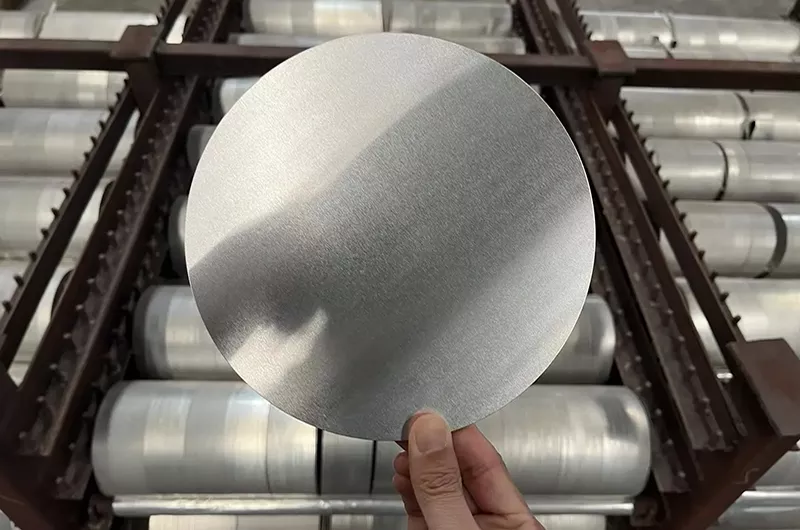

1100 Aluminum Disc Circle

1100 Aluminum Disc Circle is made from 1000 series industrial pure aluminum (Aluminum content ≥99.0%), known for its excellent workability, corrosion resistance, and thermal and electrical conductivity, making it a fundamental material choice in many industries.

The 1100 aluminum disc circle has relatively low strength and cannot be strengthened by heat treatment. This material is commonly used for stamping, spinning, and other deep processing. Typical applications include cookware, lighting fixtures, chemical containers, nameplates, and architectural decorative components.

1100 Aluminum Disc Circle Specifications

| Parameter | Range | Common Values |

| Thickness | 0.30~30.00mm | 0.5~5.0mm (for cookware) |

| Diameter | 100~1200mm | 200~800mm (general sizes) |

| Temper | O (soft), H12, H14 (half-hard), H18 | O, H14 |

| Tolerance | Thickness ±0.02~0.10mm, Diameter ±0.5~2.0mm | Precision grade customizable |

| Surface Condition | Mill finish, brushed, or PE coated, bright, matte, anodized | Customizable as required |

| Process | CC / DC | DC preferred for deep drawing |

| Tolerance (Precision) | Thickness: ±0.02mm; Diameter: ±1mm | Higher precision can be requested |

1100 Aluminum Disc Circle Common Heat Treatment States

| State | Code | Characteristics | Applicable Scenarios |

| Annealed | O | Softest, highest elongation (~40%) | Deep drawing, spinning, complex forming |

| Half-hard | H12/H22 | Medium strength, good ductility | General forming, bending |

| Full-hard | H14/H24 | Higher strength, moderate ductility | Structural parts, stamped components |

| Extra-hard | H18 | Highest strength, lowest ductility | High-strength simple formed parts |

1100 Aluminum Disc Circle Surface Finishes

| Product | Surface Treatment / Processing Method | Product Features | Typical Applications |

| 1100 Mill Finish Aluminum Disc Circle | Mill Finish | Smooth surface, retains natural metal color and luster. Usually oiled or paper-protected during transport to prevent scratches and oxidation. | Standard raw discs; can be further anodized or coated. |

| 1100 Aluminum Disc Circle with PE / PVC Protective Film | PE / PVC Film | Protective film applied to prevent scratches during stamping, spinning, or transport. | Pre-protection for cookware, lighting, and electronics; suitable for deep drawing. |

| 1100 Anodized Aluminum Disc Circle | Anodizing | Uniform and transparent oxide layer on high-purity aluminum, bright and corrosion-resistant, can be colored. | High-end lighting, decorative panels, electronic housings. |

| 1100 Non-stick Coated Aluminum Disc Circle | Teflon / Non-stick Coating | High-temperature resistant, non-stick, suitable for food contact. | Cookware (pots, baking trays, etc.) |

| 1100 Polished Aluminum Disc Circle | Polishing | Mechanical polishing achieves mirror finish, uniform light reflection. | Reflectors, decorative parts, high-end cookware. |

| 1100 Brushed Aluminum Disc Circle | Brushing | Fine surface texture, enhances feel and aesthetics, reduces fingerprint marks. | Decorative components, lighting, furniture panels. |

1100 Aluminum Circle Features

- Formability: Highly suitable for deep drawing, spinning, stamping, and processing of complex shapes.

- Corrosion Resistance: Excellent, especially in marine and corrosive environments.

- Conductivity: Good thermal and electrical conductivity.

- Weldability: Easy to weld and process.

- Strength: Lower strength compared to other aluminum alloys, but the highest strength among 1000 series aluminum alloys.

