3003 Aluminum Plate and Sheet

3003 aluminum alloy sheet is one of the most commonly used rust-resistant aluminum materials in industry. Its core characteristic is a well-balanced overall performance, achieving an excellent balance among formability, corrosion resistance, and weldability.

3003 aluminum alloy is one of the most widely used aluminum alloys among all aluminum grades. It is non-heat-treatable and is essentially commercial pure aluminum with the addition of manganese, which increases its strength by approximately 20% compared to the 1100 series aluminum alloys.

Because it achieves an outstanding balance of corrosion resistance, moderate strength, and high workability, it has become the preferred material for general sheet metal fabrication and everyday consumer products.

3003 aluminum sheet is well known for its moderate strength, excellent corrosion resistance, and good formability. It belongs to the Al-Mn alloy series (3xxx series) and is widely used in industries such as automotive, construction, packaging, and electronics. Whether used for battery systems, roofing, or food packaging, 3003 aluminum delivers consistent performance and durability.

- Alloy: 3003 (Al-Mn series)

- Basic composition: aluminum with approximately 1.0–1.5% manganese and a small amount of copper (about 0.1%)

- Series: 3xxx series, known for corrosion resistance and good formability

- Temper options: H14, H18, H24, H22, O (common cold-rolled temper conditions)

3003 Aluminum Plate Temper Options

Typical Tempers for 3003 Aluminum Sheet Plate

The 3003 aluminum alloy obtains its mechanical property states through processes such as cold rolling and annealing. The core tempers are the "H temper" (strain-hardened) and the "O temper" (annealed).

- O

- H14

- H24

- H18

- H14, H16, H18: These tempers offer different levels of hardness, typically used in applications requiring moderate strength.

- O (Annealed): This soft temper is used for forming operations because it offers the highest workability.

| Alloy Temper | Temper Description | Key Characteristics & Typical Applications |

| O (Annealed) | Fully annealed, softest condition | Extremely high ductility, suitable for deep drawing and complex formed parts, such as deep-drawn containers. |

| H14 (Half-Hard) | Strain-hardened by a certain degree of cold working | Balanced strength and formability; a commonly used temper for formed parts requiring moderate strength. |

| H18 (Full-Hard) | Fully strain-hardened by cold working | Highest strength but low ductility; suitable for flat parts with simple forming requirements where high strength is needed. |

- O (Annealed): Soft and highly suitable for forming complex shapes (e.g., battery housings).

- H12 / H14 / H16: Strain-hardened tempers providing progressively higher strength.

- H22 / H24: Partially annealed after cold working to balance strength and formability.

3003 H14 Aluminum

- Temper: H14 indicates a half-hard, strain-hardened state without annealing.

- Features: Medium strength, good corrosion resistance, good formability; suitable for applications requiring moderate strength and shaping, such as roofing, siding, tanks, and daily-use items.

3003 H22 Aluminum

- Temper: H22 indicates strain-hardened followed by slight annealing, making it quarter-hard.

- Features: Strength and hardness between H14 and O temper, good surface stability, still easy to process; suitable for packaging, architectural panels, roofing, and drainage systems.

3003 O Aluminum

- Temper: O indicates fully annealed, softest state.

- Features: Maximum ductility and formability, lowest strength; ideal for deep drawing, bending, or complex-shaped products such as cookware, pressure vessels, signage, and lighting fixtures.

Haomei 3003 Aluminum Products in Different Tempers

H Temper (strain-hardened, the number represents the degree of hardening)

- 3003 h14 aluminum sheet (3003-H14 aluminum alloy sheet)

- 3003 h14 aluminum plate (3003-H14 aluminum alloy thick plate)

- 3003 h16 aluminum sheet (3003-H16 aluminum alloy)

- 3003 h18 aluminum sheet (3003 aluminum alloy H18 temper)

- 3003 h22 aluminum diamond plate (3003-H22 aluminum alloy checkered plate)

- 3003 h22 aluminum tread plate (3003-H22 aluminum alloy tread plate)

