1060 Aluminum Plate Sheet

1060 aluminum sheet belongs to the 1000 series aluminum alloys (commercially pure aluminum), with an aluminum content of no less than 99.6%. It is a basic aluminum material known for its high purity and stable performance. Compared with 1050 aluminum sheet, 1060 offers slightly higher purity and shows more outstanding performance in electrical conductivity, thermal conductivity, and corrosion resistance. Therefore, it has greater advantages in applications where high performance stability is required.

Since it does not contain alloying elements that can be strengthened, 1060 aluminum sheet cannot improve its strength through heat treatment. Its strength is mainly obtained through cold working processes such as rolling and stretching. However, it is precisely this “soft aluminum” characteristic that gives it excellent plasticity and elongation, making it highly suitable for deep drawing, bending, stamping, and other forming processes. At the same time, it is less prone to cracking during processing, and the finished products show good consistency.

- High Purity: 1060 alloy is a high-purity aluminum alloy with stable composition, suitable for applications requiring high-purity aluminum materials.

- Strength: It is a low-strength aluminum alloy, suitable for non-structural applications.

- Workability: It has excellent weldability and formability, including various forming processes such as stamping, cold drawing, deep drawing, and bending.

Benefiting from its high purity, 1060 aluminum sheet demonstrates excellent corrosion resistance, electrical conductivity, and thermal conductivity, and can maintain stable performance even in chemical environments and humid conditions. This makes it an ideal material for many applications where high strength is not required, but formability and functional performance are more important.

From an overall performance perspective, 1060 aluminum sheet can be regarded as a typical representative of “high purity, high corrosion resistance, high formability, and low strength.” Its advantages in flexibility, chemical stability, and processing adaptability often have greater practical value than strength itself. At the same time, it is relatively economical in price and offers outstanding cost performance.

In practical applications, 1060 aluminum sheet is widely used in signage and advertising boards, lighting fixtures, decorative panels, curtain wall systems, chemical equipment, food-grade containers, battery connectors, industrial storage tanks, and other fields. Thicker specifications of 1060 aluminum sheet can also be cut and processed into aluminum strips, which are used in transformers, electrical equipment, and other conductive components. Overall, 1060 aluminum sheet is particularly suitable for industries and products that place higher demands on electrical conductivity, thermal conductivity, corrosion resistance, and formability than on structural strength.

1060 Aluminum Sheet Specifications

| Item | Specification Range |

| Thickness | 0.1 mm to 500 mm (customizable) |

| Width | 20 mm to 2640 mm |

| Length | Up to 10, 000 mm |

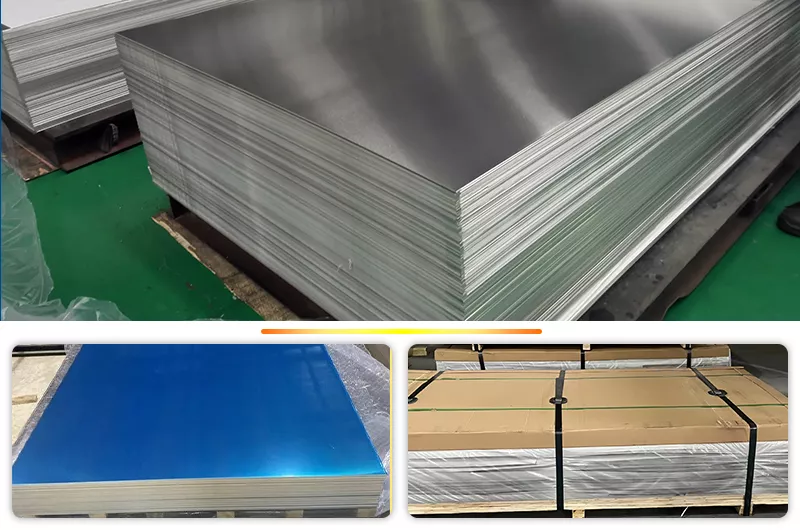

| Surface Treatment | Smooth, protective film (blue PE or paper), or polished |

1060 Aluminum Sheet Supply Availability

1060 Aluminum Sheet is a high-purity aluminum sheet whose mechanical properties are mainly adjusted through cold working and annealing processes. Different supply conditions show obvious differences in strength, hardness, and formability, making them suitable for different processing scenarios.

| Temper | Characteristics | Typical Applications |

| O Temper (Annealed) | Softest, best plasticity | Deep drawing, stretching, bending, and other complex forming processes |

| H14 / H24 Temper | Semi-hard, moderate strength | General structural parts, decorative components |

| H16 / H26 Temper | Hard temper, relatively high strength | Stamped parts with certain strength requirements |

| H18 Temper | Hardest, highest strength | Parts requiring higher strength and minimal deformation |

O Temper (Annealed)

O temper is the softest condition of 1060 aluminum sheet. Internal stresses are basically eliminated, resulting in excellent ductility and flexibility. In this condition, the aluminum sheet has the best plasticity and is not prone to cracking, making it especially suitable for deep drawing, deep stamping, spinning, and other large-deformation forming processes. It is commonly used for components with high forming requirements.

H Temper (Strain-Hardened)

H temper aluminum sheet is strengthened through strain hardening generated by cold rolling, thereby improving strength and rigidity, while plasticity decreases accordingly. According to the degree of strain hardening and whether partial annealing is applied, it can be subdivided into multiple tempers:

H12 / H14 / H16 / H18:

Hardness increases progressively as the number increases. Among them, H14 is a half-hard temper that achieves a good balance between strength and formability and is one of the most commonly used supply conditions. H18 is the full-hard temper, offering the highest strength but limited formability, making it more suitable for flat or simple processing.

H22 / H24:

After strain hardening, partial annealing is performed to improve ductility while maintaining a certain level of strength. Among them, H24 is considered a relatively well-balanced temper, suitable for applications that require both strength and a certain degree of formability.

Recommendations for Selecting 1060 Aluminum Sheet Tempers

- Deep drawing and complex forming: O temper is recommended

- General stamping and bending: H14 / H24 can be selected

- Higher strength and rigidity requirements: H16 or H18 may be considered

Reasonable selection of the supply temper for 1060 Aluminum Sheet helps improve processing stability, reduce the risk of cracking, and achieve a better balance between cost and performance.

1060 Aluminum Plate Standards

- ASTM B209

- ASTM B210

- ASTM B211

- ASTM B632 / B632M

- ASTM B947

- ASTM B548

- EN 573

- EN 485

- AMS 4001

- AMS 4003

- GB/T3880.1-2006

- UNS A91060

Equivalents of AA 1060

UNS A91060, Aluminium 1060, AA1060, Al1060

1060 Aluminum Plate Sheet Surface Treatments

1060 Aluminum Anodized Plate

Surface treated by electrochemical anodizing to form a dense oxide layer — improves corrosion and wear resistance, provides durable decorative finishes and optional colors; commonly used in architectural trim, appliance housings, and industrial parts.

