8011 H14 aluminum is a non-heat-treatable alloy foil/strip that is widely used in the packaging field, especially in bottle cap manufacturing.

With its balanced strength, excellent formability, and high hygiene standards, 8011 H14 aluminum has become the preferred material for high-end bottle caps and sealing products.

The H14 temper of 8011 aluminum alloy is a widely used material, especially in the packaging industry. This alloy belongs to the 8000 series and is mainly composed of iron and silicon.

- Bottle cap manufacturing: Due to strict thickness tolerance, cap output per ton is 5–10% higher than competitors.

- Sustainability: Highly recyclable (energy saving: 95% compared to primary production).

8011 H14 aluminum is a versatile and cost-effective alloy optimized for precision-formed packaging. Its balanced mechanical properties, controllable anisotropy, and compliance with international standards make it an indispensable material for bottle caps, aluminum foil, and industrial components.

The H14 temper indicates strain hardening (cold working) to a “semi-hard” condition, between annealed (O) and full hard (H18) states.

8011 H14 aluminum combines medium strength, excellent formability, and corrosion resistance. Its low earing rate (<2%) ensures minimal material waste during deep drawing, which is critical for high-speed production of packaging components.

Aluminum 8011 H14 Core Characteristics and Advantages

- Excellent deep drawing performance: Low earing rate, easily stamped into complex bottle cap shapes (e.g., for alcoholic beverages, cosmetics, pharmaceutical bottles)

- High surface quality: Clean and free of foreign matter, reaching brushing grade A standard, meeting hygiene requirements for food and pharmaceutical packaging

- Barrier and sealing properties: Effectively moisture-proof, light-blocking, protects contents from contamination

- Corrosion resistance: Suitable for environments with long-term contact with liquids or chemicals

Aluminum 8011 H14 Product Specifications

- Thickness: 0.15–0.5 mm (tolerance: ±0.005 mm)

- Width: 330 mm to 1250 mm (tolerance: +0.5/–0 mm)

- Thickness tolerance: ±0.005 mm

- Width tolerance: ±1 mm

- Surface finish: Smooth, free of scratches or visible defects

- Standards compliance: ASTM B209, EN 573-3, ISO 6361-2

- Testing: Earing rate <2%, diagonal difference ≤1 mm

- Other tempers: Besides H14, also available in H13, H16, H18, O temper, and other hardness levels

Aluminum 8011 H14 Alloy Composition

The chemical composition of 8011 aluminum alloy typically includes:

- Aluminum (Al): 97.3% to 98.9%

- Iron (Fe): 0.60% to 1.0%

- Silicon (Si): 0.50% to 0.90%

- Manganese (Mn): ≤ 0.20%

- Copper (Cu): ≤ 0.10%

- Magnesium (Mg): ≤ 0.05%

- Zinc (Zn): ≤ 0.10%

- Titanium (Ti): ≤ 0.08%

- Chromium (Cr): ≤ 0.05%

- Other elements: Each ≤ 0.05%, Total ≤ 0.15%

Aluminum 8011 H14 Mechanical Properties

| Property | Value | Significance |

| Tensile Strength (UTS) | 125–170 MPa | Suitable for structural applications |

| Yield Strength | 120–157 MPa | Resists deformation under stress |

| Elongation at Break | 2–4% | Maintains formability despite strain hardening |

| Brinell Hardness | 41 | Balances durability and machinability |

| Fatigue Strength | 58 MPa | Withstands cyclic stresses |

Aluminum 8011 H14 Physical and Functional Properties

- Thermal Properties: Thermal conductivity: 210 W/m·K; Melting range: 630–650°C; Coefficient of thermal expansion: 23 µm/m·K.

- Electrical Properties: Electrical conductivity: 56% IACS (by volume); suitable for use in capacitors.

- Surface: Smooth surface with uniform texture; suitable for painting, printing, or coating.

- Environmental Properties: Density: 2.71 g/cm³; Embodied carbon: 8.2 kg CO₂/kg; Recyclability >95%.

