3003 corrugated aluminum sheet is an aluminum alloy material widely used in construction, decoration, and industrial fields. It features lightweight properties, corrosion resistance, and excellent plasticity.

3003 corrugated aluminum sheet is made of 3003 aluminum alloy as the base material, processed through cold rolling and profiling into wavy sheets. It combines light weight, corrosion resistance, and high cost-effectiveness. Common surface treatment processes include color coating, PVDF coating, and baking paint, which enhance weather resistance and decorative effects.

3003 aluminum alloy is made from aluminum and manganese, offering good corrosion resistance, weldability, and formability. Its strength is relatively high, making it suitable for bearing certain loads.

Haomei Aluminum specializes in supplying corrugated aluminum panels for roofing, flooring, and wall cladding applications. These aluminum profiled sheets are known for their strength, durability, and lightweight properties, offering excellent resistance to various weather conditions and broad adaptability across multiple uses.

As a leading manufacturer of high-quality corrugated aluminum metal panels, we have the capability to customize sheets in a wide range of materials, dimensions, and specifications to meet diverse project requirements. In addition, we provide an array of surface finish options to align with different aesthetic and functional preferences.

Advantages of 3003 Corrugated Aluminum Sheet

- Lightweight: With a density of only 2730kg/m³, about 1/3 that of steel, it significantly reduces building loads and transportation costs.

- Corrosion resistance: A natural aluminum oxide film forms on the surface, resisting acid rain, salt spray, and industrial exhaust erosion. The service life exceeds 15 years, suitable for harsh environments such as chemical and coastal areas.

- Easy to process: Excellent cold bending properties allow quick forming into various wave patterns, improving construction efficiency.

- Environmental characteristics: Highly recyclable with a recycling value of up to 80%, aligning with green building trends.

Limitation

It has a relatively low melting point (660℃), and its strength drops rapidly at high temperatures. Its fire resistance is weaker than that of color steel sheets (melting point 1515℃), requiring the application of fireproof coatings as compensation.

Popular 3003 Aluminum Corrugated Panels for Roofing and Cladding

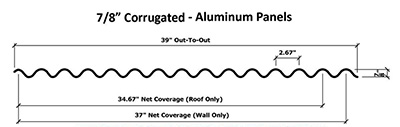

7/8" 3003 Corrugated Aluminum Sheet

Rib Height: 7/8"Rib Distance (Pitch): 2.67"

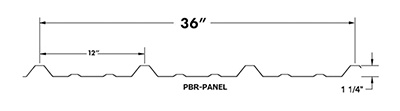

PBR 3003 Aluminum Wall Panels

Rib Height: 1.25 inchesRib Distance (Pitch): 12"

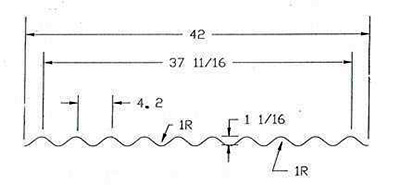

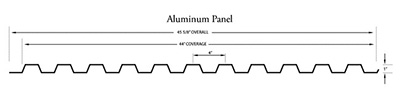

4.2 Inch 3003 Corrugated Aluminum Sheet

Rib Height: 1/16"Rib Distance (Pitch): 4.2"

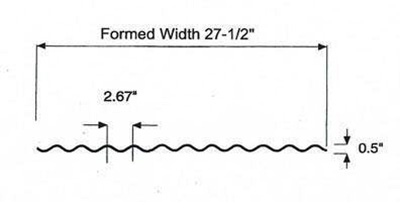

2.5" x 0.5" 3003 Corrugated Aluminum Panel

Rib Height: 1/2"Rib Distance (Pitch): 2.67"

1.25 inch x 0.25 inch 3003 Corrugated Aluminum Panel

Rib Height: 1/4"Rib Distance (Pitch): 1 1/4"

3003 Aluminum Stucco Embossed Mill Finish 4" Rib

Rib Height: 1"Rib Distance (Pitch): 4"

