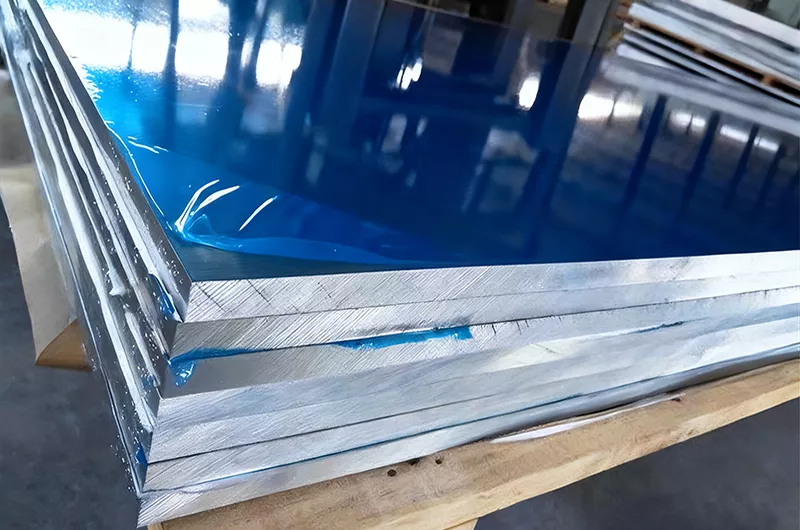

5083 h111 aluminum plate sheet

5083-H111 is a temper of the 5083 aluminum alloy, where the metal undergoes strain hardening to achieve strength lower than the H11 state (1/8 hardness).

What material is 5083 H111?

5083-H111 is an aluminum alloy that combines excellent seawater corrosion resistance, weldability, moderate strength, and good formability.

5083-H111 refers to 5083 aluminum alloy in the H111 temper. This temper involves annealing and slight strain hardening to improve strength and formability. It is a non-heat-treatable alloy, commonly used in shipbuilding, rail vehicles, automotive body panels, and pressure vessels.

The H111 temper indicates that the material has undergone a certain degree of strain hardening through forming (or plastic deformation), but less than what is required for the H11 temper. It achieves a balance: the strength is higher than the fully annealed ("O") state, yet the formability and weldability are better than the higher hardness tempers.

Meaning of H111:

- It indicates that the material has undergone some work hardening, but the hardening level is insufficient to reach the H11 temper.

- Subsequently, a low-temperature annealing process is applied to partially relieve internal stresses, making its strength slightly lower than the H11 temper.

- The H111 temper can be understood as a "semi-hard" or "stabilized" state. It is harder and stronger than the fully annealed O temper, yet softer than fully hardened tempers like H14, offering better formability.

Characteristics of H111:

- Good balance of strength and formability: It provides moderate strength while allowing reasonable bending, stretching, and other forming operations.

- Low internal stress: Compared to higher work-hardened states, its internal stresses are partially relieved, reducing deformation tendencies after processing.

Haomei 5083 H111 Aluminum Alloy Product Specifications

| Alloy | 5083 |

| Material temper | h111 |

| Thickness (mm) | 0.1-500 |

| Width (mm) | 100-2800 |

| Length (mm) | Customize |

| Typical product | boat buling, vehicle bodies, welding parts, tread plate, etc. |

Haomei 5083 H111 Aluminum Product Forms

5083 H111 Sheet

5083 H111 aluminum sheet is a thin, flat form of aluminum alloy with excellent corrosion resistance and moderate strength. It is widely used in marine, transportation, and construction applications where lightweight and durability are required. The sheet can be easily cut, bent, or formed into complex shapes.

5083 H111 Plate

5083 H111 aluminum plate is a thicker version of the alloy, offering higher strength and rigidity compared to the sheet. It is suitable for heavy-duty structural components, pressure vessels, and marine equipment. Its excellent weldability and corrosion resistance make it ideal for harsh environments.

5083 H111 Round Bar

5083 H111 round bar is a cylindrical aluminum alloy form, designed for machining into shafts, rods, and other mechanical components. It retains excellent corrosion resistance and good mechanical strength, suitable for marine, automotive, and aerospace industries. The round bar can be cut, drilled, or machined to precise specifications.

5083 H111 Aluminum Sheet Plate Properties

- Excellent corrosion resistance: Particularly outstanding resistance to seawater and marine atmospheric environments. This is its most prominent advantage.

- Good weldability: Can be joined using various welding methods, with stable weld performance.

