Embossed aluminum sheet is a type of aluminum alloy plate that has undergone special processing. By embossing various regular or irregular patterns on the surface of the aluminum sheet, not only is its decorative appeal enhanced, but its physical properties are also improved, such as anti-slip, wear resistance, and compression resistance. Embossed aluminum sheets are widely used in construction, industry, decoration, and many other fields, making them one of the indispensable materials in modern engineering and design.

The production of embossed aluminum sheets is mainly carried out through embossing machines. The pre-treated aluminum sheet is fed into the embossing machine equipped with specific patterned molds, and under a certain pressure, the desired embossed patterns are formed on the surface of the sheet. During the embossing process, the thickness of the aluminum sheet will slightly increase, usually by 0.1mm–0.25mm. This process can endow the aluminum sheet with more functionality and decorative effects while maintaining its original properties.

Advantages of Embossed Aluminum Sheet

- Corrosion resistance: Aluminum sheets have excellent acid corrosion resistance, effectively resisting the impact of various corrosive environments.

- Strong adhesion: The protective film on the surface has strong adhesion, making it difficult to peel or fall off.

- Impact resistance: Embossed aluminum sheets possess high impact resistance and are not easily damaged by external impacts.

- Safe and environmentally friendly: Aluminum sheets are non-toxic and comply with environmental standards, ensuring high safety.

Specifications and Alloy Materials of Embossed Aluminum Sheet

Embossed Aluminum Sheet Specifications and Dimensions

Thickness Specifications

- Regular thickness range: 0.15mm-6.00mm

- Special thickness range: 0.08mm-250mm (can be customized according to customer requirements)

- Common thickness for curtain wall embossed aluminum sheets: 2.0mm, 2.5mm, 3.0mm

- Commonly used thickness: 0.20mm-10.0mm

Width Specifications

- Regular width range: 600mm-2000mm

- Wide width specification: up to 2200mm

- Narrow width specification: minimum up to 100mm

- Commonly used width: 300mm-1600mm

Length Specifications

- Regular lengths: 2000mm, 2438mm, 3048mm, etc. standard lengths

- Custom lengths: produced according to customer requirements, up to a maximum of 8000mm

Embossed Aluminum Sheet Typical Sizes and Grades

| Aolly | Temper (Base materal) | Specification(mm) | ||||

| Thickness (Base material) | Width | Length | Embossing depth | Surface Treatment | ||

| 1050 1100 1060 1070 3003 3105 5052 | O, H12, H14, H16, H18, H22, H24, H26, H32 | 0.25~2.0 | ≤1500 | As per customer’s requirements | 0.08~0.25 | MilFinish, bright finish, anodized, color coated |

Dimensional Changes After Embossing

After embossing, the thickness of the aluminum sheet will increase by 0.1mm-0.25mm. This is because the raised parts of the pattern add to the overall thickness of the sheet. When selecting and using embossed aluminum sheets, this factor needs to be considered to ensure that the final product dimensions meet design requirements.

Embossed Aluminum Sheet Alloy Materials

Pure Aluminum Series

- 1050 Series: Purity up to 99.5%

- 1060 Series: Purity 99.6%, most commonly used

- 1100 Series: Purity 99.0%, contains a small amount of copper

- 1200 Series: Purity 99.0%, similar performance to 1100

3xxx Series

- 3003 Series: Manganese as the main alloying element

- 3004 Series: Contains manganese and magnesium

- 3105 Series: Contains a small amount of magnesium

5xxx Series

- 5005 Series: Contains a small amount of magnesium

- 5052 Series: Magnesium as the main alloying element

- 5083 Series: Contains magnesium, excellent corrosion resistance

- 5754 Series: Contains magnesium, good formability

In addition, there are also 6xxx series embossed aluminum sheets

- 6061 Series: Contains magnesium and silicon

- 6063 Series: Contains magnesium and silicon, excellent extrusion performance

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.

Principles of Alloy Selection

Different alloy materials have different characteristics, and the selection should be determined according to the requirements of specific application scenarios. For example, in situations where high corrosion resistance is required, the 1060 or 3003 series can be chosen; for situations requiring higher strength, the 5052 or 6061 series can be selected; for situations with high welding performance requirements, the 5083 series can be chosen, and so on.

