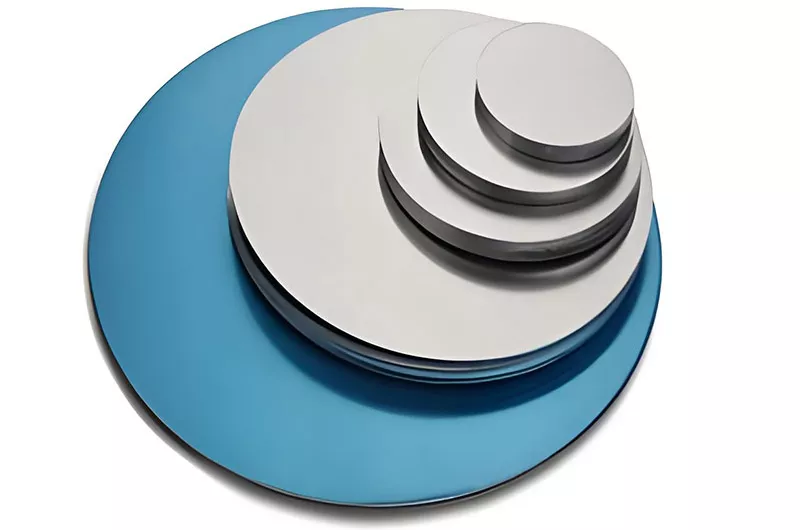

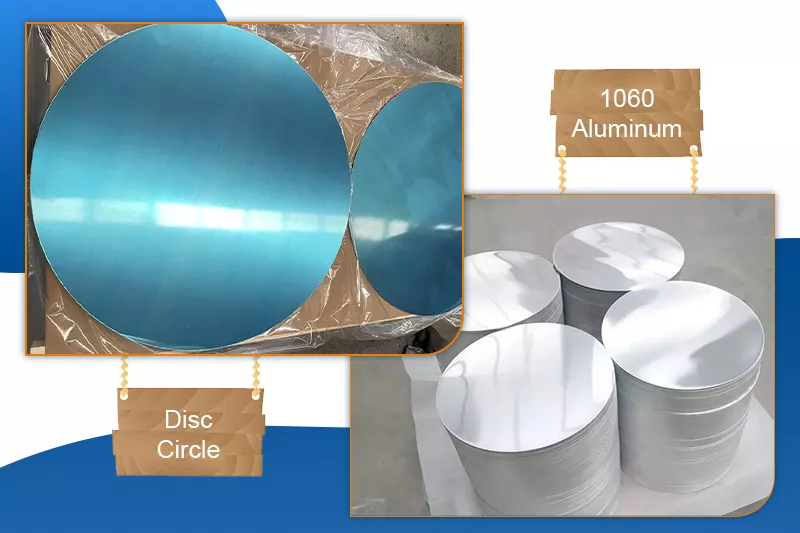

1060 Aluminum Disc Circle

1060 aluminum disc, also known as aluminum circle or aluminum sheet, is a high-purity aluminum product with an aluminum content of over 99.6%. This type of aluminum disc is renowned for its excellent processing performance, superior electrical conductivity, and wide range of applications.

1060 Aluminum Disc Circle features a bright and smooth surface, free from white rust, oil stains, edge damage, and other defects.

1060 aluminum disc is a circular aluminum product made from industrial pure aluminum 1060, offering excellent workability and a broad application spectrum.

Due to its low cost and mature manufacturing process (primarily cast rolling technology), 1060 aluminum disc is irreplaceable in applications requiring high formability but not high strength. Its corrosion resistance can be further enhanced through surface treatments.

1060 aluminum disc is a round-shaped commercial pure aluminum sheet, highly regarded for its light weight, corrosion resistance, and excellent thermal and electrical conductivity. It is easy to form, weld, and machine, making it an ideal choice for cookware, lighting reflectors, electrical components, decorative signs, and handicrafts. However, it is not suitable for structural applications requiring high strength.

1060 aluminum disc is widely recognized for its outstanding machinability and excellent electrical conductivity. Its high purity makes it perform exceptionally well in kitchenware, lighting equipment, electronics, and chemical containers.

Thanks to its light weight and ease of deep drawing and spinning, the 1060 aluminum disc is also extensively used in cookware, construction, and the automotive industry.

Specifications of 1060 Aluminum Circle Plate

| Specification | Details |

| Shape | Round circle, Rectangle, Oval circle, Elliptical circle |

| Alloy | 1100, 1050, 1060, 1070, 3003 DC CC Grade |

| Temper | O, H12, H14 |

| Thickness | 0.36mm ~ 5mm |

| Diameter | 120mm - 1000mm |

| Type | Discs, Sheet, Coil, Plate, Strip |

| Min Order | 500kgs each size |

| Payment | TT or Irrevocable LC at sight |

| Shape Options | Round, Disc, Rectangle, Oval circle, Elliptical circle |

Features of 1060 Aluminum Disc Circle

- High Purity: The aluminum content of 1060 aluminum discs is at least 99.6%, providing excellent electrical and thermal conductivity.

