8011 aluminum foil is the core material of air‑conditioning heat exchangers, holding an important position in the air‑conditioning industry. Its excellent mechanical properties, processability, and heat‑exchange performance make it an ideal choice for heat‑exchange components such as air‑conditioner evaporators and condensers.

As a professional manufacturer of air‑conditioning aluminum foil, Haomei Aluminum is committed to providing air‑conditioning manufacturers with high‑performance, highly reliable integrated solutions. Our standard aluminum foil, hydrophilic aluminum foil, hydrophobic aluminum foil, coated aluminum foil, HVAC‑system aluminum foil tubes, and air‑conditioning duct insulation tapes are all made from high‑quality 8011 aluminum material.

Specifications of 8011 Aluminum Foil for Air Conditioning

Thickness Specifications

The thickness range of 8011 air‑conditioning aluminum foil is quite broad; depending on different application scenarios and processing requirements, the main thickness specifications are as follows:

- Standard thickness: 0.08 mm–0.2 mm — this is the most commonly used thickness range in air‑conditioner heat exchangers

- Ultrafine specification: as thin as 0.03 mm — mainly used for high‑efficiency heat exchangers with special requirements

- Thicker specifications: up to 0.5 mm — mainly used for structural parts requiring higher strength

- The mainstream market thickness for air‑conditioning aluminum foil has now decreased from the former 0.15–0.2 mm to between 0.09–0.15 mm.

Width Specifications

The width specifications of 8011 air‑conditioning aluminum foil are also quite flexible, mainly including:

- Narrow width: 15 mm–500 mm — mainly used for small air‑conditioners or heat exchangers with special structure

- Medium width: 500 mm–1000 mm — the most common width range, suitable for most residential and commercial air conditioners

- Wide width: 1000 mm–1200 mm — mainly used for large air‑conditioning equipment or customized products

Coil Specifications

8011 air‑conditioning aluminum foil is usually supplied in coil form. The main coil specifications include:

- Inner coil diameter: Φ75 mm, 150 mm, 300 mm, 400 mm, 500 mm, etc.

- Outer coil diameter: typically 100 mm–1500 mm, specifically determined based on customer requirements

- Coil weight: depending on thickness and width, a single coil can weigh from several hundred kilograms to several tonnes

Types and Temper Conditions of 8011 Aluminum Foil for Air Conditioning

Alloy Temper Classification of 8011 Aluminum Foil

According to the degree of work hardening and heat‑treatment condition, 8011 aluminum foil is mainly classified into the following temper conditions:

- O‑temper: fully annealed condition, offering the highest ductility and lowest strength

- H14 temper: cold‑worked without subsequent annealing; provides medium strength and hardness

- H16 temper: higher degree of work hardening; higher strength and hardness

- H18 temper: maximum work hardening; achieves highest strength and hardness

- H22 temper: cold‑worked followed by partial annealing; strikes a good balance between strength and ductility

- H24 temper: cold‑worked then stabilized; offers high strength and good formability

- H26 temper: even greater work hardening; strength further increased

Different temper conditions of 8011 aluminum foil are used differently in air‑conditioning: O‑temper is mainly used for parts that require bending or deep drawing; H22 and H24 tempers are widely used for air‑conditioning heat‑exchanger fins.

Surface Treatment Types of 8011 Air‑Conditioning Aluminum Foil

Depending on surface treatment method, 8011 air‑conditioning aluminum foil is mainly classified into:

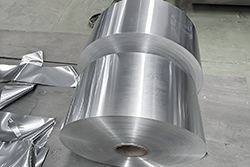

- Bare foil: untreated surface aluminum foil, mainly used in scenarios where surface performance requirements are low

- Hydrophilic aluminum foil: treated by special process to form a highly hydrophilic film on the surface

- Epoxy aluminum foil: surface coated with epoxy, offering good corrosion resistance and decorative properties

- Gold aluminum foil: surface specially treated to present a golden appearance; combines decoration and functionality

- Blue aluminum foil: surface treated to a blue finish; usually has good hydrophilicity and corrosion resistance

Among these, hydrophilic aluminum foil is the most widely used type in air‑conditioning, accounting for approximately 80 % of the total air‑conditioning aluminum foil usage.

Coating Treatments and Applications of 8011 Aluminum Foil

Hydrophilic coated 8011 aluminum foil

Hydrophilic aluminum foil is the primary application form of 8011 foil in the air‑conditioning field, and the coating technology is key. Hydrophilic foil is produced by chemically generating a stable, highly hydrophilic film on the aluminum surface, causing condensation water to form a film instead of droplets.

