1100 Corrugated Aluminum Sheet refers to roofing or wall panels made of 1100 aluminum alloy. 1100 aluminum alloy is a corrugated aluminum sheet processed from 1100 pure aluminum, featuring light weight, corrosion resistance, and excellent formability. It is widely used in architectural decoration, industrial equipment, and other fields.

Due to its light weight, seismic resistance, and fireproof performance, it is used for building roofs, wall panels, and decorative purposes. However, its low strength makes it unsuitable for high-pressure applications.

The aluminum content of 1100 aluminum alloy exceeds 99%, making it a relatively low-strength alloy suitable for applications requiring good corrosion resistance and easy machinability but not high strength.

1100 Corrugated Aluminum Sheet Informations

| Feature Dimension | Detailed Description | Example Applications |

| Material Properties | 1100 aluminum alloy, aluminum content ≥99.0%, commercial pure aluminum | Chemical equipment, food processing equipment, decorative components |

| Corrosion Resistance | Excellent | Roofs and walls, anti-corrosion insulation, power plant and chemical plant projects |

| Strength | Low strength, cannot be strengthened by heat treatment, can be strengthened through cold working | Suitable for industrial projects with complex forming operations |

| Workability | Good ductility, soft, easy to form, weldable (gas welding, atomic hydrogen welding, contact welding), bendable | Rivets, heat exchanger fins, gifts, hollow utensils |

| Lightweight | Approximately one-third the weight of steel | Large-span steel structures, stadiums, airport terminals |

| Surface Treatment | Excellent surface treatment capability | Color-coated aluminum coils, decorative applications |

| Common Models | 7/8", 7.2" RIB, etc. | Building roofs/walls, power plant desulfurization |

| Common Thickness | Usually between 0.2mm - 2.0mm (finished corrugated sheets), aluminum coil raw material can be thicker | Selected according to different models and load requirements |

Popular 1100 Aluminum Corrugated Panels for Roofing and Cladding

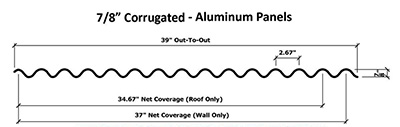

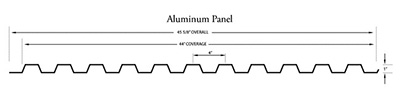

7/8" 1100 Corrugated Aluminum Sheet

Rib Height: 7/8"Rib Distance (Pitch): 2.67"

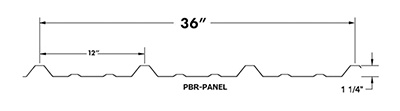

PBR 1100 Aluminum Wall Panels

Rib Height: 1.25 inchesRib Distance (Pitch): 12"

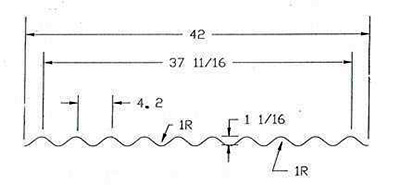

4.2 Inch 1100 Corrugated Aluminum Sheet

Rib Height: 1/16"Rib Distance (Pitch): 4.2"

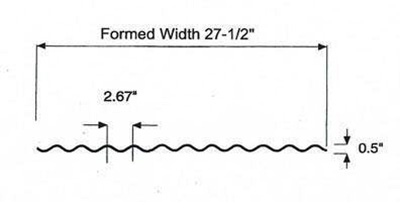

2.5" x 0.5" 1100 Corrugated Aluminum Panel

Rib Height: 1/2"Rib Distance (Pitch): 2.67"

1.25 inch x 0.25 inch 1100 Corrugated Aluminum Panel

Rib Height: 1/4"Rib Distance (Pitch): 1 1/4"

1100 Aluminum Stucco Embossed Mill Finish 4" Rib

Rib Height: 1"Rib Distance (Pitch): 4"