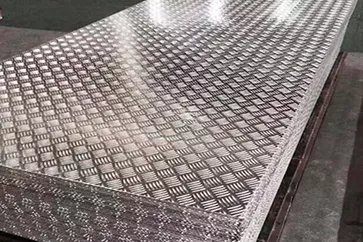

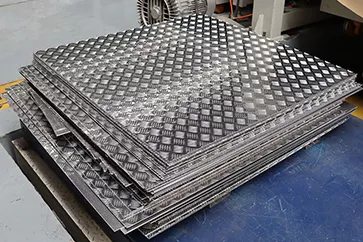

1060 Aluminum Embossed Plate

Rolled plate with raised/debossed patterned textures (e.g., diamond, pebble, ripple) that increase slip resistance and hide scratches; ideal for flooring, truck beds, decorative cladding and anti-slip surfaces.

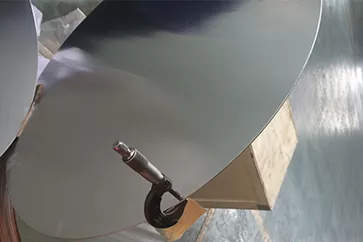

1060 Aluminum Mirror Plate

Highly polished and finished to a mirror-like reflectivity — excellent for reflectors, decorative panels, signage and lighting applications where a bright reflective surface is required.

1050 Color Coated Aluminum Sheet

1050 substrate coated with weather-resistant paint or coil coating to provide long-lasting color, improved corrosion protection and aesthetic versatility; widely used for roofing, facades, signage and appliance panels.

Brushed 1050 Aluminum Plate

Mechanically brushed to create fine linear or circular grain patterns that give a textured matte metallic finish — reduces visible fingerprints, offers a premium look, and is common in electronic housings and interior trim.

Polished 1050 Aluminum Plate

Mechanically or chemically polished to a smooth, high-gloss surface with enhanced visual appeal; used for decorative components, lamp fixtures, trim and applications needing a clean reflective finish.

1060 Corrugated Aluminum Plate

Formed with a regular corrugated (wavy) profile to increase stiffness and load-bearing capacity while keeping weight low; commonly applied in roofing, siding, decking and transport panels for improved drainage and strength.

1060 Aluminum Perforated Plate

Plate punched with patterned holes of various shapes and sizes to allow airflow, light transmission and decorative effects; used in façades, acoustic panels, filters, guards and ventilation systems.

1060 Aluminum Plate Sheet Color Options

1060 Aluminum Sheet Key Characteristics

| Key Characteristics | Description |

| High Purity | 1060 aluminum alloy contains at least 99.6% aluminum, providing exceptional purity. This high purity grants 1060 aluminum alloy excellent performance in various fields, particularly in applications that require high aluminum material purity, offering better corrosion resistance and stability. |

| Excellent Workability | 1060 aluminum alloy offers excellent workability, making it suitable for various processing methods such as stamping, stretching, and cutting. Its excellent forming characteristics make it very easy to process during manufacturing, capable of meeting complex shape and precision requirements, which is why it is widely used across industries. |

| Good Corrosion Resistance | 1060 aluminum alloy exhibits strong corrosion resistance, especially in chemical or marine environments, where it can effectively resist oxidation and corrosion. This property makes 1060 aluminum alloy ideal for use in industries like aerospace, construction, and electronics, where high corrosion resistance is required. |

| High Electrical and Thermal Conductivity | 1060 aluminum alloy has excellent electrical and thermal conductivity, making it outstanding in applications that require efficient electrical conductivity. It is particularly suitable for power equipment, cable materials, radiators, and other applications that require high thermal conductivity. |

| Low Strength | Although 1060 aluminum alloy has exceptional workability, its mechanical strength is relatively low. Compared to other high-strength aluminum alloys, it may not have enough load-bearing capacity in high-stress applications. However, it is very suitable for applications that do not require high strength but demand good plasticity and forming performance. |

| High Ductility | 1060 aluminum alloy exhibits extremely high ductility, allowing it to perform excellently in forming processes like stamping, bending, and deep drawing. Its high ductility makes it very suitable for complex forming processes, especially in cases where large-scale deformation is required while maintaining structural integrity and excellent processing performance. |

| Low Strength | 1060 aluminum alloy cannot increase its strength through heat treatment, so it has low strength. However, its strength can be somewhat increased through cold working (such as H14, H18 tempering), though it still does not match other high-strength aluminum alloys. It is suitable for applications that do not require high strength, or when better processing performance and ductility are more important. |

1060 Aluminum Plate Performance Data

| Property | Description |

| Machinability | Fair to poor, improved in harder (cold worked) tempers like H16 and H18; use carbide or high-speed steel tooling; lubricants recommended but some cutting can be done dry. |

| Forming | Excellent forming capability by both cold or hot working using commercial techniques. |

| Welding | Can be welded by standard commercial methods; if filler rod is needed, use AL 1060; trial and error may be required for resistance welding. |

| Heat Treatment | Does not harden by heat treatment; may be annealed after cold working. |

| Forging | Can be forged in the temperature range of 950 to 700°F. |

| Hot Working | Can be hot worked in the range of 900 to 500°F. |

| Cold Working | Excellent cold working characteristics; can be readily cold worked by all conventional methods. |

| Annealing | May be annealed at 650°F followed by air cooling. |

| Aging | Not applicable. |

| Tempering | Not applicable. |

| Hardening | Hardens only from cold working; tempers H12, H14, H16, H18 determined by the amount of cold work. |

1060 Aluminum Sheet Chemical Composition

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.15 | Remain |

Physical Properties of 1060 Aluminum Sheet

| Alloy Temper | Specified | Tensile | Yield | Elongation(%) |

| Thickness(in.) | strength(ksi) | strength(ksi) | ||

| 1060-O(annealed) | 0.006-0.019 | 8.0-14.0 | 2.5 | Min15 |

| 0.020-0.050 | Min22 | |||

| 0.051-3.000 | Min25 | |||

| 1060-H12/1060-H22 | 0.017-0.050 | 11.0-16.0 | 9 | Min6 |

| 0.051-2.000 | Min12 | |||

| 1060-H14/1060-H24 | 0.006-0.019 | 12.0-17.0 | 10 | Min1 |

| 0.020-0.050 | Min5 | |||

| 0.051-1.000 | Min10 | |||

| 1060-H16/1060-H26 | 0.006-0.019 | 14.0-19.0 | 11 | Min1 |

| 0.020-0.050 | Min4 | |||

| 0.051-0.162 | Min5 | |||

| 1060-H18/1060-H28 | 0.006-0.019 | Min16.0 | Min12.0 | Min1 |

| 0.020-0.050 | Min3 | |||

| 0.051-0.128 | Min4 | |||

| 1060-H112 | 0.250-0.499 | Min11.0 | Min7.0 | Min10 |

| 0.500-1.000 | Min10.0 | Min5.0 | Min20 | |

| 1.001-3.000 | Min9.0 | Min4.0 | Min25 |

1060 Aluminum Plate Applications

1060 aluminum plate is widely used in products that do not require high strength.