- 3003 h24 aluminum sheet (3003 aluminum alloy H24 temper)

O Temper (annealed, fully softened state)

- 3003 o aluminum plate (3003 aluminum alloy O temper)

- 3003 o aluminum sheet (3003 aluminum alloy O temper sheet)

- 3003 o aluminum tubing (3003 aluminum alloy O temper tube)

Haomei 3003 Aluminum Sheet Popular Thicknesses

-

0.025" 3003 Aluminum Sheet

-

0.032" 3003 Aluminum Sheet

-

0.04" 3003 Aluminum Sheet

-

0.05" 3003 Aluminum Sheet

-

0.063" 3003 Aluminum Sheet

-

0.08" 3003 Aluminum Sheet

-

0.1" 3003 Aluminum Sheet

-

0.125" 3003 Aluminum Sheet

-

0.1875" 3003 Aluminum Sheet

-

0.25" 3003 Aluminum Sheet

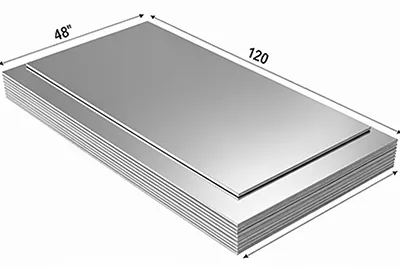

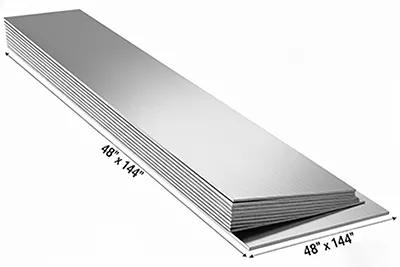

Haomei 3003 Aluminum Sheet Popular Sizes

-

12" x 12" (1 x 1 ft.) 3003 Aluminum Sheet

-

12" x 24" (1 x 2 ft.) 3003 Aluminum Sheet

-

12" x 36" (1 x 3 ft.) 3003 Aluminum Sheet

-

12" x 48" (1 x 4 ft.) 3003 Aluminum Sheet

-

24" x 24" (2 x 2 ft.) 3003 Aluminum Sheet

-

24" x 36" (2 x 3 ft.) 3003 Aluminum Sheet

-

24" x 48" (2 x 4 ft.) 3003 Aluminum Sheet

-

36" x 36" (3 x 3 ft.) 3003 Aluminum Sheet

-

36" x 48" (3 x 4 ft.) 3003 Aluminum Sheet

-

48" x 48" (4 x 4 ft.) 3003 Aluminum Sheet

-

48" x 120" (4 x 10 ft.) 3003 Aluminum Sheet

-

48" x 144" (4 x 12 ft.) 3003 Aluminum Sheet

3003 Aluminum Sheet: Available Surface Treatments

3003 Color-Coated Aluminum Sheet

- Description: Aluminum sheet coated with colored paint, enhancing aesthetics and corrosion resistance.

- Applications: Exterior cladding, decorative panels, signage, roofing.

3003 Embossed Stucco Sheet

- Description: Aluminum sheet with stucco-embossed surface for texture and anti-slip effect.

- Applications: Roofing, siding, ceilings, decorative panels.

3003 Aluminum Corrugated Sheet

- Description: Corrugated aluminum sheet offering high rigidity and lightweight structure.

- Applications: Roofing, wall panels, industrial sheds, temporary structures.

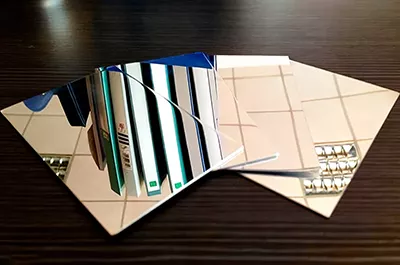

3003 Mirror Aluminum Sheet

- Description: Highly polished aluminum sheet with reflective mirror finish.

- Applications: Signage, decorative panels, mirrors, interior design accents.

3003 Anodized Aluminum Sheet

- Description: Aluminum sheet treated with anodizing for enhanced corrosion resistance and surface hardness.

