Embossed aluminum coil is an aluminum product in which various patterns are formed on the surface of the coil through special processes. It not only has the advantages of ordinary aluminum coils but also enhances decorative appeal, functionality, and mechanical performance through surface pattern designs.

Embossed aluminum coil is a versatile material characterized by decorative or functional patterns imprinted on its surface during manufacturing. This type of aluminum coil is widely used in industries that have strict requirements for durability, aesthetics, and corrosion resistance.

Common materials for embossed aluminum coil include 1060, 3003, and 5052 aluminum alloys. Among them, 1060 and 3003 are mostly used for insulation and corrosion resistance, while 5052 is suitable for load-bearing and anti-slip applications.

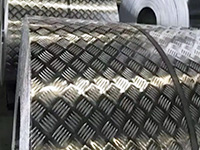

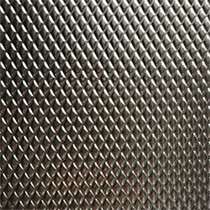

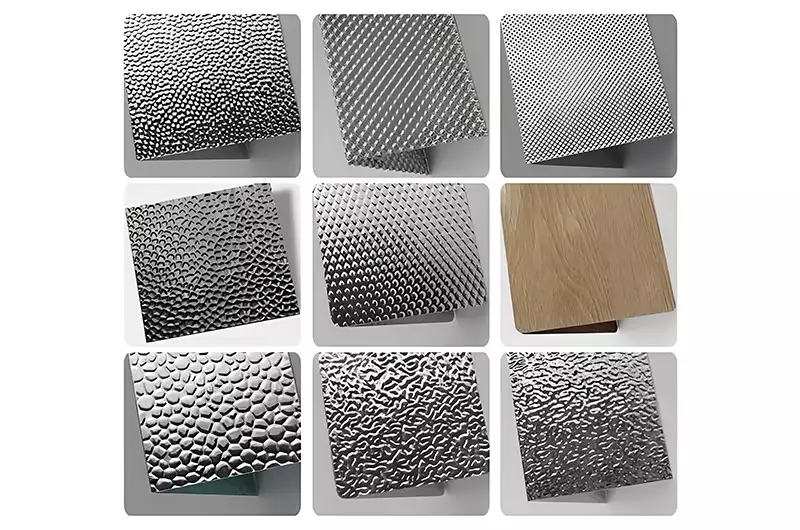

Embossed aluminum coil includes textures such as orange peel, diamond, and five-rib patterns. Different pattern designs can meet needs for anti-slip, drainage, or decorative purposes.

Haomei Aluminum’s embossed aluminum products offer a variety of textures and surface treatments, including anodizing, color coating, and mirror polishing finishes, ensuring durability, aesthetic appeal, and performance for various applications.

Specifications of Embossed Aluminum Coils

| Item | Specification / Description |

| Common Alloys | 1060, 1100, 3003, 5052, 8011, etc. |

| Tempers | O, H14, H24, H26, H32, etc. |

| Thickness Range | 0.06mm – 3.0mm |

| Width Range | 30mm – 1500mm |

| Coil ID | 505mm |

| Common Thicknesses | 0.016", 0.032", 0.040", 1/8" |

| Surface Textures | Orange Peel, Rhombus, Hemisphere, Cobblestone, Water Ripple, Lychee Peel |

| Available Colors | Gold, Silver, Regal Blue, Regal Red, Terra Cotta, Matte Black, Sandstone Almond, Regal White, Medium Bronze, Mansard Brown, etc. |

| Main Features | Decorative appearance; Wear-resistant and anti-slip; Higher strength and hardness (compared to smooth aluminum coil); Corrosion-resistant; Good processability (easy forming, bending, welding) |

| Typical Applications | Building decoration (curtain walls, anti-slip flooring, background walls); Transportation (ship decks, vehicle panels, automotive interior); Electrical appliances (refrigerator/freezer liner, panels); Lighting (reflectors, lamp covers) |

Alloy Materials of Embossed Aluminum Coils

Pure Aluminum Series (1000 Series)

- 1060 Alloy: Aluminum content reaches 99.6%, featuring soft texture, excellent plasticity, and relatively low cost.