1060 aluminum plate is widely used in signs, billboards, building exterior decoration, bus bodies, high-rise buildings and factory wall decoration, kitchen sinks, lamp holders, fan blades, electronic parts, chemical equipment, mechanical parts, thin plate deep drawing or spinning concave parts, welded parts, heat exchangers, watch surfaces and plates, nameplates, kitchen utensils, decorations, reflective equipment, making automotive insulation boards, chemical and ship equipment, etc.

1060 aluminum material, with its unique combination of properties, is widely used in various fields, including:

- Architectural Decoration: billboards, curtain walls, bus bodies, exterior wall decoration of buildings.

- Industrial Components: kitchen sinks, lamp holders, fan blades, heat exchangers, welding parts.

- Electronics and Light Industry: wire protective covers, capacitors, electronic components, thin sheet processing.

- Daily Products: kitchenware, decorations, reflectors.

- Electrical and Chemical Industry: its high conductivity and corrosion resistance make it suitable for electrical conductors and chemical equipment.

- Railway Tank Cars and Chemical Equipment Manufacturing: its durability and corrosion resistance make it beneficial in these fields.

- Reflective Surfaces: the alloy's excellent surface finish and reflectivity make it ideal for applications requiring reflective materials.

- Decorative Items: its high polish makes it suitable for decorative applications.

1060 Aluminum for Curtain Wall Panel

1060 Aluminum for curtain wall panels is durable and corrosion-resistant, making it ideal for sleek and modern building facades.

1060 Aluminum for Ventilation Duct

1060 Aluminum for ventilation ducts, particularly in the H24 alloy, offers excellent thermal conductivity and rust resistance.

1060 Aluminum for Stamping Parts

1060 Aluminum for stamping parts is highly malleable, making it suitable for precision-stamped components.

1060 Aluminum for Busbar

1060 Aluminum for busbars provides excellent electrical conductivity, making it ideal for electrical busbars.

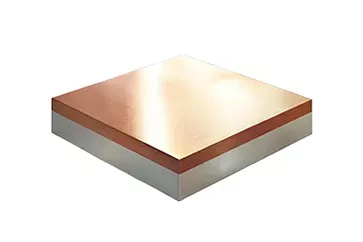

1060 Aluminum for Aluminum-Based Copper-Clad Plate

1060 Aluminum for aluminum-based copper-clad plates combines lightweight aluminum with conductive copper for specialized applications.

1060 Aluminum for Disinfection Cabinet Liner

1060 Aluminum for disinfection cabinet liners, with a thickness of 0.3mm, is a thin, corrosion-resistant plate used for easy cleaning in disinfection cabinets.

1060 Aluminum for Automotive Parts

1060 Aluminum for automotive parts is lightweight and durable, making it ideal for use in various automotive components.

1060 Aluminum for Anti-Theft Bottle Cap

1060 Aluminum for anti-theft bottle caps is made from a stamping plate in the H24 condition, designed for easy stamping and durability.

1060 Aluminum for Decorative Plate

1060 Aluminum for decorative plates is used for aesthetic purposes, offering a sleek appearance for various decorative applications.

1060 Aluminum for Carriage Floor

1060 Aluminum for carriage floors provides a strong, durable surface resistant to wear and tear.

1060 Aluminum for Lamps

1060 Aluminum for lamps is hot-rolled, ideal for lamp housings due to its heat dissipation properties and ease of shaping.

1060 Aluminum for Kitchenware

1060 Aluminum for kitchenware is lightweight and corrosion-resistant, suitable for various kitchen utensils and cookware.

1060 Aluminum for Anti-Slip Pattern

1060 Aluminum for anti-slip pattern features an anti-slip surface that enhances safety in high foot traffic areas.

1060 Aluminum for Mask Nose Clips

1060 Aluminum for mask nose clips is used to create flexible and comfortable nose clips for face masks.

1060 Aluminum for Bottle Cap

1060 Aluminum for bottle caps is thin and durable, making it ideal for bottle caps due to ease of manufacturing and sealing.

1060 Aluminum for Heat Sink

1060 Aluminum for heat sinks provides effective heat dissipation in electronic components, improving performance and longevity.

1060 Aluminum for CTP Base

1060 Aluminum for CTP base material serves as a base for computer-to-plate (CTP) printing processes, ensuring high-quality prints.

1060 Aluminum for Automobile Insulation Board

1060 Aluminum for automobile insulation boards offers excellent thermal insulation properties for automotive applications.

1060 Aluminum for Capacitor Shell

1060 Aluminum for capacitor shells provides protective and conductive casing for capacitors in electronic devices.

1060 Aluminum for Outdoor Billboard

1060 Aluminum for outdoor billboards is durable and weather-resistant, making it ideal for creating long-lasting outdoor advertisements.

1060 Aluminum for PCB Circuit Board Substrate

1060 Aluminum for PCB circuit board substrates is used as a base for printed circuit boards (PCBs), providing excellent thermal and electrical conductivity.

1060 Aluminum for Pipeline Insulation

1060 Aluminum for pipeline insulation offers effective protection and insulation for pipelines in industrial applications.

1060 Tread Chequered Plate

1060 tread chequered plate has one to five raised anti-slip rib patterns on the surface. It is commonly used for pedals, flooring, elevator bottoms, and platform plates in both industrial and civil sectors. It also offers good corrosion resistance and workability.

1060 Aluminum Sublimation Plate

1060 aluminum sublimation plate is specially treated for sublimation printing, suitable for transferring personalized patterns such as photos, artworks, and signs. It is widely used in souvenir production, advertising displays, and decorative artworks.

Haomei 1060 Aluminum Product Forms and Common Specifications

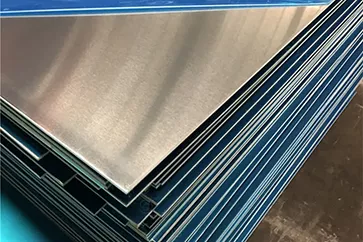

1060 Aluminum Sheet

Flat rolled aluminum with a smooth surface, excellent corrosion resistance, and good formability. Widely used in signage, building facades, and decorative applications.

1060 Aluminum Plate

A thicker form of aluminum sheet, offering higher strength and rigidity. Commonly applied in machinery parts, mold making, and structural components.

1060 Aluminum Coil

Supplied in continuous rolled form, easy for transportation and processing. Suitable for roofing materials, curtain walls, insulation, and packaging.

1060 Aluminum Busbar

Rectangular or customized solid bars with excellent electrical conductivity. Commonly used in electrical engineering, power distribution equipment, and transformers.

1060 Aluminum Strip

Narrow cut strips from coil, with good ductility and conductivity. Used in transformers, cable wrapping, heat exchangers, and automotive parts.

1060 Aluminum Tread Plate (Checker Plate)

Embossed with raised patterns (diamond, five-bar, etc.) to provide anti-slip performance. Ideal for flooring, truck beds, stair treads, and cold storage projects.

1060 Aluminum Circle (Disc/Blank)

Round blanks cut from sheet or coil, featuring good stamping and spinning properties. Extensively used for cookware, lampshades, road signs, and utensils.