Embossed Aluminum Sheet Typical Size Tolerance

| Tolerance | |||||

| Thickness (Base material) | Thickness | Embossing depth | Width | Length | Diagonal |

| 0.25-0.50 | 0-0.05 | +/-0.01 | +/-0.5 | +/-1.0 | +/-1.5 |

| >0.50-2.0 | 0-0.10 | +/-0.02 | +/-1.0 | +/-1.5 | +/-2 |

| Remark: We can produce as per customers’speciarequirements | |||||

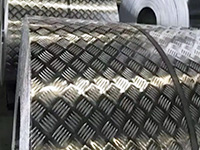

Embossed Aluminum Sheet Pattern Type

-

A Stucco embossed aluminum coil is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco embossed aluminum coils are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil

Orange peel embossed aluminum coil has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel embossed aluminum coils are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

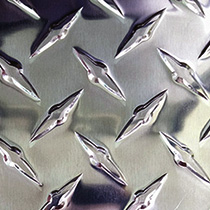

Diamond Embossed Aluminum Sheet Coil

Diamond embossed aluminum coils are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond embossed aluminum coils can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer embossed aluminum coils have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop embossed aluminum coils are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil

A Hemispherical embossed aluminum coil refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

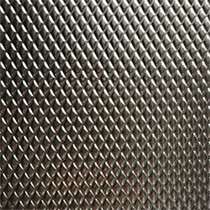

Rhombus embossed aluminum coil

Rhombus-embossed aluminum coil features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of embossed aluminum coils and offers a variety of materials for embossed aluminum coils.

Embossed Aluminum Coil Surface Finish

Anodized Stucco Embossed Aluminum Sheet Coil

- Features: Forms a dense aluminum oxide layer, strong corrosion resistance

- Thickness: Oxide film thickness 5-25 microns

- Applications: Architectural decoration, electronics, automotive industry, etc.

Mirror Embossed Aluminum Sheet Coil

- Features: Extremely high gloss and reflectivity

- Process: Mechanical polishing, chemical polishing, etc.

- Applications: High-end architectural decoration, display cabinets, signage, etc.

Color-Coated Embossed Aluminum Sheet Coil

- Features: Rich surface coating colors

- Alloy: Common alloys include 1060, 3003, 5052

- Applications: Suitable for roofing and cladding

Kraft Paper Clad Stucco Embossed Aluminum Sheet Coil

- Features: Stucco embossed finish enhances strength and reduces reflectivity

- Applications: Architectural decoration, insulation materials, wall cladding

Brushed Embossed Aluminum Sheet Coil

- Features: Uniform surface texture and high scratch resistance

- Process: Linear brushing, random brushing, etc.

- Applications: Architectural decoration, furniture, electronic product casings, etc.

Composite Finish Embossed Aluminum Sheet Coil

- Features: Combined with multiple processes, diverse appearances

- Combination: Anodizing + coloring, coating + brushing, etc.

- Applications: High-end architectural decoration, special industrial products, etc.

Fluorocarbon Coated Embossed Aluminum Sheet Coil

- Features: Excellent weather resistance, corrosion resistance, and chemical resistance, color remains stable and durable

- Thickness: Coating thickness ≥25 microns

- Applications: High-rise building curtain walls, roofs, exterior wall decoration, etc.

Polyester Coated Embossed Aluminum Sheet Coil

- Features: Strong coating adhesion and high cost-effectiveness

- Thickness: Coating thickness ≥18 microns

- Applications: Interior decoration, furniture, signage, etc.

Typical Chemical Composition of Embossed Aluminum Sheet

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.6 |

| 1070 | 0.25 | 0.2 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.03 | 0.03 | 0.03 | 99.7 |

| 1100 | 0.95 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.1 | - | - | - | 0.05 | 99 |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | - | - | - | 0.15 | 96.95-96.75 |

Applications of Embossed Aluminum Sheet

Applications in the Construction Field

Architectural Curtain Walls

- Common specifications: 2.0mm, 2.5mm, 3.0mm

- Common alloys: 3003, 5052, 6061

- Application examples: Commercial buildings, office towers, exhibition halls, etc.

Roofing Systems

- Common specifications: 0.5mm-3.0mm

- Common alloys: 3003, 5052

- Application examples: Industrial plants, stadiums, exhibition halls, etc.

Interior Decoration

- Common specifications: 0.5mm-3.0mm

- Common alloys: 1060, 3003

- Application examples: Hotels, shopping malls, office buildings, etc.

Stairs and Flooring

- Common specifications: 1.5mm-5.0mm

- Common alloys: 3003, 5052

- Application examples: Stairs and corridors in various types of buildings

Applications in the Industrial Field

Transportation

- Applications: Automotive, trains, ships, aircraft interior decoration

- Common alloys: 5052, 5083, 6061

Electronics and Electrical Appliances

- Applications: Product casings, heat sinks, shielding materials

- Common alloys: 1060, 3003, 5052

Refrigeration and Ventilation

- Applications: Cold storage, air conditioning, ventilation ducts

- Common alloys: 1060, 3003

Chemical and Food Industries

- Applications: Chemical equipment, food processing equipment, storage containers

- Common alloys: 1060, 3003, 5052

Applications in Decoration and Art

Furniture and Home Decoration

- Applications: Furniture surfaces, decorative panels, household items

- Common alloys: 1060, 3003, 5052

Display and Advertising

- Applications: Display racks, cabinets, billboards, signage

- Common alloys: 1060, 3003

Art and Handicrafts

- Applications: Artwork, handicrafts, souvenirs

- Common alloys: 1060, 3003

Architectural Decorative Accessories

- Applications: Door handles, hinges, decorative strips, etc.

