Hammer embossed aluminum coil, also known as pebble embossed aluminum coil, is an aluminum sheet or coil material with a hammered or dimpled surface pattern created by mechanical rolling or embossing techniques. This pattern is produced through the embossing process, which adds texture to the material. Due to its aesthetics and functional advantages (such as enhanced grip and reduced glare), this aluminum coil is widely used in architecture, automotive, and decorative fields.

Hammer embossed aluminum sheet coil combines aesthetics, durability, and functionality, making it the preferred choice across various industries.

Hammer Embossed Aluminum Sheet Details

| Alloy | 1050 1060 1070 1100 3003 5052 5754 6061 6063 6082 |

| Temper | O H12 H14 H16 H18 H22 H24 H26 H32 T4 T6 |

| Thickness (base) | 0.1-5.0 mm |

| Embossing depth | 0.08~0.25 |

| Width | 100mm-1650mm |

| Length | 500mm-16000mm |

| Pattern | hammer |

| Surface treatment | mirror polishing & embossing, coating, anodizing |

| MOQ | 1 metric ton |

| Payment Terms | T/T L/C D/P |

| Delivery Time | About 20 working days |

Hammer Embossed Aluminum Sheet Alloys

Hammer embossed aluminum sheets and coils are available in a variety of aluminum alloys, each with unique properties suited for different applications. The most commonly used alloys for embossed aluminum products include the 1000 series (particularly 1050, 1060, and 1100), 3003 alloy, and 5052 alloy. Each alloy provides a different balance of formability, strength, and corrosion resistance.

3003 aluminum alloy is one of the most popular choices for embossed aluminum applications. Essentially a commercially pure aluminum with about 1.2% manganese added, it offers about 20% higher strength than 1100-grade aluminum while maintaining excellent corrosion resistance. This alloy has good workability and can be effectively deep drawn, spun, welded, or brazed. It is non-heat-treatable and is usually supplied in tempers such as H114, H134, etc., with thicknesses ranging from 0.025 inch (0.635 mm) to 0.080 inch (2.032 mm) or greater.

Hammer Embossed Aluminum Sheet Surface Treatments

Surface treatment methods for hammer embossed aluminum significantly extend its functionality and aesthetics.

Anodized Hammer Embossed Aluminum Sheet

Anodizing forms a dense alumina film on the surface, enhancing corrosion resistance, and allows color impregnation while retaining the hammered texture.

Color Coated Hammer Embossed Aluminum Sheet

Color coating options include Polyester (PE), High Durability Polyester (HDP), and Fluorocarbon (PVDF) coatings, with service lives ranging from 7-8 years for standard polyester coatings to 20-25 years for PVDF coatings.

Polished Mirror Hammer Embossed Aluminum Sheet

Polished mirror finishing provides high reflectivity (over 82%) while retaining the hammered texture, making it suitable for decorative lighting applications.

Surface quality of Hammer Embossed Aluminum Sheet Coil

- Horizontal difference: The horizontal thickness difference between the embossed oxide plate and the pattern is within 0.02mm.

- Pattern height: The hammer pattern height is between 0.11mm and 0.15mm, and special height can be customized.

- Anodizing thickness: 5μm to 10μm.

- Mechanical properties: Meet conventional application requirements and international standards.

- Surface: No cracks, corrosion, oil spots, tiger stripes, etc.

Features of Hammer Embossed Aluminum Sheet

- Reflectivity: The hammered pattern diffuses light, ideal for applications requiring low glare or uniform illumination.

- Corrosion Resistance: Anodized surface (5-10 μm oxide layer) resists moisture and chemicals, suitable for marine or humid environments.

- Formability: Easy to cut, bend, or weld, can be custom manufactured to client requirements. Common tempers include H14, H24, and O (annealed) to provide different flexibility.

Chemical Composition of Hammer Embossed Aluminum

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

| Single | Total | ||||||||||

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.05 | 0.15 | 99.50 min |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.05 | 0.15 | 99.60 min | |

| 1100 | 0.95 | 0.05-0.20 | 0.05 | - | - | 0.10 | - | 0.05 | 0.15 | 99.0min | |

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remainder |

| 3105 | 0.6 | 0.7 | 0.30 | 0.30-0.8 | 0.20-0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | Remainder |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | - | 0.05 | 0.15 | Remainder |

| 5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.6-3.6 | 0.30 | 0.20 | 0.15 | 0.05 | 0.15 | Remainder |

Applications of Hammer Embossed Aluminum Sheet

Architecture and Decoration

- Exterior walls, ceilings, and wall panels: The embossed texture increases visual depth and reduces glare.

