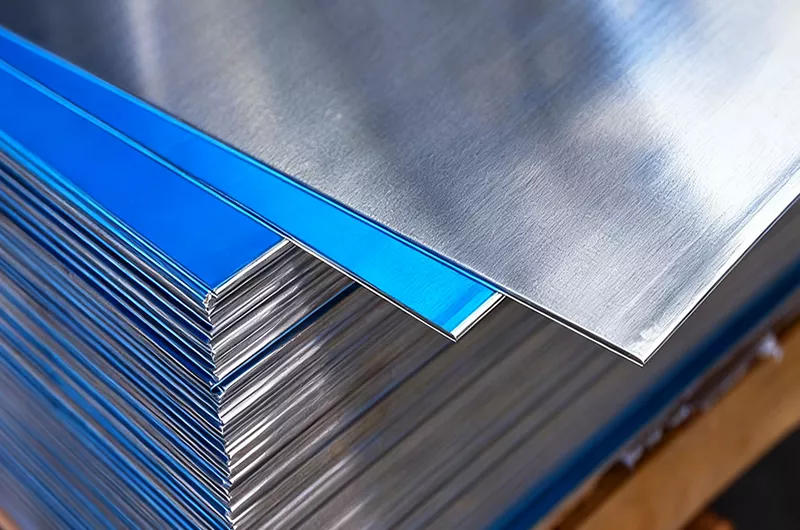

5454 Marine Grade Aluminum Sheet belongs to the aluminum-magnesium alloy (5xxx series), specifically designed for marine environments, featuring excellent corrosion resistance, medium strength, and good weldability.

The core value of 5454 aluminum sheet lies in:

- Reducing maintenance costs: Resistant to seawater / salt spray corrosion, it can reduce more than 50% of anti-corrosion maintenance frequency (such as painting, rust removal).

- Enhancing vessel performance: Lightweight design reduces the total weight of the hull, lowering fuel consumption (according to estimates, for every 10% reduction in ship weight, fuel consumption can decrease by 5%-8%), while improving sailing stability.

With its balance of corrosion resistance, strength, and cost-effectiveness, 5454 Marine Grade Aluminum Sheet is an ideal material for marine engineering, especially suitable for scenarios requiring lightweight design and long-term reliability. When selecting, it is necessary to match the temper (e.g., H32, H111) according to specific working conditions (such as load, corrosion severity), and optimize performance with surface treatment and welding techniques.

5454 marine aluminum sheet is a high-strength, corrosion-resistant alloy, very suitable for welded structures such as hulls and pressure vessels, but it is more expensive than 5052. Its outstanding strength and resistance to harsh marine environments make 5454 a better choice for critical hull structures and pressure vessels.

What is 5454 Aluminum Alloy?

- 5454 alloy is an aluminum-magnesium (5xxx series) wrought alloy.

- It is non-heat-treatable; its strength is obtained through cold working / strain hardening / annealing (e.g., H32, H34, etc.).

- Due to its good corrosion resistance in seawater, medium strength, and good weldability, it is commonly used in marine / shipbuilding / welded structures.

5454 Marine Grade Aluminum Sheet Specifications and Standards

| Item | Specification |

| Alloy | 5454 |

| Standard | AMS-QQ-A-250, AMS-QQ-A-250/10 |

| Temper | O, H12, H14, H18, H22, H24, H32, H34 |

| Certification | DNV GL, ABS and other marine classification societies; Complies with international maritime standards |

| Common Size | 4×8 ft, 4×10 ft, 5×10 ft aluminum sheets |

| Thickness | 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 5mm, 6mm, 10mm (thick) |

| Width (mm) | 100 – 2600 |

| Length (mm) | 500 – 16000 |

Why choose Haomei marine grade aluminum 5454?

Classification society certification

With CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification society certification, quality fully in line with the world Marine grade standards.

Haomei Offers 5454 Marine Aluminum Products

| Product Form | Specification | Marine Applications | Key Advantages |

| 5454 aluminum sheet and plate | Thickness range 0.5-600mm, common temper H32 | Superstructure decks, cabin partitions, equipment base plates | Lightweight (density 2.69g/cm³), seawater corrosion resistant (magnesium content 2.4-3.0%), easy to weld |

| 5454 aluminum tread plate | Surface embossed with diamond, lentil, or circular patterns | Outdoor deck walkways, small boat decks, anchor winch platforms | High slip resistance (0.6-0.8), patterns prevent dirt accumulation, composite structure reduces weight by 30% |

