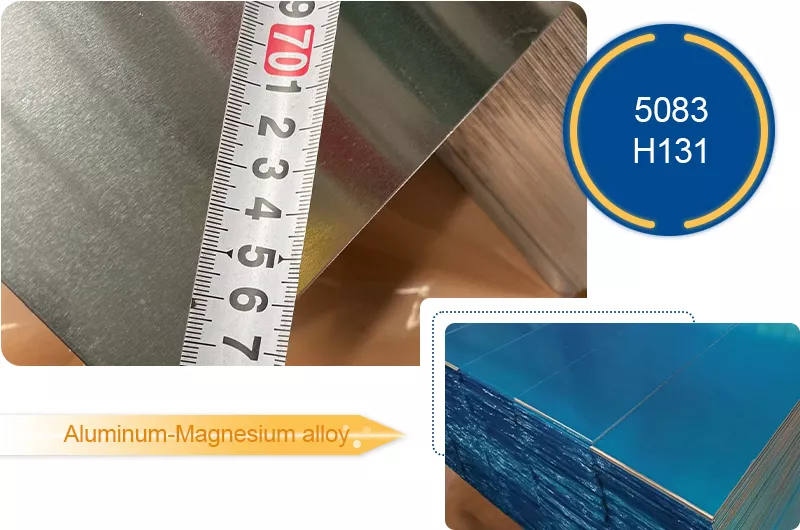

5083 H131 Aluminum Plate

Aluminum alloy 5083 H131 is an Al-Mg high-magnesium alloy, belonging to the non-heat-treatable aluminum alloy series. It achieves high strength and good impact resistance through cold work hardening and stabilization treatment.

Aluminum alloy 5083-H131 is an Al-Mg corrosion-resistant aluminum alloy with magnesium (content 4.0%–4.9%) as the main alloying element. It offers well-balanced overall performance, particularly excelling in corrosion resistance and weldability.

- H: Indicates a strain-hardened condition (strength increased through cold working)

- 1: Indicates strain hardening only (without additional heat treatment)

- 3: Indicates stabilization treatment (improves dimensional stability)

- 1: Indicates a specific degree of hardening

H131 process: After cold work hardening, the material undergoes low-temperature stabilization treatment, allowing the strength to reach the highest level among non-heat-treatable alloys while maintaining a certain level of toughness.

5083 H131 Aluminum Plate Characteristics

- Alloy series: 5XXX series (Al-Mg series) wrought aluminum alloy.

- Heat treatability: Cannot be strengthened by heat treatment; strength is mainly improved through cold working.

- Excellent corrosion resistance: Especially resistant to seawater corrosion, which is one of its main advantages.

- Excellent weldability: Good welding performance, suitable for various welding processes.

- Good cold workability: Offers good forming and processing performance.

- High strength: Among the highest-strength non-heat-treatable alloys.

- Impact resistance: Impact resistance is significantly improved after H131 treatment.

- Service temperature limitation: Not recommended for use above 65°C.