- Moderate strength: Its strength is higher than pure aluminum and 1xxx, 3xxx series aluminum alloys, but lower than 2xxx and 7xxx series high-strength aluminum alloys.

- Good workability: Suitable for cold forming such as stamping and bending.

- Non-heat-treatable: 5083 alloy cannot significantly increase strength through "quenching + aging" heat treatment like 6061; its strength is mainly obtained through cold working (work hardening).

5083 H111 Aluminum Sheet Plate Corrosion Resistance

- 5083 aluminum alloy is a high-magnesium alloy with excellent corrosion resistance, especially resistance to seawater corrosion. This makes it an ideal choice for marine applications.

- The 5083-H116 and 5083-H321 tempers also have especially excellent resistance to exfoliation and stress corrosion.

- High corrosion resistance is a key feature that enables the widespread use of 5083 aluminum alloy in marine engineering.

5083 H111 Aluminum Sheet Plate Workability

5083 H111 aluminum alloy has good workability:

- Weldability: Excellent, can be joined using various welding methods

- Machinability: Good, suitable for various mechanical processing

- Formability: Relatively soft and tough, easy to bend and shape

- Heat treatment: Cannot be strengthened by heat treatment; strength can only be increased through cold working or work hardening

5083 H111 Aluminum Sheet Plate Chemical Composition

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 h111 aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5083 | O | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 |

| 5083 | H111 | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 |

| 5083 | H22, H32 | 3.00-6.00 | 305-380 | ≥215 | ≥8 | - |

| 5083 | H116 | 3.00-50.00 | ≥305 | ≥215 | ≥10 | ≥10 |

| 5083 | H321 | 3.00-50.00 | 305-385 | ≥215 | ≥12 | ≥10 |

| 5083 | H112 | 6.00-50.00 | ≥275 | ≥125 | ≥12 | ≥10 |

5083 h111 aluminum plate sheet reference data for some physical properties (for guidance only)

| Property | Value |

| Density | 2.65 kg/m³ |

| Melting Point | 570 °C |

| Thermal Expansion | 25 x 10⁻⁶ /K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 121 W/m·K |

| Electrical Resistivity | 0.058 x 10⁻⁶ Ω·m |

5083 H111 Equivalent

Standard equivalent grades of 5083 aluminum alloy

| Standard System | Equivalent Grade |

| USA (UNS) | A95083 |

| International Standard (ISO) | AlMg4.5Mn |

| UK (BS) | N8 |

| Germany (DIN) | 3.3547, AlMg4.5Mn |

| European Standard (EN) | EN AW-5083 |

Alternative aluminum alloys to 5083

| Alloy | Main Features | Applications |

| 5005 | Medium strength, good corrosion resistance | General use |

| 5052 | Medium strength, excellent corrosion resistance | General structural components |

| 5251 | Slightly higher strength than 5052 | Construction applications |

| 5383 | High strength, good weldability | High-strength structural components |

| 5086 | High corrosion resistance, moderate strength | Marine environments |

| 5454 | Medium strength, good weldability | Pressure vessels |

| 5754 | Good corrosion resistance, medium strength | General structural components |

These 5xxx series alloys have different chemical and mechanical properties, allowing selection of suitable alternative materials from low to high strength according to application needs.

5083 H111 aluminum plate sheet welding

When welding 5083 to itself or to other alloys from the same subgroup, the recommended filler metal is 5183. Other suitable filler materials include 5356 and 5556.

5083 H111 Aluminum Plate Sheet Stock List

| Description | Temper | Thickness/in | Form |

| ASTM B209 ASME SB209 5083-H111 Aluminum Sheet | H111 | 0.04" | Sheet |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Sheet | H111 | 0.04" | Sheet |

| ASTM B209, ASTM B928 5083-H111 Aluminum Sheet | H111 | 0.06" | Sheet |

| ASTM B209 ASME SB209 5083-H111 Aluminum Sheet | H111 | 0.06" | Sheet |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Sheet | H111 | 0.08" | Sheet |

| ASTM B209 ASME SB209 5083-H111 Aluminum Sheet | H111 | 0.08" | Sheet |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Sheet | H111 | 0.1" | Sheet |

| ASTM B928 5083-H111 Aluminum Sheet | H111 | 0.12" | Sheet |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Sheet | H111 | 0.16" | Sheet |

| ASTM B209, ASTM B928 5083-H111 Aluminum Sheet | H111 | 0.16" | Sheet |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Sheet | H111 | 0.2" | Sheet |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.24" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.31" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.39" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.47" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.63" | Plate |