- Excellent Formability: Its high ductility makes it easy to form into discs, enabling the production of components with complex designs and precise dimensions without compromising integrity.

- Corrosion Resistance: The natural oxide layer on 1060 aluminum offers excellent resistance to corrosion, ensuring long-term durability and reliability, especially in humid and chemically exposed environments.

- Thermal and Electrical Conductivity: The high thermal and electrical conductivity of 1060 aluminum makes it suitable for applications in the electrical industry, such as heat exchangers and electrical connectors.

1060 Aluminum Circle Temper Grades

- O Temper (Annealed): Maximum formability (Elongation: ≥20–43%)

- H12/H22: Medium strength/formability

- H14/H24: Higher strength, moderate formability

- H18: Highest strength, limited formability.

A wide range of tempers (O, H12, H14, H16, H18) are available to meet different forming requirements.

| Product | Hardness / Strength Description | Typical Forming Processes & Applications |

| 1060 O Aluminum Circle | Fully Annealed (Softest) | Deep drawing and spinning. Suitable for deep pots, pressure cookers, and irregular-shaped cookware. |

| 1060 H12 Aluminum Circle | 1/4 Hard | Shallow drawing and bending. Suitable for frying pans, lids, and simple stamped parts. |

| 1060 H14 Aluminum Circle | 1/2 Hard (Medium Hard) | Stamping and general forming. The most widely used temper on the market, applied in signage and general cookware. |

| 1060 H16 Aluminum Circle | 3/4 Hard | Limited bending. Used for structural parts that require certain strength with relatively simple forming. |

| 1060 H18 Aluminum Circle | Full Hard | Very high strength, basically not suitable for drawing. Mainly used for flat decorative panels and reflectors. |

Selection Recommendations

- If deep drawing is required (drawing depth greater than 1/2 of the diameter): be sure to choose 1060 aluminum in O temper, otherwise the material is prone to cracking during the drawing process.

- If only simple bending or blanking is required: choosing H14 provides better flatness and rigidity.

- If high reflectivity is required: please consult the supplier about the availability of “DC (hot rolled) grade” material, which has a finer grain structure and delivers better reflectivity after polishing.

Table: Mechanical properties of different tempers

| Temper | Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| O | 0.2–0.5 | 60–100 | ≥15 | ≥20 |

| H24 | 0.2–0.5 | 95–135 | ≥70 | ≥6 |

| H18 | 0.2–0.5 | ≥125 | ≥85 | ≥2 |

1060 Aluminum Circle Surface Treatment Solutions

- 1060 Mill Finish Aluminum Circle: Basic condition with a smooth surface, free of obvious scratches and oil stains, suitable for products requiring further secondary processing.

- 1060 Bright / Reflective Aluminum Circle: Treated by special polishing or rolling processes to achieve high reflectivity, commonly used for lighting reflectors and decorative parts.

- 1060 Brushed Aluminum Circle: Features uniform fine-line textures on the surface, enhancing metallic appearance; commonly used for high-end cookware or appliance housings.

- 1060 Anodized Aluminum Circle: Forms a hard protective oxide layer on the surface and can be colored (gold, silver, coffee, etc.), significantly improving corrosion and wear resistance.

- 1060 Spray-Coated / Non-stick Coated Aluminum Circle: Customized for the cookware industry; the surface can be coated with PTFE (Teflon) or ceramic coatings to produce non-stick cookware.

- 1060 Color Coated / Pre-painted Aluminum Circle (Pre-roll Coating): A layer of PE (polyester) or PVDF (fluorocarbon) paint is applied during production. Rich and uniform colors, commonly used for traffic signs, interior decoration, and architectural panels.

- 1060 PE / PVC Film Protected Aluminum Circle: A transparent or blue plastic protective film is applied to the surface. This functional treatment is designed to prevent scratches during deep drawing, stamping, or transportation.

- 1060 Sandblasted Aluminum Circle: The surface is impacted by high-speed abrasive flow to create a uniform matte / frosted texture. Commonly used for high-end electronic enclosures or lighting fixtures; it effectively reduces glare and resists fingerprints.

| Standard Product Name | Key Advantages | Best Application Scenarios |

| 1060 Mill Finish Aluminum Circle | Low cost, excellent electrical conductivity, high processing flexibility | Electronic components, basic stamped parts, heat sinks |

| 1060 Bright / Reflective Aluminum Circle | Extremely high reflectivity (80%–95%), high visual brightness | Commercial lighting reflectors, solar collectors, decorative trims |

| 1060 Brushed Aluminum Circle | Silk-like texture, effectively conceals daily scratches | Home appliance control panels, high-end cookware housings, electronic products |

| 1060 Anodized Aluminum Circle | High surface hardness, excellent corrosion resistance, long-lasting colors | Architectural exterior decoration, cosmetic bottle caps, outdoor signage |

| 1060 Non-stick Coated Aluminum Circle | Outstanding non-stick performance, high temperature resistance, easy to clean | Frying pans, woks, pizza baking trays, rice cooker inner pots |

| 1060 Color Coated Aluminum Circle | Strong paint adhesion, good color consistency, excellent weather resistance | Traffic signs, aluminum curtain walls, interior ceilings |

| 1060 Sandblasted Aluminum Circle | Fine matte texture, diffuse reflection, fingerprint-resistant | Digital accessories, office lighting fixtures, high-end gift boxes |

| 1060 Embossed Aluminum Circle | High structural strength, anti-slip and scratch-resistant, increased surface area | Freezer / refrigerator liners, industrial anti-slip parts, heat exchange equipment |