1060 Aluminum Rod/Bar

Solid cylindrical or rectangular bars with good machinability. Applied in electrical conductors, hardware, and mechanical parts.

1060 Aluminum Tube/Pipe

Hollow round or square profiles with light weight and good corrosion resistance. Common in heat exchangers, pipelines, and structural applications.

1060 Aluminum Foil

Very thin rolled aluminum with excellent barrier and thermal conductivity. Widely used in packaging, insulation materials, and household foil.

1060 Aluminum Wire

Drawn into fine round wires, featuring high electrical conductivity and flexibility. Mainly applied in cables, motor windings, and conductive parts.

1060 Aluminum Sheet Common Specifications

Applications: Decorative panels, reflectors, signage.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Thickness | 0.004" – 0.118" | ±0.001" | O, H12, H14, H18 |

| Width | 3.94" – 104" | ±0.125" | |

| Length | Up to 394" | ±0.25" | |

| Surface Finish | Mill, polished, anodized | N/A |

1060 Aluminum Plate

Applications: Chemical tanks, heat exchangers.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Thickness | 0.118" – 19.685" | ±0.5% of thickness | O, H112, H32 |

| Width | Up to 104" | ±0.25" | |

| Length | Custom (max 394") | ±0.5" |

1060 Aluminum Seamless Tubes

Applications: HVAC, refrigeration lines.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Outer Diameter | 0.118" – 19.69" | ±0.002" (OD <0.5") | O, H112 |

| Wall Thickness | 0.004" – 0.157" | ±10% | |

| Length | Straight: 394"; Coiled: 192" | ±0.08" |

1060 Aluminum Bar

Applications: Structural frames, machining stock.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Diameter/Width | 0.2" – 11.8" (round/square) | ±0.003" | O, H112, T6 |

| Length | 118" – 394" | ±0.12" |

1060 Aluminum Rod

Applications: Fasteners, electrical components.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Diameter | 0.04" – 2" | ±0.001" | O, H14 |

| Length | 118" – 394" (straight) | ±0.08" |

1060 Aluminum Wire

Applications: Welding filler, conductors.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Diameter | 0.04" – 0.2" | ±0.0005" | O, H18 |

| Form | Coiled or straight | N/A |

1060 Aluminum Extruded Bars

Applications: Custom machined parts.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Cross-Section | Round, square, hexagonal | ±0.005" | O, T4 |

| Diameter/Width | 0.5" – 7.9" | Custom | |

| Length | Up to 394" | ±0.25" |

1060 Aluminum Profiles

Applications: Architectural trim, frames.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Cross-Section | Custom shapes (L, U, T, etc.) | ±0.01" | O, T5 |

| Max Dimension | 11.8" (width/depth) | Profile-dependent | |

| Length | Up to 394" | ±0.5" |

1060 Aluminum Strip

Applications: Packaging, capacitors, transformers.

| Parameter | Specifications (inches) | Tolerances | Temper Options |

| Thickness | 0.002" – 0.059" | ±0.0002" | O, H18 |

| Width | 0.6" – 78.7" | ±0.005" | |

| Coil Length | Continuous | N/A |

Haomei 1060 Aluminum Material Inventory List

Note: All dimensions align with ASTM B209 (sheet/plate), ASTM B210 (tubes), and ASTM B211 (bar). Custom sizes available per request.

1060 Aluminum Sheet Inventory List

| Description | Thickness(in) | Size(in) | Temper | Surface Finish |

| 0.016" x 48" x 96" 1060 aluminum sheet | 0.016" | 48" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 48" x 120" 1060 aluminum sheet | 0.016" | 48" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 48" x 144" 1060 aluminum sheet | 0.016" | 48" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 48" x 240" 1060 aluminum sheet | 0.016" | 48" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 60" x 96" 1060 aluminum sheet | 0.016" | 60" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 60" x 120" 1060 aluminum sheet | 0.016" | 60" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 60" x 144" 1060 aluminum sheet | 0.016" | 60" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 60" x 240" 1060 aluminum sheet | 0.016" | 60" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 72" x 96" 1060 aluminum sheet | 0.016" | 72" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 72" x 120" 1060 aluminum sheet | 0.016" | 72" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 72" x 144" 1060 aluminum sheet | 0.016" | 72" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 72" x 240" 1060 aluminum sheet | 0.016" | 72" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 96" x 96" 1060 aluminum sheet | 0.016" | 96" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 96" x 120" 1060 aluminum sheet | 0.016" | 96" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 96" x 144" 1060 aluminum sheet | 0.016" | 96" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.016" x 96" x 240" 1060 aluminum sheet | 0.016" | 96" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 48" x 96" 1060 aluminum sheet | 0.032" | 48" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 48" x 120" 1060 aluminum sheet | 0.032" | 48" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 48" x 144" 1060 aluminum sheet | 0.032" | 48" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 48" x 240" 1060 aluminum sheet | 0.032" | 48" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 60" x 96" 1060 aluminum sheet | 0.032" | 60" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 60" x 120" 1060 aluminum sheet | 0.032" | 60" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 60" x 144" 1060 aluminum sheet | 0.032" | 60" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 60" x 240" 1060 aluminum sheet | 0.032" | 60" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 72" x 96" 1060 aluminum sheet | 0.032" | 72" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 72" x 120" 1060 aluminum sheet | 0.032" | 72" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 72" x 144" 1060 aluminum sheet | 0.032" | 72" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 72" x 240" 1060 aluminum sheet | 0.032" | 72" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 96" x 96" 1060 aluminum sheet | 0.032" | 96" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 96" x 120" 1060 aluminum sheet | 0.032" | 96" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 96" x 144" 1060 aluminum sheet | 0.032" | 96" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.032" x 96" x 240" 1060 aluminum sheet | 0.032" | 96" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 48" x 96" 1060 aluminum sheet | 0.040" | 48" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 48" x 120" 1060 aluminum sheet | 0.040" | 48" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 48" x 144" 1060 aluminum sheet | 0.040" | 48" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 48" x 240" 1060 aluminum sheet | 0.040" | 48" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 60" x 96" 1060 aluminum sheet | 0.040" | 60" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 60" x 120" 1060 aluminum sheet | 0.040" | 60" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 60" x 144" 1060 aluminum sheet | 0.040" | 60" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 60" x 240" 1060 aluminum sheet | 0.040" | 60" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 72" x 96" 1060 aluminum sheet | 0.040" | 72" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 72" x 120" 1060 aluminum sheet | 0.040" | 72" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 72" x 144" 1060 aluminum sheet | 0.040" | 72" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 72" x 240" 1060 aluminum sheet | 0.040" | 72" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 96" x 96" 1060 aluminum sheet | 0.040" | 96" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 96" x 120" 1060 aluminum sheet | 0.040" | 96" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 96" x 144" 1060 aluminum sheet | 0.040" | 96" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.040" x 96" x 240" 1060 aluminum sheet | 0.040" | 96" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 48" x 96" 1060 aluminum sheet | 0.063" | 48" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 48" x 120" 1060 aluminum sheet | 0.063" | 48" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 48" x 144" 1060 aluminum sheet | 0.063" | 48" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 48" x 240" 1060 aluminum sheet | 0.063" | 48" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 60" x 96" 1060 aluminum sheet | 0.063" | 60" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 60" x 120" 1060 aluminum sheet | 0.063" | 60" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 60" x 144" 1060 aluminum sheet | 0.063" | 60" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 60" x 240" 1060 aluminum sheet | 0.063" | 60" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 72" x 96" 1060 aluminum sheet | 0.063" | 72" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 72" x 120" 1060 aluminum sheet | 0.063" | 72" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 72" x 144" 1060 aluminum sheet | 0.063" | 72" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 72" x 240" 1060 aluminum sheet | 0.063" | 72" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 96" x 96" 1060 aluminum sheet | 0.063" | 96" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 96" x 120" 1060 aluminum sheet | 0.063" | 96" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 96" x 144" 1060 aluminum sheet | 0.063" | 96" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.063" x 96" x 240" 1060 aluminum sheet | 0.063" | 96" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 48" x 96" 1060 aluminum sheet | 0.080" | 48" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 48" x 120" 1060 aluminum sheet | 0.080" | 48" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 48" x 144" 1060 aluminum sheet | 0.080" | 48" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 48" x 240" 1060 aluminum sheet | 0.080" | 48" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 60" x 96" 1060 aluminum sheet | 0.080" | 60" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 60" x 120" 1060 aluminum sheet | 0.080" | 60" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 60" x 144" 1060 aluminum sheet | 0.080" | 60" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 60" x 240" 1060 aluminum sheet | 0.080" | 60" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 72" x 96" 1060 aluminum sheet | 0.080" | 72" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 72" x 120" 1060 aluminum sheet | 0.080" | 72" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 72" x 144" 1060 aluminum sheet | 0.080" | 72" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 72" x 240" 1060 aluminum sheet | 0.080" | 72" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 96" x 96" 1060 aluminum sheet | 0.080" | 96" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 96" x 120" 1060 aluminum sheet | 0.080" | 96" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 96" x 144" 1060 aluminum sheet | 0.080" | 96" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.080" x 96" x 240" 1060 aluminum sheet | 0.080" | 96" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 48" x 96" 1060 aluminum sheet | 0.100" | 48" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 48" x 120" 1060 aluminum sheet | 0.100" | 48" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 48" x 144" 1060 aluminum sheet | 0.100" | 48" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 48" x 240" 1060 aluminum sheet | 0.100" | 48" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 60" x 96" 1060 aluminum sheet | 0.100" | 60" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 60" x 120" 1060 aluminum sheet | 0.100" | 60" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 60" x 144" 1060 aluminum sheet | 0.100" | 60" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 60" x 240" 1060 aluminum sheet | 0.100" | 60" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 72" x 96" 1060 aluminum sheet | 0.100" | 72" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 72" x 120" 1060 aluminum sheet | 0.100" | 72" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 72" x 144" 1060 aluminum sheet | 0.100" | 72" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 72" x 240" 1060 aluminum sheet | 0.100" | 72" x 240" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 96" x 96" 1060 aluminum sheet | 0.100" | 96" x 96" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 96" x 120" 1060 aluminum sheet | 0.100" | 96" x 120" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 96" x 144" 1060 aluminum sheet | 0.100" | 96" x 144" | O, H14, H18 | Mill, polished, anodized |

