1100 Aluminum Plate Sheet

What is Aluminum Plate Grade 1100?

1100 aluminum sheet is a commercial pure aluminum alloy, with an aluminum content of at least 99.0%. This high purity gives it excellent properties such as outstanding corrosion resistance, good electrical and thermal conductivity, and excellent machinability. However, compared to other aluminum alloys, its strength is relatively low.

1100 aluminum alloy is not capable of being strengthened by heat treatment, but it performs excellently in other aspects. 1100 aluminum sheet is one of the representative products of industrial pure aluminum.

1100 aluminum sheet is commonly used in chemical, food and beverage, decorative, and thermal applications. It is known for its outstanding corrosion resistance, high formability, electrical conductivity, and weldability. Its strength and hardness are relatively low. 1100 aluminum sheet is available in full-size and custom-length stock options.

Due to its excellent corrosion resistance, conductivity, thermal conductivity, and good formability, 1100 aluminum alloy is widely used in various industrial fields. However, due to its low strength, it is suitable for applications where strength requirements are not high.

- Corrosion Resistance: Excellent

- Formability/Workability: Excellent

- Heat Treating: Poor

- Machining: Good

- Weldability: Excellent

1100 aluminum sheet and strip belongs to the pure aluminum sheet series, and its strength is relatively low. After anodizing, the corrosion resistance can be further improved, and a beautiful surface can be obtained.

Common 1100 Aluminum Sheet Metal Tempers

- O

- H14

- H18

- H12

1100 aluminum sheet excels in applications where formability, corrosion resistance, and conductivity are prioritized over strength. It is available in three temper options: O (soft), H14 (strain-hardened), and H18 (full-hard), meeting diverse needs from food processing to aerospace industries. Note that it is not suitable for load-bearing components, and alternatives such as 3003 may be considered for balanced performance.

1100 O Aluminum Sheet

1100 O aluminum sheet is a commercially pure aluminum product in a fully annealed state, offering excellent ductility, corrosion resistance, and workability. It is especially suitable for applications requiring deep drawing, bending, or spinning, such as cookware, signage, and chemical storage equipment. Its soft condition ensures ease of fabrication and suitability for both cold forming and welding.

1100 H18 Aluminum Sheet

1100 H18 aluminum sheet is a strain-hardened, non-heat-treatable alloy in its hardest temper, providing maximum strength among 1100 series grades while retaining excellent corrosion resistance and good surface finish. It is ideal for applications like nameplates, reflectors, fin stock, and rigid packaging components, where mechanical strength and flatness are crucial but formability is less critical.

1100 H14 Aluminum Sheet

1100 H14 aluminum sheet is a half-hard temper product that strikes a balance between moderate strength and formability. It maintains high corrosion resistance and is commonly used in architectural panels, decorative trim, roofing, and electrical applications. Its good machinability and weldability make it a versatile material for general-purpose use in both industrial and consumer products.

1100 Aluminum Sheet Standards

- ASTM B209

- EN573

- EN485

- QQ-A-250/1

Haomei 1100 Aluminum Sheet Specifications

| Item | Specification Information |

| Thickness | 0.02" to 0.25" (0.5–6.35 mm) |

| Width | 2", 4", 6", 12", 24", 48" (50.8–1219 mm) |

| Length | 6" to 144" (152–3658 mm), with custom cuts available |

| Temper | - O (Annealed): Soft, suitable for forming - H14 / H18: Cold worked, higher strength |

| Certification Standards | ASTM B209, AMS 4001/4003, and EN standards |

| Minimum Order Quantity | Standard orders typically range from 3-5 tons |

| Packaging | Exported on wooden pallets/boxes; customized cutting available |

1100 Aluminum Plate Sheet Surface Treatments

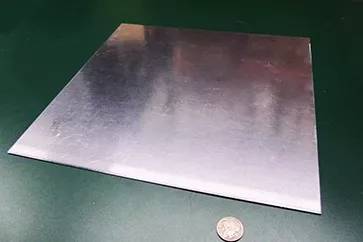

Pure 1100 Aluminum Sheet

A commercially pure aluminum sheet with excellent corrosion resistance, high ductility, and workability. Ideal for applications requiring high formability and lightweight properties.