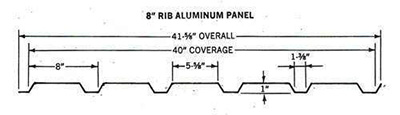

3003 Aluminum Stucco Embossed Mill Finish (8" Rib)

Rib Height: 1"Rib Distance (Pitch): 8"

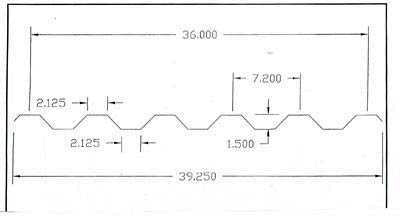

7.2 3003 Corrugated Aluminum Sheet

Rib Height: 1.5"Rib Distance (Pitch): 7.2"

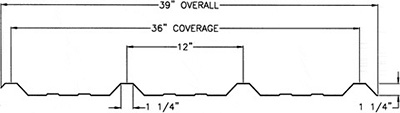

12" rib (R Panel) 3003 Corrugated Aluminum Sheet

Rib Height: 1 1/4"Rib Distance (Pitch):12"

Surface Treatments of 3003 Corrugated Aluminum Sheet

Common surface treatments include anodizing, PVDF coating (such as charcoal gray, matte black), and pre-roller coating. Among them, PVDF coating provides resistance to acid rain, UV erosion, and has salt spray test durability exceeding 3000 hours, with a service life of more than 25 years.

3003 Anodized corrugated aluminum sheet

3003 anodized corrugated aluminum sheet is made of manganese-based aluminum alloy, offering excellent corrosion resistance, lightweight strength, and durability. Its anodized surface enhances weather resistance, wear resistance, and aesthetics, making it a reliable material for roofing, cladding, and decorative architectural applications.

3003 Coated aluminium roofing sheet

3003 coated aluminum roofing sheet combines the inherent rust resistance and formability of the alloy with high-quality surface coatings, improving durability and color retention. It is designed for long-term outdoor use, providing strong, lightweight, and aesthetically pleasing roofing solutions for residential, commercial, and industrial projects.

3003 Corrugated Aluminum Sheet Properties

- Moderate strength: 3003 aluminum alloy has moderate strength, stronger than pure aluminum, making it suitable for applications that bear certain loads. The hardness is moderate, suitable for structural components in various environments.

- Excellent corrosion resistance: Due to the addition of manganese, 3003 aluminum alloy has outstanding corrosion resistance, particularly suited for marine environments, areas with high humidity, and places with severe chemical corrosion.

- Excellent formability: 3003 aluminum alloy has very good formability, making it suitable for deep processing and shaping. It can be manufactured into various shapes through processes such as stamping, stretching, and bending, especially suited for the production of corrugated sheets.

- Good weldability: This aluminum alloy has good weldability and can be welded using common welding methods such as TIG welding, MIG welding, etc. The performance after welding remains stable without significant degradation.

- Lightweight and easy to transport and install: Aluminum material itself has low density, and 3003 aluminum alloy corrugated sheets are very lightweight, making them easy to transport and install on-site, suitable for large-scale use.

3003 Corrugated Aluminum Sheet Structural Features

The corrugated design of the 3003 aluminum sheet not only gives it a unique appearance but also increases the strength and rigidity of the sheet. The corrugated structure makes the sheet more structurally stable than flat sheets when bearing certain pressure, effectively distributing the load. Common corrugated shapes include V-shaped, U-shaped, and semicircular, with specific shapes and sizes available upon request.

Applications of 3003 Corrugated Aluminum Sheet

3003 corrugated aluminum sheet is widely used in construction, transportation, storage boxes, refrigerated trucks, and truck compartments. Due to its excellent corrosion resistance and lightweight properties, it is often used for external decoration and protection.

Construction Field

- Roofing and wall panels: Replacing color steel sheets for industrial plants, logistics warehouses, stadiums. For example, 750-type aluminum tiles used for chemical plant roofing provide both corrosion resistance and lightweight performance.