When offering these surface treatments, please note the difference between “DC (hot rolled)” and “CC (continuous cast)” slabs for 1060 aluminum circles:

If anodizing or deep drawing is required, it is recommended to use DC-grade slabs, as they feature a finer grain structure, more uniform color after anodizing, and a lower risk of cracking during drawing.

1060 DC / CC Aluminum Circle

| Comparison Item | 1060 DC Aluminum Circle | 1060 CC Aluminum Circle |

| Deep Drawing Performance | Excellent, suitable for complex deep drawing / spinning parts | Average, not suitable for deep drawing |

| Surface Quality | Better; no color difference after anodizing, suitable for surface treatments (coating / anodizing) | Relatively average |

| Cost | Higher | More price-competitive |

| Typical Applications | High-quality cookware (non-stick pans / pressure cookers), reflectors, precision electronic components | General cookware, simple drawn parts, products with low requirements for surface quality and deep drawing |

1060 DC Aluminum Circle

DC stands for Direct Chill Casting (hot rolling). In this process, aluminum ingots are heated and rolled at high temperatures.

- Key features: excellent grain structure and high ductility.

- Best use: deep drawing. If you are manufacturing deep pots, pressure cookers, or complex industrial parts that require large deformation without cracking, the DC process is essential.

- Surface quality: generally higher; more suitable for anodizing and polishing.

- Typical applications: high-end cookware, pressure cookers, lighting reflectors, and high-quality electronic components.

1060 CC Aluminum Circle

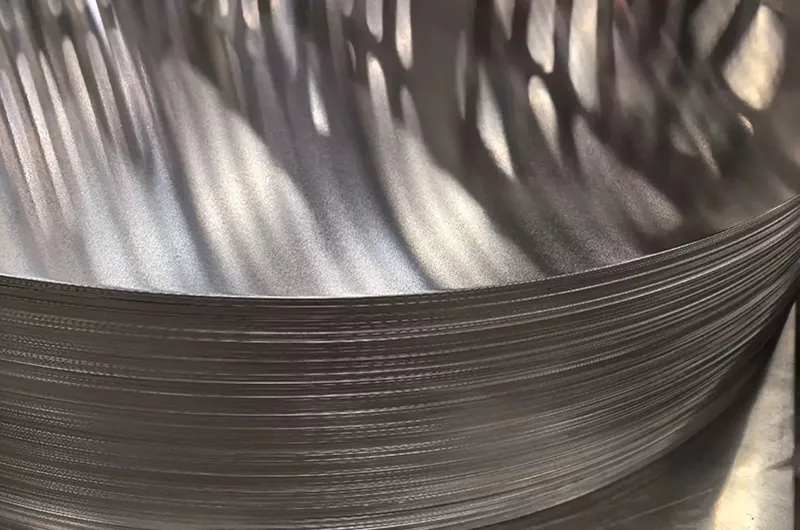

CC stands for Continuous Casting (cast rolling). This process casts molten aluminum directly into coils, followed by cold rolling.

- Key features: more economical price and slightly higher hardness.

- Best use: spinning and simple stamping. Ideal for products that do not require extreme stretching.

- Surface quality: good, but compared with DC material, more “orange peel” or grainy appearance may occur during deep drawing.

- Typical applications: shallow trays, pot lids, road signs, nameplates, and general household utensils.

Selection Recommendations

- Pursuing high quality + complex processing: choose 1060 DC

- Cost control + simple processing: choose 1060 CC or 1160 CC

- Slightly higher strength requirement: consider 1160 CC

1060 Aluminum Discs Properties

Material Quality

Alloy: 1060 Aluminum Discs are crafted from high-purity 1060 aluminum, known for its deep drawing quality and superior spinning characteristics.

Forming and Anodizing: They exhibit excellent forming capabilities, making them ideal for various applications. The discs respond well to anodizing processes without developing any four ears (creases or defects).

Reflectivity and Polishing

Reflective Properties: The discs have excellent reflective qualities, which enhance their suitability for applications requiring high reflectivity.

Polishing: They are well-suited for polishing, providing a smooth and lustrous finish that is ideal for decorative and functional purposes.

Anodizing Quality

Anodizing Performance: The aluminum discs possess exceptional anodizing quality, making them appropriate for both standard and hard anodizing processes.

Enameling: They also support enameling applications, ensuring durability and resistance to wear.

