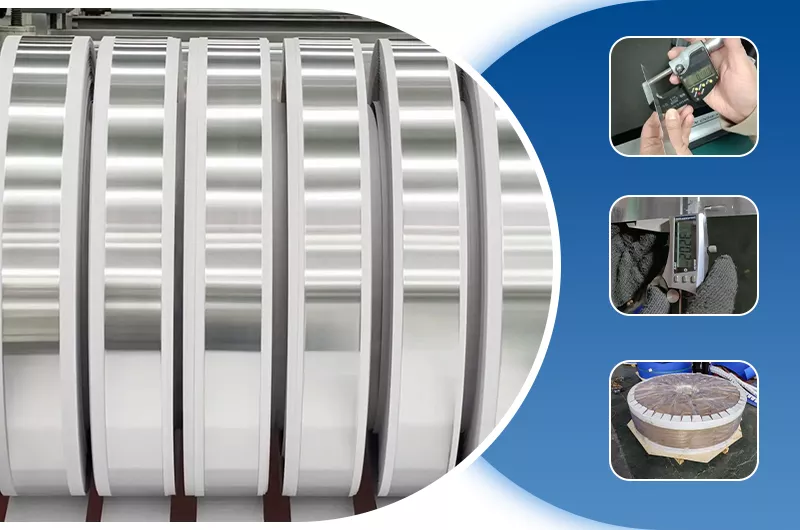

1060 Aluminum Strip

1060 aluminum strip is a commercial pure aluminum product, renowned for its high ductility, excellent corrosion resistance, and outstanding electrical conductivity. Due to its low alloying element content, it is relatively soft and cannot be hardened through heat treatment; instead, its strength is enhanced through cold working (tempering).

1060 aluminum strip is widely used in applications where electrical conductivity, corrosion resistance, and formability are more important than structural strength. 1060 aluminum strip is suitable for scenarios where strength requirements are not high, but processing and functionality are prioritized.

With its high cost-performance ratio, stable properties, and broad applicability, 1060 aluminum strip has become an indispensable basic material in industrial and civil sectors, especially holding an important position in electronics, electrical, packaging, and architectural decoration industries.

Why choose 1060 aluminum strip?

- When you need to balance formability and conductivity rather than high strength.

- Suitable for cost-effective components in non-structural applications.

1060 Aluminum Strip Specifications

| Temper | O, H12, H14, H16, H18 |

| Aluminum Purity | 99.60% |

| Thickness | 0.1mm to 3mm (most commonly 0.3mm-1.0mm) |

| Width | 15mm to 1500mm (can be cut to requirements) |

| Quantity Tolerance | ±10% |

| Length | Customized according to coil weight and application, usually in coil form |

| Surface Condition | Bright, matte, anodized, etc. |

1060 Aluminum Strip Temper Options

- O / H14 / H18 (other temper options available upon request)

- Choice depends on required hardness and forming needs

- O temper: soft, best ductility, suitable for deep drawing and complex forming

- H12 / H14 / H16 / H18: different hardness levels, balancing strength and formability

- H22/H24/H26/H28: partially annealed after cold work, combining strength and plasticity

- Custom temper: hardness and thickness tolerance can be adjusted according to customer requirements

| Temper | Characteristics |

| O temper (fully annealed soft) | Best plasticity, suitable for deep drawing and stretching |

| H14 (half-hard) | Moderate strength, suitable for general stamping and bending |

| H18 (full-hard) | Highest strength, suitable for simple bending and cutting |

1060 Aluminum Strip Features

- High purity: aluminum content ≥99.6%, high conductivity, suitable for electrical applications.

- Conductivity: excellent electrical and thermal conductivity, second only to copper among common metals.

- Formability: excellent ductility; ideal for deep drawing, stamping, and complex bending.

- Corrosion resistance: natural protective oxide layer provides strong resistance to atmospheric and chemical corrosion.

- Weldability: can be easily joined using standard commercial welding, brazing, and soldering methods.