- Decoration projects: Formed by rolling into special curved surfaces to achieve architectural aesthetics, such as wave-shaped exterior walls of airport terminals.

- Fire isolation: Although the material itself has limited fire resistance, it can be compounded with insulation materials such as rock wool to meet Class A fire protection requirements.

Industry and Transportation

- Equipment protection: Pipeline insulation cladding for refineries and power plants, using its corrosion resistance to extend equipment life.

- Vehicle manufacturing: New energy vehicle battery housings (3003-H24 material), refrigerated truck bodies, ensuring lightweight performance while maintaining structural strength.

Other Scenarios

- Packaging materials: High-precision corrugated aluminum sheets used for shockproof outer packaging of electronic products, combining protection with aesthetics.

- Agricultural facilities: Greenhouse roofing with balanced light transmission and wind/snow resistance.

| Application | Description |

| Construction Industry | 3003 corrugated aluminum sheet is commonly used in the construction industry, especially in exterior cladding such as roofs, walls, ceilings, and curtain walls. Due to its excellent corrosion resistance and water resistance, 3003 corrugated aluminum sheet effectively prevents moisture penetration, maintaining the structural stability and durability of buildings. Additionally, the modern appearance of 3003 corrugated aluminum sheet adds a fashionable and contemporary touch to buildings, widely used in the façade design of commercial and industrial buildings. This aluminum sheet is also used in some interior decorative spaces to enhance the overall visual effect. |

| Transportation | In the transportation sector, 3003 corrugated aluminum sheet is widely used in lightweight vehicle bodies, truck roofs, vehicle shells, and the exteriors of rail transport vehicles. Due to its excellent corrosion resistance, 3003 corrugated aluminum sheet is particularly suitable for external decoration and protection of various transportation vehicles, able to withstand harsh weather and environmental conditions. Its lightweight characteristics help reduce the overall weight of vehicles, improving transportation efficiency, while providing necessary external protection for the vehicles. |

| Packaging Industry | 3003 corrugated aluminum sheet is commonly used in the packaging industry to manufacture lightweight, sturdy packaging containers, particularly for the storage and transportation of food, chemicals, and other goods. This aluminum sheet not only provides sufficient mechanical strength to protect the packaged items but also effectively prevents moisture and corrosion, ensuring the safety of the contents. Additionally, the corrugated design of the aluminum sheet enhances the aesthetic appeal and modern look of the packaging containers. |

| Refrigeration Industry | 3003 corrugated aluminum sheet is widely used in refrigeration equipment, refrigerated trucks, radiators, and other shells in the refrigeration industry. Due to the excellent thermal conductivity of aluminum, 3003 corrugated aluminum sheet helps effectively dissipate heat, maintaining the temperature stability of equipment during operation. Additionally, the corrosion resistance of the aluminum sheet makes it suitable for external protection of refrigerated trucks and other cold storage equipment, maintaining long-term stability in humid and cold environments. |

| Shipbuilding Industry | 3003 corrugated aluminum sheet is widely used in the shipbuilding industry, primarily for external protective materials for hulls. Its excellent seawater corrosion resistance makes it an ideal material for external armor in shipbuilding, effectively preventing seawater corrosion and extending the lifespan of the hull. Due to the lightweight nature of aluminum, 3003 corrugated aluminum sheet helps reduce the overall weight of the ship, thus improving speed and fuel efficiency. |

| Machinery and Industrial Equipment | 3003 corrugated aluminum sheet is used in machinery and industrial equipment as exterior shells, storage boxes, and other corrosion-resistant components. Due to its excellent corrosion resistance and lightweight properties, 3003 corrugated aluminum sheet is widely used in machinery and tools that require protection, especially in humid or corrosive environments. It not only provides robust physical protection but also reduces the overall weight of the equipment, improving efficiency and extending the service life. |

| Decorative Uses | 3003 corrugated aluminum sheet is often used in modern architectural and interior decoration. Its corrugated surface not only enhances the visual effect but also adds a sense of depth and modernity to the space. 3003 corrugated aluminum sheet is widely used in wall and ceiling designs of office buildings, commercial centers, residential areas, etc., and can also be used as partitions, decorative panels, or ceiling materials in interior spaces, achieving a balance between aesthetics and functionality. |