Surface Finish

Clean Surface: The discs feature a clean, smooth surface with precise edges, thanks to their hot-rolled quality and fine grain structure.

Deep Drawing: After deep drawing, the discs do not exhibit loop lines or other surface defects, maintaining a high-quality appearance.

Color Quality: The discs are excellent candidates for pearl color anodizing, resulting in a refined and aesthetically pleasing finish that adds value to the end product.

Advantages of 1060 Aluminum Discs

| Advantage | Description |

| Conductivity | Electrical: High purity ensures excellent electrical conductivity, ideal for efficient electrical transmission. |

| Thermal: Superior thermal conductivity aids in effective heat dissipation, preventing overheating. | |

| Formability | Ease of Forming: Easily shaped into various designs through processes like deep drawing and spinning. |

| Design Flexibility: Allows for intricate and customized shapes. | |

| Weldability | Excellent weldability facilitates easy joining of components, simplifying the manufacturing process. |

| Cost-Effectiveness | More affordable compared to alloyed aluminum counterparts, providing good performance at a lower cost. |

Haomei 1060 aluminum disc

Comprehensive Specifications

Size Range: Available in a wide range of sizes, including both standard and specialized discs with thicknesses from 0.2 mm to 8 mm.

Surface Quality

Surface Finish: Discs are produced with a flawless surface, free from visible defects such as scratches, oil stains, oxidation, and black spots, ensuring high standards of appearance and performance.

Edge Quality

Edge Cleanliness: For discs with a thickness greater than 0.5 mm, the edges are meticulously maintained to be neat and burr-free, ensuring a premium finish and reducing the need for additional processing.

Defect-Free Assurance

Quality Standards: Discs are guaranteed to be free from common defects including white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches, and coil set, ensuring consistently high-quality and defect-free products.

Advanced Production Equipment

Efficiency: Employs state-of-the-art production equipment to enhance manufacturing efficiency and material utilization, shortening production cycles and improving service responsiveness.

1060 Aluminium Circle Diameter Tolerance

| Nominal Diameter | Tolerance |

| Multiple of 5mm | +/- 0.5mm |

| Not multiple of 5mm | +/- 3.0mm |

Mechenical Property of 1060 Aluminum Circle

| Alloy | Temper | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 1060 | 0 | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 |

Chemical Compositions of 1060 Aluminium Circle

| Alloy | Min. AL | Si | Fe | Cu | Mn | Mg | Ni | Zn | V | Other |

| 1050 | 99.5 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.05 | 0.03 |

| 1060 | 99.6 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.05 | 0.03 |

| 1070 | 99.7 | 0.25 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.05 | 0.03 |

| 1100 | 99 | 0.95 | 0.95 | 0.05-0.2 | 0.05 | - | - | 0.1 | - | 0.05 |

| 3003 | 96.75 | 0.7 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.15 |

Applications of 1060 Aluminum Circle

Typical Application Scenarios of 1060 Aluminum Disc Circle

| Application Field | Specific Uses | Advantages Description |

| Cookware and Kitchen Utensils | Pots, frying pans, kettles, and pressure cooker bases | Non-toxic surface, excellent thermal conductivity, corrosion-resistant to food acids, suitable for hard anodizing or enamel coating processes |

| Lighting and Reflectors | Lampshades, streetlight reflectors, downlight fixtures | High reflectivity (over 85%), good polishability, excellent heat dissipation |

| Printing Industry (CTP Plates) | Offset printing plate substrates | Uniform anodized surface ensures image adhesion and provides good dimensional stability during high-speed printing |

| Industrial and Chemical Equipment | Chemical storage tanks, electrical housings, radiator components | Good corrosion resistance in humid or chemical environments |

| Decorative and Architectural Elements | Nameplates, ceilings, traffic signs | Excellent weather resistance, suitable for pearlescent anodizing treatment |

- Cookware and Kitchen Utensils: 1060 aluminum discs are widely used in the manufacture of cookware such as frying pans and woks. Its excellent thermal conductivity ensures even heat distribution, improving cooking performance. Cookware and heating plate substrates (commonly 0.4–0.8mm thickness). Due to its deep drawing properties, it is suitable for use in non-stick pans, pressure cookers, and soup pots.

- Lighting Industry: 1060 discs are often used in the production of lampshades and reflectors due to their high reflectivity and corrosion resistance, which are essential for lighting applications.

- Traffic Signs and Decorations: The durability and formability of 1060 discs make them ideal for traffic signs and decorative items.

- Architectural Decoration: Curtain walls, decorative panels (surface can be anodized)

- Packaging Materials: Derived products such as aluminum foil and aluminum strip

- Industry: Due to its workability, 1060 is used in automotive parts, electrical components, aluminum shells for capacitors, lighting fixtures, transformer parts, and mechanical equipment.

Kitchen Utensils

Cookware and Cooking Tools: The 1060 aluminum disc is widely used in the production of cookware, such as pots and frying pans, due to its excellent thermal conductivity. The aluminum disc provides even heat distribution, which improves cooking efficiency and ensures that food is evenly heated, reducing localized overheating or burning. This even heat transfer helps in better temperature control and enhances cooking results.

