5083 h321 aluminum plate sheet

What material is 5083 H321?

5083 H321 aluminum alloy refers to the 5083 alloy in H321 temper. H321 indicates an alloy that has been strain hardened less than the amount required for the H32 temper. Its strength is approximately between the annealed (O) condition and the fully hardened (H38) condition.

5083-H321 aluminum plate is a non-heat-treatable strengthened anti-rust aluminum alloy with medium strength, excellent corrosion resistance, and good weldability. It is widely used in shipbuilding, rail transportation, pressure vessels, and other fields.

5083 H321 aluminum has excellent corrosion resistance (especially in seawater and industrial chemical environments), outstanding weldability, good cold workability, the ability to maintain high strength after welding, and good low-temperature performance.

5083 h321 aluminum plate sheet standards

QQ-A250/6, ASTM-B928

5083 h321 aluminum plate sheet size

| Product | Thickness (inch) | Width (inch) | Length (inch) |

| 0.125" (1/8) 5083 H321 Aluminum Sheet | 0.125" (1/8) | 48", 60" | 96", 120" |

| 0.190" (3/16) 5083 H321 Aluminum Sheet | 0.190" (3/16) | 48", 60", 72" | 96", 144" |

| 0.250" (1/4) 5083 H321 Aluminum Plate | 0.250" (1/4) | 48", 60", 72" | 120", 144" |

| 0.375" (3/8) 5083 H321 Aluminum Plate | 0.375" (3/8) | 48", 60", 72" | 120", 144" |

| 0.500" (1/2) 5083 H321 Aluminum Plate | 0.500" (1/2) | 48", 60", 72" | 120", 144" |

| 0.750" (3/4) 5083 H321 Aluminum Plate | 0.750" (3/4) | 48", 60", 72" | 120", 144" |

| 1.000" (1") 5083 H321 Aluminum Plate | 1.000" (1") | 48", 60", 72" | 120", 144" |

| 1.500" 5083 H321 Aluminum Plate | 1.500" | 48", 60", 72" | 120", 144" |

| 2.000" 5083 H321 Aluminum Plate | 2.000" | 48", 60", 72" | 120", 144" |

| 3.000" – 4.000" 5083 H321 Aluminum Plate (thick) | 3.000" – 4.000" | 48", 60" | 120", 144" |

H321 temper = strain hardened + stabilized, offering excellent corrosion resistance (esp. in marine use).

5083 aluminum plate is commonly stocked in marine grade sizes: 4' × 8' (48" × 96"), 5' × 10' (60" × 120"), and 6' × 12' (72" × 144").

Custom cutting is widely available for non-standard lengths/widths.