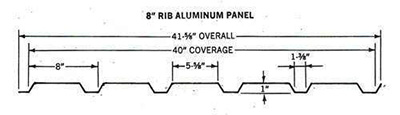

1100 Aluminum Stucco Embossed Mill Finish (8" Rib)

Rib Height: 1"Rib Distance (Pitch): 8"

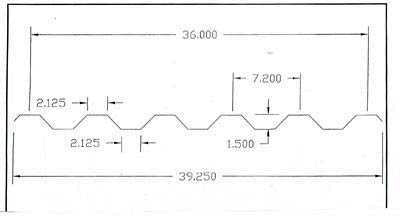

7.2 1100 Corrugated Aluminum Sheet

Rib Height: 1.5"Rib Distance (Pitch): 7.2"

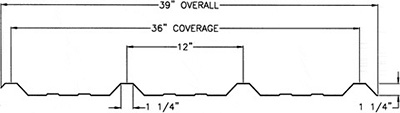

12" rib (R Panel) 1100 Corrugated Aluminum Sheet

Rib Height: 1 1/4"Rib Distance (Pitch):12"

Surface Treatments of 1100 Corrugated Aluminum Sheet

Anodized 1100 Corrugated Aluminum Sheet

Processed using anodizing, the oxide film bonds with the substrate, providing durability, wear resistance, and long-lasting color. Suitable for coastal and high-corrosion environments.

Highlights:

- Scratch-resistant, weather-resistant, significantly reduces maintenance costs

- Available in shades from light to dark, offering diverse decorative effects

- Completely non-toxic, environmentally friendly, 100% recyclable, supports green building certifications

PVDF Coated 1100 Corrugated Aluminum Sheet

Surface coated with PVDF meeting AAMA standards, with a thickness of 25–35 µm. Offers durability over 5000 hours of salt spray testing and maintains color stability for over 20 years.

Highlights:

- Excellent performance in coastal, high-temperature, and strong UV environments

- Extended maintenance cycles and significantly reduced lifecycle costs (30% lower than color steel)

Premium Metal Finish (Brushed/Mirror) 1100 Corrugated Aluminum Sheet

Features brushed metal texture or mirror finish, providing an elegant and stylish appearance. Particularly suitable for high-end building facades, lobbies, furniture surfaces, enhancing both visual and tactile experience.

Embossed/Patterned 1100 Corrugated Aluminum Sheet

Surfaces exhibit wood grain, marble, or stucco patterns, enhancing visual depth and tactile sensation. Suitable for specialty architecture and interior design, improving decorative appeal through texture design.

Cladding / Laminating 1100 Corrugated Aluminum Panels

The corrugated aluminum composite panel uses high-temperature adhesive to laminate two aluminum sheets with a corrugated aluminum core, forming a sturdy, lightweight building decorative material with excellent flatness.

Highlights:

Structural reinforcement and diversified surface treatments: optional PVDF, PE, powder coating, anodizing, etc., to meet various architectural styles and environmental requirements

Powder Coated 1100 Corrugated Aluminum Sheet

Solvent-free, colored or transparent polymer powder coating, providing a durable, scratch-resistant surface with uniform color. Highly decorative, suitable for outdoor decoration and applications.

Recommended Application Scenarios

| Scenario | Recommended Surface Treatment | Core Advantages |

| Coastal/Chemical Plant Roofs | PVDF / Anodized | High salt spray resistance, corrosion resistant |

| High-end Building Facades / Lobby Decoration | Brushed/Mirror / Embossed / Anodized | Aesthetic, wear-resistant, enhanced texture |

| Industrial Factories / Polluted Environments | Nano Coating / PVDF | Self-cleaning, anti-fouling, durable |

| High-strength Structures / Shading Systems | Anodized / Powder Coated | Lightweight, wear-resistant, low maintenance |

| Green & Sustainable Projects | Any recyclable surface treatment | Supports LEED and other certifications |

Haomei Aluminum provides a complete set of surface solutions for 1100 corrugated aluminum sheets, covering a range of needs from high corrosion resistance to premium decorative finishes. Whether for functional or aesthetic requirements, our products can precisely match your project. Combining performance and appearance while balancing cost-effectiveness and sustainability, our sheets are an ideal choice for project material selection.