- Furniture and cabinets: Used in high-end kitchen countertops, wine cabinets, and decorative trims.

- Roofing: Strong weather resistance, provides insulation when laminated with foam.

Industry

- Refrigeration and HVAC: 3003 alloy coils are widely used for refrigerator liners and air conditioning ducts due to their corrosion resistance.

- Insulation panels: Deeply embossed sheets used in automotive exhaust systems and engine compartments.

- Solar panels: Enhance light diffusion and efficiency of solar reflectors.

Lighting and Electrical

Lamp reflectors: Mirror embossed sheets can effectively redirect light, increasing lamp output by up to 60%.

Hammer Embossed Aluminum Sheet is also used in:

- Automotive: Applied in panels, trims, and other components, often favored for its strength-to-weight ratio and aesthetics.

- Others: Due to its versatility and corrosion resistance, it is widely used in packaging, electronics, and even marine applications.

Production Process of Hammer Embossed Aluminum Coil

First, the aluminum coil undergoes thorough cleaning and degreasing to remove any contaminants that may affect embossing quality.

Then, the material is preheated to a specific temperature to improve ductility, after which it passes through special embossing rollers or presses, using a combination of pressure and heat to impart the hammered pattern.

After embossing, the material is rapidly cooled to fix the pattern and stabilize its mechanical properties.

Before cutting the material into required specifications, optional surface treatments such as anodizing, painting, or coating can be applied to enhance corrosion resistance or aesthetics.

Haomei Popular Embossed Aluminum Sheet Coils

-

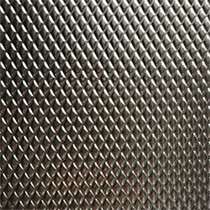

A Stucco embossed aluminum coil is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco embossed aluminum coils are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

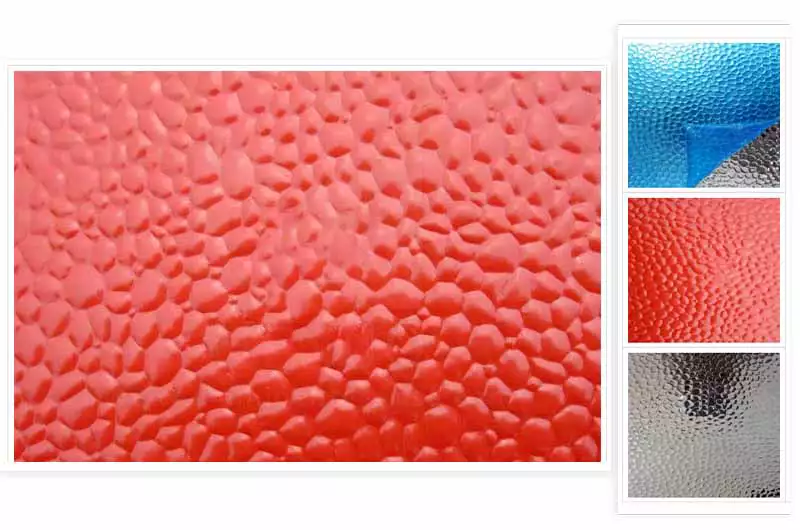

Orange Peel Embossed Aluminum Coil

Orange peel embossed aluminum coil has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel embossed aluminum coils are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

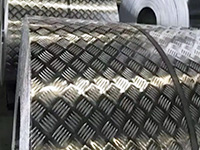

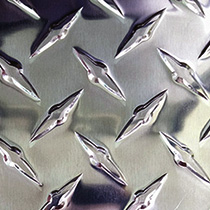

Diamond Embossed Aluminum Sheet Coil

Diamond embossed aluminum coils are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond embossed aluminum coils can be applied to the floor, and wall, for transportation and decoration purposes.

-

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop embossed aluminum coils are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil

A Hemispherical embossed aluminum coil refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

Rhombus embossed aluminum coil

Rhombus-embossed aluminum coil features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of embossed aluminum coils and offers a variety of materials for embossed aluminum coils.

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.