5083-H131 Aluminum Plate Stock Sizes

| Description | Temper | Thickness | Width × Length |

| 0.25" 5083-H131 Aluminum Plate | H131 | 0.25 in | 72 in × 144 in |

| 0.375" 5083-H131 Aluminum Plate | H131 | 0.375 in | 72 in × 144 in |

| 0.50" 5083-H131 Aluminum Plate | H131 | 0.50 in | 72 in × 144 in |

| 0.75" 5083-H131 Aluminum Plate | H131 | 0.75 in | 72 in × 144 in |

| 1.00" 5083-H131 Aluminum Plate | H131 | 1.00 in | 72 in × 144 in |

| 1.25" 5083-H131 Aluminum Plate | H131 | 1.25 in | 72 in × 144 in |

| 1.50" 5083-H131 Aluminum Plate | H131 | 1.50 in | 72 in × 144 in |

| 1.75" 5083-H131 Aluminum Plate | H131 | 1.75 in | 72 in × 144 in |

| 2.00" 5083-H131 Aluminum Plate | H131 | 2.00 in | 72 in × 144 in |

| 2.25" 5083-H131 Aluminum Plate | H131 | 2.25 in | 72 in × 144 in |

| 2.50" 5083-H131 Aluminum Plate | H131 | 2.50 in | 72 in × 144 in |

| 3.00" 5083-H131 Aluminum Plate | H131 | 3.00 in | 72 in × 144 in |

5083 H131 Aluminum Plate Chemical Composition (%)

| Element | Content Range |

| Magnesium (Mg) | 4.0–4.9 (core strengthening element) |

| Manganese (Mn) | 0.40–1.0 |

| Chromium (Cr) | 0.05–0.25 |

| Silicon (Si) | ≤0.40 |

| Copper (Cu) | ≤0.10 |

| Zinc (Zn) | ≤0.25 |

| Aluminum (Al) | Balance |

5083 H131 Aluminum Plate Mechanical Properties

| Property | Value |

| Tensile Strength | ≥470 MPa |

| Yield Strength | ≥360 MPa |

| Elongation | ≥7% |

| Compressive Strength | ≥540 MPa |

| Dynamic Compressive Strength (high strain rate) | ≥750 MPa |

| Density | 2.71 g/cm³ |

Feature: It maintains good toughness even at low temperatures of -60°C, making it one of the few aluminum alloys suitable for extremely cold conditions.

5083 H131 Aluminum Plate Applications

- Shipbuilding: Used for hull shells, decks, bulkheads, and other structural components; it is an important aluminum alloy for naval and marine vessels.

- Transportation: Used for automotive body parts, rail transit car bodies, truck structural components, etc.

- Pressure vessels: Used in the manufacture of liquefied gas storage tanks and chemical containers.

- Other fields: Also used for aerospace welded components and building structures.

Military applications:

- Military armored vehicle hulls and floors (in compliance with MIL-DTL-46027K standard)

- Armored personnel carriers

- Specialized protective equipment

Civil applications:

- Pressure vessels and cryogenic equipment (liquid oxygen / liquid nitrogen storage tanks)

- Offshore engineering and shipbuilding (seawater corrosion resistance)

- Chemical equipment (65% weight reduction compared to stainless steel, maintenance cycle extended by three times)

- Rail transit and automotive structural components

Comparison of 5083 H131 Aluminum with Other Tempers

| Temper | Characteristics | Applications |

| H131 | Highest strength, lowest ductility | Armor, high-stress structures |

| H111 | Medium strength, higher ductility | General structural components, parts requiring forming |

| H116 | Good balance of strength and corrosion resistance | Ships, marine environments |

| O (Annealed) | Lowest strength, highest ductility | Deep drawing, applications requiring high plasticity |

Key difference: H131 offers higher strength than H111 but lower ductility, sacrificing some formability in exchange for extreme strength.

5083 H131 Aluminum Plate Processing Guidelines

- Welding: TIG/MIG welding is preferred; no special post-weld heat treatment is required, with high strength retention.

- Forming: Due to high strength, cold bending requires higher-tonnage equipment; room-temperature forming is recommended.

- Machining: Good machinability; carbide cutting tools are recommended.

- Surface treatment: Anodizing, painting, and other surface treatments can be applied to further enhance corrosion resistance.

5083 H131 is an aluminum alloy that combines high strength, excellent corrosion resistance, and good weldability, making it particularly suitable for military armor and harsh industrial environments. It delivers outstanding performance among non-heat-treatable alloys and is an ideal choice for lightweight structures with high safety requirements, especially in marine engineering, pressure vessels, and military equipment, where it offers irreplaceable advantages.

Products you may be interested in

- 5083 Aluminum Plate Sheet

- 5083 h321 aluminum plate sheet

- 5083 h116 aluminum plate sheet

- 5083 h111 aluminum plate sheet

- 5083 h112 aluminum plate sheet

- 5083 h22 aluminum plate sheet

- 5083 h34 aluminum plate sheet

- 5083 o aluminum plate sheet

Further reading

Users viewing this material also viewed the following