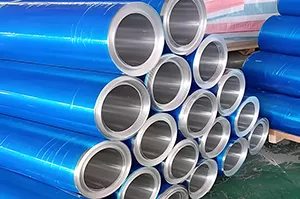

Insulation aluminum coil is a type of roll material made of aluminum alloy, mainly used for thermal insulation. It forms a protective layer through external wrapping to reduce heat energy loss.

Insulation aluminum coil not only provides excellent insulation performance but also has the functions of anti-corrosion, anti-rust, high thermal conductivity, and decoration. It is widely used in construction, industrial pipelines, chemical equipment, and cold chain transportation.

Insulation aluminum coil can enhance the durability of the insulation layer, wind pressure resistance, and overall service life, while minimizing heat transfer and energy loss. Common alloys include 1060 and 3003, with kraft paper or polyurethane laminates used to prevent corrosion.

- For economical applications in general environments requiring waterproofing and rust prevention, 1060 is recommended.

- For better corrosion resistance in industrial environments or higher-demand pipeline insulation, 3003 is a mature and reliable choice.

- For high-end industries (such as nuclear power and aerospace) or applications with extreme requirements for strength and fatigue resistance, 5052 should be considered.

Insulation Aluminum Coil Specifications

| Item | Specification |

| Alloy | 1100, 1050, 1060, 3003, 3105, 5005, 5052, etc. |

| Standard | ASTM, B209, EN573-1 |

| Common Tempers | H14, H16, H24, H26, etc. |

| Thickness Range | 0.3 mm – 1.5 mm (depending on strength and durability requirements) |

| Common Thickness | 0.3 mm, 0.5 mm, 0.6 mm, 0.8 mm, 1.0 mm |

| Width | 1000–1200 mm, can be slit into narrow strips of 100 mm |

| Surface Treatment | Stucco embossed (orange peel), polyester coating (PE), fluorocarbon coating (PVDF), anodizing, film coating, corrugated, polyurethane moisture-proof aluminum jacket, kraft paper composite, ripple finish, etc. |

| Delivery Form | Mainly in coil form, can be slit into aluminum strips of different widths or flattened into aluminum sheets |

Insulation Aluminum Coil Material Types

- 1050/1060/1100 Pure Aluminum Coil: Aluminum content ≥99.5%, excellent thermal conductivity, suitable for insulation in general environments such as building roofs and pipeline cladding.

- 3003 Aluminum-Manganese Alloy Coil: Contains 1% manganese element, outstanding rust resistance, commonly used in high-corrosion coastal environments or chemical equipment insulation, with a service life of more than 20 years.

- 5052 Aluminum-Magnesium Alloy Coil: High strength, fatigue resistance, suitable for applications with strict mechanical performance requirements, such as insulation of pressure vessels.

| Feature Dimension | 1060 (Series 1 Pure Aluminum Coil) | 3003 (Series 3 Aluminum-Manganese Alloy) | 5052 (Series 5 Aluminum-Magnesium Alloy) |

| Material Characteristics | Pure aluminum with aluminum content over 99.6% | Anti-rust aluminum coil with manganese as the main alloying element | Aluminum-magnesium alloy |

| Main Advantages | Good corrosion resistance, good weldability, most economical price | Higher strength than pure aluminum, better corrosion resistance, good formability and weldability | High strength, excellent corrosion resistance, good plasticity and fatigue resistance, weldable |

| Relative Disadvantages | Lower strength, not resistant to acid and alkali corrosion | Higher price than Series 1 | Highest price |

| Typical Application Scenarios | General building waterproofing, municipal pipeline insulation and rust prevention (non-severe corrosive environments) | Refrigeration equipment, storage tanks, chemical plant pipelines (with higher corrosion resistance requirements) | High-strength, fatigue-resistant, and corrosion-resistant applications, such as nuclear power, aerospace, and aviation fields |

| Price | Low | Medium | High |

Made of 99.6% pure aluminum, it offers excellent corrosion resistance, good weldability, and is the most economical option for general insulation needs.