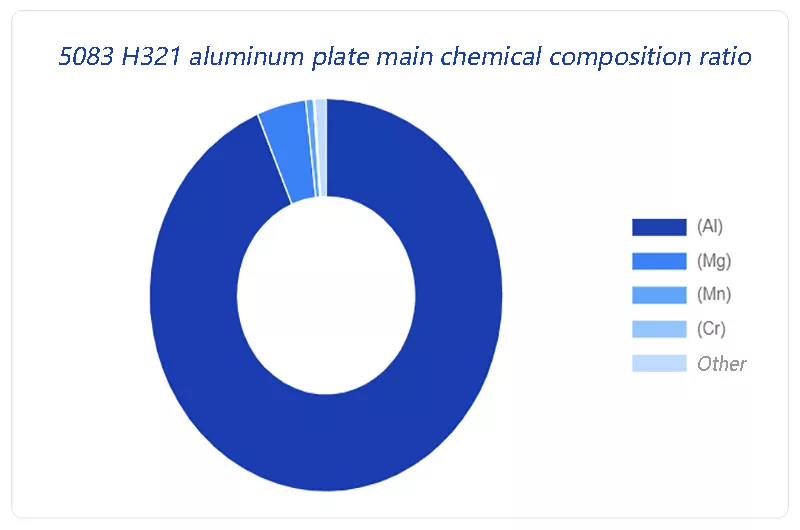

5083 h321 aluminum plate sheet chemical composition

| Limits (WT %) | |

| Silicon | 0.4 |

| Iron | 0.4 |

| Copper | 0.1 |

| Manganese | 0.40-1.0 |

| Magnesium | 4.0-4.9 |

| Chromium | 0.05-0.25 |

| Zinc | 0.25 |

| Titanium | 0.15 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum | |

5083 h321 aluminum plate sheet mechanical properties

| Typical Mechanical Properties | |||

| Temper | Tensile Strength | Yield Strength | Elongation |

| KSI | KSI | % | |

| O (annealed) | 42 | 21 | 14 |

| H112 | 43 | 23 | 10 |

| H116 | 46 | 33 | 10 |

| H321 | 46 | ||

5083 h321 aluminum plate sheet Applications

Applications of 5083 H321 Aluminum Plate in Shipbuilding

Hull structure applications

In shipbuilding, 5083 H321 aluminum plate is one of the most commonly used materials, mainly applied in:

- Hull shell: As the main material for hull plating, especially in yachts, high-speed vessels, and small ships. Replacing traditional steel reduces weight by 30%-40%.

- Deck structures: Used in main decks, superstructure decks, and platform decks of ships, providing excellent corrosion resistance and load-bearing capacity.

- Bottom plating: Withstanding hydrodynamic loads and external impacts, the high strength and corrosion resistance of 5083 H321 ensure safe long-term use.

- Side structures: Applied as side shell plating and internal bulkheads, providing structural support and watertight integrity.

Ship equipment applications

Applications of 5083 H321 aluminum plate in ship equipment include:

- Engine foundations: Supporting and securing ship engines, withstanding vibrations and impact loads.

- Ship piping systems: Used in seawater cooling systems, freshwater supply systems, and sewage discharge systems for pipes and fittings.

- Ship interior fittings: Such as cabin partitions, ceilings, and flooring, taking advantage of its lightweight and corrosion resistance.

- Deck equipment: Supporting structures for deck fittings such as bollards, fairleads, and windlass bases.

Marine engineering applications

In marine engineering, 5083 H321 aluminum plate is mainly used for:

- Offshore wind power equipment: Internal structural components of wind turbine towers, platforms, and maintenance walkways, with excellent seawater corrosion resistance and fatigue strength.

- Oil drilling platforms: Structural components, walkways, and guardrails for platforms, withstanding harsh marine environments.

- Subsea pipeline systems: Protective structures or auxiliary supports for subsea oil pipelines, providing additional corrosion resistance.

Advantages in shipbuilding applications

The main advantages of 5083 H321 aluminum plate in shipbuilding include:

- Excellent seawater corrosion resistance: Especially superior resistance to salt spray, seawater immersion, and marine atmosphere, far better than ordinary steel.

- High strength-to-weight ratio: Provides strength comparable to steel but with significantly reduced weight, enhancing ship performance and fuel efficiency.

- Good fatigue resistance: Capable of withstanding long-term wave loads and vibrations, extending the service life of vessels.

- Excellent weldability: Can be joined by various welding methods, ensuring structural integrity and watertightness.

- Full classification certifications: 5083 H321 marine aluminum plate has been certified by major classification societies such as CCS/BV/LR.

Applications of 5083 H321 Aluminum Plate in Automobile Manufacturing

Automotive body structure applications

In the automotive industry, 5083 H321 aluminum plate is mainly used for:

- Body frames and structural components: 5083 H321 aluminum plate is used in the manufacturing of key structural parts such as A/B/C pillars, sills, and longitudinal beams, providing necessary strength and crash safety.

- Body panels: Such as hoods, doors, and trunk lids, taking advantage of its good formability and surface quality.

- Chassis systems: For making chassis structural parts, suspension components, and crash beams, offering lightweight and high-strength solutions.

Applications in new energy vehicles

In the field of new energy vehicles, 5083 H321 aluminum plate has special advantages:

Battery system components:

- Battery trays: As load-bearing structures for battery packs, providing mechanical protection and thermal management support while reducing weight and ensuring safety.

- Battery housings: Protecting batteries from external environments while providing electromagnetic shielding.