| 0.100" x 96" x 240" 1060 aluminum sheet | 0.100" | 96" x 240" | O, H14, H18 | Mill, polished, anodized |

1060 Aluminum Plate Inventory List

| Description | Thickness(in) | Size(in) | Temper |

| 0.125" x 48" x 96" 1060 aluminum plate | 0.125" | 48" x 96" | O, H112, H32 |

| 0.125" x 48" x 120" 1060 aluminum plate | 0.125" | 48" x 120" | O, H112, H32 |

| 0.125" x 48" x 144" 1060 aluminum plate | 0.125" | 48" x 144" | O, H112, H32 |

| 0.125" x 48" x 240" 1060 aluminum plate | 0.125" | 48" x 240" | O, H112, H32 |

| 0.125" x 60" x 96" 1060 aluminum plate | 0.125" | 60" x 96" | O, H112, H32 |

| 0.125" x 60" x 120" 1060 aluminum plate | 0.125" | 60" x 120" | O, H112, H32 |

| 0.125" x 60" x 144" 1060 aluminum plate | 0.125" | 60" x 144" | O, H112, H32 |

| 0.125" x 60" x 240" 1060 aluminum plate | 0.125" | 60" x 240" | O, H112, H32 |

| 0.125" x 72" x 96" 1060 aluminum plate | 0.125" | 72" x 96" | O, H112, H32 |

| 0.125" x 72" x 120" 1060 aluminum plate | 0.125" | 72" x 120" | O, H112, H32 |

| 0.125" x 72" x 144" 1060 aluminum plate | 0.125" | 72" x 144" | O, H112, H32 |

| 0.125" x 72" x 240" 1060 aluminum plate | 0.125" | 72" x 240" | O, H112, H32 |

| 0.125" x 96" x 96" 1060 aluminum plate | 0.125" | 96" x 96" | O, H112, H32 |

| 0.125" x 96" x 120" 1060 aluminum plate | 0.125" | 96" x 120" | O, H112, H32 |

| 0.125" x 96" x 144" 1060 aluminum plate | 0.125" | 96" x 144" | O, H112, H32 |

| 0.125" x 96" x 240" 1060 aluminum plate | 0.125" | 96" x 240" | O, H112, H32 |

| 0.250" x 48" x 96" 1060 aluminum plate | 0.250" | 48" x 96" | O, H112, H32 |

| 0.250" x 48" x 120" 1060 aluminum plate | 0.250" | 48" x 120" | O, H112, H32 |

| 0.250" x 48" x 144" 1060 aluminum plate | 0.250" | 48" x 144" | O, H112, H32 |

| 0.250" x 48" x 240" 1060 aluminum plate | 0.250" | 48" x 240" | O, H112, H32 |

| 0.250" x 60" x 96" 1060 aluminum plate | 0.250" | 60" x 96" | O, H112, H32 |

| 0.250" x 60" x 120" 1060 aluminum plate | 0.250" | 60" x 120" | O, H112, H32 |

| 0.250" x 60" x 144" 1060 aluminum plate | 0.250" | 60" x 144" | O, H112, H32 |

| 0.250" x 60" x 240" 1060 aluminum plate | 0.250" | 60" x 240" | O, H112, H32 |

| 0.250" x 72" x 96" 1060 aluminum plate | 0.250" | 72" x 96" | O, H112, H32 |

| 0.250" x 72" x 120" 1060 aluminum plate | 0.250" | 72" x 120" | O, H112, H32 |

| 0.250" x 72" x 144" 1060 aluminum plate | 0.250" | 72" x 144" | O, H112, H32 |

| 0.250" x 72" x 240" 1060 aluminum plate | 0.250" | 72" x 240" | O, H112, H32 |

| 0.250" x 96" x 96" 1060 aluminum plate | 0.250" | 96" x 96" | O, H112, H32 |

| 0.250" x 96" x 120" 1060 aluminum plate | 0.250" | 96" x 120" | O, H112, H32 |

| 0.250" x 96" x 144" 1060 aluminum plate | 0.250" | 96" x 144" | O, H112, H32 |

| 0.250" x 96" x 240" 1060 aluminum plate | 0.250" | 96" x 240" | O, H112, H32 |

| 0.375" x 48" x 96" 1060 aluminum plate | 0.375" | 48" x 96" | O, H112, H32 |

| 0.375" x 48" x 120" 1060 aluminum plate | 0.375" | 48" x 120" | O, H112, H32 |

| 0.375" x 48" x 144" 1060 aluminum plate | 0.375" | 48" x 144" | O, H112, H32 |

| 0.375" x 48" x 240" 1060 aluminum plate | 0.375" | 48" x 240" | O, H112, H32 |

| 0.375" x 60" x 96" 1060 aluminum plate | 0.375" | 60" x 96" | O, H112, H32 |

| 0.375" x 60" x 120" 1060 aluminum plate | 0.375" | 60" x 120" | O, H112, H32 |

| 0.375" x 60" x 144" 1060 aluminum plate | 0.375" | 60" x 144" | O, H112, H32 |

| 0.375" x 60" x 240" 1060 aluminum plate | 0.375" | 60" x 240" | O, H112, H32 |

| 0.375" x 72" x 96" 1060 aluminum plate | 0.375" | 72" x 96" | O, H112, H32 |

| 0.375" x 72" x 120" 1060 aluminum plate | 0.375" | 72" x 120" | O, H112, H32 |

| 0.375" x 72" x 144" 1060 aluminum plate | 0.375" | 72" x 144" | O, H112, H32 |

| 0.375" x 72" x 240" 1060 aluminum plate | 0.375" | 72" x 240" | O, H112, H32 |

| 0.375" x 96" x 96" 1060 aluminum plate | 0.375" | 96" x 96" | O, H112, H32 |

| 0.375" x 96" x 120" 1060 aluminum plate | 0.375" | 96" x 120" | O, H112, H32 |

| 0.375" x 96" x 144" 1060 aluminum plate | 0.375" | 96" x 144" | O, H112, H32 |

| 0.375" x 96" x 240" 1060 aluminum plate | 0.375" | 96" x 240" | O, H112, H32 |

| 0.500" x 48" x 96" 1060 aluminum plate | 0.500" | 48" x 96" | O, H112, H32 |

| 0.500" x 48" x 120" 1060 aluminum plate | 0.500" | 48" x 120" | O, H112, H32 |

| 0.500" x 48" x 144" 1060 aluminum plate | 0.500" | 48" x 144" | O, H112, H32 |