Mirror Finish 1100 Aluminum Sheet

A polished 1100 aluminum sheet with a reflective, mirror-like surface. Perfect for decorative purposes, signage, and interior design applications.

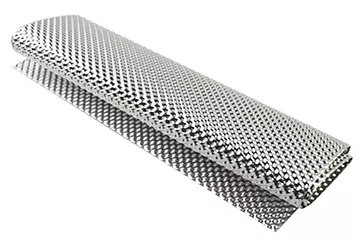

Embossed 1100 Aluminum Sheet

Features a raised pattern on the surface to improve grip, enhance aesthetics, and prevent slipping. Commonly used in decorative panels, flooring, and industrial applications.

Brushed Finish 1100 Aluminum Sheet

Mechanically brushed to create a fine linear texture. Offers a modern appearance and is resistant to visible scratches, widely used in appliances and architectural interiors.

Polished 1100 Aluminum Sheet

Surface polished to a smooth, glossy finish. Provides a shiny, high-end look suitable for decorative and reflective applications.

Color Coated 1100 Aluminum Plate

Aluminum plate coated with colored paint for enhanced aesthetics and corrosion protection. Available in a variety of colors for architectural, signage, and decorative use.

Film Laminated 1100 Aluminum Sheet

Protected with a transparent or colored film to prevent scratches, fingerprints, and surface damage during transport and installation.

Anodized 1100 Aluminum Sheet

Surface treated with an anodic oxide layer to improve corrosion resistance, surface hardness, and decorative appearance. Suitable for outdoor and architectural applications.

Perforated 1100 Aluminum Sheet

Aluminum sheet with punched holes for ventilation, decoration, or filtration purposes. Can be customized with different hole patterns and sizes.

1100 Aluminum Plate Sheet Color Options

1100 Aluminum Sheet: Advantages and Limitations

1100 Aluminum Sheet Advantages

- Excellent thermal conductivity

- Excellent corrosion resistance

- Excellent machinability

- High weldability

- High thermal conductivity

1100 Aluminum Sheet Disadvantages

Due to its low tensile strength and softness, 1100 aluminum sheet is not used for high strength or high pressure applications.

- Low Strength: Not suitable for structural or high-pressure applications.

- No Heat Treatment: Cannot be strengthened by heat treatment.

- Machinability: Poor machinability in the soft state, but improved machinability in the hard state (e.g., H14).

- Conductivity: Slightly inferior to 1060 aluminum sheet in terms of conductivity.

1100 aluminum sheet/sheet metal is highly regarded for its purity, formability, and corrosion resistance, making it a primary material in industries that require lightweight non-structural components. Although its low strength limits its use in high-stress applications, its versatility in forming and conductivity makes it widely used in cookware, chemical systems, and electrical projects.

Equivalents of AA 1100

UNS A91100, Aluminium 1100, AA1100, Al1100

1100 Aluminum Plate Features

| Feature Category | Description |

| Machinability | 1100 aluminum sheet has a soft texture and good ductility, offering excellent machinability in all temper conditions. As a representative of the pure aluminum series, it has very high ductility and softness, allowing excellent forming results in O temper or other hardened states. Whether used for deep drawing, stamping, or roll bending, 1100 aluminum sheet maintains the integrity of the material without breaking. |

| Weldability | 1100 aluminum sheet has good weldability. Due to its low alloy composition, it exhibits good welding compatibility and can be welded to itself or other aluminum alloys with high-quality results. It can achieve smooth and dense weld seams using TIG or MIG welding techniques, widely used in light structures, container manufacturing, and general engineering applications. |