- Battery module frames: Supporting and fixing battery modules, ensuring structural stability.

- Electric drive system parts: 5083 H321 aluminum plate is used for motor housings, electronic control housings, etc., taking advantage of its good thermal conductivity and electromagnetic shielding properties.

Commercial vehicle applications

In commercial vehicles, 5083 H321 aluminum plate is widely used in:

- Truck and trailer structures: Used in truck frames, trailer compartments, and partitions, reducing weight and improving fuel efficiency.

- Tanker vehicles: For manufacturing oil tankers, cement tankers, natural gas tankers, and other tanks, especially for liquefied gas transport tanks. Replacing traditional steel reduces weight by 30%-40%.

- Public transport vehicles: Such as bus body panels, roofs, and floors, providing lightweight solutions while meeting weather resistance requirements.

Advantages in automotive applications

The main advantages of 5083 H321 aluminum plate in automobile manufacturing include:

- Significant lightweight effect: Compared to traditional steel, it can reduce weight by 30%-40%, improving fuel efficiency and extending the range of electric vehicles by about 10%.

- Strong corrosion resistance: Especially resistant to road salt, moisture, and chemicals, extending vehicle service life.

- Good formability: Can be processed into complex shapes through stamping, bending, and other processes, meeting automotive design requirements.

- Excellent weldability: Easily joined by MIG, TIG, and laser welding, ensuring structural integrity.

- High recyclability: Can be 100% recycled and reused, meeting environmental requirements.

Applications of 5083 H321 Aluminum Plate in Aerospace

Aerospace structure applications

In aerospace, 5083 H321 aluminum plate is mainly used for the following structures and components:

- Aircraft fuel tanks and piping systems: 5083 H321 aluminum plate is an ideal material for manufacturing aircraft fuel systems, especially in areas requiring high corrosion resistance and weldability. Its excellent corrosion resistance ensures safety during long-term exposure to fuel and humid environments.

- Interior structural parts: Used in non-load-bearing components such as aircraft partitions, ceilings, and flooring, taking advantage of its lightweight, corrosion resistance, and easy processing.

- Non-critical wing and fuselage components: Although not as strong as high-strength alloys such as 7075, 5083 H321 is widely used in non-primary load-bearing structures such as ventilation ducts, insulation layers, and decorative panels.

Spacecraft applications

In spacecraft, 5083 H321 aluminum plate is mainly used for:

- Cryogenic propellant storage systems: Since 5083 H321 maintains good mechanical properties at extremely low temperatures, it is used for storage containers and transfer pipelines of liquid oxygen, liquid nitrogen, and other cryogenic propellants.

- Thermal protection systems: During atmospheric re-entry, 5083 H321 aluminum plate can serve as auxiliary thermal protection material, particularly in relatively low-temperature areas.

- Space station components: Used in non-pressurized structures of space stations, such as internal partitions and equipment brackets, taking advantage of its light weight and corrosion resistance.

Advantages in aerospace applications

The main advantages of 5083 H321 aluminum plate in the aerospace field include:

- Excellent low-temperature performance: Maintains good mechanical properties even at -20℃, suitable for cryogenic propellant systems.

- Excellent weldability: Easy to weld with high weld strength, suitable for manufacturing complex structures.

- Strong corrosion resistance: Especially resistant to fuels and lubricants, ensuring safety during long-term use.

- Lightweight: With a density of about 2.66 g/cm³, it is about two-thirds lighter than steel, helping reduce aircraft weight.

Applications of 5083 H321 Aluminum Plate in Other Fields

Pressure Vessels and Chemical Equipment

Applications of 5083 H321 aluminum plate in the field of pressure vessels and chemical equipment include:

- Storage tanks and reactors: Used for storing and handling corrosive substances such as acidic/alkaline media and liquefied gases, avoiding the frequent maintenance and replacement required with traditional steel.

- Piping systems: Used for conveying corrosive media pipelines, especially in chemical, pharmaceutical, and food processing industries.

- LNG storage tanks: Retains good mechanical properties even at extremely low temperatures of -196℃, with a service life of more than 30 years.