| 0.500" x 48" x 240" 1060 aluminum plate | 0.500" | 48" x 240" | O, H112, H32 |

| 0.500" x 60" x 96" 1060 aluminum plate | 0.500" | 60" x 96" | O, H112, H32 |

| 0.500" x 60" x 120" 1060 aluminum plate | 0.500" | 60" x 120" | O, H112, H32 |

| 0.500" x 60" x 144" 1060 aluminum plate | 0.500" | 60" x 144" | O, H112, H32 |

| 0.500" x 60" x 240" 1060 aluminum plate | 0.500" | 60" x 240" | O, H112, H32 |

| 0.500" x 72" x 96" 1060 aluminum plate | 0.500" | 72" x 96" | O, H112, H32 |

| 0.500" x 72" x 120" 1060 aluminum plate | 0.500" | 72" x 120" | O, H112, H32 |

| 0.500" x 72" x 144" 1060 aluminum plate | 0.500" | 72" x 144" | O, H112, H32 |

| 0.500" x 72" x 240" 1060 aluminum plate | 0.500" | 72" x 240" | O, H112, H32 |

| 0.500" x 96" x 96" 1060 aluminum plate | 0.500" | 96" x 96" | O, H112, H32 |

| 0.500" x 96" x 120" 1060 aluminum plate | 0.500" | 96" x 120" | O, H112, H32 |

| 0.500" x 96" x 144" 1060 aluminum plate | 0.500" | 96" x 144" | O, H112, H32 |

| 0.500" x 96" x 240" 1060 aluminum plate | 0.500" | 96" x 240" | O, H112, H32 |

| 1.000" x 48" x 96" 1060 aluminum plate | 1.000" | 48" x 96" | O, H112, H32 |

| 1.000" x 48" x 120" 1060 aluminum plate | 1.000" | 48" x 120" | O, H112, H32 |

| 1.000" x 48" x 144" 1060 aluminum plate | 1.000" | 48" x 144" | O, H112, H32 |

| 1.000" x 48" x 240" 1060 aluminum plate | 1.000" | 48" x 240" | O, H112, H32 |

| 1.000" x 60" x 96" 1060 aluminum plate | 1.000" | 60" x 96" | O, H112, H32 |

| 1.000" x 60" x 120" 1060 aluminum plate | 1.000" | 60" x 120" | O, H112, H32 |

| 1.000" x 60" x 144" 1060 aluminum plate | 1.000" | 60" x 144" | O, H112, H32 |

| 1.000" x 60" x 240" 1060 aluminum plate | 1.000" | 60" x 240" | O, H112, H32 |

| 1.000" x 72" x 96" 1060 aluminum plate | 1.000" | 72" x 96" | O, H112, H32 |

| 1.000" x 72" x 120" 1060 aluminum plate | 1.000" | 72" x 120" | O, H112, H32 |

| 1.000" x 72" x 144" 1060 aluminum plate | 1.000" | 72" x 144" | O, H112, H32 |

| 1.000" x 72" x 240" 1060 aluminum plate | 1.000" | 72" x 240" | O, H112, H32 |

| 1.000" x 96" x 96" 1060 aluminum plate | 1.000" | 96" x 96" | O, H112, H32 |

| 1.000" x 96" x 120" 1060 aluminum plate | 1.000" | 96" x 120" | O, H112, H32 |

| 1.000" x 96" x 144" 1060 aluminum plate | 1.000" | 96" x 144" | O, H112, H32 |

| 1.000" x 96" x 240" 1060 aluminum plate | 1.000" | 96" x 240" | O, H112, H32 |

| 2.000" x 48" x 96" 1060 aluminum plate | 2.000" | 48" x 96" | O, H112, H32 |

| 2.000" x 48" x 120" 1060 aluminum plate | 2.000" | 48" x 120" | O, H112, H32 |

| 2.000" x 48" x 144" 1060 aluminum plate | 2.000" | 48" x 144" | O, H112, H32 |

| 2.000" x 48" x 240" 1060 aluminum plate | 2.000" | 48" x 240" | O, H112, H32 |

| 2.000" x 60" x 96" 1060 aluminum plate | 2.000" | 60" x 96" | O, H112, H32 |

| 2.000" x 60" x 120" 1060 aluminum plate | 2.000" | 60" x 120" | O, H112, H32 |

| 2.000" x 60" x 144" 1060 aluminum plate | 2.000" | 60" x 144" | O, H112, H32 |

| 2.000" x 60" x 240" 1060 aluminum plate | 2.000" | 60" x 240" | O, H112, H32 |

| 2.000" x 72" x 96" 1060 aluminum plate | 2.000" | 72" x 96" | O, H112, H32 |

| 2.000" x 72" x 120" 1060 aluminum plate | 2.000" | 72" x 120" | O, H112, H32 |

| 2.000" x 72" x 144" 1060 aluminum plate | 2.000" | 72" x 144" | O, H112, H32 |

| 2.000" x 72" x 240" 1060 aluminum plate | 2.000" | 72" x 240" | O, H112, H32 |

| 2.000" x 96" x 96" 1060 aluminum plate | 2.000" | 96" x 96" | O, H112, H32 |

| 2.000" x 96" x 120" 1060 aluminum plate | 2.000" | 96" x 120" | O, H112, H32 |

| 2.000" x 96" x 144" 1060 aluminum plate | 2.000" | 96" x 144" | O, H112, H32 |

| 2.000" x 96" x 240" 1060 aluminum plate | 2.000" | 96" x 240" | O, H112, H32 |

1060 Aluminum Seamless Tubes Inventory List

| Description | Wall Thickness | Outer Diameter (OD) | Temper |

| 0.035" x 0.250" 1060 aluminum seamless tube | 0.035" | 0.250" | O, H112 |

| 0.035" x 0.375" 1060 aluminum seamless tube | 0.035" | 0.375" | O, H112 |

| 0.035" x 0.500" 1060 aluminum seamless tube | 0.035" | 0.500" | O, H112 |

| 0.035" x 1.000" 1060 aluminum seamless tube | 0.035" | 1.000" | O, H112 |

| 0.035" x 2.000" 1060 aluminum seamless tube | 0.035" | 2.000" | O, H112 |

| 0.035" x 4.000" 1060 aluminum seamless tube | 0.035" | 4.000" | O, H112 |

| 0.049" x 0.250" 1060 aluminum seamless tube | 0.049" | 0.250" | O, H112 |

| 0.049" x 0.375" 1060 aluminum seamless tube | 0.049" | 0.375" | O, H112 |