| 5454 Aluminum Seamless Tube | Outer diameter 10-300mm, wall thickness 1.2-50mm | Cooling water pipes, compressed air pipes, LNG cryogenic pipelines | High pressure resistance (20MPa), low temperature resistance (-162℃), smooth inner wall reduces fluid resistance |

| 5454 Aluminum Extrusion Profile | Custom cross-sections (e.g., T-shape, L-shape, channel) | Porthole frames, guide plates, cable tray supports | Custom cross-sections, improved bending stiffness, reduces welding processes |

| 5454 Coated Aluminum Plate | 3-20μm oxide film, PVDF coating | Helicopter decks, chemical cargo hold linings | UV aging resistance (PVDF), weld corrosion protection (epoxy zinc-rich), high surface hardness |

| 5454 Composite Aluminum Materials | Steel-aluminum composite, aluminum foam | LNG pipeline supports, lightweight cabin walls for passenger ships | Optimized strength-to-weight ratio, excellent fire and sound insulation, suitable for extreme temperatures |

5454 Aluminum Sheet

Commonly used for ship superstructures and deck panels due to its light weight and excellent seawater corrosion resistance.

5454 Aluminum Plate

Provides high strength and good weldability, ideal for hull plating, bulkheads, and structural components.

5454 Aluminum Tread Plate

Features anti-slip patterns, making it suitable for deck walkways, gangways, and operation platforms.

5454 Anodized Aluminum Sheet

Offers enhanced surface hardness and corrosion protection, often applied to marine interiors and exterior panels.

5454 Aluminum Seamless Tube / Pipe

Used in marine piping systems such as seawater cooling, air compression, and low-temperature LNG transport.

5454 Aluminum Extrusion Profile

Custom-extruded for ship fittings, window frames, cable trays, and support structures requiring high rigidity.

5454 PVDF Coated Aluminum Plate

Designed for offshore decks and chemical cargo tanks, providing UV resistance and long-term surface durability.

5454 Aluminum-Steel Composite Panel

Combines the strength of steel with the corrosion resistance of aluminum for hull reinforcements and structural transitions.

5454 Foam Aluminum Panel

Lightweight and energy-absorbing, used in marine partitions, insulation systems, and vibration-damping structures.

5454 Marine Grade Aluminum Sheet Material Properties

- Outstanding Corrosion Resistance: 5454 aluminum sheet resists industrial corrosion and high-temperature corrosion, effectively tolerating acid rain, industrial wastewater, and other corrosive environments. It is especially suitable for ship structures, pressure vessels, and marine pipelines.

- Balanced Strength and Workability: Its strength is approximately 20% higher than that of common 5052 aluminum alloy, while maintaining good plastic deformation capability, providing excellent forming performance.

- Mechanical Properties: Its tensile strength is comparable to 5086 aluminum alloy, with outstanding fatigue performance, making it suitable for withstanding dynamic loads.

- Fabrication and Welding: O-temper (annealed) material has excellent plasticity, making it easy for deep processing such as stamping and bending; H111 temper balances strength and workability.

Chemical Composition of 5454 marine grade aluminum plate

| Element | Composition % |

| Al | Rem |

| Si | ≤0.25 |

| Fe | 0.000-0.400 |

| Cu | ≤0.10 |

| Mn | 0.50-1.0 |

| Mg | 2.4-3.0 |

| Cr | 0.05-0.20 |

| Ti | ≤0.20 |

| Zn | ≤0.25 |

| Note:Each:≤0.05;Total:≤0.15 | |

Mechanical Properties of 5454 marine grade aluminum plate

| Alloy | Temper | Sample temper | Thickness mm | Tensile strength RmMPa | Extension strength RP0.2/Mpa | Elongation % | |

| A50 mm | A | ||||||

| 5454 | O | O | 3.00-6.00 | 215-285 | ≥85 | ≥17 | |

| >6.00-12.50 | 215-285 | ≥85 | ≥18 | ||||

| >12.50-50.00 | 215-285 | ≥85 | - | ||||

| H111 | H111 | 3.00-6.00 | 215-285 | ≥85 | ≥17 | ||

| >6.00-12.50 | 215-285 | ≥85 | ≥18 | ||||

| >12.50-50.00 | 215-285 | ≥85 | - | ||||

| H22, H32 | H22, H32 | 3.00-6.00 | 250-305 | ≥180 | ≥8 | ||

| H112 | H112 | 6.00-50.00 | ≥220 | ≥125 | ≥8 | ||

5454 Marine Grade Aluminum Sheet Advantages

- Excellent Corrosion Resistance: 5454 exhibits outstanding corrosion resistance in marine and seawater environments, suitable for structural components in long-term seawater exposure.