- Applications: Architectural panels, kitchenware, electronics casing, signage.

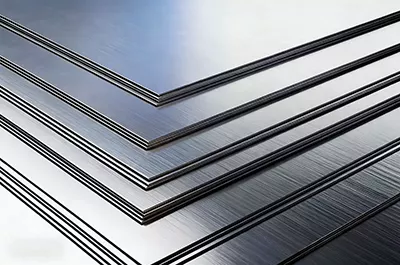

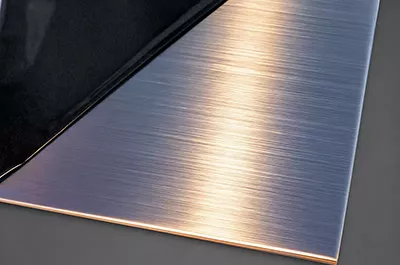

3003 Brushed Aluminum Sheet

- Description: Aluminum sheet with brushed texture finish, giving a matte metallic look.

- Applications: Appliances, elevator panels, furniture, decorative surfaces.

3003 Polished Aluminum Sheet

- Description: Aluminum sheet polished to a smooth, bright surface.

- Applications: Decorative elements, reflective surfaces, interior decoration.

3003 Film-Coated Aluminum Sheet

- Description: Aluminum sheet coated with protective film to prevent scratches and oxidation during transport and processing.

- Applications: Protective layers for construction panels, signage, or processed aluminum products.

3003 Aluminum Plate Sheet Color Options

Haomei 3003 Aluminum Typical Product Forms

- 3003 Aluminum Sheets & Plates: Thickness from 0.020" to 0.125"

- 3003 Aluminum Coils: For roll forming and cladding

- 3003 Aluminum Pre-painted Sheets: For enhanced aesthetics and corrosion protection

3003 Aluminum Sheet Features

| Characteristic Category | Description |

| Anti-Rust Performance | 3003 aluminum sheet has extremely outstanding anti-rust performance, especially suitable for humid or corrosive environments. Its aluminum-manganese alloy composition provides good oxidation resistance, enabling the material to maintain a rust-free surface for a long time even in air or liquids containing weak acids or alkaline media. It is therefore often used in kitchen equipment, roofing materials, and curtain wall decoration fields. |

| Corrosion Resistance | 3003 aluminum sheet exhibits excellent corrosion resistance, particularly prominent under outdoor exposure and marine climate conditions. It can withstand moisture, salt spray, and other corrosive media without the need for additional protective coatings, making it an ideal choice for manufacturing refrigeration equipment, transport containers, and coastal building materials. |

| Formability | Due to its relatively low strength, 3003 aluminum sheet has excellent formability and is suitable for forming processes such as drawing, bending, spinning, and deep drawing. It has very good ductility, and cold processing at low or room temperatures does not lead to cracking or brittleness. In addition, its good weldability and ductility make it easy to connect with other materials or fabricate into various complex structures. |

| Strength | The tensile strength of 3003 aluminum sheet generally ranges from 110 to 150 MPa, classifying it as a medium-strength aluminum alloy. While it is not suitable for high-load-bearing or critical structural applications, its strength is sufficient for uses such as roofing cladding, automotive interiors, billboards, and some medium-to-light structural supports, especially in scenarios requiring weight reduction. |

| Machinability | 3003 aluminum sheet has excellent machinability, allowing precise processing with various standard cutting tools without tool sticking or work hardening problems. Its machining characteristics are suitable for stamping, sawing, milling, and other conventional processes. Combined with its good weldability, it performs ideally in mechanical manufacturing, mold making, and sheet metal processing industries. |

| Weight | 3003 aluminum sheet shares the lightweight properties typical of most aluminum alloys, with a density of about 2.73 g/cm³. This makes it an ideal lightweight material, significantly reducing the overall weight of equipment or components without sacrificing structural integrity. It is widely used in transport vehicles, aviation equipment, and mobile structures. |