| Machining Performance | 1100 aluminum sheet has excellent machining performance, suitable for high-end forming applications. Due to its low strength and high plasticity, it is easy to perform turning, drilling, milling, and other machining operations, and it is also suitable for complex mold forming. Especially when manufacturing thin-walled structures, curved components, or decorative parts with high precision requirements, 1100 aluminum sheet provides excellent machining responses. |

| Corrosion Resistance | 1100 aluminum sheet has excellent corrosion resistance, performing stably in chemical and marine environments. Thanks to its high-purity aluminum-based structure, it naturally forms a dense aluminum oxide protective layer that effectively resists corrosion, especially suitable for applications in pipe cladding, heat exchanger shells, marine equipment exteriors, and other environments with high corrosion resistance requirements. |

| Formability | 1100 aluminum sheet excels in formability, suitable for bending, stamping, and deep drawing processes. In O temper, it has excellent ductility, allowing large deformations without cracking, widely used in cookware, lampshades, metal containers, and other deep drawing applications that require complex shapes and precise details. |

| Weldability | 1100 aluminum sheet has good weldability and is compatible with various welding methods. In addition to common TIG and MIG welding techniques, it is also suitable for brazing processes, making it particularly useful for precision component connections. Weld joints are stable, the surface is smooth, and post-treatment is easy. It has widespread applications in machinery, electronics, and civil structures. |

| Reflectivity | 1100 aluminum sheet has high reflectivity, making it suitable for lighting and decorative applications. The natural aluminum surface can reflect more than 85% of visible light, and after polishing, the reflectivity can reach over 95%, making it an ideal material for reflective light fixtures, mirror decorative panels, billboards, and interior components, combining aesthetics and functionality. |

| Food Grade Safety | 1100 aluminum sheet is a food-grade safe material, suitable for cookware and food packaging. Due to its non-toxic, odorless, and free of heavy metal residues, it has natural advantages in food contact applications, widely used in cookware bottoms, food sealing films, aluminum foil containers, etc., offering safety, environmental friendliness, excellent thermal conductivity, and sealing properties. |

Performance of 1100 Aluminum Plate Sheet

| Properties | Description |

| Corrosion Resistance | 1100 aluminum alloy has excellent corrosion resistance, performing well in humid or corrosive environments, effectively resisting oxidation and corrosion. |

| Electrical and Thermal Conductivity | Due to its high purity, 1100 aluminum alloy has excellent electrical and thermal conductivity, making it suitable for electrical and heat exchange applications. |

| Density | This alloy has a lower density, which helps reduce the weight of structures, suitable for applications that require lightweight materials. |

| Ductility and Formability | Exhibits good ductility and formability, allowing it to be processed into various aluminum products through stamping, stretching, and extrusion methods. |

| Strength | Relatively low in strength, but still meets the requirements for lightweight and non-structural applications. |

| Processability | Similar to 1050A aluminum alloy, it has good processability and can be shaped and sized through cold and hot processing. |