- Heat exchangers: Utilizing its good thermal conductivity and corrosion resistance, it is used to manufacture various types of heat exchangers and coolers.

Construction and Infrastructure

In the construction and infrastructure field, 5083 H321 aluminum plate is mainly used for:

- Building curtain walls and roofs: Used as exterior wall panels and roof materials for coastal buildings, resistant to salt spray and UV aging. Surfaces can be further enhanced through anodizing or nano-ceramic coating.

- Bridge structures: Applied to non-load-bearing components of cross-sea bridges, such as walkways, guardrails, and decorative panels, combining aesthetics and durability, while reducing maintenance costs by more than 50%.

- Architectural decoration: Such as ceilings, decorative moldings, and screens, utilizing its processability and surface treatment performance.

- Doors and window frames: Providing good weather resistance and thermal insulation, suitable for coastal and high-corrosion environment buildings.

Rail Transit

In the field of rail transit, 5083 H321 aluminum plate is mainly used for:

- Subway and light rail car bodies: As structural materials for car bodies, balancing strength and weather resistance.

- Train interiors: Such as interior partitions, ceilings, and floors, providing lightweight and easy-to-clean solutions.

- Rail vehicle structural parts: Such as bogie components, braking system parts, and electrical equipment housings.

Application Selection Recommendations

Shipbuilding

For key parts such as hulls, decks, and bottom plating, 5083 H321 temper should be prioritized, especially where high strength and good weldability are required.

Automobile Manufacturing

For body structural components, chassis parts, and battery system components, 5083 H321 is the ideal choice, especially in areas requiring lightweight and corrosion resistance.

Aerospace

For aircraft fuel tanks, cryogenic propellant systems, and non-load-bearing components, 5083 H321 provides good solutions, particularly in scenarios requiring low-temperature performance and weldability.

Pressure Vessels

For containers storing corrosive media and cryogenic liquids, 5083 H321 is the preferred material, especially where excellent corrosion resistance and low-temperature performance are required.

What is the difference between Aluminium 5083 H111 and H321?

| Comparison Item | 5083 H111 | 5083 H321 |

| Production Process | Light cold work after annealing, without stabilization annealing. Retains part of the work-hardening effect, balancing strength and formability. | Heavy cold work + stabilization annealing to eliminate residual stress and optimize precipitate distribution. |

| Corrosion Resistance | Moderate sensitivity to intergranular corrosion; continuous β phase may exist at grain boundaries. Suitable for freshwater or general atmospheric environments; long-term seawater exposure requires protection. | Intergranular corrosion mass loss: 18.7 mg/cm² (better than H111). Significantly improved resistance to stress corrosion cracking (SCC), suitable for high-salinity marine environments. |

| Typical Applications | Secondary ship structures (decks, bulkheads), building curtain walls, vehicle frames, and medium-strength components requiring welding. | Primary ship structures, LNG storage tanks, pressure vessels, aerospace frameworks, and critical parts under high load and corrosion for long periods. |

| Selection Recommendation | Preferred when budget is limited, frequent welding or forming is required, and the corrosion environment is relatively mild. | Preferred in high-corrosion environments (such as seawater), high-load conditions, or where dimensional stability requirements are strict. |

Comparison of 5083 H321 Aluminum Plate with Other Tempers

Comparison between 5083 H321 and H116

5083 H321 and H116 are the two most commonly used tempers in the marine field. Their main differences are:

| Characteristics | 5083 H321 | 5083 H116 |

| Processing Technology | Work-hardened followed by partial annealing | Work-hardened followed by stabilization treatment |

| Strength | Higher | Slightly lower |

| Corrosion Resistance | Excellent, resistant to stress corrosion | Excellent, resistant to exfoliation corrosion |

| Application Scenarios | Welded structures and areas requiring higher strength | Areas requiring higher exfoliation corrosion resistance |

H321 temper is more suitable for scenarios requiring higher strength and weldability, while H116 temper is more suitable for scenarios requiring higher resistance to exfoliation corrosion.