- 1100 Alloy: Aluminum content over 99.0%, with good formability and corrosion resistance.

Aluminum-Manganese Alloy (3000 Series)

3003 Alloy: Contains approximately 1.2% manganese, offering higher strength and good corrosion resistance. 3004 Alloy: Based on 3003, with added magnesium, providing higher strength and improved corrosion resistance.

Aluminum-Magnesium Alloy (5000 Series)

5052 Alloy: Contains about 2.5% magnesium, with high strength and good corrosion resistance, especially excellent resistance to seawater corrosion. 5005 Alloy: Contains about 1.0% magnesium, with moderate strength and good workability.

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.

Available Textures for Embossed Aluminum Coil

Patterns such as orange peel, cobblestone, etc., significantly increase surface friction, offering excellent anti-slip performance, suitable for stair treads, loading platforms, etc.

-

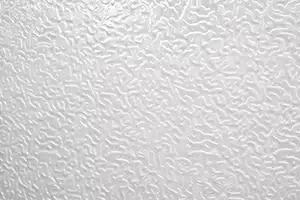

A Stucco embossed aluminum coil is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco embossed aluminum coils are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil

Orange peel embossed aluminum coil has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel embossed aluminum coils are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

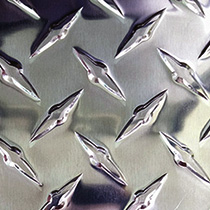

Diamond Embossed Aluminum Sheet Coil

Diamond embossed aluminum coils are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond embossed aluminum coils can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer embossed aluminum coils have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop embossed aluminum coils are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil

A Hemispherical embossed aluminum coil refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

Rhombus embossed aluminum coil

Rhombus-embossed aluminum coil features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of embossed aluminum coils and offers a variety of materials for embossed aluminum coils.

Embossed Aluminum Coil: Surface Finish Options

-

Anodized stucco embossed aluminum coil combines stucco embossing with an anodized coating. Anodizing is an electrochemical process that thickens the natural oxide layer on the aluminum surface, enhancing its corrosion resistance and color retention.

Advantages: Provides a durable, corrosion-resistant surface with additional decorative texture. The anodized layer enhances color stability and offers extra protection against environmental factors.

Applications: Ideal for high-exposure environments where aesthetics and exceptional durability are required, such as in architectural applications and outdoor installations.

-

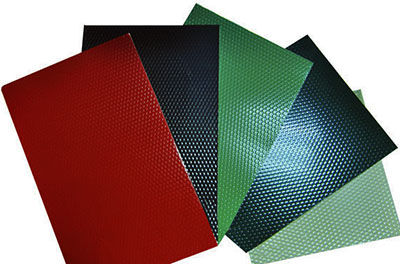

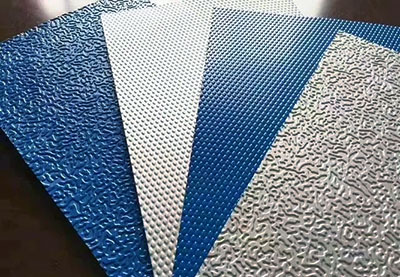

Color-coated embossed aluminum coil is coated with paint or lacquer after the embossing process. This finish allows for various colors and finishes ranging from matte to glossy.

Advantages: Offers a wide range of color choices and finishes with aesthetic versatility. The coating provides additional protection against weathering and UV degradation.

Applications: Used in decorative and functional applications, such as external building panels, roofing, and interior wall cladding.

-

This finish combines a mirror-reflective surface with an embossed pattern. The aluminum is polished to achieve a high-gloss, reflective surface before embossing.