Lighting Equipment

Light Fixtures and Lamp Shades: The 1060 aluminum circle is used in making light fixtures and lamp shades, as its excellent reflective properties can significantly enhance lighting performance. The high-gloss surface of the aluminum disc effectively reflects light, increasing the brightness and coverage of the light source. This makes the 1060 aluminum disc an ideal material for producing high-efficiency lighting equipment, improving indoor lighting quality.

Signs and Nameplates

Durable Signs and Nameplates: Due to its corrosion resistance and good workability, the 1060 aluminum circle is highly suitable for making traffic signs, labels, and decorative nameplates. The durability and lightweight characteristics of the aluminum disc make it perform well in outdoor environments, resisting various weather conditions and maintaining long-term clarity and readability.

Electronic Products

Appliance Housings and Heat Sinks: The 1060 aluminum disc is used for manufacturing housings and heat sinks for electronic products, effectively dissipating heat and extending the lifespan of the equipment. The good thermal conductivity of aluminum helps in quickly dissipating the heat generated by electronic components, preventing overheating and ensuring the stability and reliability of the device.

Reflectors

Traffic Signs and Signal Lights: Due to its high reflectivity, the 1060 aluminum disc is widely used in reflective applications such as traffic signs, signal lights, and reflectors. These applications require materials with very high light reflectance to enhance visibility and safety, particularly in low-light or nighttime conditions.

1060 Aluminum Circle Application Selection Guide

| Application Field | Recommended Temper | Key Selection Rationale |

| Non-stick Cookware | 1060-O | O temper (annealed soft state) offers the highest ductility and is suitable for deep drawing processes. Non-stick pans usually have deep bodies and must use soft aluminum to prevent cracking during forming. |

| LED Reflector | 1060-H18 | H18 (full hard) provides extremely high hardness and surface flatness. Aluminum circles in full hard temper are easier to achieve mirror polishing or anodizing, resulting in excellent light reflectivity. |

| Traffic Signs | 1060-H24 | H24 (half-hard / partially annealed) strikes a balance between strength and formability. It ensures outdoor signs resist deformation under wind and weather while still allowing edge bending. |

| Heat Sinks | 1060-H14 | H14 (half-hard) balances thermal conductivity and structural strength. Heat sink fins or bases require certain rigidity, and H14 ensures stability after assembly. |

| Pressure Cookers | 1060-O | Similar to non-stick cookware, pressure cookers involve deep drawing processes and require good toughness under pressure. O temper is the preferred choice for safety and formability. |

| Lampshades | 1060-H16 | H16 (3/4 hard) is suitable for spinning processes. Compared with O temper, it provides better support, keeping lamp edges firm and resistant to deformation. |

Selection Advice: Why Is Temper So Important?

When selecting 1060 aluminum circles, you should focus on the following three key dimensions:

Processing method:

For deep drawing (such as high-depth cylindrical parts), be sure to choose O temper.

For spinning processes, H14 or H16 is usually selected to achieve better surface finish and structural strength.

Strength requirements:

H18 offers the highest strength but almost no ductility, while O temper is the softest with the best formability.

Surface treatment:

If anodizing or mirror finishing is required in subsequent processing, 1060 pure aluminum is an ideal choice. However, please note that aluminum circles in H temper usually achieve better gloss after anodizing than those in O temper.

Other Aluminum Circle Applications

| Series | Alloy | Characteristics | Typical Applications |

| 1 series | 1050 | Aluminum content not less than 99.5%, very high cost performance, excellent thermal conductivity. | Ordinary kitchen sinks, plates, daily household utensils. |

| 1060 | Aluminum content not less than 99.6%, excellent electrical and thermal conductivity and reflectivity. | LED lamp reflectors, heat dissipation base plates, chemical gaskets. | |

| 1070 | Higher purity, extremely high brightness after surface anodizing. | High-end reflectors, decorative parts, electronic bus bars. | |

| 1100 | Contains a small amount of copper, slightly higher strength than 1060, attractive surface appearance. | Deep-drawn cookware, printed photosensitive plates, gifts. | |

| 3 series | 3003 | Manganese added, about 20% higher strength than 1 series, strong corrosion resistance. | Non-stick cookware substrates, rice cooker inner pots, pressure cookers. |

| 3004 | Higher strength than 3003, greater hardness, good compressive resistance. | High-end cookware, lamp holder components, thin-wall deep-drawn parts. | |

| 3005 | Good corrosion resistance, excellent paint coating adhesion. | Color-coated aluminum circles, architectural decorative components. | |

| 3105 | Moderate strength, often produced with recycled material, environmentally friendly and economical. | Simple cookware, sunshades, decorative spinning parts. | |

| 5 series | 5052 | Medium to high strength, fatigue resistant, excellent salt spray corrosion resistance. | Traffic signs, aviation fuel tank components, high-end enclosures. |

| 5754 | Excellent weldability, outstanding resistance to industrial and marine corrosion. | Marine equipment, chemical containers, automotive structural parts. | |

| 5083 | The strongest alloy in the 5 series, outstanding low-temperature performance. | Pressure vessels, LNG tank components, military parts. | |

| 8 series | 8011 | Good stamping consistency, balanced tensile strength, low earing rate. | Anti-counterfeit bottle caps, pharmaceutical bottle seals, sealing lids, shallow drawn cups. |