- Exceptional Machinability: Excellent deep drawing, spinning, and bending performance; no "four-corner" defects, suitable for complex shape processing.

- Good Surface Finishing: Easy to polish, anodize, and paint, achieving aesthetically pleasing surface effects.

- Non-toxic and Environmentally Friendly: Complies with food contact standards, recyclable, green and sustainable.

- Cost Advantage: Industrial pure aluminum has relatively stable prices, offering high cost-performance ratio.

Limitations: Low strength, not suitable for high-load structural parts; cannot be strengthened by heat treatment, strength can only be improved by cold working.

1100 Aluminum Circle Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.A1 |

| 1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 0.05 | 99 | |||||||

1100 Aluminum Circle Mechanical Properties

| Alloy Temper | Thinckness mm | Tensile Strength Mpa | Elongation % |

| 1100 O(SOFT) | 0.5-10 | 60-100 | ≥20 |

| 1100 H12 | 0.5-10 | 70-120 | ≥4 |

| 1100 H24 | 0.5-10 | 85-120 | ≥2 |

1100 DC/CC Aluminum Circle

| Performance Indicators | 1100 DC (Hot Rolled) | 1100 CC (Cold Rolled) |

| Recommended Processing | Deep Drawing | Spinning / Shallow Stamping |

| Elongation | Excellent | Average |

| Earing | Very low (smooth edges) | Higher (uneven edges) |

| Grain Structure | Fine, equiaxed | Coarse, elongated |

| Oxidation Effect | Uniform, high gloss | May have color variation or shading |

| Cost / Price | Higher | Lower |

1100 DC Aluminum Circle

DC material is usually called "hot rolled". Its production process involves melting aluminum ingots, casting into thick slabs (billets), homogenization annealing, surface milling, heating, and then hot rolling.

Core Features:

- Internal Structure: Fine, uniform, equiaxed grains.

- Elongation: Extremely high, excellent ductility.

- Isotropy: Metal exhibits uniform deformation resistance in all directions; during stretching, “earing” is unlikely (edges are smooth, not jagged).

- Surface Quality: Highly uniform color after anodizing, no streaks.

Best Use: Deep Drawing – suitable for high-depth pressure cooker pots, rice cooker inner pots, and high-end deep containers.

High Surface Finish Requirement: Cookware requiring high-quality anodizing or mirror polishing.

Drawbacks: Higher price and relatively longer production lead time.

1100 CC Aluminum Circle

CC material is called "cold rolled". Its process involves casting molten aluminum directly through a continuous casting machine into ~8mm strips, without hot rolling, and then cold rolling directly to final thickness.

Core Features:

- Internal Structure: Coarser grains, elongated along the rolling direction, showing clear anisotropy.

- Elongation: Relatively lower.

- Processing Performance: Prone to cracking during deep drawing, or visible "orange peel" texture (rough surface).

- Cost Advantage: Shorter production process, lower energy consumption, typically 15%-25% cheaper than DC material.

Best Use:

Spinning: Suitable for making lampshades, ordinary aluminum basins, frying pans, etc.

Shallow Stamping: Such as signage, manhole covers, decorative panels, or products that do not require severe deformation.

Drawbacks: Not suitable for deep drawing; may exhibit color variation or texture after anodizing.

1100 Aluminum Circle Applications

- Cookware: Non-toxic and compliant with food safety standards, commonly used for pots, frying pans, kettles, and non-stick pan bottoms.

- Lighting: Lampshades, reflectors, and high-reflectivity lighting fixtures.

- Signage & Architecture: Traffic signs, decorative panels, and building components.

- Machinery: Components for various mechanical and electrical equipment.

- Chemical & Pharmaceutical: Food storage, packaging, chemical tanks, heat exchanger fins, hollow containers, and processing equipment.

Cookware Industry:

- Pots, frying pans, pressure cookers, kettles – body and lid

- Baking trays, cake molds, utensils, and other food contact items

- Advantages: Non-toxic, uniform heat conduction, easy to clean

Lighting & Decoration:

- Lampshades, reflectors, lighting housings

- Signboards, advertising panels

- Advantages: High reflectivity, easy to form, corrosion-resistant

Electronics & Electrical:

- Heat sinks, conductive components, PCB drilling backplates

- Transformer housings, capacitor housings

- Advantages: Good thermal and electrical conductivity, lightweight

Chemical & Pharmaceutical:

- Chemical containers, pipe fittings, reactor liners

- Pharmaceutical packaging, medical device components

- Advantages: Strong corrosion resistance, non-toxic, easy to clean

Other Applications:

- Automotive parts (decorative parts, heat dissipation components)

- Aluminum bottle caps, sealing components

- Craft items, metal components for gift boxes

| Application | Recommended Product | Recommended Process (DC/CC) | Key Considerations |

| High-end Non-stick / Deep Pots | 1100 O Aluminum Circle | DC (Hot Rolled) | Stretching without cracking, no orange peel |

| Standard Frying Pans / Lampshades | 1100 O / H14 Aluminum Circle | CC (Cold Cast) | Cost-effective, smooth spinning |

| Traffic Signs | 1100 H14 Aluminum Circle | CC | Surface flatness, hardness |

| Capacitor Housings | 1100 O Aluminum Circle | DC | Dimensional tolerance, sealing |

Recommendation: If you are performing deep drawing (e.g., making deep soup pots), be sure to specify DC-grade O temper aluminum circles to prevent "orange peel" or cracking during processing.