Advantages: Offers a striking visual effect with reflective properties. The embossed texture adds depth and interest to the reflective surface while still providing a degree of durability.

Applications: Commonly used in decorative applications requiring a high-gloss appearance, such as interior design, elevator panels, and signage.

-

The combination of kraft paper and embossed aluminum enhances both durability and protection, while also improving the overall performance and lifespan of the coil in demanding environments.

Advantages: The kraft paper layer further enhances corrosion resistance. Additionally, the kraft paper has some moisture absorption properties, which are beneficial for internal pipe insulation.

Applications: It is also used in anti-corrosion and insulation projects, commonly in pipelines for industries such as oil and gas.

-

Blue Polymer Coating Embossed Aluminum Coil

Blue polymer coating embossed aluminum coil uses a multi-layer composite film known as Sandlin film (Blue Sandlin film), which consists of polyethylene and Sandlin polymer. The total thickness of the film is 76 microns. The Sandlin film is firmly bonded to the metal surface under high temperature and pressure, providing effective anti-corrosion protection for metal surfaces in applications such as refinery pipelines, power plants, and chemical plants.

-

Anti-Corrosion Coated Embossed Aluminum Coil

This embossed aluminum coil is coated with a specialized anti-corrosion layer that protects the aluminum from environmental factors that cause rust and degradation.

Applications: Used in environments exposed to moisture and chemicals, such as marine applications, chemical processing facilities, and external building panels.

Haomei Embossed Aluminum Coil Customization Options

Color

-

Black Embossed Aluminum Coil

-

Blue Embossed Aluminum Coil

-

Silver Embossed Aluminum Coil

-

Gold Embossed Aluminum Coil

-

Green Embossed Aluminum Coil

-

Red Embossed Aluminum Coil

-

Bronze Embossed Aluminum Coil

-

Copper Embossed Aluminum Coil

-

White Embossed Aluminum Coil

-

Grey Embossed Aluminum Coil

Coatings

- Polyester (PE): Moderate weather resistance and corrosion resistance, with a service life of 7-8 years.

- High-Durability Polyester (HDP): High weather resistance, with a service life of up to 15 years.

- Fluorocarbon (PVDF): Excellent corrosion resistance and weatherability, with a service life of 20-25 years.

Embossed Aluminum Coil Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each | Others: Total | Al: Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.50 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.60 |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | - | - | 0.10 | - | 0.05 | 0.15 | 99.0 | |

| 3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | - | - | 0.10 | - | 0.05 | 0.15 | remainder |

Key Features and Benefits of Embossed Aluminum Coils

Lightweight

Aluminum has a density of approximately 2.71 g/cm³, much lower than many other metals, making embossed aluminum coils lightweight and easy to handle and install.

Corrosion Resistance

Aluminum readily forms a dense aluminum oxide film in the air, providing good corrosion resistance, especially for embossed aluminum coils with surface treatments.

Increased Strength

The embossing process induces work hardening on the aluminum coil surface, enhancing material strength and hardness, making it more durable.

Strong Decorative Appeal

A wide variety of patterns offers more design possibilities, meeting decorative needs in different scenarios.

Anti-Slip Performance

Specific pattern types (such as five-rib patterns) can significantly increase surface friction, enhancing anti-slip effects.

Good Heat Dissipation

Aluminum has excellent thermal conductivity, and embossing increases the surface area, further improving heat dissipation.

Applications of Embossed Aluminum Coil Across Industries

Applications in Architectural Decoration

- Building Facades: Embossed aluminum coils treated with fluorocarbon coating or anodizing can be used as panel materials for building facades.

- Roof Decoration: Embossed aluminum coils can be used for roof decoration and waterproofing, especially in historic and distinctive buildings.

- Interior Decoration: Embossed aluminum coils can be used for wall panels, ceilings, partitions, and other interior decoration projects.

- Door and Window Decoration: Embossed aluminum coils can be applied to door and window frames, louvers, and other decorative parts.