- Common alloys: 1060, 3003, 5052

Selection and Application Recommendations for Embossed Aluminum Sheet

Factors to Consider When Selecting Embossed Aluminum Sheets

- Usage Environment: Consider factors such as temperature, humidity, and chemicals to choose suitable alloys and surface treatments.

- Load Requirements: Select appropriate alloys and sheet thickness based on weight, pressure, and impact.

- Decorative Effect: Choose suitable patterns and surface treatments according to the design style.

- Processing Performance: Consider the difficulty of processing methods such as cutting, bending, and welding.

- Cost Factors: Take into account material cost, processing cost, and installation cost comprehensively.

Selection Recommendations for Different Application Scenarios

Architectural Curtain Walls

- Recommended alloys: 3003, 5052, 6061

- Recommended thickness: 2.0mm, 2.5mm, 3.0mm

- Recommended patterns: Orange peel, water ripple, diamond

- Recommended surface treatments: Fluorocarbon coating, anodizing

Roofing Systems

- Recommended alloys: 3003, 5052

- Recommended thickness: 0.5mm-3.0mm

- Recommended patterns: Corrugated, wave

- Recommended surface treatments: Fluorocarbon coating, polyester coating

Interior Decoration

- Recommended alloys: 1060, 3003

- Recommended thickness: 0.5mm-3.0mm

- Recommended patterns: Orange peel, pebble, water ripple

- Recommended surface treatments: Anodizing, wood grain transfer, color coating

Stairs and Flooring

- Recommended alloys: 3003, 5052

- Recommended thickness: 1.5mm-5.0mm

- Recommended patterns: Five ribs, three ribs

- Recommended surface treatments: Anodizing, fluorocarbon coating

Installation and Maintenance Recommendations for Embossed Aluminum Sheets

Installation Recommendations

- Inspect the surface for damage or deformation before installation

- Choose an appropriate installation method (screw fastening, riveting, etc.)

- Leave adequate gaps to allow for thermal expansion and contraction

- Seal joints properly

Maintenance Recommendations

- Clean regularly with neutral detergents

- Use specialized cleaners for stubborn stains

- Regularly inspect the installation and surface condition

- Apply protective wax or film in harsh environments

Extending Service Life

- Avoid contact with sharp objects

- Avoid prolonged exposure to chemicals

- Perform regular maintenance

- Apply protective treatments periodically for outdoor use

Browse our inventory of embossed aluminum sheets

| Description | Width | Size | Surface Finish |

| .032" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .032" | 4' x 8' | Mill Finish |

| .032" Stucco Embossed Aluminum Sheet 4' x 8' Clear Anodized | .032" | 4' x 8' | Clear Anodized |

| .032" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .032" | 4' x 8' | Mill Finish |

| .032" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .032" | 4' x 10' | Mill Finish |

| .032" Stucco Embossed Aluminum Sheet 4' x 10' Clear Anodized | .032" | 4' x 10' | Clear Anodized |

| .032" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .032" | 4' x 10' | Mill Finish |

| .040" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .040" | 4' x 8' | Mill Finish |

| .040" Stucco Embossed Aluminum Sheet 4' x 8' Clear Anodized | .040" | 4' x 8' | Clear Anodized |

| .040" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .040" | 4' x 8' | Mill Finish |

| .040" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .040" | 4' x 10' | Mill Finish |

| .040" Stucco Embossed Aluminum Sheet 4' x 10' Clear Anodized | .040" | 4' x 10' | Clear Anodized |

| .040" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .040" | 4' x 10' | Mill Finish |

| .100" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .100" | 4' x 8' | Mill Finish |

| .100" Stucco Embossed Aluminum Sheet 4' x 8' Clear Anodized | .100" | 4' x 8' | Clear Anodized |

| .100" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .100" | 4' x 8' | Mill Finish |

| .100" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .100" | 4' x 10' | Mill Finish |

| .100" Stucco Embossed Aluminum Sheet 4' x 10' Clear Anodized | .100" | 4' x 10' | Clear Anodized |

| .100" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .100" | 4' x 10' | Mill Finish |

| .125" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .125" | 4' x 8' | Mill Finish |

| .125" Stucco Embossed Aluminum Sheet 4' x 8' Clear Anodized | .125" | 4' x 8' | Clear Anodized |

| .125" Stucco Embossed Aluminum Sheet 4' x 8' Mill Finish | .125" | 4' x 8' | Mill Finish |

| .125" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .125" | 4' x 10' | Mill Finish |

| .125" Stucco Embossed Aluminum Sheet 4' x 10' Clear Anodized | .125" | 4' x 10' | Clear Anodized |

| .125" Stucco Embossed Aluminum Sheet 4' x 10' Mill Finish | .125" | 4' x 10' | Mill Finish |