What is embossed aluminium foil?

Embossed aluminum foil is a type of aluminum foil product in which various patterns are imprinted on the surface of plain foil through a special process. It is made by passing smooth aluminum foil through a rolling mill or embossing roller to create concave-convex patterns on the surface, thereby giving the aluminum foil additional functionality and decorative appeal.

Production process

- Prepare plain foil (unprocessed aluminum foil)

- Feed it into embossing equipment with specific patterns

- Apply pressure to form surface patterns consistent with the mold

Comprehensive Advantages of Embossed Aluminum Foil

- Performance Advantages Lightweight yet strong, good thermal conductivity, strong corrosion resistance, excellent flexibility, and good barrier and mechanical properties.

- Functional Advantages Strong decorative appeal, good anti-slip performance, excellent thermal insulation, good moisture and water resistance, along with good printability and processability.

- Application Advantages Widely used in packaging, architectural decoration, industry, electronics, and other fields to meet various application needs.

- Environmental Advantages Recyclable, in line with modern environmental concepts, and beneficial for sustainable development.

Haomei Premium Embossed Aluminum Foil Products

- Main materials: Common alloys include 1050, 1060, 3003, and 8011, selected for their corrosion resistance and ductility.

- Thickness range: Typically from 0.03 mm (30 microns) to 0.3 mm (300 microns); thinner foils are more prone to tearing during embossing.

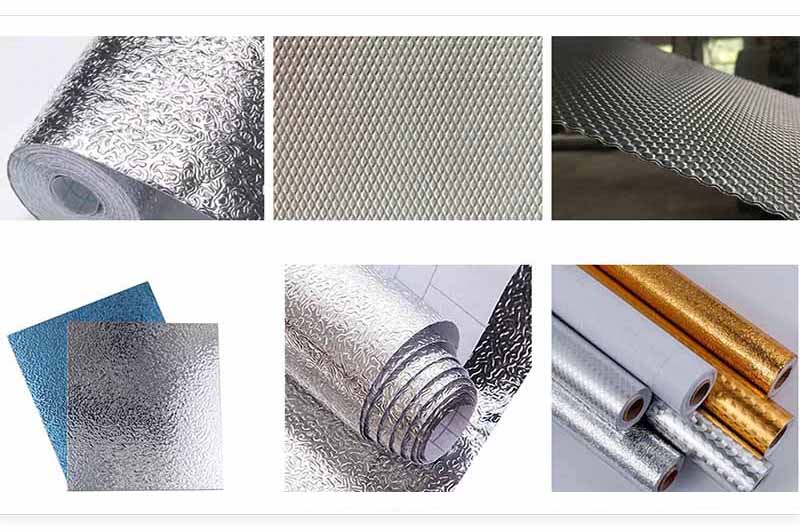

- Patterns: Includes orange peel, diamond, hemispherical, and parallel line embossing.

- Surface treatments: Options include anodizing (corrosion resistance), pre-coating (UV resistance), and self-adhesive coating.

- Custom sizes: Width range from 10 mm to 1, 500 mm, with coil length and thickness customizable.

Popular Embossed Aluminum Foil Products

Embossed Aluminum Foil Popular Patterns

- Orange Peel Embossed Aluminum Foil Surface texture similar to orange peel, available in classic and modified types, commonly used for building exteriors, pipe coverings, refrigeration equipment, etc.

- Square Pattern Embossed Aluminum Foil Surface shows a regular square pattern, such as 5×5 embossed square foil, widely used in insulation materials and decoration.

- Five-Bar Pattern Aluminum Foil Surface with five longitudinal raised bars, similar to anti-slip plate designs, providing excellent anti-slip performance, mainly for applications requiring slip resistance.

- Diamond Pattern Embossed Aluminum Foil Surface shows diamond-shaped patterns, aesthetically pleasing and functional, commonly used in architectural decoration and packaging.