A manganese-aluminum alloy with higher strength than pure aluminum, providing superior anti-rust performance, good formability, and durability in humid or corrosive environments.

5052 Insulation Aluminum Coil

An aluminum-magnesium alloy with high strength, excellent corrosion resistance, and fatigue resistance, suitable for demanding industrial and marine insulation applications.

3003 aluminum coil is an aluminum-manganese alloy. Compared with 1100 or 1060 aluminum, its strength is about 20% higher, while maintaining excellent corrosion resistance and formability.

- Series 1 Pure Aluminum (such as 1060): Cost-effective, strong corrosion resistance, suitable for general insulation needs

- Series 3 Aluminum-Manganese Alloy (such as 3003): Better rust resistance, suitable for humid or high-corrosion environments

- Series 5 Aluminum-Magnesium Alloy (such as 5052): Higher strength, mostly used in special industrial applications

Surface Treatment Options for Insulation Aluminum Coil

Aluminum insulation coil can undergo color coating, embossing (such as orange peel pattern), brushing, film coating, and other treatments to enhance aesthetics and weather resistance.

Surface treatment and coatings are applied to improve weather resistance and appearance. Insulation aluminum coils are often treated with fluorocarbon spraying. This treatment resists acid rain, corrosion, and UV radiation, ensuring the coating does not fade, chalk, or peel for more than 20 years.

Mill Finish Aluminum Insulation Coil

Provides a natural aluminum surface without additional coatings, offering good corrosion resistance and excellent thermal conductivity.

Aluminum Embossed Insulation Roll

Features textured surfaces such as stucco or orange peel patterns, enhancing aesthetics and surface rigidity.

Color Coated Aluminum Insulation Coil

Coated with decorative paint for improved appearance, UV resistance, and long-lasting protection against corrosion.

PE Coated Aluminum Insulation Coil

Polyester (PE) coated for basic weather resistance and corrosion protection, suitable for indoor and semi-outdoor applications.

PVDF Coated Aluminum Insulation Coil

Fluorocarbon (PVDF) coated for superior UV, corrosion, and weather resistance, ensuring the coating remains durable for over 20 years outdoors.

Anodized Aluminum Insulation Coil

Treated with anodizing to increase surface hardness and corrosion resistance, ideal for high-humidity or harsh environments.

Corrugated Aluminum Insulation Coil

Features a corrugated surface for added structural strength and improved insulation performance in certain industrial applications.

Polysurlyn Moisture Barrier Aluminum Coils

Laminated with Polysurlyn to prevent moisture penetration, protecting the insulation layer and extending its service life.

PolyKraft Paper Aluminum Insulation Coils

Coated with a kraft paper layer to provide extra durability, moisture protection, and ease of handling during installation.

Coating Types: Polyester (PE) coating has general weather resistance, while fluorocarbon (PVDF) coating can resist UV radiation for 20 years without fading, suitable for outdoor use.

Anodizing: Enhances surface hardness and corrosion resistance, suitable for high-humidity environments.

Main Characteristics of Insulation Aluminum Coil

- Excellent Thermal Insulation: Insulation aluminum coil effectively prevents heat loss, enhancing insulation performance. It is commonly used in pipe insulation and building insulation.

- Corrosion Resistance: Compared to galvanized iron sheets, aluminum coils offer superior anti-corrosion and rust-resistant properties, ensuring long-term use in harsh environments.

- Strength and Stability: Aluminum coil has high compressive strength, capable of withstanding external pressure and impact, thereby maintaining insulation effectiveness.

- Aesthetic Appeal: Surface treatments and coatings can provide various colors and gloss, making insulation equipment not only functional but also visually attractive.

- Durability: The material is highly durable, resistant to damage, and requires minimal maintenance over long-term use.

Insulation Aluminum Coil Application Scenarios

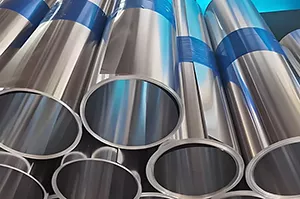

- Architectural Decoration: Aluminum panels, metal roofs, curtain walls, etc.