The main features of the hydrophilic coating on 8011 air‑conditioning aluminum foil are:

- Initial contact angle less than 5° — ensures excellent initial hydrophilicity

- Sustained contact angle less than 30° — ensures long‑term hydrophilicity during use

- Good water wetting performance — no film shrinkage after five cycles of water flow drying

- Strong adhesion — firmly bonded to the aluminum substrate

Coating Structure and Performance

The coating of 8011 air‑conditioning aluminum foil typically consists of two layers:

Primer coating: usually employs a water‑borne epoxy resin with excellent corrosion resistance; it works by reacting water‑borne epoxy emulsion with latent curing agents at elevated temperature to form a film

Top coating: usually made from a polyurethane resin prepolymer copolymerized with various monomers in an aqueous medium, forming a polymeric interpenetrating network structure, providing good hydrophilicity

Regarding coating performance, the coating thickness of 8011 air‑conditioning aluminum foil is typically 1–3 μm and has the following performance characteristics:

- Neutral salt spray resistance: at least 500 hours, meeting Level 10 standard; for special requirements, can reach over 2000 hours

- Alkali resistance: more than 5 minutes (20 % NaOH solution), satisfying alkali resistance requirements in air‑conditioner production

- Adhesion: meets qualified standards in cross‑hatch adhesion test

- Cupping value: reflecting coating bond strength and flexibility, typically required to be ≥ 5.8 mm

Coating Colors and Appearance

Coating colors of 8011 air‑conditioning aluminum foil are varied, mainly including:

- Blue 8011 aluminum foil: the most common hydrophilic aluminum foil color, with good hydrophilicity and corrosion resistance

- Gold 8011 aluminum foil: good decorative and functional properties, mainly used in high‑end air‑conditioning products

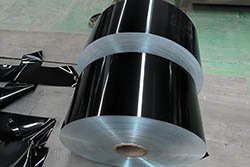

- Black 8011 aluminum foil: good heat‑absorption performance, suitable for certain special scenarios

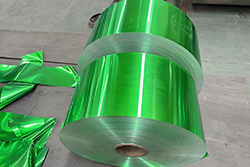

- Green 8011 aluminum foil: environmentally friendly coating, meeting modern eco‑requirements

- Other colors: such as antique bronze; customizable per customer needs

-

gold aluminum foil

-

blue aluminum foil

-

pink aluminum foil

-

silver aluminum foil

-

black aluminum foil

-

bronze aluminum foil

-

green aluminum foil

-

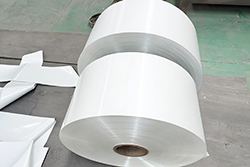

white aluminum foil

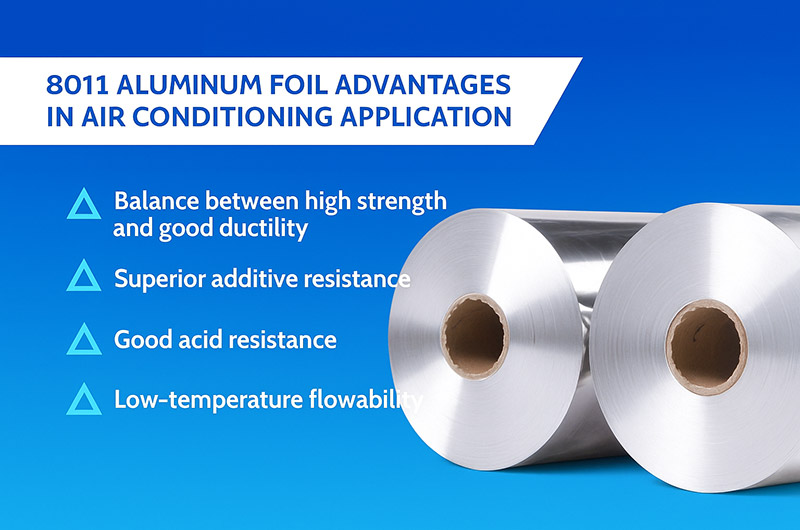

Advantages of 8011 Aluminum Foil in Air‑Conditioning Applications

- The balance of high strength and good toughness: 8011 aluminum foil has tensile strength up to 140–145 MPa, with elongation of 13–15 %

- Excellent processability: 8011 foil exhibits good stamping and bending performance, meeting the requirements for fabrication of complex‑shaped fins

- Good corrosion resistance: although in certain environments it may not outperform 3000‑series foil, 8011 foil with appropriate surface treatment achieves sufficient corrosion resistance

- Outstanding low‑temperature performance: studies show that at –170 °C, the elongation of 8011 foil is 2.4 times that at room temperature

- High cost‑performance ratio: compared to pure aluminum foil, 8011 offers significantly improved strength and corrosion resistance; compared to 3000‑series foil, it offers similar performance at lower cost

Applications of 8011 Aluminum Foil in the Air‑Conditioning Field

Main application areas of 8011 aluminum foil in air‑conditioning:

8011 foil is mainly applied in the following parts of air‑conditioning units:

- Evaporators: used as heat‑exchange fins in the evaporator, one of the most important heat‑exchange components in air conditioners

- Condensers: used as heat‑exchange fins in the condenser; requires good thermal conductivity and corrosion resistance

- Air‑conditioning heat exchangers: collectively refers to evaporator and condenser—this is the primary application for 8011 foil

- Cooling fins: as an important part of the air‑conditioning cooling system, improving overall heat‑dissipation efficiency

Benefits of applying 8011 foil in air‑conditioning:

8011 foil in air‑conditioning offers the following advantages:

- Good thermal conductivity: 8011 foil offers high heat‑transfer efficiency in air‑conditioners

- Excellent processability: its ductility and formability meet requirements for complex fin shapes

- Light and strong: aluminum foil is lightweight and high‑strength, reducing overall unit weight while maintaining performance

- Good corrosion resistance: with specialized coatings, 8011 foil adapts well to the humid environment inside air‑conditioners

- Economical: compared to copper and other materials, aluminum foil is significantly more cost‑effective, reducing manufacturing cost of air‑conditioners

Heat‑exchanger fins:

As conductive fins in the evaporator/condenser, 8011 aluminum foil enables high‑efficiency heat‑exchange through rapid conduction of refrigerant heat.