- Water Ripple Embossed Aluminum Foil Surface shows wave-like patterns similar to water ripples, with strong decorative effects, mainly used in decoration.

- Hammer Pattern Embossed Aluminum Foil Surface resembles hammered texture, with unique tactile and decorative qualities, commonly used for high-end decoration and special packaging.

- Hemispherical Embossed Aluminum Foil Surface has evenly distributed small hemispherical patterns, increasing contact area and improving heat dissipation; suitable for automotive heat shields, engine, and exhaust pipe insulation.

Embossed Aluminum Foil Popular Applications

- Insulation Embossed Aluminum Foil Mainly used for underfloor heating systems, building insulation, and pipe insulation, such as red-blue embossed insulation pipes, offering good thermal insulation and moisture resistance.

- Decorative Embossed Aluminum Foil With beautiful patterns and metallic texture, mainly used in building decoration, furniture decoration, automotive decoration, etc.

- Packaging Embossed Aluminum Foil Includes food, pharmaceutical, and cosmetic packaging, offering excellent barrier and decorative properties.

- Anti-Slip Embossed Aluminum Foil Surface pattern designed to increase friction coefficient, such as five-bar embossed foil, commonly used in stairs, car pedals, and other slip-prevention applications.

- Electrical Insulation Embossed Aluminum Foil Laminated with other materials (such as kraft paper) for insulation in transformers, cables, and other electrical equipment, offering excellent dielectric strength and thermal stability.

- Heat Dissipation Embossed Aluminum Foil Special pattern designs enhance air convection and improve heat dissipation efficiency, mainly used in high-temperature automotive engine compartments.

Main Surface Treatment Methods for Embossed Aluminum Foil

- Anodized embossed aluminum foil Aluminum foil is embossed and then anodized to form a dense oxide film on the surface, providing better corrosion and wear resistance, suitable for refrigerators, air conditioners, and outdoor environments.

- Color-coated embossed aluminum foil Color coating is applied to the embossed aluminum foil surface, offering various colors and decorative effects, widely used in architectural decoration and packaging.

- Laminated embossed aluminum foil Embossed aluminum foil is laminated with other materials (such as paper, plastic film, cardboard, etc.) to form composite materials with multiple properties.

- Printed embossed aluminum foil Printing on the surface of embossed aluminum foil to form various patterns, texts, or images, available in single or up to 12 colors.

- Polished embossed aluminum foil Aluminum foil with polished surface and three-dimensional embossed patterns, providing decorative and reflective effects.

- Self-adhesive embossed aluminum foil Embossed aluminum foil with adhesive backing for easy direct application.

Common Thicknesses and Specifications of Embossed Aluminum Foil

Embossed Aluminum Foil Thickness Categories and Applications

- Ultra-thin foil (double zero foil) Thickness less than 0.01 mm (i.e., 0.005~0.009 mm), extremely lightweight, mainly used for special packaging and decoration.

- Thin foil (single zero foil) Thickness between 0.01 mm and 0.1 mm, the most widely used category, including food packaging, pharmaceutical packaging, decorative materials, etc.

- Medium-thick foil Thickness between 0.1 mm and 0.2 mm, with good strength and toughness, mainly used for building insulation, automotive heat insulation, electrical insulation, etc.

- Thick foil Thickness over 0.2 mm, high strength, mainly for applications requiring higher mechanical properties, such as architectural decoration and heavy-duty packaging.

Common Thicknesses and Specifications of Embossed Aluminum Foil

- Packaging embossed aluminum foil Thickness usually 0.0045~0.02 mm, width customizable (generally 10 mm~600 mm). Common household embossed foil rolls: 0.009~0.04 mm thick, width 300 mm or 450 mm.

- Building insulation embossed aluminum foil Thickness usually 0.01~0.1 mm, width 20~1600 mm. Underfloor heating embossed foil thickness typically 0.07~0.25 mm.

