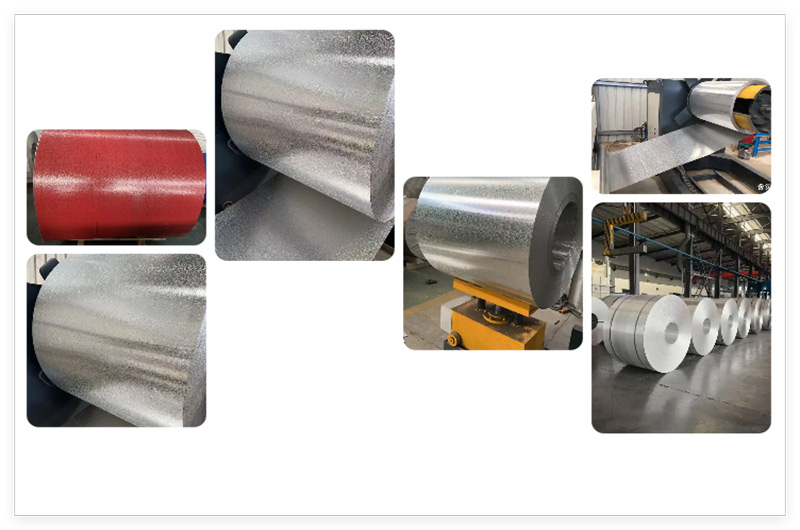

Anodized stucco embossed aluminum sheet coil is an aluminum coil material that combines anodizing process with stucco texture embossing, providing both functionality and decorative appeal. This aluminum sheet not only possesses the lightweight and corrosion-resistant properties of aluminum but also enhances surface wear resistance and aesthetics through the anodizing process. The embossed texture increases the visual appeal and practicality of the aluminum sheet, making it widely applicable across multiple industries.

Anodized embossed aluminum sheets are commonly used for interior and exterior decoration of refrigerators and cooling systems. Aluminum has excellent corrosion resistance, and since cooler interiors are always filled with moisture, ice, and water, stucco aluminum sheets usually feature anodized surfaces or pre-coated finishes. For this type of aluminum stucco embossed sheet, they are cut into various panel sizes because different coolers require different shapes, with typical thickness ranging from 0.2 mm to 0.8 mm.

Anodized stucco embossed aluminum sheet coil Surface Treatment Process

- Anodizing: Forms a dense oxide layer on the aluminum coil surface (thickness 0.03-200μm), with microhardness reaching HV550, salt spray corrosion resistance exceeding 3000 hours, and reduced porosity (<15%) through chromic acid sealing.

- Embossed Texture: Single-sided embossing technology creates stucco, orange peel, and other three-dimensional textures; supports customized designs to meet personalized requirements.

- Sulfuric acid anodizing process is used, producing an oxide film with level 9 salt spray corrosion resistance (5% NaCl solution, 500 hours without rust), hardness of 200-300HV, and wear resistance exceeding 100, 000 cycles. Electrolytic coloring can achieve stucco, champagne gold, antique copper, and other color series, with color difference controlled at ΔE≤1.5.

Anodized stucco embossed aluminum sheet coil specifications

- Alloy: 1060 1070 1100

- State: H24 O

- Thickness: 0.2-0.8mm

- ID: 505mm, roll weight according to customer requirements.

- Width: 300-1000mm

- Surface treatment: anodized and plastered

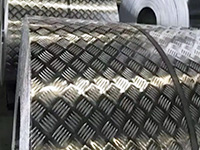

Diverse textures: The surface of the embossed aluminum sheet adopts different embossing processes to form a variety of textures, such as diamonds, corrugations or other artistic patterns. These textures not only enhance the visual effect, but also effectively increase the surface area, thereby improving the adhesion of coatings and adhesives.

Anodized stucco embossed aluminum sheet coil Material

Common substrates include 1060 pure aluminum, 3003 aluminum-manganese alloy, or 5052 aluminum-magnesium alloy.

-

1060 Anodized Embossed Aluminum Sheet

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

3003 Anodized Embossed Aluminum Sheet

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Anodized Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.

-

1050 Anodized Embossed Aluminum Sheet

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1100 Anodized Embossed Aluminum Sheet

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

Anodized stucco embossed aluminum sheet coil Performance Advantages

- Strong Weather Resistance: Oxide film can resist acid rain and chemical pollution; PVDF coating ensures color durability (ΔE≤1.5) and excellent UV resistance, suitable for long-term outdoor use.

- Lightweight and Easy to Process: Supports cutting, bending, stamping, and other processes, facilitating the fabrication of complex shapes such as curved curtain walls and reducing structural load.

Anodized stucco embossed aluminum sheet coil features

- Corrosion resistance: The anodizing process forms a thick layer of aluminum oxide film on the aluminum surface, which greatly enhances the corrosion resistance of the aluminum plate and is suitable for various environments, including places with moisture and chemical corrosion.

- Wear resistance: The anodized layer has good wear resistance and can resist scratches and wear in daily use.

- Color selection: Anodized aluminum plates can achieve a variety of colors through dyeing processes to meet different design requirements while maintaining the durability and stability of the color.