| ASTM B209, ASTM B928 5083-H111 Aluminum Plate | H111 | 0.71" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.87" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 0.98" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 1.1" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 1.38" | Plate |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Plate | H111 | 1.77" | Plate |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Plate | H111 | 1.97" | Plate |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Plate | H111 | 2.36" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 2.56" | Plate |

| AMS4056, QQ-A-250/6 5083-H111 Aluminum Plate | H111 | 2.76" | Plate |

| ASTM B209 ASME SB209 5083-H111 Aluminum Plate | H111 | 3.15" | Plate |

| ASTM B928 5083-H111 Aluminum Plate | H111 | 3.54" | Plate |

Applications of 5083 H111 Aluminum Plate Sheet

The 5083-H111 aluminum plate is widely used in various industries due to its excellent performance, including marine, aerospace, construction, and transportation sectors.

Marine and Shipbuilding Applications

5083 H111 aluminum alloy is an ideal material for shipbuilding, mainly used in:

- Hull structural components, including decks, sides, and bottom plates

- Superstructures of yachts and cruise ships

- Ship engine mounts

- Port infrastructure

- Offshore engineering structures

The high corrosion resistance and good weldability of 5083 H111 aluminum alloy make it particularly suitable for marine environments.

Transportation Applications

In the transportation sector, 5083 H111 aluminum alloy is mainly used for:

- Subway and light rail vehicle structural components

- Automotive body structures and panels

- Automotive fuel tanks and air reservoirs

- Bus and truck body panels

- Railway freight cars, such as C82 coal cars

The high strength and corrosion resistance of 5083 H111 aluminum alloy make it an ideal choice for lightweight transportation vehicles.

Pressure Vessels and Tanks

Applications of 5083 H111 aluminum alloy in pressure vessels include:

- Tanker trucks and transport containers

- Refrigerated trucks and refrigerated containers

- Aluminum ceilings for LNG storage tanks

- Air reservoirs

- GIS (Gas-Insulated Switchgear) housings

These applications take advantage of the excellent strength, corrosion resistance, and weldability of 5083 aluminum alloy.

Building and Structural Applications

In the construction field, 5083 H111 aluminum alloy can be used for:

- Building curtain walls and roof structures

- Architectural decorations and trims

- Bridge structural components

- Balcony and stair railings

- Building formwork and scaffolding

The corrosion resistance and moderate strength of 5083 aluminum alloy make it a reliable choice for construction applications.

Other Applications

Other applications of 5083 H111 aluminum alloy include:

- Drilling equipment and oil industry machinery

- Missile and aerospace components

- Rail transit equipment

- Side panels for power battery modules

- Precision machined components

5083 H111 Marine Grade Aluminum Plate

5083 H111 is a high-strength marine-grade aluminum alloy renowned for its excellent corrosion resistance, especially in marine environments. Due to its durability and performance, it is widely used in the construction of ships and structures.

| Property | Details |

| Corrosion Resistance | Excellent resistance to saltwater and marine environments. |

| Strength | High strength compared to other marine aluminum alloys. |

| Weldability | Good weldability for ease of fabrication and repair. |

| Typical Applications | Marine vessels, offshore platforms, structural components exposed to seawater. |

| Specifications | Thickness: 3mm to 100mm; Customizable width and length; Meets international marine and industrial standards. |

Aluminum 5083 H111 for Tankers

5083 H111 aluminum is specifically used in the construction of tankers due to its high strength and corrosion resistance. This alloy is suitable for harsh environments and demanding applications in the maritime industry.

| Property | Details |

| Strength | High tensile strength essential for structural integrity of tankers. |

| Corrosion Resistance | Superior resistance to seawater and corrosive substances. |

| Fabricability | Easily formed and welded, suitable for complex tanker designs. |

| Typical Applications | Tanker hulls, superstructures, storage tanks for marine fuels and cargo, various structural components. |

| Specifications | Thickness: 6mm to 50mm; Custom sizes based on design requirements; Conforms to industry standards for tanker construction. |

Other Temper Conditions for 5083 Aluminum Plate

- O: Fully annealed condition, the softest, suitable for further processing.

- H22: Semi-hard condition after solution treatment.

- H32: Hard condition after solution treatment and stabilizing annealing.

- H116: Provides higher corrosion resistance, suitable for harsh environments.

- H321: More stable than H32, suitable for applications requiring higher strength and stability.

Comparison of 5083 Tempers

- 5083-O (Annealed): The softest temper, lowest strength, but best plasticity and formability. Suitable for operations requiring severe deformation.