- Sunshades: Embossed aluminum coils can be manufactured into various sunshade structures, such as panels and blinds.

- Thermal Insulation: Embossed aluminum coils can serve as the exterior protective layer for building insulation systems, especially in pipe and equipment insulation.

Applications in Home Appliance Manufacturing

- Refrigerators and Freezers: Embossed aluminum coils are used for inner linings and evaporators, with patterns like orange peel increasing surface area and enhancing heat exchange efficiency.

- Air Conditioning Equipment: Embossed aluminum coils are used in evaporators, condensers, and heat sinks, with orange peel patterns increasing surface area for better heat dissipation.

- Kitchen Appliances: Embossed aluminum coils are used for the inner liners and housings of ovens, microwaves, rice cookers, and other kitchen appliances.

- Water Heaters: Embossed aluminum coils are used in solar water heater tanks and collectors, with orange peel patterns increasing light absorption area and improving thermal efficiency.

- Sterilizers: Embossed aluminum coils are used in sterilizer inner linings and housings, with orange peel patterns increasing surface area to enhance sterilization effectiveness.

Applications in Transportation

- Automotive Manufacturing: Embossed aluminum coils are used in engine heat shields, exhaust heat shields, etc., with semi-spherical patterns enhancing thermal insulation.

- Shipbuilding: Embossed aluminum coils are used for decks, hulls, and interior decoration, with five-rib patterns providing excellent anti-slip performance.

- Railway Vehicles: Embossed aluminum coils are applied to floors, wall panels, and ceilings, with directional pointer patterns enhancing spatial perception.

- Aerospace: High-strength aluminum alloy embossed coils can be used for non-load-bearing structural components of aircraft and spacecraft, such as interior panels and flooring.

- Transportation Facilities: Embossed aluminum coils are used for highway guardrails, sound barriers, traffic signs, and other infrastructure.

Applications in Packaging

- Food Packaging: Ultra-thin embossed aluminum coils can be used for food packaging materials, such as aluminum foil bags and containers.

- Pharmaceutical Packaging: Embossed aluminum coils can be used for pharmaceutical packaging materials, such as aluminum-plastic blisters and foil bags.

- Cosmetic Packaging: Embossed aluminum coils can be applied to cosmetic packaging, such as lipstick tubes, powder cases, and perfume bottles.

- Gift Packaging: Embossed aluminum coils can be used for gift packaging materials, including boxes, bags, and decorative foils.

- Industrial Product Packaging: Embossed aluminum coils can be used for packaging high-end industrial products, such as precision instruments, electronics, and optical devices.

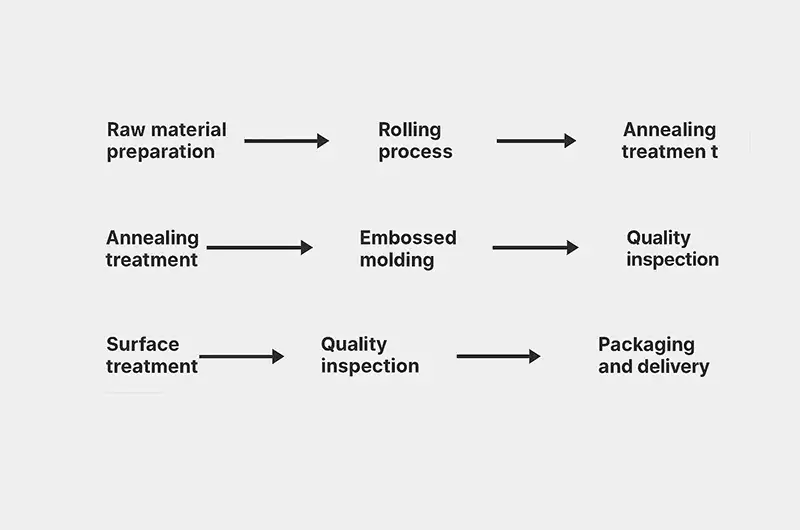

Production Process of Embossed Aluminum Coil

- Raw Material Preparation Select aluminum alloys such as 1050A and 3003 as base materials, ensuring their composition and dimensions meet the requirements for subsequent processing.

