safety for operators. Additionally, the material offers good wear and corrosion resistance, adapting to various industrial environments and transportation conditions. |

| Consumer Goods and Appliance Decoration | Nameplates, lamp housings, appliance casings, DIY decorative parts | In the consumer goods sector, 1060 embossed aluminum sheet is used to combine functionality with aesthetic design for manufacturing nameplates, lighting housings, home appliance casings, and DIY decorative components. While maintaining strength and processability, its unique metallic luster and embossed texture add a sense of technology and quality to the final product, enhancing users' visual and tactile experience. |

Advantages of 1060 Embossed Aluminum Sheet in Industry Applications

| Industry Sector | Application Area | Specific Uses and Advantage Descriptions |

| Automotive and Transportation | Heat Shields | Used in engine compartments and exhaust systems; capable of reflecting about 90% of radiant heat, improving thermal efficiency and safety. |

| Anti-Slip Flooring | Applied in truck trailers and cargo areas; embossed surface (e.g., tread pattern) provides excellent anti-slip performance. | |

| Architecture and Construction | Building Facades | Used for curtain walls and architectural decorative panels; features lightweight, durability, aesthetic appeal, and corrosion resistance. |

| Interior Decoration | Applied in ceilings, partition panels, and thermal insulation materials in HVAC systems; balances functionality and decorative value. | |

| Industry and Consumer Goods | Refrigeration Equipment | Inner liners of refrigerators and inner/outer panels of freezers; excellent corrosion resistance in humid and condensation-prone environments. |

| Electrical Systems | Used for transformer winding strips and conductive components; electrical conductivity up to 55% IACS, ensuring stable electrical performance. | |

| Decoration / Handicrafts | Used in nameplates, lamp covers, and DIY projects; visually appealing surface, easy to form and process. |

The 1060 embossed aluminum sheet combines high purity, excellent thermal conductivity, and outstanding formability. Its diverse textures and patterns make it a versatile choice for both functional and decorative applications across various industries.

Processing Characteristics of 1060 Embossed Aluminum Sheet

- Forming: Suitable for cold drawing, stamping, and bending. Due to its softness, machining should be avoided.

- Welding: Easily weldable using standard methods (filler: 1060 alloy).

- Heat treatment: Not heat-treatable; hardening only through cold working.

- Surface treatment: Anodizing enhances its corrosion resistance in harsh environments (e.g., refrigerators).

Processing Advantages

- Excellent ductility, suitable for forming processes such as stamping, drawing, and bending.

- Mature production process with lower cost than alloy aluminum sheets.

Comparison with Flat 1060 Sheet

| Property | Flat 1060 Sheet | Embossed 1060 Sheet |

| Surface Area | Smooth, limited area | Textured, increased surface contact |

| Structural Rigidity | Lower | Higher (due to embossing) |

| Aesthetics | Plain | Decorative finishes (stucco, orange-peel) |

| Applications | Kitchenware, signage | HVAC, refrigeration, architecture, transport |

Limitations and Considerations of 1060 Embossed Aluminum Sheet

- Strength: Lower than alloys like 5052; avoid using in high-stress structural applications.

- Machinability: Poor in soft temper; requires lubricants/tools for cutting.

- Heat Resistance: Maximum 590°C (direct contact); performance degrades above melting point ~640°C.

1060 Embossed Aluminum Sheet Purchasing Guide

- Certifications: Ensure compliance with ASTM B209, ISO 9001, or EN 485 standards.

- Customization: Available in thickness, width, patterns, and surface treatments.

- Packaging: Export-grade wooden pallets with waterproof film.

- Pricing Factors: Size, temper condition, surface treatment, and order quantity (bulk discounts typically around 5%).

1060 embossed aluminum sheet performs excellently in applications requiring formability, corrosion resistance, and thermal management. Its embossed surface enhances functionality (anti-slip, insulation) while retaining the advantages of pure aluminum. When selecting, give priority to temper condition (H24 for balanced strength and formability) and anodizing treatment to adapt to harsh environments. For special requirements (e.g., automotive heat shields), verify IATF16949 certification.

Other Alloy Embossed Aluminum Sheet Coil

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.