Processing Performance Advantages of 1060 Aluminum Disc Circle

| Characteristic | Specific Performance | Application Value |

| Deep Drawing Performance | High plasticity supports complex drawing and forming without cracking | Stamped cookware, concave utensils |

| Spinning Performance | Better spinning adaptability than other metals | Forming of lighting products and handicrafts |

| Surface Treatment | Suitable for spraying/anodizing/sandblasting; orange peel texture provides anti-slip and decorative effects | Architectural decoration, industrial anti-slip applications |

| Weldability | Compatible with gas welding, atomic hydrogen welding, and resistance welding | Welding of structural parts |

1060 Aluminum Disc Circle Manufacturing and Temper Variants

Production steps: melting → rolling/extruding → blanking into discs → annealing (stress relief) → finishing .

Temper codes:

- O = fully annealed (softest),

- H12, H14, H18, H24, etc. = varying levels of strain hardening, increasing strength while retaining formability .

1060 Aluminum Disc Circle Production and Quality Control

The production of 1060 aluminum discs follows a strict process to ensure product consistency and performance:

Raw Material Selection: Uses high-purity aluminum ingots with controlled impurity content.

Processing Technology:

- Hot Rolling/Cold Rolling: Achieves precise thickness tolerance (e.g., ±0.02 mm for thin gauge products).

- Stamping/Spinning: Used to form cookware and lighting components, preventing cracking.

- Annealing: Performed at 343°C (650°F) to relieve stress and enhance formability.

Quality Assurance:

- Grain size control to prevent "orange peel" or stretch marks during deep drawing.

- Surface inspection to eliminate scratches, oil stains, or oxidation defects.

- Dimensional inspection (diameter tolerance: ±0.5 mm for multiples of 5 mm).

1060 Aluminum Disc Circle Comparison to Common Alloys

| Alloy | Al Content | Yield Strength | Formability | Corrosion Resistance |

| 1060 | 99.6 % | ~35 MPa | Excellent | Very high |

| 3003 | 97 % | ~80 MPa | Good | Medium |

| 5052 | 95 % | ~228 MPa | Fair | High |

1060 Aluminum Disc Circle Selection Guide and Technical Recommendations

Temper Selection:

- For deep drawing/spinning processes (e.g., cookware pots), use O temper.

- For structural parts requiring high rigidity (e.g., lamp bases), choose H24/H18 temper.

Thickness-to-Diameter Ratio:

- Spinning applications: For diameters <500 mm, select thinner discs (0.5–3 mm).

- Pressure vessels: Choose thicker discs (>4 mm) in H24 temper.

Comparison with Competing Alloys:

- Compared to 1050A: 1060 offers 5–10% higher tensile strength and better formability.

- Compared to 3003: 1060 provides excellent electrical conductivity but lower strength; 3003 is better suited for high-stress applications.

Cost-Effectiveness Trade-off:

1060 is 3–8% more expensive than 1050A, but for applications requiring higher formability or conductivity, it remains a reasonable choice.

1060 Aluminum Disc Circle Limitations

Compared with 3xxx/5xxx alloys, it has lower mechanical strength, limiting its use in structural applications. It is non-heat-treatable; strength can only be improved through cold working.

For special applications requiring precise tolerances (such as CTP plates or spun cookware), 1060 remains the preferred choice due to its balanced performance and manufacturing flexibility.

Processing Techniques for 1060 Aluminum Disc Circle

The 1060 aluminum disc circle can be processed using various techniques to suit different applications.

| Processing Technique | Process Description | Application Advantages |

| Stamping | Using molds to shape the 1060 aluminum disc into various forms under high pressure. This technique is suitable for producing complex geometries or specific parts. | Efficiently produces a large number of consistent aluminum discs, ensuring precise dimensions and shapes. Ideal for high-volume production, maintaining high processing accuracy and surface quality. |

| Stretching | Applying external force to thin and elongate the aluminum disc, used to manufacture deep parts. | Provides high material forming flexibility, allowing thickness adjustments to meet different design requirements. Suitable for producing deep-drawn components. |

| Rolling | Compressing the aluminum disc between two or more rollers to reduce its thickness, meeting specific application needs. | Efficiently produces thin aluminum sheets while maintaining material consistency and uniformity. Ideal for high-volume production with strict thickness control requirements. |

| Cutting | Cutting the aluminum disc into predetermined sizes and specifications using laser cutting, mechanical cutting, or water jet cutting. | Provides precise cutting of aluminum discs, suitable for customized and small-batch production. Offers high precision in size control and flexible design options. |

Manufacturing Process for 1060 Aluminum Disc Circle

Manufacturing Process

- Stamping/Punching: Using molds to punch aluminum coils into discs, which is ideal for mass production.