- High Strength: For non-heat-treatable aluminum alloys, 5454 has relatively high strength, meeting the load-bearing requirements of hull structures.

- Good Weldability and Formability: Suitable for TIG, MIG, and other welding methods, with excellent forming and rolling properties, facilitating fabrication.

- Wide Applications: Commonly used in hull plates, decks, internal structural parts, fuel tanks, etc., with good fatigue resistance.

- High Impact Resistance: 5454 marine aluminum sheets maintain structural integrity under impact or compression, effectively resisting forces such as wave impact, enhancing overall vessel safety.

- Environmentally Friendly and Recyclable: Aluminum alloy materials can be recycled multiple times, providing good sustainability and helping reduce resource waste and environmental pollution.

Limitations of 5454 Marine Aluminum

- Since its strength is achieved through cold working, higher strain increases hardness but reduces ductility.

- 5454 aluminum has average/moderate machinability; heavy processing is not ideal.

- 5454 is not suitable for applications requiring complex or fine extrusion.

- For extremely high-strength applications, other 5xxx alloys (e.g., 5083, 5086) may offer higher strength, but their corrosion resistance or weldability may be lower.

5454 Marine Grade Aluminum Sheet Applications

Used for manufacturing marine pipelines, ship components, and offshore facilities. Subsea pipelines often have a design life exceeding 20 years, requiring materials with corrosion resistance and low maintenance; 5454 aluminum sheet is a suitable choice.

Ship Structures

- Hull and Decks: Lightweight and corrosion-resistant, reducing hull weight, improving fuel efficiency, and withstanding wave impact.

- LNG Tanks: Maintains toughness at low temperatures, meeting ABS and DNV GL requirements for liquefied natural gas transport.

Marine Engineering Equipment

- Pipelines and Pressure Vessels: Used in seawater desalination equipment and chemical pipelines, resisting salt solution corrosion.

- Offshore Platform Components: Such as walkways and protective railings, reducing maintenance costs.

Hull and Auxiliary Structures: Core requirement is seawater corrosion resistance

The main hull requires extremely high strength to withstand wave impact and loads, so ship steel remains dominant. 5454 aluminum sheets are mainly used for non-primary load-bearing hull components and auxiliary structures.

- Small / Work Boat Hulls: Applied to patrol boats, lifeboats, and pilot boats for full or partial hulls. 5454 meets requirements with seawater corrosion resistance (reducing frequent rust removal and painting, lowering maintenance costs), lightweight (40%-50% weight reduction compared to steel boats, reducing propulsion system power demand, increasing speed or reducing fuel consumption), and good plasticity (easily stamped and rolled into curved surfaces for streamlined designs).

- Local Hull Linings and Protective Structures: Used for anchor chain locker linings (corrosion-resistant, with certain hardness to resist anchor chain wear), partial anti-corrosion layers in ballast/freshwater tanks in easily corroded areas (welds, corners), and guard plates around side scuppers/through-hull valves (prevent seawater erosion and corrosion).

- Auxiliary Components of Ship Propulsion Systems: Suitable for small vessel propeller ducts and stern tube bushings. 5454's seawater corrosion resistance prevents seawater damage to critical propulsion components, and its lightweight nature does not add stern load, ensuring propulsion efficiency.

Superstructure: Combining lightweight and weather resistance

Ship superstructures (bridge, deckhouse, external living quarters) require both lightweight (to lower ship center of gravity and improve stability) and resistance to marine atmospheric corrosion (salt spray, humidity). 5454 aluminum sheet is a mainstream choice.

- Superstructure Decks and Cabin Walls: Used in bridge decks and non-load-bearing external walls of living quarters and bulwarks. 5454’s lightweight (superstructures account for 15%-20% of total ship weight; weight reduction reduces rolling and improves stability), corrosion resistance (forms a dense oxide film in exposed salt spray environments, reducing painting frequency), and weldability (fast assembly via MIG/TIG welding, suitable for modular construction) meet requirements.

- Deck Underlayment and Anti-Slip Plates: Used as underlayment for outdoor superstructure decks (supporting anti-slip tiles/rubber mats), or directly processed into anti-slip deck panels (crew walkways, equipment platforms). 5454’s smooth surface allows easy attachment, and corrosion resistance prevents water accumulation (seawater/rainwater) from causing deck corrosion, extending service life.

Interior Facilities and Piping: Focused on moisture resistance and ease of fabrication

Ship interiors (kitchen, bathroom, engine room, etc.) in humid areas require materials with water resistance and ease of cleaning. 5454 aluminum sheet’s flexibility and corrosion resistance provide significant advantages.