- Smooth surface quality: highly suitable for anodizing and decorative surface treatments.

- Lightweight and recyclable: cost-effective and environmentally friendly.

- Cannot be strengthened by heat treatment: strength can only be increased through cold working, softens again after annealing.

- Machinability: poor (especially in soft temper), requiring specialized tools and processes.

1060 Aluminum Strip Applications

Power Transmission and Electrical Systems

1060 aluminum strip is high-purity aluminum, with weight-to-conductivity efficiency close to copper, achieving a good balance between cost and performance, making it a commonly used material in the power industry.

- Transformer aluminum: commonly used for high and low-voltage windings in dry-type and oil-immersed transformers, providing good electrical performance while reducing material cost.

- Busbars and electrical distribution: suitable for distribution cabinets, switchgear, and power distribution systems, ensuring stable and efficient current transmission.

- Battery components for EVs: widely used as battery busbars, flexible connections, and cathode materials in electric vehicles and energy storage systems, combining conductivity and lightweight advantages.

- Cable shielding: effectively suppresses electromagnetic interference, protecting the stable operation of sensitive electronic equipment.

HVAC and Thermal Management Applications

1060 aluminum strip has a high thermal conductivity (approximately 230 W/m·K) and excellent processability, making it an ideal choice for aluminum heat exchangers and cooling systems.

- Heat exchanger fins: used in radiators, air conditioning systems, and industrial cooling equipment to improve overall heat exchange efficiency.

- Thermal shields: used in automotive engine compartments and exhaust systems to divert heat and protect critical components.

- Electronic heat sinks: used for power modules and processor cooling fins to ensure stable operation under high loads.

Chemical, Pharmaceutical, and Food Packaging Industries

The natural oxide layer on 1060 aluminum strip provides excellent corrosion resistance and safety, making it ideal for pharmaceutical, chemical, and food packaging applications.

- Pharmaceutical and beverage caps: suitable for medical vials, wine, and beverage bottle caps; non-toxic, tasteless, and easy to deep draw.

- Chemical equipment lining: used for storage tanks and pipelines handling mildly corrosive liquids, extending equipment lifespan.

- Food packaging containers: used in aluminum foil, stamped food trays, and food-grade packaging products, combining safety and ductility.

Architectural Decoration and Signage Systems

With excellent ductility and adaptability for surface treatment, 1060 aluminum strip is also widely used in architectural decoration and visual display applications.

- Architectural cladding: curtain wall panels, roofing materials, and eaves decorations; aesthetically refined and easy to maintain.

- Signage and advertising boards: flat surface suitable for painting, lamination, or UV printing, meeting indoor and outdoor signage needs.

- Reflective materials: after polishing, high reflectivity, commonly used in lamp reflectors, traffic signs, and lighting systems.

Comparison of 1060 Aluminum Strip with Similar Materials

| Material | Aluminum Content | Advantages | Disadvantages | Application Differences |

| 1060 Aluminum Strip | 99.6% | Best conductivity, moderate price | Lowest strength | Electrical and heat-conducting applications |

| 1050 Aluminum Strip | 99.5% | Similar performance to 1060, slightly lower price | Slightly lower purity | Applications with slightly lower purity requirements |

| 1100 Aluminum Strip | 99.0% | Slightly higher strength, good workability | Slightly lower conductivity | General industrial and decorative uses |

| 3003 Aluminum Strip | 97% (contains 1.2% Mn) | Higher strength, good corrosion resistance | Reduced conductivity | Applications with certain strength requirements |

Comparison of 1060 Aluminum Strip with 1050/1100 Aluminum Strips

With its higher aluminum content, 1060 aluminum strip offers slightly better conductivity than 1050 aluminum strip, providing more stable current transmission performance for electrical and industrial applications.

Compared to 1100 aluminum strip, 1060 aluminum strip has improved strength while maintaining excellent corrosion resistance and good workability, making it more balanced in forming, welding, and surface treatment processes.