Aluminum 8011 H14 Applications

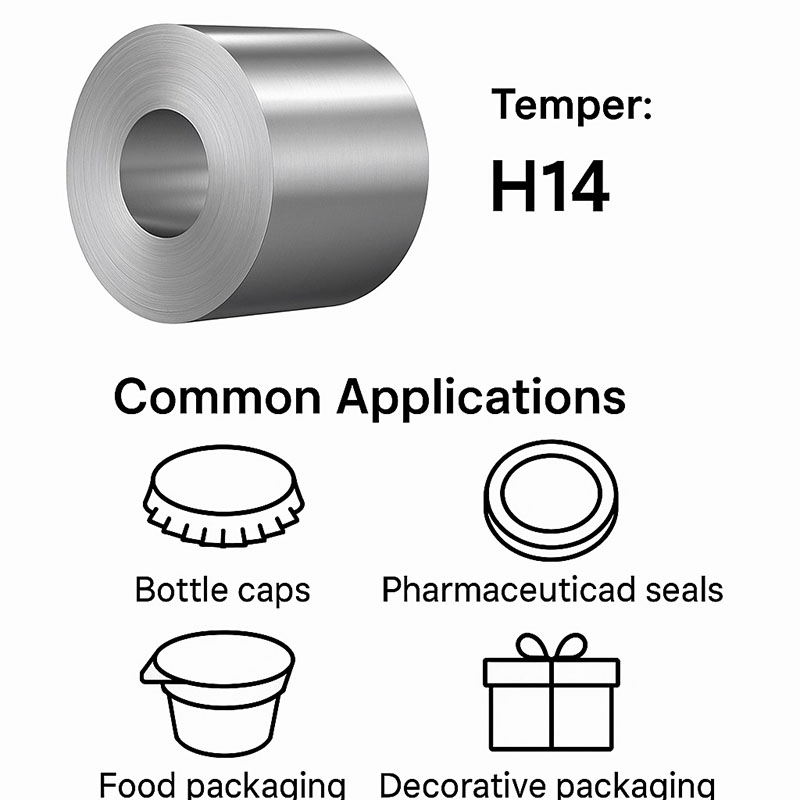

- Bottle Cap Manufacturing: Caps for liquor/wine bottles, cosmetics bottles, pharmaceutical oral liquid vials, milk powder lids, beverage caps.

- Packaging Materials: Pharmaceutical aluminum-plastic composite caps (PTP foil), food container sealing foil, aluminum foil tape base material.

| Application Field | Specific Uses |

| Bottle Caps | Tamper-evident caps (ROPP, PP caps), fewer earing defects and excellent deep drawing capability (up to 75 mm), free from “orange peel” surface issues. |

| Aluminum Foil Packaging | Food/pharmaceutical foil (thickness 0.006–0.2 mm), with moisture-proof and light-blocking properties. |

| Industrial Components | Gaskets, transformer windings, embossed roofing panels. |

- Bottle Caps: Including ROPP (roll-on pilfer-proof), screw caps, and flip-top seals.

- Pharmaceutical Sealing: Used for vials and ampoules.

- Food Packaging: Including yogurt lids and other sealing applications.

- Decorative Packaging: Used for beverages and cosmetics.

Its excellent formability, low earing rate (typically below 2%), and smooth surface finish make it an ideal choice for these applications.

Aluminum 8011 H14 Comparison with Other Tempers

| Temper | Tensile Strength | Elongation | Primary Use |

| H14 | 125–170 MPa | 2–4% | Closures, structural parts |

| O | 85–120 MPa | ≥15% | High-formability foils |

| H18 | 185–205 MPa | 1–2% | Rigid packaging |

Aluminum 8011 H14 Manufacturing and Processing

Aluminum 8011 H14 can be directly used in stamping, laminating, printing, and gluing processes, and is compatible with the cold stamping forming requirements of pharmaceutical caps.

Production Process:

- Homogenization: The DC-cast ingot is heated to dissolve iron/silicon precipitates.

- Hot Rolling: Rolled at high temperatures into medium thickness sheets.

- Intermediate Annealing: Two-step recovery annealing (300–400°C) to reset the microstructure.

- Finishing Rolling: Final cold rolling (reduction rate 5–15%) to achieve H14 properties.

- Texture Control: Critical for minimizing earing. By combining recrystallization and rolling texture, uniform earing is achieved at 0°/90° and ±45° during deep drawing.

Products you may be interested in

- 8011 Aluminum Foil

- 8021 Aluminum Foil

- 8079 Aluminum Foil

- 8006 Aluminum Foil

- 1235 Aluminum Foil

- 1100 Aluminum Foil

Users viewing this material also viewed the following

- Aluminum Foil for Air Conditioner

- Aluminium Fin Stock

- 8011 1235 aluminum foil gaskets for container sealing

- Aluminum Hydrophilic Foil

- Aluminum foil for cigarette packaging

- 8011 8079 1235 Aluminum foil for yogurt packaging

- Hot sealing aluminum foil 8011 1235

- 8011 Aluminium foil for beer bottle neck label

- Blister Aluminium Foil 8011 8021 8079

- Aluminium foil for flexible packaging

- Pharmaceutical Aluminum Foil 8011 8021 8079

- PTP Aluminum Foil

- Aluminum Foil Jumbo Rolls

- Double Zero Aluminum Foil

Recommended Content