The 1050 embossed aluminum sheet is a decorative and anti-slip aluminum plate made from 1050 aluminum alloy through an embossing process. The main component of 1050 aluminum alloy is aluminum, with an aluminum content of 99.5%, making it a pure aluminum series. It has excellent corrosion resistance, thermal conductivity, and high ductility, and is widely used in various industrial and decorative fields.

The 1050 embossed aluminum sheet is widely used in automotive engine hoods, chassis heat shields, and to protect components from high temperatures. It is also used in building decoration, mechanical equipment insulation, and more.

1050 Embossed Aluminum Sheet’s embossing process imparts functional textures (such as anti-slip and thermal insulation) while retaining its inherent advantages.

1050 embossed aluminum sheet is a widely used, lightweight material whose variety of thicknesses, embossed patterns, and surface finishes make it a popular choice in HVAC, home appliances, construction, signage, transportation, thermal management, and even cookware manufacturing.

Advantages of 1050 Embossed Aluminum Sheet

- Increased surface area, enabling radiant heat reflectivity up to 90% (insulation layer).

- Anti-slip performance (patterned surface for industrial flooring).

- Light diffusion capability (architectural ceilings, lighting).

1050 Embossed Aluminum Sheet Information Table

| Feature | Details |

| Alloy | AA 1050 (99.5% Al) |

| Tempers | O, H12–H32, H112, etc. |

| Thickness | 0.05–6 mm (coils); plates up to ~260 mm |

| Widths | 300–1, 600 mm (coils) |

| Patterns | Stucco, orange-peel, diamond, 5 rib, pebble |

| Finishes | Mill, anodized, color/PE/PVDF coated |

| Strength (tensile) | 65–145 MPa (depending on temper) |

| Conductivity | Thermal ~121–222 W/m·K; high electrical (~40% IACS) |

| Good for | Corrosion, formability, conductivity, aesthetics |

1050 Embossed Aluminum Sheet Coil Pattern Type

- Embossing Patterns: Stucco, orange peel, diamond (checkered/square), five-bar, pebble, etc.

- Optional Surface Treatments: Mill finish, anodized, or coated (PE, PVDF, oleophobic), typically packaged with protective film.

-

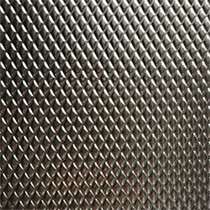

Stucco Embossed Aluminum Coil 1050

A Stucco Embossed Aluminum Coil 1050 is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco Embossed Aluminum Coil 1050s are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil 1050

Orange peel Embossed Aluminum Coil 1050 has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel Embossed Aluminum Coil 1050s are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

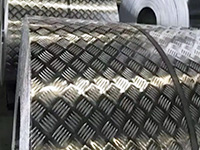

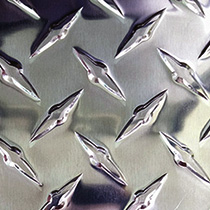

Diamond Embossed Aluminum Sheet Coil

Diamond Embossed Aluminum Coil 1050s are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond Embossed Aluminum Coil 1050s can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer Embossed Aluminum Coil 1050

Hammer Embossed Aluminum Coil 1050s have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean Embossed Aluminum Coil 1050

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil 1050

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop Embossed Aluminum Coil 1050s are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil 1050

A Hemispherical Embossed Aluminum Coil 1050 refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

Rhombus embossed aluminum coil

Rhombus-Embossed Aluminum Coil 1050 features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of Embossed Aluminum Coil 1050s and offers a variety of materials for Embossed Aluminum Coil 1050s.

1050 Embossed Aluminum Sheet Material Grades and Specifications

Table: Mechanical Properties by Temper

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| O | 65–95 | ≥20 | ≥20–40 |

| H14 | 105–145 | ≥85 | ≥2–6 |

| H18 | ≥135–155 | ≥120–140 | ≥1–2 |

1050 Embossed Aluminum Sheet Manufacturing and Embossing Process

Process: After cold rolling, patterns are embossed using patterned rollers.

Common Tempers:

- O (Annealed): Maximum ductility, suitable for deep drawing.

- H14/H24: Semi-hard temper, balances strength and formability.

- H18: Full hard temper, suitable for rigid applications.

1050 Embossed Aluminum Sheet Surface Treatment

- Finish: Natural aluminum appearance.

- Anodizing: Enhances corrosion resistance (e.g., for building facades).

- PVC/PVDF Coating: Rich color options and enhanced durability.

Key Advantages of 1050 Embossed Aluminum Sheet

- High formability — easy to bend, shape, and roll.

- Excellent electrical and thermal conductivity — suitable for radiators, reflectors, and cookware parts.

- Embossing increases rigidity without adding thickness, providing anti-slip and aesthetic benefits.

- Easy to process: outstanding ductility supports stamping, shearing, bending, and other secondary processes.

- Superior corrosion resistance — ideal for indoor/outdoor use, refrigerant liners, and roofing.

- Lightweight and recyclable, making it a cost-effective alternative to high-alloy-grade materials.

- High cost performance: more affordable than 5-series and 6-series embossed aluminum sheets, suitable for budget-sensitive projects.

- Environmental adaptability: excellent weather resistance with stable performance in environments from -40°C to 150°C.