- Spinning: Used for forming cookware or reflectors without compromising structural integrity.

- Quality Control: Includes ultrasonic thickness measurement, chemical testing, and edge deburring to ensure a smooth surface.

Our factory strictly follows the detailed manufacturing process outlined below to ensure the quality and performance of 1060 aluminum discs:

- Selection of High-Quality Raw Materials: We use top-grade aluminum alloy materials, ensuring that alloy composition, oxygen content, and hardness meet the standards.

- Controlled Production Process: At each processing stage, including temperature, pressure, speed, and cooling methods, strict controls are implemented to ensure consistency and product quality.

- Equipment Maintenance: We regularly clean and maintain equipment to ensure production process stability and high product quality.

- Inspection and Quality Control: Each batch of products undergoes rigorous inspection of dimensions, surface finish, hardness, and other parameters to ensure compliance with standards.

Choosing the Right Processing Technique for Aluminum Disc Circle

| Application Type | Processing Technique | Description |

| High-Strength Products (e.g., Pressure Vessels) | Stretching | Stretching the aluminum sheet into the desired shape using molds, enhancing strength and durability through plastic deformation. Suitable for high-strength products such as pressure vessels. |

| Rolling | Compressing the aluminum sheet between multiple rollers to form thin sheets or plates, improving uniformity and strength. Suitable for manufacturing large and structural products. | |

| High-Precision Products (e.g., Aluminum Caps) | Stamping | Using molds to stamp the aluminum disc, cutting or forming it quickly and precisely into complex shapes. Suitable for high-precision components like aluminum caps. |

| Cutting | Cutting the aluminum disc using laser or mechanical cutting techniques, providing high precision and good surface finish. Suitable for applications requiring detailed processing, such as aluminum caps. |

Advantages of 1060 Aluminum Over Other Alloys

- Cost-effective: Lower cost compared to 3003 or 5052 alloys.

- Environmentally Friendly: Recyclable and meets environmental standards.

- Versatility: Suitable for both industrial and decorative applications.

Precautions for 1060 Aluminum Disc Circle

- Selection Advice: Choose the appropriate temper based on the application (e.g., O temper is suitable for deep drawing, H24 for moderate strength requirements).

- Surface Quality: Minor scratches may occur after stamping; surface treatment requirements should be communicated in advance.

1060 aluminum discs are highly regarded for their high purity, excellent formability, corrosion resistance, and superior thermal and electrical conductivity, making them indispensable materials in industries such as cookware manufacturing, lighting, and signage.

Export Countries for 1060 Aluminum Disc Circle

Vietnam, Uzbekistan, Ukraine, Turkey, Thailand, Slovenia, Singapore, Sweden, Saudi Arabia, Romania, Qatar, Paraguay, Poland, Pakistan, Mexico

1060 Aluminum Circle Frequently Asked Questions

The aluminum circles from the same batch have different colors. Is there a difference in material quality?

Please rest assured that the material of 1060 aluminum circles from the same batch is completely consistent. The color difference is mainly caused by variations in the thickness of the surface oxide film, which is a normal phenomenon and does not affect material properties or processing performance. If you have very high requirements for appearance consistency, we can provide surface treatment services such as anodizing to ensure uniform color.

1060 aluminum circles tend to crack during stamping or deep drawing. Which temper is the most suitable?

- The temper of 1060 aluminum circles directly affects processing performance. O temper (soft state) offers the best plasticity and is suitable for deep drawing and complex stamped parts.

- H12 / H14 tempers provide certain strength and are suitable for shallow stamping or products that do not require deep drawing.

- H18 temper has the highest hardness and poor ductility, and is not recommended for stamping or drawing.

If your product involves deep drawing, it is recommended to choose O temper. We can supply aluminum circles in the corresponding temper and provide free guidance on drawing process parameters.

Can 1060 aluminum circles undergo secondary processing such as bending and welding?

Absolutely. 1060 pure aluminum has excellent plasticity and weldability, and can be subjected to secondary processing such as bending, stamping, drawing, and TIG welding. It is recommended to use pure aluminum welding wire during welding. The strength after welding is slightly lower than that of the base material. If you have specific requirements for weld strength, we can also provide guidance on subsequent heat treatment.

How should aluminum circles be stored to prevent oxidation and deformation?

Please pay attention to the following three points during storage:

- Keep the warehouse dry and well ventilated, control relative humidity below 60%, and avoid outdoor storage.

- Wrap the aluminum circle surface with PE protective film and seal it with moisture-proof cartons on the outside to prevent contact with moisture and corrosive gases.

- Control stacking height; it is recommended not to exceed 50 pieces per stack, or use layered racks to avoid deformation caused by excessive pressure.

Is 1060 aluminum circle resistant to acids and alkalis? Can it be used in humid environments?