- 5083-H112 (Hot Worked): Temper achieved by forming at high temperature followed by natural cooling, with certain strength, typically used for thick plates or profiles.

- 5083-H116/H321: Tempers specifically designed for marine environments, with more stable resistance to exfoliation corrosion and higher strength than H111. Commonly used for high-performance marine aluminum plates.

5083 H111 vs H116

Production Process Differences

5083 H111

Suitable for products that have undergone sufficient work hardening but whose hardening level does not fully meet the H11 requirements. This temper is achieved by applying sufficient work hardening without reaching the full annealed state, but the hardening does not completely match the H1 temper.

5083 H116

Specifically suitable for 5xxx series alloys with magnesium content ≥3%. This is a special strain hardening treatment, where temperature is precisely controlled to enhance the corrosion resistance of the aluminum-magnesium alloy. H116 is a special heat-treated temper, between H112 and H321, optimizing corrosion resistance and strength.

It can be seen that the strength of 5083 H116 is significantly higher than H111, but its elongation is lower, making the material relatively harder and more brittle.

Corrosion Resistance Comparison

In terms of corrosion resistance, H116 is clearly superior to H111:

- H116 has excellent resistance to exfoliation corrosion, with exfoliation corrosion rating ≤ PB

- Intergranular corrosion value of H116 ≤ 15 Mg/cm²

- H111 temper does not have special treatments targeting corrosion resistance

This makes H116 particularly suitable for marine and other harsh corrosive environments.

Application Differences

5083 H111

Suitable for applications requiring good formability and weldability, such as ship hulls and decks, automotive body structural components, etc.

5083 H116

Mainly used for applications in marine environments requiring high corrosion resistance, such as underwater parts of ships, offshore engineering structures, and pressure vessels requiring high strength and corrosion resistance.

What is the difference between 5083 H116 and 5083 H321?

Production Process Differences

5083 H116

A special temper designed for 5xxx series alloys with magnesium content ≥3%, using controlled temperature strain hardening to enhance corrosion resistance.

5083 H321

Suitable for products that have undergone rolling work hardening followed by low-temperature heat treatment or mechanical property stabilization due to thermal effects during hot processing. H321 is a stabilized temper after cold working, typically improving ductility.

In some cases, H321 can be used interchangeably with H111 and H116, and it is considered a marine-grade material.

The strength range of H321 is relatively wide; the lower limit is comparable to H116, but the upper limit is higher, and elongation is also slightly greater, indicating better overall performance.

Corrosion Resistance Comparison

In terms of corrosion resistance:

- H116 has excellent resistance to exfoliation corrosion, with an exfoliation corrosion rating ≤ PB

- Intergranular corrosion value of H116 ≤ 15 Mg/cm²

- H321 also has good corrosion resistance, but the standards do not explicitly specify its exfoliation corrosion performance

Both tempers are suitable for marine environment applications requiring high corrosion resistance.

Application Differences

5083 H116

Mainly used in marine environments with extremely high corrosion resistance requirements, such as underwater parts of ships and offshore engineering structures.

5083 H321

Suitable for applications requiring high strength and good weldability, such as pressure vessels, tanker trucks, refrigerated trucks, and refrigerated containers.

H321 is an ideal choice for marine aluminum plates because it maintains excellent tensile strength in welded areas.

5083 H111 vs H112

- H111 has a lower degree of work hardening, suitable for scenarios requiring moderate strength.

- H112 is suitable for hot-formed products with stricter mechanical property requirements.

5083 Aluminum Selection Recommendations

5083 H111 aluminum alloy, as a high-strength, corrosion-resistant Al-Mg series alloy, offers excellent overall performance, especially in marine environments and applications requiring lightweight structures.

- When good formability and weldability are required, prioritize the 5083 H111 temper

- When higher strength and superior corrosion resistance are needed, consider the 5083 H116 temper

- When high strength and good weldability are required, the 5083 H321 temper can be considered

- In marine environments, especially for parts exposed to seawater, H116 or H321 tempers of 5083 aluminum should be prioritized

Products you may be interested in

- 5083 Aluminum Plate Sheet

- 5083 h321 aluminum plate sheet

- 5083 h116 aluminum plate sheet

- 5083 h112 aluminum plate sheet

- 5083 h22 aluminum plate sheet

- 5083 h34 aluminum plate sheet

- 5083 o aluminum plate sheet

- 5083 H131 Aluminum Plate

Further reading

Users viewing this material also viewed the following