1100 Aluminum Sheet Stock and Availability

| Description | Width(In) | Length(In) | Size |

| 0.02" Aluminum Sheet 1100-H14 2" x 24" | 2" | 24" | 2" x 24" |

| 0.032" Aluminum Sheet 1100-H14 2" x 24" | 2" | 24" | 2" x 24" |

| 0.04" Aluminum Sheet 1100-H14 2" x 24" | 2" | 24" | 2" x 24" |

| 0.05" Aluminum Sheet 1100-H18 2" x 24" | 2" | 24" | 2" x 24" |

| 0.063" Aluminum Sheet 1100-H18 2" x 24" | 2" | 24" | 2" x 24" |

| 0.08" Aluminum Sheet 1100-H18 2" x 24" | 2" | 24" | 2" x 24" |

| 0.09" Aluminum Sheet 1100-O 2" x 24" | 2" | 24" | 2" x 24" |

| 0.125" Aluminum Sheet 1100-O 2" x 24" | 2" | 24" | 2" x 24" |

| 0.02" Aluminum Sheet 1100-O 4" x 24" | 4" | 24" | 4" x 24" |

| 0.032" Aluminum Sheet 1100-H14 4" x 24" | 4" | 24" | 4" x 24" |

| 0.04" Aluminum Sheet 1100-H14 4" x 24" | 4" | 24" | 4" x 24" |

| 0.05" Aluminum Sheet 1100-H14 4" x 24" | 4" | 24" | 4" x 24" |

| 0.063" Aluminum Sheet 1100-H18 4" x 24" | 4" | 24" | 4" x 24" |

| 0.08" Aluminum Sheet 1100-H18 4" x 24" | 4" | 24" | 4" x 24" |

| 0.09" Aluminum Sheet 1100-H18 4" x 24" | 4" | 24" | 4" x 24" |

| 0.125" Aluminum Sheet 1100-O 4" x 24" | 4" | 24" | 4" x 24" |

| 0.02" Aluminum Sheet 1100-O 6" x 6" | 6" | 6" | 6" x 6" |

| 0.032" Aluminum Sheet 1100-O 6" x 6" | 6" | 6" | 6" x 6" |

| 0.04" Aluminum Sheet 1100-H14 6" x 6" | 6" | 6" | 6" x 6" |

| 0.05" Aluminum Sheet 1100-H14 6" x 6" | 6" | 6" | 6" x 6" |

| 0.063" Aluminum Sheet 1100-H14 6" x 6" | 6" | 6" | 6" x 6" |

| 0.08" Aluminum Sheet 1100-H18 6" x 6" | 6" | 6" | 6" x 6" |

| 0.09" Aluminum Sheet 1100-H18 6" x 6" | 6" | 6" | 6" x 6" |

| 0.125" Aluminum Sheet 1100-H18 6" x 6" | 6" | 6" | 6" x 6" |

| 0.02" Aluminum Sheet 1100-O 6" x 12" | 6" | 12" | 6" x 12" |

| 0.032" Aluminum Sheet 1100-O 6" x 12" | 6" | 12" | 6" x 12" |

| 0.04" Aluminum Sheet 1100-O 6" x 12" | 6" | 12" | 6" x 12" |

| 0.05" Aluminum Sheet 1100-H14 6" x 12" | 6" | 12" | 6" x 12" |

| 0.063" Aluminum Sheet 1100-H14 6" x 12" | 6" | 12" | 6" x 12" |

| 0.08" Aluminum Sheet 1100-H14 6" x 12" | 6" | 12" | 6" x 12" |

| 0.09" Aluminum Sheet 1100-H18 6" x 12" | 6" | 12" | 6" x 12" |

| 0.125" Aluminum Sheet 1100-H18 6" x 12" | 6" | 12" | 6" x 12" |

| 0.02" Aluminum Sheet 1100-H18 6" x 24" | 6" | 24" | 6" x 24" |

| 0.032" Aluminum Sheet 1100-O 6" x 24" | 6" | 24" | 6" x 24" |

| 0.04" Aluminum Sheet 1100-O 6" x 24" | 6" | 24" | 6" x 24" |

| 0.05" Aluminum Sheet 1100-O 6" x 24" | 6" | 24" | 6" x 24" |

| 0.063" Aluminum Sheet 1100-H14 6" x 24" | 6" | 24" | 6" x 24" |

| 0.08" Aluminum Sheet 1100-H14 6" x 24" | 6" | 24" | 6" x 24" |