- Internal Cabin Structural Parts: Used for partitions, ceilings, and cabinet bodies (lightweight reduces cabin load, smooth surface for easy cleaning, no moisture-related mold or corrosion). Also suitable for kitchen countertops and bathroom wall panels (oil-resistant, resistant to freshwater/seawater corrosion, lighter than stainless steel, lower cost).

- Ship Piping Systems: Applied to freshwater, cooling water, and ballast water pipes. 5454 offers water resistance (resistant to freshwater and seawater, no rust or blockage issues like steel pipes), good plasticity (can be fabricated into seamless or welded pipes of various diameters, adaptable to complex routing), and lightweight (reduces total ship weight and piping support requirements).

What Other Applications Does 5454 Aluminum Sheet Have?

Special Vehicles

Tanker Cylinders: Corrosion-resistant and recyclable, used for transporting chemicals and liquefied gases, complying with EN 14286 standard.

Refrigerated Truck Bodies: Lightweight design improves load efficiency while adapting to humid environments.

Transportation Sector

Automobile Wheels: As a key material for vehicle lightweighting, can reduce weight by 30%-40%, lower rolling resistance, and improve fuel efficiency.

Tanker Truck Cylinders: Used for tanker truck bodies and for transporting tank containers.

Pressure Vessels: Suitable for manufacturing pressure vessels with operating pressure ranges of 0.6-6.4MPa.

Comparison of 5454 Aluminum with Other Marine-Grade Alloys

| Property | 5454 | 5052 | 5083 |

| Tensile Strength | 240-300 MPa (H32) | 200-240 MPa (H32) | 270-310 MPa (H116) |

| Corrosion Resistance | Excellent, better than 5052 | Good | Outstanding (salt spray test >1000 hours) |

| Weldability | Excellent, minimal post-weld strength loss | Good | Excellent, but higher cost |

| Cost | Medium | Low | High |

| Typical Applications | Hulls, pressure vessels | General marine components | High-strength structural parts (e.g., warships) |

5454 Marine Aluminum Sheet

Advantages: Higher strength than 5052, excellent seawater and harsh environment resistance, high fatigue strength, good weldability. Highly recommended for hull structures, pressure vessels, and marine chemical handling tanks.

Disadvantages: More expensive than 5052 and some other alternatives.

5052 Marine Aluminum Sheet

Advantages: Good corrosion resistance, excellent formability, low cost; versatile and economical choice for superstructures and other components.

Disadvantages: Lower strength than 5454 or 5083, thus not suitable for high-stress primary hull structures.

5083 Marine Aluminum Sheet

Advantages: Very high strength, excellent low-temperature performance, ideal for LNG tanks and applications requiring high low/high temperature performance.

Disadvantages: Not the best choice for applications requiring resistance to stress corrosion cracking; the 150°F to 300°F (65°C to 150°C) range is the main concern.

Key Points for Selecting 5454 Marine Aluminum Sheet

- Pay Attention to Material Temper: 5454 aluminum alloy cannot be strengthened by heat treatment and relies on cold working (e.g., cold rolling) to enhance strength. Common tempers include O (annealed), H12, H32, H34, etc. Different tempers correspond to different strength, hardness, and elongation. Selection should consider product processing methods (e.g., stamping, bending) and final performance requirements (e.g., strength, toughness).

- Specifications: Aluminum sheet thickness, width, and length vary; choose according to needs.

- Corrosion Resistance and Composition: Excellent corrosion resistance mainly comes from 2.4%-3.0% magnesium content and additional elements such as manganese and chromium.

- Production Process Assurance: Large-scale production lines (e.g., "1+1" lines) and six-roll cold rolling ensure stable product performance, flat surface, and precise thickness.

- Strength and Pressure: For high-stress areas like the main hull, select 5454 or 5083.

- Corrosion Resistance: 5454 provides excellent resistance to seawater and other chemicals, making it ideal for corrosive marine environments.

- Cost: For non-critical components and superstructures, 5052 is the most cost-effective choice.

- Temperature: 5454 is stable over a wide temperature range, while 5083 is especially suitable for low-temperature applications.

Precautions for Using 5454 Marine Aluminum Sheet

- Surface Treatment: Anodizing (film thickness ≥10μm) or painting is recommended to further enhance corrosion resistance.

- Welding Process: Strictly remove surface oxide layer, use ER5356 welding wire, and avoid weld porosity.

- Fabrication Deformation: Stress relief after cold working is necessary to prevent long-term deformation during use.