- Strength and toughness: Anodized embossed aluminum plates have good strength and toughness while maintaining light weight, and are suitable for bearing certain mechanical stress.

- Impact resistance: Aluminum plates that have been embossed and anodized can effectively resist external impacts and extend their service life.

- Anti-slip performance: The embossed surface provides better anti-slip effect and is suitable for floors, corridors and other places that require anti-slip treatment.

Anodized stucco embossed aluminum sheet coil applications

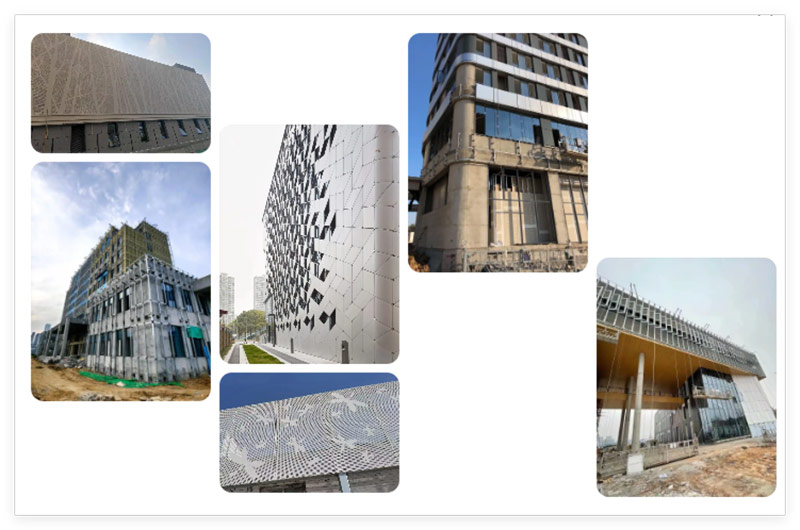

Architectural Decoration

- Curtain Walls/Ceilings: Matte metallic texture enhances architectural flow; for example, Shanghai Tower uses stone-like embossed aluminum panels to achieve high-end decorative effects.

- Interior Decoration: Elevator interiors, feature walls, etc., with sanded surface treatment reducing fingerprint coefficient (<0.85).

Industrial and Transportation

- Vehicles/Ships: Anti-slip aluminum panels (e.g., five-rib pattern) used for vehicle and ship flooring, balancing anti-slip performance with lightweight requirements.

- Industrial Components: Equipment protective housings, radiators, etc., with hard anodized film (60μm) combined with microporous oil impregnation to improve wear resistance (friction coefficient 0.12).

Architectural Curtain Walls and Decoration

- Exterior Facade Systems: Projects like Tianmuli use imported anodized aluminum panels; embossing enhances shading effect and architectural depth, with oxide film thickness of 15μm meeting 25-year outdoor weathering requirements.

- Interior Decoration: Jiaxing Railway Station waiting hall uses honeycomb composite panels; embossed surface provides both sound absorption and fingerprint resistance (noise reduction coefficient NRC≥0.8).

Anodized stucco embossed aluminum sheet coil for Industrial and Home Appliances

- Appliance Panels: Refrigerators and freezers use 1060 stucco aluminum coils, oxide film thickness 3-5μm, resistant to refrigerant corrosion, with embossed surface enhancing adhesion of insulation layers.

- Mechanical Equipment: Control cabinet enclosures use 5052 alloy embossed panels, oxide film thickness 10μm, resistant to industrial oil and dirt corrosion, embossed texture hides surface scratches.

Anodized stucco embossed aluminum sheet coil for Automotive and Transportation

- Interior Components: Car door panels use 3003 alloy embossed aluminum coils, oxide film thickness 8μm, embossed surface slip resistance ≥0.6 (wet), lightweight design reduces total vehicle weight by 15%.

- Rail Transportation: High-speed train carriage ceilings use honeycomb embossed aluminum panels, embossing depth 0.2mm, combined with anodizing to achieve Class A fire resistance and electromagnetic interference protection.

Anodized stucco embossed aluminum sheet coil Selection and Procurement Recommendations

Material Selection

- Outdoor High-Corrosion Environment: Prefer 5052 alloy, oxide film thickness ≥15μm, paired with nano sealing process.

- Load-Bearing Structural Components: 3003 alloy with tensile strength ≥140MPa, suitable for curtain wall frameworks and other load-bearing applications.

Process Control Key Points

- Texture Consistency: Suppliers should provide first-piece samples; use 3D scanner to check texture depth deviation ≤±0.03mm.

- Oxide Film Uniformity: Use eddy current thickness gauge for spot checking, at least 5 points per coil, film thickness deviation ≤±1.5μm.

- Certification Documents: For export projects, request CE certification and SGS test reports (salt spray test, adhesion test).

Anodized stucco embossed aluminum sheet coil demonstrates unique advantages in architecture, industry, and transportation through material innovation and process optimization. When procuring, it is necessary to consider the specific application scenario, comprehensively evaluating material, process, certifications, and other multidimensional factors.