- Architectural decorative embossed aluminum sheet Thickness usually 0.2~3.0 mm, width up to 1.5 m, length customizable. Common thicknesses: 0.2 mm, 0.3 mm, 0.35 mm, 0.4 mm, 0.5 mm, 0.6 mm, 0.7 mm, 0.8 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, etc.

- Industrial embossed aluminum foil For example, air conditioner foil thickness usually 0.15~0.2 mm, cable foil thickness 0.12~0.20 mm. Transformer aluminum strip thickness 0.3~3.0 mm.

- Special-purpose embossed aluminum foil For example, PET lid sealing embossed foil sheets typically about 0.08 mm thick; chocolate packaging embossed foil thickness 9~50 microns (0.009~0.05 mm).

Effect of Embossing on Thickness

It should be noted that the embossing process changes the thickness of aluminum foil. Generally, the thickness of aluminum foil increases after embossing, with an increase of about 0.2 mm, depending on embossing depth and pattern design. For example, base foil thickness of 0.5 mm typically reaches 0.6–0.65 mm after embossing.

Features and Advantages of Embossed Aluminum Foil

Physical Performance Features of Embossed Aluminum Foil

- Lightweight yet strong Aluminum has a density of about 2.7 g/cm³, about one-third that of steel, yet its strength meets most usage requirements. Embossing increases rigidity and hardness to some extent, enhancing mechanical performance.

- Excellent thermal conductivity Aluminum has good thermal conductivity, and embossed aluminum foil can quickly transfer heat throughout the material, serving both insulation and heat retention purposes. This makes it excellent for insulation and heat dissipation applications.

- Good barrier properties Embossing forms numerous tiny concave-convex textures on the aluminum foil surface, improving barrier effects and effectively blocking oxygen and moisture penetration. This gives embossed aluminum foil a significant advantage in packaging.

- Excellent flexibility Aluminum foil has good flexibility and ductility, and retains these properties even after embossing, making it easy to process and form.

Chemical Performance Features of Embossed Aluminum Foil

- Corrosion resistance Aluminum itself has good corrosion resistance, and embossed aluminum foil with surface treatment has even better corrosion resistance, allowing long-term use in humid, acidic, and alkaline environments.

- Oxidation resistance Aluminum easily forms a dense oxide film in air, preventing further oxidation of the internal metal. The oxide film of embossed aluminum foil is more stable, giving better oxidation resistance.

- Safe and hygienic Aluminum foil is rolled from primary aluminum alloy, containing no heavy metals or harmful substances. High-temperature annealing and sterilization are used in production, and its dense oxide layer and stable chemical properties ensure it does not react with food in most cases, making it safe for direct food contact.

Embossed Aluminum Foil Functional Features and Advantages

- Strong Decorative Effect The surface of embossed aluminum foil features a rich variety of patterns, such as orange peel pattern, diamond pattern, pointer pattern, etc., to meet different decorative needs. These patterns not only enhance the visual effect of the aluminum foil but also give it a unique artistic sense.

- Anti-slip Performance Some embossed aluminum foils have excellent anti-slip performance; the surface patterns can increase the friction of the contact surface, preventing people from slipping. Therefore, they are often used in stair treads, car pedals, and other scenarios that require anti-slip properties.

- Thermal Insulation The concave and convex surface of embossed aluminum foil can form an air layer, improving thermal insulation performance, suitable for building insulation, pipeline insulation, and other fields.

- Moisture-proof and Waterproof Embossed aluminum foil has excellent moisture-proof and waterproof properties, effectively preventing water penetration and protecting packaged or covered items.

- Good Printability The surface of embossed aluminum foil can undergo printing, coating, hot stamping, and other treatments, making it convenient for brand identification and decorative design.

- Eco-friendly and Recyclable Aluminum has a very high recycling rate and regenerability; it can be infinitely recycled and reused with limited quality loss while maintaining its original characteristics. Recycled aluminum can be used to produce many products, and the energy required for aluminum foil recycling is less than 5% of that needed for primary aluminum production.