- Rolling Process Gradually roll the aluminum material to the target thickness through multiple passes of cold or hot rolling, typically controlled between 0.2 mm and 3.0 mm.

- Annealing Treatment Anneal the rolled aluminum sheets to eliminate work hardening, adjust material hardness and ductility, and improve forming stability.

- Embossing Use specialized embossing equipment to imprint specific textures, such as orange peel or diamond patterns, on the aluminum sheet surface. The pattern depth is generally between 0.08 mm and 0.25 mm.

- Precision Cutting Cut the sheets to the required specifications according to customer requirements, with common finished widths being 48".

- Surface Treatment Form a corrosion-resistant oxide layer through anodizing, apply diverse color effects through coating, or achieve a high-gloss mirror finish via mechanical polishing.

- Quality Inspection Conduct comprehensive checks on dimensions, pattern consistency, and surface defects to ensure the products meet relevant standards and customer requirements.

Embossed Aluminum Alloy Comparison

| Alloy | Tensile Strength (MPa) | Elongation (%) | Electrical Conductivity (% IACS) | Density (g/cm³) | Thermal Expansion Coefficient (μm/m·K) | Melting Range (°C) | Corrosion Resistance | Machinability |

| 1050 | 110-136 | 10-15 | 30 | 2.73 | 23.3 | 630-660 | Excellent | Excellent |

| 1060 | 110-136 | 10-15 | 30 | 2.73 | 23.3 | 630-660 | Excellent | Excellent |

| 1100 | 110-136 | 10-15 | 30 | 2.73 | 23.3 | 630-660 | Excellent | Excellent |

| 3003 | 140-160 | 10-15 | 35 | 2.73 | 23.8 | 570-640 | Good | Good |

| 3004 | 140-160 | 10-15 | 35 | 2.73 | 23.8 | 570-640 | Good | Good |

| 5052 | 175-195 | 12 | 35 | 2.72 | 23.8 | 607-650 | Excellent | Good |

| 8011 | 110-136 | 10-15 | 30 | 2.73 | 23.3 | 630-660 | Excellent | Excellent |

Key Points for Selecting Embossed Aluminum Coil

Clarify Usage and Environment: This is the basis for selection. For example, for interior dry environment decoration, a cost-effective 1060 alloy can be chosen; if it is used in humid environments (such as kitchens and bathrooms) or situations requiring load-bearing, more corrosion-resistant and higher-strength alloys like 5052 or 5083 should be considered.

Pay Attention to Pattern Type and Depth: Different patterns not only affect aesthetics but also directly relate to slip resistance, wear resistance, and cleaning difficulty. For example, public area anti-slip flooring requires deeper patterns.

Thickness Specifications: The thickness of the aluminum coil directly affects its strength and application. Common thickness ranges from 0.1mm to 6.0mm or even wider. Thinner sheets are mostly used for appliance linings, packaging, etc., while thicker sheets are used in construction, machinery, and other fields.

Surface Treatment Methods:

- Color Coating: Coating on the embossed base provides multiple color options, enhances decoration, and improves weather resistance.

- Anodizing: Forms a hard and wear-resistant oxide layer, providing corrosion resistance, good wear resistance, and can be colored.

- Mirror Finish: Has high reflectivity, commonly used in lamp reflectors, etc.

Superior to Other Solutions

- Sustainability: Embossed aluminum coil is fully recyclable, lightweight, and reduces environmental impact.

- Cost-Effectiveness: Due to its corrosion resistance, maintenance costs are lower compared to steel or copper.

- Aesthetic Flexibility: Embossed aluminum coil offers various patterns and finishes to meet design requirements.