| 0.049" x 0.500" 1060 aluminum seamless tube | 0.049" | 0.500" | O, H112 |

| 0.049" x 1.000" 1060 aluminum seamless tube | 0.049" | 1.000" | O, H112 |

| 0.049" x 2.000" 1060 aluminum seamless tube | 0.049" | 2.000" | O, H112 |

| 0.049" x 4.000" 1060 aluminum seamless tube | 0.049" | 4.000" | O, H112 |

| 0.065" x 0.250" 1060 aluminum seamless tube | 0.065" | 0.250" | O, H112 |

| 0.065" x 0.375" 1060 aluminum seamless tube | 0.065" | 0.375" | O, H112 |

| 0.065" x 0.500" 1060 aluminum seamless tube | 0.065" | 0.500" | O, H112 |

| 0.065" x 1.000" 1060 aluminum seamless tube | 0.065" | 1.000" | O, H112 |

| 0.065" x 2.000" 1060 aluminum seamless tube | 0.065" | 2.000" | O, H112 |

| 0.065" x 4.000" 1060 aluminum seamless tube | 0.065" | 4.000" | O, H112 |

| 0.083" x 0.250" 1060 aluminum seamless tube | 0.083" | 0.250" | O, H112 |

| 0.083" x 0.375" 1060 aluminum seamless tube | 0.083" | 0.375" | O, H112 |

| 0.083" x 0.500" 1060 aluminum seamless tube | 0.083" | 0.500" | O, H112 |

| 0.083" x 1.000" 1060 aluminum seamless tube | 0.083" | 1.000" | O, H112 |

| 0.083" x 2.000" 1060 aluminum seamless tube | 0.083" | 2.000" | O, H112 |

| 0.083" x 4.000" 1060 aluminum seamless tube | 0.083" | 4.000" | O, H112 |

| 0.120" x 0.250" 1060 aluminum seamless tube | 0.120" | 0.250" | O, H112 |

| 0.120" x 0.375" 1060 aluminum seamless tube | 0.120" | 0.375" | O, H112 |

| 0.120" x 0.500" 1060 aluminum seamless tube | 0.120" | 0.500" | O, H112 |

| 0.120" x 1.000" 1060 aluminum seamless tube | 0.120" | 1.000" | O, H112 |

| 0.120" x 2.000" 1060 aluminum seamless tube | 0.120" | 2.000" | O, H112 |

| 0.120" x 4.000" 1060 aluminum seamless tube | 0.120" | 4.000" | O, H112 |

1060 Aluminum Bar Inventory List

| Parameter | Common Specifications (inches) |

| Diameter (Round) | 0.250", 0.500", 1.000", 2.000", 3.000", 4.000" |

| Cross-Section (Square) | 0.5"×0.5", 1"×1", 2"×2" |

| Length | 96", 120", 144", 240" |

What is the difference between 1050 and 1060 Aluminum?

Both 1050 and 1060 aluminum are well-suited for applications requiring high purity, good corrosion resistance, and excellent machinability. However, 1060 is the preferred choice for applications that demand higher electrical conductivity and corrosion resistance.

| Property | 1050 Aluminum | 1060 Aluminum |

| Aluminum Content | Minimum 99.5% | Minimum 99.6% |

| Other Elements | Small amounts of iron (up to 0.40%) | Very low amounts of other elements |

| Strength | Slightly lower | Slightly higher |

| Workability | Good machinability; excellent forming characteristics | Excellent machinability; excellent forming characteristics |

| Corrosion Resistance | Good, but slightly lower than 1060 | Better, especially in atmospheric environments |

| Thermal Conductivity | Good | Higher |

| Electrical Conductivity | Good, but lower than 1060 | Higher (around 55% IACS) |

| Common Applications | Heat exchangers, chemical containers, decorative uses | Electrical conductors, chemical processing, decorative elements |

1060 Aluminum Sheet Advantages and Limitations

1060 Aluminum Sheet Advantages

| Advantages | Description |

| Cost-effective | 1060 aluminum alloy sheet is a highly cost-effective material. Due to its higher aluminum content and lower production costs, the 1060 aluminum alloy sheet can meet various application requirements while reducing overall manufacturing costs. This makes it a cost-effective choice in many industrial applications, especially for cost-sensitive projects. |

| Lightweight | 1060 aluminum alloy sheet is very light, with good specific strength and specific stiffness, which helps to reduce structural weight in many applications, especially in aviation, transportation, and construction fields. Reducing weight not only helps improve energy efficiency but also reduces transportation costs, enhancing overall performance. |

| Easy to Manufacture | 1060 aluminum alloy sheet has excellent machinability, making it easy to form, cut, and process. This characteristic of easy manufacturing allows it to adapt to various complex processing techniques, such as stamping, bending, and deep drawing, making it widely applicable in different manufacturing fields and meeting various design requirements. |

1060 Aluminum Sheet Limitations

Poor machinability in soft conditions and lower strength compared to alloy steels.