| 0.09" Aluminum Sheet 1100-H14 6" x 24" | 6" | 24" | 6" x 24" |

| 0.125" Aluminum Sheet 1100-H18 6" x 24" | 6" | 24" | 6" x 24" |

| 0.02" Aluminum Sheet 1100-H18 12" x 12" | 12" | 12" | 12" x 12" |

| 0.032" Aluminum Sheet 1100-H18 12" x 12" | 12" | 12" | 12" x 12" |

| 0.04" Aluminum Sheet 1100-O 12" x 12" | 12" | 12" | 12" x 12" |

| 0.05" Aluminum Sheet 1100-O 12" x 12" | 12" | 12" | 12" x 12" |

| 0.063" Aluminum Sheet 1100-O 12" x 12" | 12" | 12" | 12" x 12" |

| 0.08" Aluminum Sheet 1100-H14 12" x 12" | 12" | 12" | 12" x 12" |

| 0.09" Aluminum Sheet 1100-H14 12" x 12" | 12" | 12" | 12" x 12" |

| 0.125" Aluminum Sheet 1100-H14 12" x 12" | 12" | 12" | 12" x 12" |

| 0.02" Aluminum Sheet 1100-H18 12" x 24" | 12" | 24" | 12" x 24" |

| 0.032" Aluminum Sheet 1100-H18 12" x 24" | 12" | 24" | 12" x 24" |

| 0.04" Aluminum Sheet 1100-H18 12" x 24" | 12" | 24" | 12" x 24" |

| 0.05" Aluminum Sheet 1100-O 12" x 24" | 12" | 24" | 12" x 24" |

| 0.063" Aluminum Sheet 1100-O 12" x 24" | 12" | 24" | 12" x 24" |

| 0.08" Aluminum Sheet 1100-O 12" x 24" | 12" | 24" | 12" x 24" |

| 0.09" Aluminum Sheet 1100-H14 12" x 24" | 12" | 24" | 12" x 24" |

| 0.125" Aluminum Sheet 1100-H14 12" x 24" | 12" | 24" | 12" x 24" |

| 0.02" Aluminum Sheet 1100-H14 24" x 24" | 24" | 24" | 24" x 24" |

| 0.032" Aluminum Sheet 1100-H18 24" x 24" | 24" | 24" | 24" x 24" |

| 0.04" Aluminum Sheet 1100-H18 24" x 24" | 24" | 24" | 24" x 24" |

| 0.05" Aluminum Sheet 1100-H18 24" x 24" | 24" | 24" | 24" x 24" |

| 0.063" Aluminum Sheet 1100-O 24" x 24" | 24" | 24" | 24" x 24" |

| 0.08" Aluminum Sheet 1100-O 24" x 24" | 24" | 24" | 24" x 24" |

| 0.09" Aluminum Sheet 1100-O 24" x 24" | 24" | 24" | 24" x 24" |

| 0.125" Aluminum Sheet 1100-H14 24" x 24" | 24" | 24" | 24" x 24" |

| 0.02" Aluminum Sheet 1100-H14 24" x 48" | 24" | 48" | 24" x 48" |

| 0.032" Aluminum Sheet 1100-H14 24" x 48" | 24" | 48" | 24" x 48" |

| 0.04" Aluminum Sheet 1100-H18 24" x 48" | 24" | 48" | 24" x 48" |

| 0.05" Aluminum Sheet 1100-H18 24" x 48" | 24" | 48" | 24" x 48" |

| 0.063" Aluminum Sheet 1100-H18 24" x 48" | 24" | 48" | 24" x 48" |

| 0.08" Aluminum Sheet 1100-O 24" x 48" | 24" | 48" | 24" x 48" |

| 0.09" Aluminum Sheet 1100-O 24" x 48" | 24" | 48" | 24" x 48" |

| 0.125" Aluminum Sheet 1100-O 24" x 48" | 24" | 48" | 24" x 48" |

Chemical Composition of 1100 Aluminum Sheet

| Si | Fe | Cu | Mn | Zn | Others | Al |

| 0.95% max | 0.40% max | 0.05% max | 0.05% max | 0.10% max | 0.05% max | 99.00% min |