Common Alloy Materials for Embossed Aluminum Foil

Common Alloy Series and Characteristics

1000 Series (Pure Aluminum Series)

- Main alloys: 1060, 1100, 1050, 1145, etc.

- Characteristics: Aluminum content greater than 99%, good corrosion resistance, thermal conductivity, and processing performance, but relatively low strength.

- Applications: Mainly used in situations where strength requirements are not high, such as general packaging and decoration.

3000 Series (Aluminum-Manganese Alloy Series)

- Main alloys: 3003, 3004, etc.

- Characteristics: Contains manganese (content between 1.0-1.5%), a series with good anti-rust properties, good formability, high corrosion resistance, and weldability.

- Applications: Used for parts that require good formability, high corrosion resistance, and good weldability, such as architectural decoration and pipeline insulation.

8000 Series (Other Alloy Series)

- Main alloys: 8011, 8021, 8079, etc.

- Characteristics: Alloys in this series usually add other elements to achieve specific properties, such as 8011 alloy having good processing performance and surface quality.

- Applications: Mainly used in packaging and decoration fields, such as food packaging and pharmaceutical packaging.

5000 Series (Aluminum-Magnesium Alloy Series)

- Main alloys: 5052, 5083, etc.

- Characteristics: Main element is magnesium, with magnesium content between 3-5%, also known as aluminum-magnesium alloy. Main features include low density, high tensile strength, high elongation, good fatigue strength, but cannot be strengthened by heat treatment.

- Applications: With the same area, aluminum-magnesium alloy weighs less than other series and is widely used in conventional industries, such as building decoration and industrial applications requiring high strength.

Application Selection of Different Alloys

- Packaging Embossed Aluminum Foil usually uses 1000 series or 8000 series alloys, such as 8011, 8079, etc. These alloys have good processing performance and surface quality, suitable for packaging applications.

- Architectural Decorative Embossed Aluminum Foil usually uses 3000 series or 5000 series alloys, such as 3003, 5052, etc. These alloys have higher strength and good corrosion resistance, suitable for architectural decoration.

- Industrial Embossed Aluminum Foil usually uses 3000 series or 5000 series alloys, such as 3003, 5052, etc. These alloys have good mechanical properties and processing performance, suitable for industrial applications.

- Special Purpose Embossed Aluminum Foil selects suitable alloys according to specific needs; for example, for high-strength requirements, 5000 series alloys can be chosen, and for high corrosion resistance, 3000 series alloys can be chosen.

Alloy Temper Selection

- O Temper (Annealed) Fully annealed state, material is soft with good plasticity, suitable for applications requiring deep drawing and bending.

- H Temper (Work-Hardened) Includes H14, H18, H24, etc. Material is cold-work hardened, with higher strength, suitable for applications requiring higher strength.

- T Temper (Heat-Treated) After solution heat treatment, naturally aged to a basically stable state; material has higher strength and hardness, suitable for high-strength applications.

Why Choose Embossed Aluminium Foil?

- Functional Enhancement: Embossing increases the strength and tear resistance of the aluminium foil, making it more resistant to tearing and puncturing. The textured surface can also enhance its reflective properties and, in some cases, improve adhesion when laminated with other materials.

- Improved Thermal Insulation: The textured surface expands the heat exchange area, enhancing heat reflection and insulation efficiency.

- Aesthetics: Embossed textures give aluminium foil decorative qualities, making it suitable for high-end packaging and gift wrapping.

- Versatility: Embossed patterns can be customized for various applications, including branding, product differentiation, and even specific functional requirements, such as creating microchannels for improved thermal control in packaging.

- Anti-slip Properties: Diamond or orange peel patterns provide better grip, making it ideal for construction and packaging.