1060 Aluminum Sheet Manufacturing and Processing Characteristics

- Processing Techniques: supports gas welding, hydrogen atom welding, contact welding, but brazing is more difficult.

- Annealing: rapid annealing (350-410℃), high-temperature annealing (350-500℃) can optimize formability.

- Limitations: poor cutting performance, not suitable for high-precision machining.

Comparison of 1060 Aluminum Sheet with Other Common Aluminum Sheets

| Property | 1060 (Pure Aluminum) | 3003 (Aluminum-Manganese Alloy) | 5052 (Aluminum-Magnesium Alloy) |

| Main Composition | Al ≥ 99.6% | Al + approx. 1.2% Mn | Al + approx. 2.5% Mg |

| Strength | Low | Medium (about 20% higher than 1060) | High (one of the highest among commonly used medium-strength alloys) |

| Corrosion Resistance | Excellent | Very good (close to pure aluminum) | Very good (especially resistant to seawater) |

| Workability | Excellent (soft) | Good | Good (but harder than 1060) |

| Typical Applications | Decoration, reflective materials, electrical conductivity | Anti-rust aluminum, used for cookware, tank trucks, curtain walls | Marine, vehicles, pressure vessels, mobile phone frames |

Key Purchasing Considerations for 1060 Aluminum Sheet

As a manufacturer long dedicated to aluminum sheet production and export, Haomei Aluminum believes that selecting the right 1060 Aluminum Sheet is not only about the material itself, but more importantly about whether it truly matches the specific application scenario. Before purchasing, it is recommended to evaluate the material from multiple dimensions, including application purpose, temper condition, dimensional specifications, and quality standards.

Clarify the Application Scenario and Performance Requirements

1060 Aluminum Sheet is a typical 1000 series industrial pure aluminum sheet with an aluminum content of not less than 99.6%. Its key advantages include good electrical conductivity, high reflectivity, and excellent formability. As a result, it is widely used in decorative panels, electrical conductive components, reflective materials, and general stamping and bending applications.

It should be noted that 1060 aluminum sheet is not known for high strength. If a project has higher requirements for structural strength, fatigue resistance, or load-bearing capacity, we usually recommend that customers also compare medium-strength aluminum alloy sheets such as 3003 and 5052 to achieve a more balanced performance combination.

Select the Appropriate Temper According to the Processing Method

Different processing techniques place significantly different demands on aluminum sheet temper. Proper selection helps improve finished product yield and reduce processing costs:

- O temper (annealed): best plasticity and elongation, suitable for deep drawing, stretching, and complex forming

- H14 / H24 temper: balanced strength and formability, commonly used for decoration, general stamping, and industrial applications

- H18 temper: higher hardness and rigidity, suitable for applications with stricter deformation control requirements

Haomei Aluminum can provide targeted temper matching recommendations based on customers’ processing methods and end-use applications.

Confirm Dimensional Specifications and Equipment Compatibility

Before purchasing 1060 aluminum plate, existing processing equipment and production workflows should be fully evaluated, and thickness, width, and length should be reasonably confirmed to avoid subsequent processing limitations.

Standard supply thickness range: 0.2 mm – 50 mm

Fixed-length cutting and non-standard size customization are supported to meet engineering projects or bulk order requirements.

Emphasize Surface Quality and Post-Treatment Requirements

High-quality 1060 Aluminum Sheet should feature a flat surface, high smoothness, and be free from obvious rolling marks, scratches, or oxidation color differences. These factors are especially critical for subsequent processing and final appearance.

According to different usage environments and decorative requirements, aluminum sheets can be further processed with:

- Anodizing

- Coating

- Brushing or polishing

to enhance overall aesthetics, corrosion resistance, and service life.

Standards Compliance and Quality Assurance

Haomei Aluminum’s 1060 Aluminum Sheet is produced in strict accordance with major international and regional standards, including but not limited to:

GB/T 3880 (China)

ASTM B209 (USA)

All outgoing products can be supplied with complete material certification documents, ensuring stable and traceable chemical composition and mechanical properties.

Storage and Usage Precautions

To maintain the performance and appearance of industrial pure aluminum sheets, it is recommended to observe the following during storage and use:

- Store in a moisture-proof and acid/alkali-free environment

- Avoid heavy pressure, impacts, and surface scratches

- Keep the storage area dry, well-ventilated, and clean

With its high purity, excellent processing performance, and economical price, 1060 aluminum sheet has become a widely used basic material in both industrial and civilian fields. It is especially suitable for applications that do not require high strength but place emphasis on formability, electrical conductivity, or corrosion resistance.

1060 aluminum sheet, with its high purity, excellent formability, and low cost, is considered a "universal material" in industrial pure aluminum, especially suitable for scenarios that require low strength but complex forming. Its limitations lie in hardness and cutting performance, and alternative materials (such as 6061) should be chosen based on specific needs.

Products you may be interested in

- 1060 h12 aluminum sheet plate

- 1060 h24 aluminum sheet plate

- 1060-O Aluminum

- 1060-H14 Aluminum

- 1060-H16 Aluminum

- 1060-H18 Aluminum

- 1060 H22 Aluminum

- 1060 H26 Aluminum

- 1060 H28 Aluminum

Further reading

Users viewing this material also viewed the following

- 1060 Aluminum Mirror Sheet Coil

- 1060 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1060 Aluminum Plate for Curtain Wall Panel

- 1060 Aluminum Plate for Stamping Parts

- 1060 Aluminum Plate for Automotive Parts

- 1060 H24 Stamping Aluminum Plate for Aluminum Bottle Cap

- 5 Bar 1060 Aluminum Checker Plate

- 1060 Decorative Aluminum Plate

- 1060 Aluminum Tread Plate for Carriage Floor

- 1060 Hot-rolled Aluminum Plate for Lamps

- 1060 Embossed Aluminum Sheet for Automotive Heat Shields

- 1060 Aluminum Plate for Outdoor Billboard

- 1060 Aluminum Plate for Printed Circuit Board (PCB) Substrates

- 1060 Aluminum Plate for Aluminum-based Copper-clad Plate

- 1060 O Aluminium Strips for Transformers Winding

- 1060 Aluminum Circle Disc for Kitchenware

- 1060 O Aluminum Coil Strip for Mask Nose Clip

- 1060 Aluminum Strip for Vial Seals

- 1060 Aluminum Plate Strips for Capacitor Shells – High Purity & Durable

- 1060 Aluminum Sheet Coil for Pipeline Insulation

Recommended Content

- Key Differences Between 1050 and 1060 Aluminum What You Need to Know

- 1060-O Aluminum vs. 1100-H14 Aluminum: A Comparative Analysis

- 1060 Aluminum vs. 1100-H14 Aluminum: Key Differences

- Performance Comparison: 1060-H16 Aluminum vs. 1060-H24 Aluminum

- Differences Between 1060-H22 Aluminum and 1070-H22 Aluminum

- Comparison of 1060-H28 Aluminum vs. 1100-H28 Aluminum