Comparative Analysis of Typical Applications of Corrugated Aluminum Sheet

| Scenario | 3003 Corrugated Aluminum Sheet | Color Steel Sheet | Aluminum Alloy 5052 |

| Chemical plant roofing | Resistant to acid and alkali corrosion, service life over 15 years, low maintenance cost | Easily rusts, needs replacement every 5–8 years, high overall cost | Higher strength but slightly weaker corrosion resistance, 20% cost premium |

| New energy vehicle battery housing | Lightweight (30% weight reduction), excellent electromagnetic shielding performance | Not suitable, heavy weight and highly conductive | Higher strength but difficult welding |

| Coastal area buildings | 1000-hour salt spray test without rust, suitable for high-humidity environments | Requires galvanized layer ≥80μm, service life still less than 10 years | Cost too high, poor cost-effectiveness |

3003 Corrugated Aluminum Alloy Composition

The main components of 3003 aluminum alloy are aluminum and manganese (Mn), with the manganese content typically ranging from 1% to 1.5%. The addition of manganese gives 3003 aluminum alloy better strength and corrosion resistance, particularly outstanding in acidic and alkaline environments. 3003 aluminum alloy belongs to the aluminum-manganese alloy series and is commonly used in applications requiring medium strength and high corrosion resistance.

| Element | Composition % | |

| Al | Remainder | |

| Cu | 0.05-0.20 | |

| Si | 0.60 max | |

| Fe | 0.70 max | |

| Mn | 1.0-1.5 | |

| Zn | 0.10 max | |

| Others | 0.05 each | 0.15 total |

Selection Suggestions and Precautions for 3003 Corrugated Aluminum Sheet

Selection Suggestions

Performance Matching

- For high-humidity environments, choose 3003-H24 temper; for coastal areas, PVDF coating is recommended.

- Load-bearing structures require stiffness calculation of wave type. For roof spans >6m, strengthened aluminum sheets with wave height ≥35mm are recommended.

Installation Points

- Use concealed clips or self-tapping screws for fastening, spacing ≤300mm, to avoid deformation caused by thermal expansion and contraction.

- Overlap length ≥150mm; sealant at joints must be compatible with aluminum base material to prevent galvanic corrosion.

Cost Optimization

- Bulk purchases can lower unit prices (e.g., discounts of 5–8% for orders over 10 tons), but a 10% allowance for loss should be reserved.

- Compare life cycle costs: initial investment of 3003 aluminum sheet is higher than color steel sheet, but maintenance cost is lower, offering better overall economic performance.

Precautions

Service Environment:

- For buildings in general corrosive environments (such as ordinary atmospheric conditions), 3003 alloy is usually sufficient.

- For harsher environments with higher humidity and stronger corrosion (such as coastal and industrial areas), consider more corrosion-resistant alloys such as 5052 or 5083 aluminum-magnesium-manganese alloys.

Strength Requirements:

- 3003 alloy has higher strength than pure aluminum but lower than 5000 series alloys.

- For higher strength or stiffness requirements (such as large spans or heavy wind/snow loads), consider thicker sheets or higher-strength alloys (such as 5000 series).

Corrugation Type:

Different corrugation types have varying load-bearing capacity, drainage performance, and appearance effects. Selection should be based on structural calculations and architectural design plans.

Surface Treatment:

- Mill finish aluminum: mainly used in anti-corrosion and insulation fields, focusing on corrosion resistance and physical properties.

- Color coating (PVDF, PE, etc.): used for building roofs and walls, providing multiple color options while enhancing weather resistance and decorative effects.

- Anodizing and film covering treatments can provide additional protection or special functions.