Chemical Composition of embossed aluminum foil

| Alloy | Aluminum (Al) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Iron (Fe) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Other Elements |

| 1100 | 99.00% | 0.05% | 0.05% | 0.10% | 0.12% | - | - | - | - |

| 1235 | 99.35% | 0.05% | - | 0.15% | 0.15% | - | - | - | - |

| 3003 | 89.0-91.0% | 0.20-0.60% | 1.0-1.5% | 0.10-0.40% | 0.70-0.90% | - | - | - | Other Elements (e.g., Nickel) |

| 8079 | 88.0-92.0% | 0.10-0.40% | 0.30-0.60% | 0.30-0.60% | 0.10-0.30% | - | - | 0.30-0.90% | Other Elements (e.g., Nickel) |

Application Fields of Embossed Aluminum Foil

Applications in the Packaging Field

- Food Packaging Embossed aluminum foil has good barrier properties and heat-sealing performance, which can effectively maintain the freshness and flavor of food. Gold polka dot embossed aluminum foil is often used for chocolate packaging, not only beautiful but also able to enhance the product grade.

- Pharmaceutical Packaging Embossed aluminum foil is used in pharmaceutical packaging, especially in blister packaging (PTP packaging), with good sealing and barrier properties, which can effectively protect medicines from the influence of the external environment.

- Cosmetic Packaging Embossed aluminum foil is used in cosmetic packaging, especially for high-end cosmetics, to enhance the grade and visual effect of the product. Embossed aluminum foil can also be used for sealing cosmetic bottle mouths.

- Gift Packaging The metallic texture and beautiful patterns of embossed aluminum foil make it an ideal choice for gift packaging, enhancing the grade and attractiveness of gifts.

Applications in the Construction and Decoration Field

- Building Insulation Embossed aluminum foil composite insulation materials are used for building insulation, with good thermal insulation and moisture-proof properties. For example, red and blue embossed insulation pipes are used in underfloor heating systems to effectively isolate the influence of the external environment on the temperature inside the pipes.

- Architectural Decoration Embossed aluminum plates and embossed aluminum foil are used for decoration of ceilings, walls, roofs, etc., with beautiful patterns and metallic texture. Orange peel embossed aluminum plates are commonly used materials in the refrigerator and air-conditioning refrigeration industry, water heater inner tank insulation industry, and pipeline equipment anti-corrosion and insulation industry.

- Thermal Insulation Materials Embossed aluminum foil is used for building insulation, especially in high-temperature environments. Embossed aluminum plates with concave-convex texture design enhance air convection, focusing on efficient insulation and heat dissipation, and can be used in high-heat areas such as engine rooms.

- Waterproof and Moisture-proof Embossed aluminum foil has good waterproof and moisture-proof performance, and can be used in building waterproof projects and moisture-proof treatments.

Applications in the Industrial and Electrical Field

- Refrigeration Equipment Orange peel embossed aluminum foil is widely used in refrigeration equipment such as refrigerators and air conditioners, serving as heat dissipation and insulation materials. For example, orange peel embossed aluminum plates are common materials in the refrigerator and air-conditioning refrigeration industry.

- Electrical Insulation After being laminated with other materials (such as kraft paper), embossed aluminum foil is used for insulation of electrical equipment such as transformers and cables, with excellent dielectric strength and thermal stability.

- Automotive Industry Embossed aluminum foil is used for heat insulation, sound insulation, and decoration in automobiles. Embossed aluminum plates are used for insulation in high-heat areas such as the engine compartment, while grid aluminum foil focuses on lightweight design for the body chassis sandwich structure, providing solid insulation and easy installation.

- Pipeline Anti-corrosion and Insulation Embossed aluminum foil is used for anti-corrosion and insulation of pipelines, especially for pipeline protection in harsh environments.

Other Application Fields

- Household Appliances Embossed aluminum foil is used for the shells, liners, and insulation layers of household appliances such as refrigerators, air conditioners, microwave ovens, dishwashers, etc.