| Surface Treatment | The surface of 3003 aluminum sheet is naturally smooth and can be further treated to achieve better aesthetic effects. Its surface is easy to polish and adaptable to anodizing, electrophoresis coating, painting, and other surface treatments. These processes not only enhance its decorative appearance but also improve corrosion resistance, making it highly favored in applications with high visual requirements such as interior and exterior decorative panels, ceilings, and signage. |

| Processing Performance and Coating | 3003 aluminum sheet performs excellently in both hot and cold processing, adapting to various industrial processing conditions. It is compatible with multiple surface coatings, including organic coatings, protective films, and functional coatings, further enhancing the material's appearance, aesthetics, and functionality. This makes it an important material for packaging containers, decorative panels, and industrial components. |

| Weldability | 3003 aluminum sheet has good weldability and can be welded using common methods such as gas welding, resistance welding, and MIG or TIG welding. The welding process is stable, and the welds are of high quality. It is suitable for manufacturing piping systems, food processing equipment, and containers requiring airtightness and liquid-tightness. |

| Anodizing Properties | Although 3003 aluminum sheet may exhibit slight discoloration during the anodizing process, it still maintains good decorative effects overall. It adapts well to organic coatings and mechanical polishing treatments, making it widely used in applications requiring both corrosion protection and aesthetics, such as decorative panels and electronic device housings. Despite the availability of various welding methods, torch welding is still recommended for some fine welding applications. |

3003 Aluminum Plate Standards

- ASTM B209

- AMSQQA250/2

In-Stock Haomei 3003 Aluminum Plates and Sheets

3003 Aluminum Plate Chemical Composition

| Element | Composition % | |

| Al | Remainder | |

| Cu | 0.05-0.20 | |

| Si | 0.60 max | |

| Fe | 0.70 max | |

| Mn | 1.0-1.5 | |

| Zn | 0.10 max | |

| Others | 0.05 each | 0.15 total |

3003 Aluminum Plate Physical Properties

| Infomations | 3003-O | 3003-H14 | 3003-H22 |

| Shear Strength | 75MPa | 96MPa | 81MPa |

| Tensile Strength | 40-110MPa | 130-160MPa | 94-140MPa |

| Elastic Modulus | 70GPa | 70GPa | 70GPa |

| Hardness Brinell | 28HB | 42HB | 37HB |

| Elongation | 28% | 8% | 8% |

More Information on 3003 Aluminum Plates

- Hardness Brinell: 40

- Poissons Ratio: 0.33

- Modulus of Elasticity: 10, 000 ksi

- Shear Modulus: 3, 630 ksi

- Shear Strength: 14, 000 psi

- Melting Point: 1, 190-1, 210 F

- Density: 0.1 lb/in3

- Ultimate Tensile Strength: 22, 000 psi

- Yield Tensile Strength: 21, 000 psi

- Fatigue Strength: 9, 000 psi

3003 Aluminum Plate Applications

3003 aluminum plate is used for processing parts and components that require good formability, high corrosion resistance and good weldability, or work that requires both these properties and higher strength than 1XXX series alloys, such as kitchen utensils, food and chemical product processing and storage equipment, tanks and cans for transporting liquid products, various pressure vessels and pipes processed with thin plates, general utensils, heat sinks, cosmetic panels, photocopier rollers, and ship materials.

Transportation / Automotive Sector

Automotive Fuel Tanks

- Common tempers: 3003 O, H14

- Thickness range: 0.8–2.5 mm

Reasons:

- O temper offers the best deep-drawing performance

- H14 balances strength and formability

- Excellent corrosion resistance, suitable for fuel environments

New Energy Vehicle Battery Systems

(Battery enclosures / liquid cooling plates / partitions)

Common tempers: 3003 H14, H24

Thickness range:

- Battery enclosures: 0.8–2.0 mm

- Liquid cooling plates: 0.5–1.2 mm

Surface:

- Rolled finish / cleaned and degreased

- Cladded material or special surface treatment available for brazing

Reasons:

- Good formability combined with impact resistance

- Stable welding and brazing performance

Radiators / Heat Exchangers

- Common tempers: 3003 H14, O

- Thickness range: 0.2–1.0 mm

Reasons:

- High thermal conductivity

- Easy to bend, weld, and braze

Building & Architectural Decoration

Roofing Panels / Wall Panels / Curtain Walls

- Common tempers: 3003 H14, H24

- Thickness range: 0.6–3.0 mm

Surface:

- Mill Finish

- Coated (PE / PVDF)

Reasons:

- H24 provides higher strength than H14

- Resistant to wind pressure, weathering, and corrosion

- Suitable for large-size, wide sheets (≤ 2650 mm)

Gutters / Downspouts

- Common temper: 3003 H14

- Thickness range: 0.6–1.2 mm

- Surface: Coated / anodized

Reasons:

- Easy to bend and form

- Long-term resistance to rainwater corrosion

Ceilings / Interior Decorative Panels

- Common temper: 3003 H24

- Thickness range: 0.4–1.0 mm

- Surface: Spray coating, film lamination, embossing

Reasons:

- H24 offers better rigidity and resistance to deformation

- Strong decorative surface appearance

Household & Industrial Applications

Kitchenware / Cookware

- Common temper: 3003 O

- Thickness range: 1.0–4.0 mm

Reasons:

- Excellent deep drawing and spinning performance

- Food-grade safety with uniform thermal conductivity

Home Appliance Panels (Refrigerators / Washing Machines)

- Common tempers: 3003 H14, H24

- Thickness range: 0.6–1.2 mm

- Surface: Brushed / coated / film-laminated

Reasons:

- Good surface quality

- Balanced strength and decorative appearance

Industrial Piping / Chemical Equipment (Non-pressure-bearing)

- Common temper: 3003 H14

- Thickness range: 1.0–6.0 mm

Reasons:

- Good corrosion resistance

- Stable welding performance

Packaging / Containers / Tanks

Food Containers / Packaging Trays

Common tempers: 3003 O, H14 Thickness range: 0.2–0.8 mm

Reasons:

- Non-toxic and corrosion-resistant

- Easy to form and resistant to cracking

Storage Tanks / Pressure Vessels (Medium to Low Pressure)

Common tempers: 3003 H14, H24 Thickness range: 2.0–8.0 mm

Reasons:

- Higher strength than O temper

- Still maintains good weldability

Electronics / Signage

Electronic Heat Sinks

- Common temper: 3003 H14

- Thickness range: 0.5–2.0 mm

Reasons:

Good thermal conductivity and easy processing into complex structures

Signboards / Nameplates / Decorative Panels

- Common temper: 3003 H24

- Thickness range: 0.5–3.0 mm

- Surface: Anodized / screen printed / coated

Reasons:

- High flatness

- Stable surface treatment results

Typical Applications

| Type | Features | Application Fields |

| 3003 Checker Aluminum Plate | Surface with anti-slip patterns, excellent corrosion resistance, and strength. | Stairs, platforms, and workshop floors requiring anti-slip surfaces. |

| 3003 Hot-rolled Aluminum Plate | Produced through hot rolling, with good plasticity and strength. | Structural parts and welded components in aerospace, automotive, and construction fields. |

| 3003 Honeycomb Aluminum Plate | Lightweight, high strength, excellent thermal insulation, and compression resistance. | Aerospace, transportation, and architectural decoration. |

| 3003 Anti-rust Aluminum Plate | Excellent anti-rust performance due to manganese content. | Suitable for damp or corrosive environments like construction, transportation, and storage. |

| 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell | Good strength and corrosion resistance, ensuring battery safety and stability. | Lithium battery shells for new energy vehicles. |

| 3003 Aluminum Plate for Non-stick Pan | Excellent thermal conductivity and corrosion resistance, ensuring even heating and non-stick surfaces. | Manufacturing non-stick pans. |

| 3003 Aluminum Plate for New Energy Vehicle Battery Box | Superior protective performance and corrosion resistance, ensuring battery safety and reliability. | Battery boxes for new energy vehicles. |