1060 pure aluminum has relatively good corrosion resistance, but long-term exposure to strong acids, strong alkalis, or salt spray environments may still cause corrosion. If used in humid environments, it is recommended to apply surface treatments such as anodizing or coating to form a protective layer, which can significantly enhance corrosion resistance. When used in cookware, the oxide layer on the surface is non-toxic and safe for use.

What is the hardness of 1060 aluminum circles? What are the differences between O temper and H temper, and what products are they suitable for?

The hardness varies significantly among different tempers:

- O temper 1060 aluminum circles offer the best plasticity and are suitable for deep drawn parts, tableware, and signage.

- H12 temper provides certain strength and is suitable for shallow stamped parts and decorative components.

- H14 temper has a hardness of approximately 40–45 HB, offering higher strength and suitable for brackets and hardware accessories.

- H18 temper has a hardness of approximately 60–65 HB, the highest hardness, and is suitable for wear-resistant components.

You can choose the appropriate temper based on your product processing requirements.

Compared with 3003 and 5052 aluminum circles, what are the advantages and disadvantages of 1060 aluminum circles?

| Alloy | Advantages | Disadvantages | Typical Applications |

| 1060 | High purity, excellent plasticity, easy processing, low cost | Low strength, poor wear resistance | Cookware, signage, deep drawn parts |

| 3003 | Higher strength than 1060, good corrosion resistance | Slightly lower plasticity than 1060 | Fuel tanks, pipelines, light stamped parts |

| 5052 | High strength, excellent corrosion resistance | Higher cost, average plasticity | Marine components, high-requirement hardware parts |

If your product does not require high strength and prioritizes cost-effectiveness, 1060 aluminum circles are the best choice.

Do different thicknesses of 1060 aluminum circles affect processing performance?

Yes, they do.

- Thin material (≤1.0 mm) offers better plasticity and is suitable for stamping, bending, and signage production.

- Thick material (>1.0 mm) provides slightly higher strength and is suitable for drawing, cookware substrates, and brackets. However, deep drawing of thick material requires higher die pressure. It is recommended to use O temper to reduce the risk of cracking.

Can you provide samples? Is the sample quality consistent with bulk production?

Yes, free samples are available. The sample specifications and temper are exactly the same as bulk production, ensuring consistent quality. You only need to provide the delivery information, and we will ship the samples within 24 hours. If you require customized thickness or temper samples, please feel free to let us know.

For bulk purchases, can you ensure stable quality for each batch of aluminum circles?

Yes, we can guarantee it. We have a comprehensive quality management system covering raw material procurement, rolling, cutting, and packaging, with strict inspection standards at every stage. For mass production, we use aluminum ingots from the same batch and unified process parameters to ensure consistent material properties, dimensions, and appearance across each batch. In addition, we can sign a quality assurance agreement with you to clearly define quality standards and after-sales responsibilities.

Further reading

- 1060 Aluminum Coil

- 1060 Aluminum Plate Sheet

- 1060 h12 aluminum sheet plate

- 1060 h24 aluminum sheet plate

- 1060-O Aluminum

- 1060-H14 Aluminum

- 1060-H16 Aluminum

- 1060-H18 Aluminum

- 1060 H22 Aluminum

- 1060 H26 Aluminum

- 1060 H28 Aluminum

- 1060 Aluminum Strip

- 1060 Aluminum Foil

Users viewing this material also viewed the following

- 1060 Aluminum Circle Disc for Kitchenware

- 1060 O Aluminium Strips for Transformers Winding

- 1060 Aluminum Mirror Sheet Coil

- 1060 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1060 Aluminum Plate for Curtain Wall Panel

- 1060 Aluminum Plate for Stamping Parts

- 1060 Aluminum Plate for Automotive Parts

- 1060 H24 Stamping Aluminum Plate for Aluminum Bottle Cap

- 5 Bar 1060 Aluminum Checker Plate

- 1060 Decorative Aluminum Plate

- 1060 Aluminum Tread Plate for Carriage Floor

- 1060 Hot-rolled Aluminum Plate for Lamps

- 1060 O Aluminum Coil Strip for Mask Nose Clip

- 1060 Aluminum Strip for Vial Seals

- 1060 Embossed Aluminum Sheet for Automotive Heat Shields

- 1060 Aluminum Plate Strips for Capacitor Shells – High Purity & Durable

- 1060 Aluminum Plate for Outdoor Billboard

- 1060 Aluminum Plate for Printed Circuit Board (PCB) Substrates

- 1060 Aluminum Sheet Coil for Pipeline Insulation

- 1060 Aluminum Plate for Aluminum-based Copper-clad Plate

Recommended Content

- Key Differences Between 1050 and 1060 Aluminum What You Need to Know

- 1060-O Aluminum vs. 1100-H14 Aluminum: A Comparative Analysis

- 1060 Aluminum vs. 1100-H14 Aluminum: Key Differences

- Performance Comparison: 1060-H16 Aluminum vs. 1060-H24 Aluminum

- Differences Between 1060-H22 Aluminum and 1070-H22 Aluminum

- Comparison of 1060-H28 Aluminum vs. 1100-H28 Aluminum