- HVAC Systems: Wrapping pipes and ducts to maintain required temperature and prevent energy loss.

- Industrial Applications: Protecting the insulation layers of pipelines and equipment in the petroleum, chemical, power, and heating industries.

- Storage Tanks: Jacketed tanks, providing a protective outer layer for insulation.

Building Energy Efficiency

External wall insulation system: Combined with rock wool and polyurethane to form a "sandwich" structure, reducing building energy consumption by more than 30%.

Roof insulation: Reflects solar radiation, reducing air conditioning load. For example, an airport terminal used diffuse-reflection coated aluminum coils, improving energy efficiency by 32%.

Industrial Equipment

Pipeline insulation: Wrapping steam pipelines and chemical tanks to prevent heat loss, such as a power plant using 3003 aluminum coils to protect high-temperature pipelines.

Cold storage and cold chain: Used with aerogel coating, achieving stable insulation across a wide temperature range from -40℃ to 120℃, reducing cold loss by 15–18%.

New Energy Sector

Solar collectors: High-reflectivity aluminum coils improve photo-thermal conversion efficiency, while photovoltaic module frames use 5052 alloy to enhance wind pressure resistance.

Battery thermal management: Nano-coated aluminum coils are used in new energy vehicle battery packs to suppress thermal runaway risk.

Alloy Selection for Insulation Aluminum Coil in Building Applications

- 1060 Pure Aluminum: Aluminum content up to 99.6%, excellent thermal conductivity, good ductility and plasticity, suitable for general building insulation needs such as waterproofing in ordinary buildings and insulation/rust prevention of municipal pipelines.

- 1100 Pure Aluminum: Aluminum content above 99.0%, high thermal conductivity coefficient, excellent insulation performance. Compared with 1060, 1100 aluminum coil has slightly higher strength and good processing performance.

- 3003 Alloy: Belongs to the Series 3 aluminum-manganese alloy, with good anti-rust properties, lightweight, high strength, strong durability, and excellent coating weather resistance. 3003 alloy is particularly suitable for building environments with higher corrosion resistance requirements, such as coastal areas and chemical plant surroundings.

- 3105 Alloy: A primary choice in the North American building products market, with good surface treatment performance. It can be partially annealed to H2x temper to provide desired bending characteristics.

Alloy Selection for Industrial Equipment Insulation Aluminum Coils

- 3003 Alloy: Widely used in industrial equipment insulation, especially in the insulation of pipelines and storage tanks in chemical, petroleum, and power industries. 3003 alloy has excellent corrosion resistance, making it very suitable for harsh industrial environments.

- 3A21 Alloy: An aluminum-manganese alloy similar to 3003 but with higher manganese content, providing better corrosion resistance and strength. 3A21 alloy is widely used in desulfurization flue insulation of power plants, gas, chemical plants, oilfields, petrochemical, and nuclear power plants.

- 5052 Alloy: An aluminum-magnesium alloy containing 2.2–2.8% magnesium and 0.15–0.35% chromium, featuring high strength and fatigue resistance, capable of withstanding various stresses during long-term use in industrial equipment.

Alloy Selection for Automotive Insulation Aluminum Coils

- 1100 Aluminum Coil: Mainly used in automotive insulation mats and similar parts. Its high purity gives it excellent thermal conductivity, effectively transferring and reflecting heat, providing good insulation.

- 3003 Aluminum Coil: Widely applied in the automotive industry, especially in fuel tanks, lubrication oil pipes, and other liquid storage components. The high corrosion resistance and weldability of 3003 alloy make it an ideal material for automotive fuel tanks and similar components.

- 5052 Aluminum Coil: Belongs to the Al-Mg series alloy, an important material choice in the automotive field, with higher strength and fatigue resistance, capable of withstanding various stresses during long-term automotive use.

- 5754 Aluminum Coil: A typical alloy in the Al-Mg series, featuring medium strength, good corrosion resistance, weldability, and ease of forming. It is very suitable for automotive stamping parts.