| 3003+4343 Power Battery Cooling Plate | Composite of 3003 and 4343 aluminum alloys, excellent thermal conductivity and corrosion resistance. | Battery cooling systems, ensuring temperature control. |

| 3003 Aluminum Plate for Brazing Water Cooling Plate | Excellent weldability and corrosion resistance. | Water cooling plates for automotive and industrial cooling systems. |

| Aluminum Brazing Composite Material 3003+4045 Aluminum Plate | Composite of 3003 and 4045 aluminum alloys with excellent welding properties. | Heat exchangers and other welding applications. |

| 3003 Aluminum Plate for Mobile Phone Battery Shell | Lightweight and corrosion-resistant, extending battery lifespan. | Mobile phone battery shells. |

| 3003 Aluminum Plate for Automobile Fender | Good strength and corrosion resistance. | Manufacturing automobile fenders to protect structure and appearance. |

| 3003 Aluminum Plate for Transformer Shell Material | Good thermal conductivity and corrosion resistance. | Transformer shells, ensuring safe and stable operation. |

| 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip | Excellent anti-slip performance and corrosion resistance. | Anti-slip floors for cold storage. |

| 3003 Aluminum Plate for Building Decoration | Elegant appearance and excellent corrosion resistance. | Interior and exterior walls, ceilings, and other architectural decorations. |

| 3003 Aluminum Plate for Roof Decoration | Good weather resistance and aesthetics. | Roof decoration, enhancing overall building appearance. |

| 3003 Aluminum Plate for Thermal Insulation Material | Good thermal conductivity and corrosion resistance. | Thermal insulation systems in buildings and industries. |

| 3003 Aluminum Plate for Aluminum-plastic Plate H16 Aluminum Plate | Good strength and processability. | Manufacturing aluminum-plastic composite plates for construction and decoration materials. |

| 3003 Stair Anti-slip Checker Aluminum Plate | Surface with anti-slip patterns, ensuring safety. | Anti-slip surfaces for stairs in public and industrial spaces. |

| 3003 Ultra-wide Curtain Wall Aluminum Plate | Extra-wide design with excellent strength and corrosion resistance. | Curtain wall systems, providing aesthetics and protection for buildings. |

3003 Aluminum Sheet Processing and Treatment

- Formability: Excellent cold working properties (bending, stamping, spinning).

- Weldability: Suitable for gas welding, arc welding, and resistance welding.

- Machinability: Fair, but due to the softness in O temper, sharp tools are required.

3003 Aluminum Sheet Core Advantages

- Corrosion Resistance: Comparable to commercially pure aluminum, suitable for humid and chemical environments.

- Good balance of strength and weight.

- Relatively low cost compared to high-strength alloys.

Workability:

- Excellent formability, suitable for deep drawing and stamping processes.

- Good welding performance, but poor cutting performance.

- Not heat-treatable: Strength is enhanced through cold working (e.g., rolling, stretching).

3003 Aluminum Sheet Standards and Equivalent Standards

- Primary Standards: ASTM B209, ASME SB209, AMS 4008.

- Equivalent Alloys: EN AW-3003, UNS A93003, DIN 3.0517.

- Thickness Differences: Thin sheet thickness ≤ 6 mm, while thick sheet thickness exceeds 6 mm.

- Cost-effectiveness: Initial cost is relatively high, but due to durability, lifetime cost is low.

- Comparison: Higher strength than 1100 series, but lower than 5052 or 6061 alloys. Better formability than 5052, better corrosion resistance than 6061.

3003 Aluminum Sheet Limitations

- May experience exfoliation corrosion after cold deformation, with greater deformation increasing the risk.

- Prone to color variation after anodizing; thus, this surface treatment is generally not used.

- Limited strength compared to other aluminum alloys such as 7075 or 6061.

- May not be suitable for high-stress structural applications.

3003 aluminum sheet is ideal for applications where corrosion resistance, ease of processing, and moderate strength are more important than high mechanical strength.