1100 Aluminum Sheet Typical Mechanical Properties

| Alloy-Temper | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

| 1100-O | 13 | 5 | 30 |

| 1100-H14 | 18 | 17 | 3 |

| 1100-H18 | 24 | 22 | 2 |

Physical Properties of 1100 Aluminum Sheet

| Performance | AMS 4001 | AMS 4003 |

| Density | 2.70 g/cm3 | 2.70 g/cm3 |

| Melting point | 643-657 °C | 643-657 °C |

| Coefficient of thermal expansion(20-100°C) | 23.1 μm/m°C | 23.1 μm/m°C |

| Thermal conductivity(20°C) | 222 W/m-K | 222 W/m-K |

| Conductivity(20°C) | 62.5% IACS | 62.5% IACS |

| Yield strength(0.2%) | 55 MPa min | 110 MPa min |

| Tensile strength | 75 MPa min | 145 MPa min |

| Elongation | 20% min | 4% min |

More Information About 1100 Aluminum Sheet

- Density: 0.1 lb/in3

- Fatigue Strength: 7, 000 psi

- Hardness Brinell: 32

- Melting Point: 1, 190-1, 215 F

- Modulus of Elasticity: 10, 000 ksi

- Poissons Ratio: 0.33

- Shear Modulus: 3, 7700 ksi

- Shear Strength: 11, 000 psi

- Ultimate Tensile Strength: 18, 000 psi

- Yield Tensile Strength: 13, 800 psi

1100 Aluminum Sheet Applications

1100 aluminum sheet is most common in the chemical, food and beverage industries.

1100 aluminum sheet is generally used in utensils, heat sinks, bottle caps, printing plates, building materials, heat exchanger components, and can also be used as deep stamping products. It is widely used in various fields from cookware to industrial equipment.

| Industry Classification | Application Fields | Specific Application Examples | Core Performance Advantages |

| Industrial Applications | Chemical Equipment | Storage tanks, pipelines, processing units, corrosion-resistant containers, reactor components | Corrosion resistance, formability |

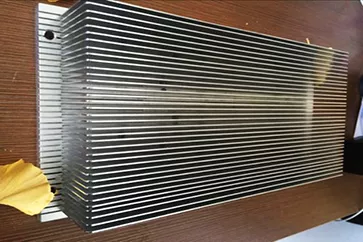

| Heat Exchange Systems | Heat exchanger components (chemical/HVAC), radiators, fins (HVAC systems) | Thermal conductivity, corrosion resistance | |

| Industrial Machinery | Hardware components, food industry machinery (corrosion-resistant processing units) | Formability, lightweight | |

| Construction and Decoration | Functional Decoration | Curtain wall aluminum panels, roofing materials, decorative trims, nameplates, plaques | Formability, corrosion resistance, lightweight |

| Structural Auxiliary | Building radiators, reflectors | Thermal conductivity, corrosion resistance | |

| Consumer Products | Food-Related | Food packaging containers, bottle caps, cookware (pots, frying pans, utensils) | Corrosion resistance, thermal conductivity, non-toxic safety |

| Daily Use Products | Decorative items, nameplates | Formability, aesthetics | |

| Electrical and Electronics | Conductive Components | Busbars, electrical components | Conductivity, lightweight |

| Transportation and Aerospace | Non-Structural Components | Aerospace interior panels (H14 temper) | Lightweight, formability |

Typical Applications

- Food and Beverages

- Chemical Processing

- Electrical Conductors

- Insulation Boards

- Aerospace Parts

- Signages

- Decorations

Haomei 1050 Aluminum Plate Sheet Popular Products

1100 Aluminum Sheet for PCB

The 1100 aluminum sheet for PCBs offers excellent thermal conductivity and electrical insulation, making it an ideal material for printed circuit boards (PCBs) in electronic applications.

Heat Sink 1100 Aluminum Plate

The 1100 aluminum plate designed for use as a heat sink is highly valued for its superior thermal conductivity, efficiently dissipating heat and ensuring the longevity of electronic components.