With multiple advantages in conductivity, corrosion resistance, and overall mechanical properties, 1060 aluminum strip is an ideal choice for transformer windings, electrical busbars, industrial machinery components, and lightweight structural parts.

- Compared to 1050 aluminum strip: higher purity, slightly better conductivity

- Compared to 1100 aluminum strip: slightly higher strength, more balanced overall performance

Why Choose 1060 Aluminum Strip?

If your application requires high electrical conductivity, surface quality, and ease of processing, 1060 aluminum strip is a more ideal choice than high-strength alloys like 3003 or 5052. It not only offers excellent conductivity and good formability but also provides more competitive cost.

- Wide applicability: especially suitable for industrial parts and electronic/electrical components requiring high conductivity and formability.

- Cost-performance advantage: ensures performance while keeping costs controllable, suitable for mass production.

- Preferred for export and industrial production: stable material quality and processing performance make it reliable in international trade and large-scale industrial applications.

1060 Aluminum Strip Processing and Usage Notes

- Forming: O temper 1060 aluminum strip has excellent ductility, suitable for deep drawing, stretching, and other complex forming; H temper is more suitable for simple bending and stamping operations.

- Welding: recommended to use gas or resistance welding; avoid brazing as much as possible to ensure weld quality and structural integrity.

- Surface treatment: can undergo anodizing, spraying, plating, etc., not only enhancing decorative effect but also improving corrosion resistance and durability.

- Storage and protection: avoid humid and acidic/alkaline environments to prevent surface oxidation and discoloration, maintaining stable material performance.

Notes: 1060 aluminum strip cannot be strengthened by heat treatment; if higher strength is required, cold working should be used. During cutting, it is recommended to use sharp tools and reduce cutting speed to minimize burrs and material loss.

Further reading

- 1060 Aluminum Coil

- 1060 Aluminum Plate Sheet

- 1060 h12 aluminum sheet plate

- 1060 h24 aluminum sheet plate

- 1060 Aluminum Disc Circle

- 1060-O Aluminum

- 1060-H14 Aluminum

- 1060-H16 Aluminum

- 1060-H18 Aluminum

- 1060 H22 Aluminum

- 1060 H26 Aluminum

- 1060 H28 Aluminum

- 1060 Aluminum Foil

Users viewing this material also viewed the following

- 1060 O Aluminium Strips for Transformers Winding

- 1060 O Aluminum Coil Strip for Mask Nose Clip

- 1060 Aluminum Strip for Vial Seals

- 1060 Aluminum Plate Strips for Capacitor Shells – High Purity & Durable

- 1060 Aluminum Mirror Sheet Coil

- 1060 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1060 Aluminum Plate for Curtain Wall Panel

- 1060 Aluminum Plate for Stamping Parts

- 1060 Aluminum Plate for Automotive Parts

- 1060 H24 Stamping Aluminum Plate for Aluminum Bottle Cap

- 5 Bar 1060 Aluminum Checker Plate

- 1060 Decorative Aluminum Plate

- 1060 Aluminum Tread Plate for Carriage Floor

- 1060 Hot-rolled Aluminum Plate for Lamps

- 1060 Aluminum Circle Disc for Kitchenware

- 1060 Embossed Aluminum Sheet for Automotive Heat Shields

- 1060 Aluminum Plate for Outdoor Billboard

- 1060 Aluminum Plate for Printed Circuit Board (PCB) Substrates

- 1060 Aluminum Sheet Coil for Pipeline Insulation

- 1060 Aluminum Plate for Aluminum-based Copper-clad Plate

Recommended Content

- Key Differences Between 1050 and 1060 Aluminum What You Need to Know

- 1060-O Aluminum vs. 1100-H14 Aluminum: A Comparative Analysis

- 1060 Aluminum vs. 1100-H14 Aluminum: Key Differences

- Performance Comparison: 1060-H16 Aluminum vs. 1060-H24 Aluminum

- Differences Between 1060-H22 Aluminum and 1070-H22 Aluminum

- Comparison of 1060-H28 Aluminum vs. 1100-H28 Aluminum