3003 Aluminum Alloy vs. 5052 Aluminum Alloy

If you are considering these two commonly used aluminum alloys, the following is a brief comparison:

- If you need the lowest cost and the best formability (for example, for complex bending or deep-drawn parts such as cookware), choose 3003 aluminum alloy.

- If you require higher strength, better fatigue resistance, or superior performance in marine/saltwater environments, choose 5052 aluminum alloy.

Welding and Joining of 3003 Aluminum Sheet

Methods:

Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding are preferred. Proper welding techniques can minimize porosity.

Laser welding: Suitable for high-speed and precision applications (such as battery modules). Proper parameter settings are required, such as 1500 W power and -1 mm defocus.

Filler materials:

- 1100 aluminum is used for welding 3003 alloy to itself.

- 4043 (Al-Si) alloy is used for joining with other alloys (such as 5052 and 6061).

Notes: In strain-hardened tempers (such as H14), the strength of the heat-affected zone (HAZ) may decrease slightly.

Related Questions

What is Aluminium 3003 used for?

Aluminium 3003 is used for applications requiring good formability, corrosion resistance, and moderate strength, such as cooking utensils, storage tanks, and architectural panels.

What is 3003 H14 aluminum used for?

3003 H14 aluminum is used for applications that require both formability and moderate strength, including kitchen equipment, chemical equipment, and signage.

What is the difference between 3003 and 6061?

The difference between 3003 and 6061 aluminum is that 3003 offers better corrosion resistance and formability, while 6061 provides significantly higher strength and is more suitable for structural applications.

What is the difference between 5052 and 3003 aluminum sheet?

The difference between 5052 and 3003 aluminum sheet is that 5052 has higher strength and better corrosion resistance, making it suitable for marine environments and heavy-duty applications, whereas 3003 is more easily formable and is typically used in less demanding applications.

Haomei Aluminum Supplied Forms About 3003 Aluminum

- 3003 Aluminum Plate

- 3003 Aluminum Sheet

- 3003 Aluminum Tread Plate

- 3003 Aluminum Round Bar

- 3003 Aluminum Round Tube

Products you may be interested in

Further reading

Users viewing this material also viewed the following

- Aluminum Tread Plate 3003

- 3003 Embossed Aluminum Sheet

- 3003 Aluminum Diamond Plate

- 3003 Hot-rolled Aluminum Plate

- 3003 Honeycomb Aluminum

- 3003 Aluminum Plate for New Energy Automobile Lithium Battery Power Battery Shell

- 3003+4343 Power Battery Cooling Plate

- 3003 Aluminum Plate for Brazing Water Cooling Plate

- Aluminum Brazing Composite Material 3003+4045 Aluminum Plate

- 3003 Aluminum Disc for Non-stick Pan

- 3003 Aluminum Plate for Mobile Phone Battery Shell

- 3003 Corrugated Aluminum Sheet

- 3003 Aluminum Plate for Automobile Fender

- 3003 Checker Aluminum Plate for Stair Anti-slip

- 3003 Tread Aluminum Plate for Cold Storage Floor Anti-slip

- 3003 Ultra-wide Curtain Wall Aluminum Plate

- 3003 Aluminum Plate for Building Decoration

- 3003 Roof Aluminum Plate for Decoration

- 3003 Aluminum Sheet Coil for Thermal Insulation Material

- 3003 Pre-painted Aluminum Coil

Recommended Content

- What is 3003 aluminum used for?

- 3003 Aluminum Tubing

- 3003 Aluminum vs. 3005 Aluminum

- 3003-H18 Aluminum vs. 3005-H18 Aluminum

- What is the difference between 3003 H14 and 3105 H14?

- 3003 Aluminum vs. 3104 Aluminum

- 3003-H18 Aluminum vs. 3004-H18 Aluminum

- 3003-O Aluminum vs. 3004-O Aluminum

- What is the difference between 3003 and 3004 aluminum?

- 3003-H22 Aluminum vs. 3003-H24 Aluminum

- What is the difference between 3003 O and 3003 H14?

- What is the difference between 3003 H14 and H24?