Comparison between 5083 H321 and H112

The main differences between 5083 H321 and H112 tempers are:

| Characteristics | 5083 H321 | 5083 H112 |

| Processing Technology | Work-hardened followed by partial annealing | Hot rolled and naturally cooled |

| Strength | Higher | Lower |

| Formability | Moderate | Better |

| Application Scenarios | Areas requiring higher strength and weldability | Areas requiring better formability |

H321 temper is more suitable for scenarios requiring higher strength and weldability, while H112 temper is more suitable for scenarios requiring better formability.

5083 H321 aluminum plate is the ideal choice for harsh corrosive environments, especially marine environments. Its high strength, excellent corrosion resistance, and weldability are its core advantages.

5083 H321 Aluminum Properties

- Non-heat-treatable strengthening: 5083 aluminum plate belongs to non-heat-treatable alloys, which cannot be strengthened through heat treatment. However, it is one of the strongest grades among the non-heat-treatable alloys. Its H321 temper is obtained through work hardening and stabilization treatment.

- High-temperature performance: This alloy is not recommended for long-term use in environments exceeding 65°C (about 150°F).

- Machining and welding: 5083 aluminum plate has excellent formability, but its machinability is considered relatively poor. It has excellent weldability and can be joined using arc welding and resistance welding processes, while still maintaining outstanding strength after welding.

- Corrosion resistance: The magnesium content gives it excellent resistance to seawater, salt spray, and industrial atmospheric corrosion, making it especially suitable for marine environments.

- Low-temperature toughness: It retains good toughness even at -196℃, making it suitable for ultra-low temperature applications such as LNG storage tanks.

Haomei 5083 h321 aluminum plate stock list

| Description | Temper | Thickness/in | Form |

| 0.125" ASTM B209, ASTM B928 5083 H321 Aluminum Sheet | H321 | 0.125" | Sheet |

| 0.25" ASTM B209 ASTM B928 5083-H321 Aluminum Plate | H321 | 0.25" | Plate |

| 0.375" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 0.375" | Plate |

| 0.375" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 0.375" | Plate |

| 0.500" ASTM B928 5083 H321 Aluminum Plate | H321 | 0.500" | Plate |

| 0.500" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 0.500" | Plate |

| 0.625" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 0.625" | Plate |

| 0.750" ASTM B928 5083 H321 Aluminum Plate | H321 | 0.750" | Plate |

| 0.750" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 0.750" | Plate |

| 1.000" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 1.000" | Plate |

| 1.250" ASTM B209, ASTM B928 5083 H321 Aluminum Plate | H321 | 1.250" | Plate |

| 1.250" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 1.250" | Plate |

| 1.500" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 1.500" | Plate |

| 2.000" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 2.000" | Plate |

| 2.250" ASTM B928 5083 H321 Aluminum Plate | H321 | 2.250" | Plate |

| 2.500" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 2.500" | Plate |

| 3.000" ASTM B209, ASTM B928 5083 H321 Aluminum Plate | H321 | 3.000" | Plate |

| 3.250" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 3.250" | Plate |

| 3.500" ASTM B209, ASTM B928 5083 H321 Aluminum Plate | H321 | 3.500" | Plate |

| 4.250" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 4.250" | Plate |

| 6.000" AMS4056, QQ-A-250/6 5083 H321 Aluminum Plate | H321 | 6.000" | Plate |

Questions related to 5083 H321 Aluminum Plate Sheet

What is aluminum plate grade 5083?

5083 grade aluminum plate is a high-strength, corrosion-resistant aluminum alloy often used in marine environments and military applications.

What is the difference between 6061 and 5083 Aluminium?

The difference between 6061 and 5083 aluminum is that 6061 is a general-purpose, heat-treatable alloy with good mechanical properties and machinability, while 5083 is specifically designed for high strength and corrosion resistance in harsh environments.

Products you may be interested in

- 5083 Aluminum Plate Sheet

- 5083 h116 aluminum plate sheet

- 5083 h111 aluminum plate sheet

- 5083 h112 aluminum plate sheet

- 5083 h22 aluminum plate sheet

- 5083 h34 aluminum plate sheet

- 5083 o aluminum plate sheet

- 5083 H131 Aluminum Plate

Further reading

Users viewing this material also viewed the following