Bottle Cap 1100 Aluminum Plate

The 1100 aluminum plate used for bottle caps is prized for its corrosion resistance and formability, making it an excellent choice for producing high-quality, durable caps.

1100 Aluminum Plate for Printing Plate

The 1100 aluminum plate, utilized in printing applications, provides a smooth surface with excellent machinability, ensuring high-quality prints and ease of processing.

1100 Aluminum Plate for Building Exterior Walls

The 1100 aluminum plate used for exterior wall cladding in buildings offers both aesthetic appeal and durability, providing a strong, weather-resistant material for building facades.

5mm 1100 Aluminum Sheet

A 5mm thick sheet of aluminum alloy 1100, known for its excellent corrosion resistance, high thermal and electrical conductivity, and formability. Ideal for applications requiring moderate strength and good machinability.

1100 Aluminum Tread Plate

A 1100 aluminum plate with a raised tread pattern, providing enhanced slip resistance and durability. Often used in flooring, stair treads, and other applications where traction and durability are important.

1100 H24 Aluminum Plate for Bus Door

The 1100 aluminum plate in H24 temper, used for bus doors, is highly resistant to wear and corrosion, providing a robust and long-lasting solution for high-traffic applications.

Aluminum Veneer 1100 Aluminum Plate

The 1100 aluminum plate used in aluminum veneer applications delivers both durability and a decorative finish, making it an ideal material for building facades and exterior finishes.

1100 Aluminum Plate for Capacitor Shell

The 1100 aluminum plate, used in capacitor shells, is lightweight, corrosion-resistant, and offers an excellent balance of strength and durability for electronic components.

1060 Aluminum Plate for Kitchenware

The 1060 aluminum plate used for kitchenware is well-known for its excellent corrosion resistance and formability, making it a popular choice for cooking utensils and kitchen accessories.

1100 Aluminum Plate for Pressure Tank

The 1100 aluminum plate used in pressure tank manufacturing is valued for its strength and resistance to corrosion, making it an ideal material for tanks that need to withstand high pressure and environmental challenges.

1100-H16 Aluminum Sheet Roll for Refrigerator Lining

The 1100-H16 aluminum sheet roll, used for refrigerator linings, offers excellent durability and resistance to temperature fluctuations, making it ideal for maintaining consistent internal temperatures in refrigeration systems.

1100 Aluminum Plate for Aluminum Composite Panel

The 1100 aluminum plate, used in aluminum composite panels, offers a smooth surface and durability, making it an excellent choice for applications requiring both strength and a polished appearance.

1100 Automotive Aluminum Embossed Heat Shield Sheet

The embossed 1100 aluminum sheet used as a heat shield in automotive applications provides exceptional thermal resistance and durability, protecting sensitive components from heat exposure.

1100 Aluminum Sheet Processing Characteristics

Formability

- Excellent ductility, suitable for cold processing (stamping, drawing, spinning, etc.)

- Good welding performance, supports gas welding, TIG welding, MIG welding, and other processes.

Surface Treatment

- Anodizing can enhance corrosion resistance and improve aesthetics.

- Suitable for painting, chemical plating, and other processes.

1100 Aluminum Sheet vs. Other Aluminum Grades

| Properties | 1100 Aluminum Sheet | 1060 Aluminum Sheet | 3003 Aluminum Sheet |

| Aluminum Content | 99.00% | 99.60% | Contains manganese alloy |

| Strength | Medium (lower than 3003) | Low | Higher (contains manganese for strengthening) |

| Suitable Application | High formability, low strength requirements | High purity for conductivity/heat dissipation | Needs rust resistance and higher strength |

The 1100 aluminum sheet, with its high formability, corrosion resistance, and cost advantages, is a commonly used material in industrial and construction fields. However, its low strength limits its range of applications.