- Art and Handicrafts Embossed aluminum foil is used for artistic creation, handicraft making, and decoration, such as making embossed paintings and decorative items.

- Medical Field Embossed aluminum foil is used for medical equipment and packaging, such as sterile packaging of medical devices, insulation and protection of medical equipment, etc.

- Electronics Industry Embossed aluminum foil is used for shielding, heat dissipation, and insulation of electronic equipment such as computers, mobile phones, televisions, and other electronic products.

Embossed Aluminum Foil vs Ordinary Aluminum Foil

- Appearance Difference Ordinary aluminum foil has a smooth and flat surface, while embossed aluminum foil has distinct patterned textures with a three-dimensional effect.

- Functional Difference The embossing process creates tiny concave-convex structures on the aluminum foil surface, increasing the surface area, thereby enhancing physical properties such as increasing the coefficient of friction, improving thermal insulation, and enhancing tear resistance.

- Application Scope Difference Ordinary aluminum foil is mainly used for packaging and simple isolation purposes, whereas embossed aluminum foil, due to its unique surface structure and enhanced properties, is widely used in applications requiring higher surface performance.

- Processing Technology Difference Ordinary aluminum foil is completed simply through rolling, while embossed aluminum foil requires an additional embossing process, making production more complex.

Embossed aluminium foil surpasses plain aluminium foil in durability, thermal insulation, moisture resistance, tear resistance, and aesthetics. Therefore, it finds wider applications in high-demand fields such as packaging, construction, automotive, electronics, and new energy.

| Comparison Dimension | Embossed Aluminium Foil | Plain Aluminium Foil |

| Mechanical Strength | Embossing enhances the structural stability of the material, making it more resistant to tearing and folding, suitable for applications requiring higher durability (such as food packaging and building insulation). | More fragile structure, prone to breakage or damage due to folding or compression. |

| Tear Resistance | The presence of surface textures enhances the tear resistance of embossed aluminium foil, making it particularly suitable for repeatedly opened packaging (such as yogurt lids). | Relatively easier to tear, especially when bent or subjected to external forces. |

| Wrinkle Resistance | The textured structure prevents the aluminium foil from easily wrinkling, maintaining a neat and aesthetically pleasing appearance. | Prone to creasing, affecting aesthetics and packaging integrity. |

| Flexibility | Embossing enhances the flexibility of the aluminium foil, making it easier to adapt to different shapes and surfaces. | Lower flexibility, may not conform well to uneven surfaces or complex structures. |

| Thermal Insulation | The textured surface creates air pockets, improving thermal insulation, making it suitable for building insulation, automotive heat insulation, and similar applications. | Smooth surface has higher thermal conductivity, resulting in relatively weaker insulation performance. |

| Sound Insulation | The textured structure helps reduce sound wave transmission, improving soundproofing effects, often used in automobiles, buildings, and HVAC systems. | Directly reflects sound waves, providing poor soundproofing performance. |

| Moisture and Corrosion Resistance | The embossed structure reduces direct surface contact, enhancing its resistance to corrosion in humid environments. | More susceptible to moisture or chemical exposure, potentially leading to oxidation or corrosion. |

| Aesthetic Appeal | The textured surface enhances visual and tactile appeal, providing a more premium appearance, suitable for high-end packaging (such as chocolates and cigarette packs). | Smooth and plain surface, prone to scratches or fingerprints, affecting appearance. |

| Wear Resistance | The embossed structure increases scratch resistance, making it less prone to visible marks. | Smooth surface is more susceptible to scratches or abrasions. |

| Reflectivity | The texture disperses light, reducing glare, and enhancing optical performance in certain applications (such as solar reflectors). | Directly reflects light, potentially causing glare or light pollution issues. |

| Applications | Suitable for food packaging, building insulation, automotive soundproofing, electronics protection, renewable energy applications, etc. | Mainly used in general food packaging and basic industrial applications. |

How to Choose the Right Embossed Aluminum Foil

Selection Based on Application Requirements

- Application Field Different application fields have different performance requirements for embossed aluminum foil. For example, packaging embossed aluminum foil requires good barrier and printing properties, while construction embossed aluminum foil requires higher strength and weather resistance.