Requirements: flatness of foil sheet (for vacuum‑cup feeding), defect‑free surface.

Hydrophilic treated version:

A surface film spreads condensate evenly (rather than beaded), reducing airflow resistance and noise, improving heat‑dissipation efficiency by 10–15 %.

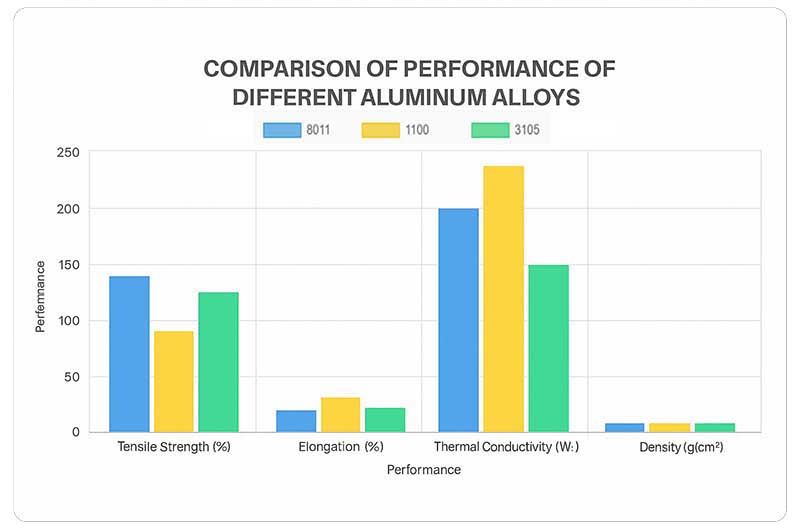

Performance Comparison: 8011 vs Other Air‑Conditioning Aluminum Foils

Comparison of 8011 vs 3000‑series Aluminum Foil

3000‑series foil (e.g., 3102, 3105, etc.) is another commonly used air‑conditioning aluminum material. Compared to 8011 foil:

- Chemical composition: 3000‑series mainly contains manganese (Mn) as alloying element; 8011 mainly contains iron (Fe) and silicon (Si)

- Strength: under the same temper, the tensile strength of 8011 is slightly higher than that of 3000‑series foil by approximately 10–15 %

- Corrosion resistance: 3000‑series may offer slightly better corrosion resistance in certain environments, particularly acidic conditions

- Composite performance: studies show that a layered structure alternating 3003/8011 yields superior toughness and strength compared to a single alloy

Comparison of 8011 vs Other 8000‑series Aluminum Foils

Among 8000‑series foils besides 8011, alloys such as 8079 are also used. Compared to 8011:

- Alloy composition: 8011 mainly contains iron (Fe) and silicon (Si), while 8079 contains more silicon (Si)

- Performance characteristics: 8011 offers a more balanced combination of strength and toughness, while 8079 may have advantages in specific properties such as corrosion resistance

- Application areas: 8011 is more widely used in air‑conditioning, while 8079 is more often used in other fields such as packaging

Comparison of 8011 vs 1000‑series Pure Aluminum Foil

1000‑series pure aluminum foil (e.g., 1100, 1030, etc.) is the earliest foil applied in air‑conditioning. Compared to 8011:

- Strength: tensile strength of 8011 (≈ 140–145 MPa) is considerably higher than that of pure aluminum, which is usually below 100 MPa

- Hardness: hardness of 8011 is higher than that of pure aluminum, making it less prone to deformation during processing and use

- Corrosion resistance: in certain corrosive environments, 8011 has slightly better corrosion resistance than pure aluminum

- Processability: pure aluminum foil has better ductility and is more suitable for deep‑drawing; 8011 foil has a higher work‑hardening rate

Users viewing this material also viewed the following

- Aluminum Foil for Air Conditioner

- Aluminium Fin Stock

- 8011 1235 aluminum foil gaskets for container sealing

- Aluminum Hydrophilic Foil

- Aluminum foil for cigarette packaging

- 8011 8079 1235 Aluminum foil for yogurt packaging

- Hot sealing aluminum foil 8011 1235

- 8011 Aluminium foil for beer bottle neck label

- Blister Aluminium Foil 8011 8021 8079

- Aluminium foil for flexible packaging

- Pharmaceutical Aluminum Foil 8011 8021 8079

- PTP Aluminum Foil

- Aluminum Foil Jumbo Rolls

- Double Zero Aluminum Foil

Recommended Content