1100 Aluminum Sheet is highly regarded for its high purity, excellent corrosion resistance, and good formability, making it suitable for a variety of applications that require these properties.

1100 Aluminum Sheet Limitations and Considerations

- Low Strength: Not suitable for high-load structural components; should be avoided in mechanically abrasive environments.

- Non-Hardenable: Cannot be strengthened through heat treatment.

1100 Aluminum Plate Sheet FAQs

What is 1100 aluminium used for?

1100 Aluminum is commonly used for applications that require good corrosion resistance and formability but do not need high strength. Typical uses include kitchen utensils, chemical containers, and decorative uses.

What is the difference between 1100 and 1145 aluminum?

- 1100 Aluminum: This is a commercially pure aluminum alloy with high ductility and excellent corrosion resistance.

- 1145 Aluminum: This alloy has similar properties to 1100 but includes additional elements that improve its corrosion resistance and strength. It’s often used in applications where improved resistance to chemical environments is needed.

1100 is used for its excellent workability and corrosion resistance, and 1145 offers enhanced corrosion resistance compared to 1100.

What is the difference between 6061 and 1100 aluminum?

1100 aluminum is used in applications that require high corrosion resistance and formability, such as chemical equipment and kitchen appliances, while 6061 aluminum is known for its strength, weldability, and versatility in structural and aerospace applications.

What is the Aluminium alloy 1100 equivalent to?

Aluminum alloy 1100 is equivalent to ISO Al99.0Cu and UNS A91100.

1100 Aluminum Plate Sheet Related Searches

1100 aluminum bar

1100 aluminum bar is an industrial pure aluminum alloy with excellent corrosion resistance and high electrical conductivity.

1100-0 aluminum sheet

1100-0 aluminum sheet is a fully annealed aluminum sheet with high formability.

1100-h14 aluminum sheet properties

1100-H14 aluminum sheet is a strain hardened aluminum sheet with a good balance of strength and ductility.

Products you may be interested in

- 1100 0 aluminum sheet

- 1100 h14 aluminum sheet

- 1100 h18 aluminum sheet

- 1100 h12 aluminum sheet plate

- 1100 H16 Aluminum

- 1100 H22 Aluminum

- 1100 H24 Aluminum

- 1100 H26 Aluminum

- 1100 H28 Aluminum

Further reading

Users viewing this material also viewed the following

- 1100 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1100 Aluminum Sheet for PCB (Printed Circuit Board)

- 1100 Aluminum Plate for Heat Sink Applications

- 1100 Aluminum Plate for Printing Plates

- 1100 Aluminum Plate for Building Exterior Cladding

- 1100 Aluminum Veneer Panel

- 1100 Aluminum Plate for Stair Handrails

- 1100 Aluminum Plate for Pressure Tanks

- 1100 O/H14 Aerospace Aluminum Sheet and Plate

- 1100 Aluminum Plate for New Energy Charging Stations

- 1100 Embossed Aluminum Sheet for Automotive Heat Shield

- 1100 Aluminum Plate for Aluminum Composite Panels

- 1100 Corrugated Aluminum Sheet

- 1100 H16 Aluminum Sheet Roll for Refrigerator Linings

Recommended Content

- 1100 vs. 1050 Aluminium Which Alloy is Right for Your Project?

- 1100-H14 Aluminum vs. 1100-H24 Aluminum

- 1100-H14 Aluminum vs. 1100-H16 Aluminum

- 1100-H14 Aluminum vs. 1100-H18 Aluminum

- 1100-H12 Aluminum vs. 1100-H14 Aluminum

- 1100-H14 Aluminum vs. 1100-O Aluminum

- 1060-O Aluminum vs. 1100-H14 Aluminum: A Comparative Analysis

- 1060 Aluminum vs. 1100-H14 Aluminum: Key Differences

- Comparison of 1060-H28 Aluminum vs. 1100-H28 Aluminum