- Environmental Conditions Consider factors such as temperature, humidity, and chemicals in the usage environment. In humid or corrosive environments, alloys with good corrosion resistance, such as 3000 series or 5000 series alloys, should be selected.

- Functional Requirements Choose suitable embossed aluminum foil according to the required functions. For example, for thermal insulation needs, choose embossed aluminum foil with good insulation performance; for anti-slip needs, choose embossed aluminum foil with anti-slip patterns.

- Decorative Needs Select suitable patterns and surface treatments according to decorative needs. For a metallic texture, choose bright-surface embossed aluminum foil; for a colored effect, choose color-coated embossed aluminum foil.

Selection of Technical Parameters

- Thickness Selection Choose the appropriate thickness according to application requirements. Generally, packaging embossed aluminum foil is thinner (0.0045~0.02mm), while construction decorative embossed aluminum plates are thicker (0.2~3.0mm).

- Width and Length Choose appropriate width and length according to usage requirements, which can generally be customized according to customer needs.

- Alloy Selection Select the appropriate alloy series according to the application environment and performance requirements. For high strength, choose the 5000 series alloy; for good processing performance, choose the 1000 series or 8000 series alloys.

- Surface Treatment Choose suitable surface treatment according to decorative and protective needs. For high corrosion resistance, choose anodized embossed aluminum foil; for a colored effect, choose color-coated embossed aluminum foil.

Quality Judgment Methods

- Appearance Inspection Check whether the surface of the embossed aluminum foil is smooth, whether the pattern is clear, and whether there are obvious scratches, dents, bubbles, and other defects. The surface of high-quality embossed aluminum foil should be free of cracks, and the pattern depth and three-dimensional effect should be uniform.

- Dimensional Accuracy Check whether the thickness, width, and other dimensions of the embossed aluminum foil meet the requirements, and whether the dimensional deviation is within the allowable range.

- Mechanical Properties Conduct simple bending and stretching tests to evaluate the flexibility and strength of the embossed aluminum foil. High-quality embossed aluminum foil should have good flexibility and sufficient strength, and should not crack or break when bent.

- Corrosion Resistance For embossed aluminum foil to be used in harsh environments, simple corrosion resistance tests can be carried out, such as placing it in a humid environment for a period of time and checking for corrosion.

Suggested Selection Process

- Clarify application requirements: Determine the application field, environmental conditions, functional requirements, and decorative needs of the embossed aluminum foil.

- Determine technical parameters: Determine the appropriate thickness, width, alloy series, and surface treatment method according to application requirements.

- Select suppliers: Choose suppliers with good reputation and qualifications. Supplier information can be obtained through online searches, industry recommendations, etc.

- Sample evaluation: Request samples from suppliers, conduct appearance inspection, dimensional measurement, and performance tests to evaluate whether the sample quality meets the requirements.

- Bulk procurement: After confirming that the sample quality meets the requirements, proceed with bulk procurement, and sign a detailed purchase contract specifying product specifications, quality standards, delivery time, and other terms.

- Quality inspection: Upon receiving the goods, conduct a comprehensive quality inspection to ensure the products meet the contract requirements.

Production Process of Embossed Aluminium Foil

- Rolling and Forming: Aluminium is first rolled into extremely thin sheets. The foil can be produced in specific thicknesses based on its intended use.

- Embossing: During the embossing process, the aluminium foil passes between rollers engraved with patterns or designs. The pressure from the rollers creates raised (embossed) and recessed areas, adding both tactile and visual elements.

- Finishing: After embossing, the aluminium foil may undergo additional treatments (such as coating or lamination) to enhance its durability, appearance, or prepare it for further applications.