Chemical composition of embossed aluminium sheet type 1050

| Chemical Element | % Present |

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.05 |

| Mn | 0.05 |

| Mg | 0.05 |

| Zn | 0.05 |

| Ti | 0.03 |

| Other (Each) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

Physical characteristics of embossed aluminium sheet alloy 1050

| Physical Property | Value |

| Density | 2.71g/cm3 |

| Melting Point | 650°C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 71GPa |

| Thermal Conductivity | 222W/m.K |

| Electrical Resistivity | 0.0282 x10^-6 Ω.m |

| Mechanical Property | Value |

| Tensile Strength | 105 - 145 MPa |

| Proof Stress | 85 Min MPa |

| Hardness Brinell | 34HB |

| Elongation | A - 12 Min % |

Typical Applications of 1050 Embossed Aluminum Sheet

- Home appliance interiors: refrigerator/freezer liners, evaporators, HVAC ducting.

- Architectural uses: stair treads, anti-slip flooring, platform walkways, decorative cladding, curtain walls, roofs, elevators.

- Industrial and transportation: ladders/steps, van side panels, vehicle floors, toolboxes, bus bodies.

- Thermal-related uses: solar/lighting reflectors, automotive/chemical insulation panels.

- Printing and signage: coated printing plates, signs, promotional display racks.

- Cookware: cookware rings, woks, frying pans, trays (due to heat resistance).

- Transportation tools: truck floors, container bases, and other anti-slip surfaces.

- Decorative uses: interior and exterior wall decoration, ceiling panels (combining aesthetics and functionality).

Applications of 1050 Embossed Aluminum Sheet in the Automotive Industry

Automotive Engine Hoods

The 1050 embossed aluminum sheet is commonly used in heat shields inside engine hoods. Since engines generate a lot of heat during operation, the embossed aluminum sheet effectively disperses the heat through its excellent thermal conductivity, preventing excessive temperatures and ensuring normal engine operation.

The embossed surface design also increases the strength and rigidity of the aluminum sheet, providing better protection and durability to safeguard the engine hood from high temperatures and mechanical damage.

Chassis Heat Shields

The vehicle chassis needs to be protected from heat originating from the road and exhaust systems. The 1050 embossed aluminum sheet is used as a chassis heat shield, isolating and reflecting heat to reduce thermal conduction and effectively protecting sensitive components on the chassis from high temperatures.

The lightweight nature of the embossed aluminum sheet also helps reduce vehicle weight, improving fuel economy and meeting modern automotive demands for lightweight and energy-efficient designs.

Applications of 1050 Embossed Aluminum Sheet in Building Decoration

Wall and Ceiling Decorations

In building decoration, the 1050 embossed aluminum sheet is commonly used in curtain walls, walls, ceilings, and other areas. It not only offers a unique aesthetic effect but also has excellent corrosion resistance, making it suitable for outdoor applications where it can maintain its appearance without oxidizing or corroding for a long time.

The special embossed textures provide anti-slip and anti-reflective properties, while the good ductility of aluminum allows it to adapt easily to complex building structures.

Insulation Material

In construction, the 1050 embossed aluminum sheet is used as an insulation material for walls, roofs, or ceilings. Its high thermal conductivity helps block external heat from entering the interior, thereby improving the building's insulation effectiveness and enhancing energy efficiency.

Applications of 1050 Embossed Aluminum Sheet in Mechanical Equipment

Equipment Heat Shields

In high-temperature mechanical equipment, the 1050 embossed aluminum sheet is often used as a heat shield to protect critical components from high temperatures. The aluminum sheet effectively dissipates heat, preventing thermal accumulation, ensuring normal equipment operation, and reducing the failure rate.

The lightweight and easy-processing characteristics of the embossed aluminum sheet also make it more convenient for equipment manufacturing and maintenance, reducing equipment weight while improving insulation efficiency.

Anti-Slip Surfaces

Using embossed aluminum sheets in machine operator panels, workbenches, and other areas enhances safety through its anti-slip texture, especially suitable for wet environments or situations where slipping is a concern.

1050 Aluminum Sheet Embossed Pattern Types and Applications

Table: Common Patterns and Uses

| Pattern | Typical Applications | Key Alloys |

| Stucco/Orange Peel | Solar reflectors, lighting fixtures, decorative panels | 1050, 1060 |

| Hemisphere | Automotive heat shields, ceiling panels | 1050, 3003 |

| Five-Bar/Rhombus | Anti-slip flooring, trailer beds, stair treads | 1050, 5052 |

| Cobblestone | Architectural cladding, interior aesthetics | 1050, 1100 |

1050 Embossed Aluminum Sheet Quality Standards and Certifications

Global Compliance: ASTM B209, EN 485, JIS H4000.

Testing Protocols:

Surface Hardness: ≥2H (coated sheets).

Impact Resistance: No cracking (50kg/cm, ASTM D-2794).

Bendability: 2T bend test.

Packaging: Wooden pallets + desiccant + waterproof film for export.

The 1050 embossed aluminum sheet excels in blending functionality (heat reflection, slip resistance) with aesthetic versatility. Its workability and compliance with industrial standards (e.g., ASTM, IATF16949) make it ideal for automotive, construction, and consumer goods.

1050 Embossed Aluminum Sheet Selection Considerations

- Choose thickness according to load requirements (e.g., ≥3mm is recommended for heavy-duty applications).

- In humid or corrosive environments, anodizing is recommended to enhance durability.

- Confirm surface pattern compatibility with mold in advance.

Other Alloy Embossed Aluminum Sheet Coil

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.