Alloy Selection for High-Temperature Applications of Aluminum Coils

3003 Alloy

Performs well in medium temperature environments (below 200°C), with certain high-temperature resistance and oxidation resistance. The manganese element in 3003 alloy helps improve its high-temperature stability and oxidation resistance.

5052 Alloy

Performs better than pure aluminum in high-temperature environments, but when the temperature exceeds 200°C, its strength and corrosion resistance decrease. Therefore, 5052 alloy is mainly used in high-temperature environments not exceeding 200°C.

Advantages of Insulation Aluminum Coil

- Corrosion Resistance: Provides excellent rust and corrosion protection, especially compared to galvanized iron.

- Durability and Strength: Can withstand bending and compression, thereby extending service life.

- Lightweight: Easier for installation and handling.

- Moisture Barrier: Laminated materials such as polyurethane rubber or kraft paper prevent moisture from entering the insulation layer, thereby preventing galvanic corrosion between dissimilar metals.

- Enhanced Performance: Helps maintain the desired temperature of transported fluids or air by reducing heat transfer.

- Recyclable: High scrap value, economical and environmentally friendly.

Chemical compositon of insulation aluminum coil

| Alloy | Si | Fe | Cu | Mn | Zn | Mg | Ti | Cr | Other Elements | AL | |

| Each | Total | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | – | 0.03 | 99.6min | |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.50 | 0.1 | – | – | – | 0.05 | 0.15 | reminder |

| 1100 | Si+Fe=0.95 | 0.05-0.20 | 0.05 | 0.1 | – | – | – | 0.05 | 0.15 | 99.0min | |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30-0.80 | 0.4 | 0.20-0.80 | 0.1 | 0.2 | 0.05 | 0.15 | reminder |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.25 | 0.50-1.10 | – | – | 0.05 | 0.15 | reminder |

Insulation Aluminum Coil Purchasing Recommendations

Material Selection

General environments: 1060 pure aluminum coil (cost-effective).

High-corrosion environments: 3003 alloy + PVDF coating.

High-humidity environments: Anodized aluminum coil.

Performance Verification

Require suppliers to provide thermal conductivity coefficient and salt spray test (ASTM B117) reports, ensuring corrosion resistance ≥ 1000 hours.

On-site inspection of case studies, such as actual performance in power plants and cold storage facilities.

Cost Balance

Short-term projects: Choose domestic 1060 aluminum coil (low cost).

Long-term projects: Invest in nano-coating or 3003 alloy, reducing lifecycle costs by 20–30%.

Purchasing Notes:

- Clarify usage environment and requirements: Is it for ordinary construction or industrial environments? Is there strong corrosion? What is the budget? This helps with preliminary material selection.

- Pay attention to coating and quality: For outdoor applications, it is essential to check the type and quality of the coating, as this directly affects durability.

- Inspect sheet type and processing: Choose products with good flatness and high processing accuracy for easier construction and installation.

- Understand manufacturer qualifications and after-sales service: Choose reputable manufacturers, and pay attention to product quality standards and after-sales guarantees.

Insulation Aluminum Coil Handling and Storage Instructions

Insulation aluminum coils are lightweight and easy to install, but care should be taken to protect the surface coating to avoid affecting the protective effect.

During storage, ensure a well-ventilated and dry environment, avoid contact with moisture to prevent oxidation and white spots. Open packaging should be resealed properly.

Insulation Aluminum Coil FAQs

How to clean aluminum insulation materials?

When cleaning aluminum insulation materials, it is recommended to use mild soapy water and a soft cloth to wipe down the surface. Avoid using strong acid or alkaline cleaners, as they may damage the aluminum surface.

What is the lifespan of aluminum insulation materials?

The lifespan of aluminum insulation materials depends on the specific application environment and maintenance conditions. Under normal conditions, aluminum insulation materials generally have long-term durability. Proper installation and maintenance can significantly extend their lifespan.

Can aluminum insulation materials be used in humid environments?

Aluminum insulation materials have some moisture resistance, but in particularly humid environments, it is recommended to choose products with an additional moisture barrier (such as polyester film or polyurethane coating) to further prevent moisture from affecting the insulation performance.