Embossed aluminium foil is not just a thin sheet of metal; it is a versatile material that combines aesthetics and functionality. Its production involves precise processes, creating products suitable for high-end packaging and various industrial applications, offering both visual appeal and structural strength.

The embossing process of aluminium foil involves imprinting specific patterns onto the surface by passing smooth aluminium foil through rollers or molds. This process is suitable for pure aluminium and aluminium alloys, with common grades including 1050, 1060, and 3003. The thickness of embossed aluminium foil typically ranges from 30 microns to 300 microns, depending on its intended application.

Embossing Procedure

- The base material is pure aluminium or alloy foil stock, embossed under high temperature and high pressure using embossing rollers to form patterns (e.g., orange peel, wood grain, geometric designs).

- Tension must be precisely controlled: too high results in blurry patterns, too low causes wrinkling or interlayer slipping.

Standards and Certifications Related to Embossed Aluminium Foil

What are the Product Quality Standards?

The quality standards of embossed aluminium foil mainly include material composition, thickness tolerance, surface characteristics, mechanical properties, and special functional requirements.

Material and Alloy Standards

- Alloy Series: Common alloys include 1xxx (1060, 1070, 1100), 3xxx (3003, 3004), 5xxx (5052), and 8xxx (8011, 8079, 8021).

- 1xxx Series (e.g., 1060/1070): Purity >99.6%, high plasticity, strong corrosion resistance, suitable for capacitors, electronic tags.

- 8xxx Series (e.g., 8011/8079): High strength, good ductility, excellent moisture and air tightness, widely used in food and pharmaceutical packaging.

- Impurity Control: Content of elements like iron (Fe) and silicon (Si) must meet national (e.g., GB/T 3198) or international standards such as ASTM/AISI. For instance, 8011 foil requires a Fe/Si ratio >1.5 to ensure deep-drawing performance.

Thickness and Tolerance

Classification:

- Thick foil (0.1–0.2 mm), single-zero foil (0.01–0.1 mm), double-zero foil (≤0.01 mm).

- Tolerance Requirements: General thickness tolerance is ±1%; for high-precision applications (such as battery foil), tolerance should be ≤±0.5%.

Surface Quality

- Pattern Clarity: Embossed patterns should be uniform and clear, with consistent depth (e.g., hairdressing foil requires designs that enhance hair adhesion).

- Defect-Free: Surface must be free from oxidation spots (white-green), black lines, bright streaks, holes, or mechanical damage.

- Finish: Glossy side should resemble a mirror, matte side must be evenly colored.

Mechanical and Functional Performance

- Tensile Strength: For example, 8079 aluminium foil requires tensile strength >100 MPa, higher than alloy 8011.

- Elongation: 8006 aluminium foil for food packaging requires elongation ≥15%, better than alloy 3003.

- Barrier Properties: Moisture-proof, light-shielding, and anti-oxidation (e.g., pharmaceutical packaging foil must pass oxygen transmission rate testing).

How to Ensure Product Quality?

The quality of embossed aluminium foil depends on the precision of alloy composition, the stability of the embossing process (temperature/tension control), and full-process inspection (mechanical properties + surface defects).

Key Points of Quality Control

- Embossing rollers must be regularly cleaned of aluminium scraps (using a copper brush) and cooled (to prevent overheating deformation).

- After embossing, avoid surface inclusions that could damage the roller surface.

Common Questions about Embossed Aluminum Foil

What are the widths available for embossed aluminum foil?

Our standard widths are 1, 000 or 1, 250 mm. However, we can also produce coils with a width of 53 mm.

What is "strip"?

Aluminum foil with an embossed surface is called embossed foil. The term "strip" is typically used for thicker embossed aluminum foil (thickness > 0.300 mm), also referred to as strip foil.

What thicknesses are available for embossed aluminum foil?

Our thinnest embossed aluminum foil has a thickness of 0.040 mm (40 µm).