1100 Aluminum Circle Production Process

- Raw Material Preparation: Electrolytic aluminum ingots + precise alloying elements

- Melting & Casting: Furnace refining → resting → grain refinement → online degassing & filtering → cast into rolls

- Rolling Process: Cold roll to target thickness → intermediate annealing (as required) → finishing roll

- Heat Treatment: Annealing (O temper) or cold work hardening (H series) as needed

- Cutting & Forming: Precision cutting on disc shearing machine → deburring → cleaning

- Quality Inspection: Full inspection of dimensions, surface, and mechanical properties

- Packaging & Storage: Moisture-proof and scratch-proof packaging

1100 Aluminum Circle Selection and Usage Tips

- Temper Selection: Use O temper for deep drawing / spinning; H22/H24 for general forming; H18 for simple high-strength parts

- Thickness Matching: Cookware commonly 1.0~3.0mm; lampshades 0.5~1.5mm; electronic heat sinks 0.3~1.0mm

- Surface Requirements: Food contact must have food-grade certification; decorative parts require high-gloss surface; outdoor use may require anodizing

- Standards Compliance: Common standards include GB/T 3880, ASTM B209, EN 485

1100 Aluminum Circle vs Other Aluminum Alloy Circles

| Alloy | Aluminum Content | Strength | Workability | Corrosion Resistance | Suitable Applications |

| 1100 | ≥99.0% | Low | Excellent | Excellent | Cookware, deep-drawn parts |

| 3003 | ~98% | Medium | Good | Excellent | Containers, heat sinks |

| 5052 | ~97% | Medium-High | Fairly Good | Excellent | Marine, automotive parts |

| 8011 | ~97% | Medium | Good | Excellent | Aluminum foil, bottle caps |

Why Choose 1100 Aluminum?

If your project requires complex shapes, excellent surface smoothness (polishable/anodizable), high purity and corrosion resistance, and does not require high structural strength, 1100 aluminum is a versatile and cost-effective choice. It is usually supplied as pre-cut discs or round sheets for convenient manufacturing.

Although 3003 is also commonly used for round parts, it contains manganese and has approximately 20% higher strength than 1100.

- If you prioritize ease of spinning or chemical purity, choose 1100.

- If you need finished parts with higher dent resistance, 3003 is usually the better option.

Further reading

- 1100 Aluminum Plate Sheet

- 1100 0 aluminum sheet

- 1100 h14 aluminum sheet

- 1100 h18 aluminum sheet

- 1100 h12 aluminum sheet plate

- 1100 H16 Aluminum

- 1100 H22 Aluminum

- 1100 H24 Aluminum

- 1100 H26 Aluminum

- 1100 H28 Aluminum

- 1100 Aluminum Coil

- 1100 Aluminum Foil

Users viewing this material also viewed the following

- 1100 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1100 Aluminum Sheet for PCB (Printed Circuit Board)

- 1100 Aluminum Plate for Heat Sink Applications

- 1100 Aluminum Plate for Printing Plates

- 1100 Aluminum Plate for Building Exterior Cladding

- 1100 Aluminum Veneer Panel

- 1100 Aluminum Plate for Stair Handrails

- 1100 Aluminum Plate for Pressure Tanks

- 1100 H16 Aluminum Sheet Roll for Refrigerator Linings

- 1100 O/H14 Aerospace Aluminum Sheet and Plate

- 1100 Aluminum Plate for New Energy Charging Stations

- 1100 Embossed Aluminum Sheet for Automotive Heat Shield

- 1100 Aluminum Plate for Aluminum Composite Panels

- 1100 Corrugated Aluminum Sheet

Recommended Content

- 1100 vs. 1050 Aluminium Which Alloy is Right for Your Project?

- 1100-H14 Aluminum vs. 1100-H24 Aluminum

- 1100-H14 Aluminum vs. 1100-H16 Aluminum

- 1100-H14 Aluminum vs. 1100-H18 Aluminum

- 1100-H12 Aluminum vs. 1100-H14 Aluminum

- 1100-H14 Aluminum vs. 1100-O Aluminum

- 1060-O Aluminum vs. 1100-H14 Aluminum: A Comparative Analysis

- 1060 Aluminum vs. 1100-H14 Aluminum: Key Differences

- Comparison of 1060-H28 Aluminum vs. 1100-H28 Aluminum