For specific product samples, customization services, technical specifications, or project cost comparison, feel free to contact us anytime. We look forward to supporting your project’s success!

1100 Corrugated Aluminum Sheet Characteristics

1100 corrugated aluminum sheet, with its excellent corrosion resistance, lightness, and good formability, is suitable for a variety of lightweight structural and decorative applications, particularly in environments where corrosion resistance is needed and only light loads are expected. Its good weldability and easy processing make it highly efficient in production, suitable for use in packaging and equipment in the food and chemical industries.

- High Purity: Aluminum content about 99%, making it softer and easier to form than high-strength alloys.

- Excellent Workability: Easy to bend, form, and cold work into various shapes.

- Corrosion Resistance: Outstanding corrosion resistance in various environments.

- High Conductivity: Excellent thermal and electrical conductivity.

- Non-Heat-Treatable: Heat treatment cannot significantly increase its strength.

| Characteristics | Description |

| Low strength | 1100 aluminum alloy has relatively low tensile strength, making it more suitable for applications that bear light loads or do not have significant structural pressure. |

| Excellent corrosion resistance | 1100 aluminum alloy offers excellent corrosion resistance, especially suitable for use in high-humidity, marine environments, or conditions of chemical corrosion. This makes 1100 corrugated aluminum sheet highly stable in outdoor and harsh environments. |

| Excellent formability | Due to its low-strength properties, 1100 aluminum alloy has very good formability, making it suitable for deep drawing, bending, and complex processing techniques. It can be easily formed into various shapes to meet different application needs. |

| Good weldability | 1100 aluminum alloy has excellent weldability, allowing it to be processed using conventional welding methods, adaptable to different production processes. |

| Lightweight | 1100 aluminum alloy has a low density, making the corrugated aluminum sheet lightweight, easy to handle and install, helping to reduce the overall structure weight. |

| Good thermal conductivity | As pure aluminum, 1100 aluminum alloy has high thermal conductivity, making it suitable for applications that require rapid heat dissipation, such as heat exchangers and radiators. |

| Easy to process | The softness and processability of 1100 aluminum alloy make it easy to cut, process, and form, simplifying the production process and helping to reduce production costs. |

| Wide range of applications | Due to its excellent corrosion resistance, formability, and lightness, 1100 corrugated aluminum sheet has a wide range of applications in industries such as construction, transportation, food processing, and chemical packaging. |

Chemical Composition of 1100 Corrugated Aluminum Sheet

| Element | Composition(%) |

| Si | 0.95 |

| Fe | |

| Cu | 0.05-0.20 |

| Mn | 0.05 |

| Mg | - |

| Zn | 0.05 |

| Al | Remainder |

1100 Corrugated Aluminum Sheet Advantages

| Advantage | Description |

| Aesthetic appeal | 1100 corrugated aluminum sheet has a unique visual effect due to its special corrugated structure, making it very popular in decorative applications. The corrugated surface not only enhances the material's three-dimensional and layered appearance but also creates rich reflective effects under different lighting conditions, enhancing its visual impact. Its appearance makes it highly popular for architectural facades, wall decorations, ceilings, partitions, and other designs, especially suitable for modern and industrial-style interiors. Additionally, the decorative nature of the corrugated aluminum sheet makes it an attractive choice for high-end buildings and commercial environments as an exterior element. |

| Lightweight | 1100 aluminum alloy has a low density, making the 1100 corrugated aluminum sheet much lighter than other common metals like steel. This lightweight feature makes it ideal for applications that require reducing the overall structure weight, such as building facades, roofs, and interior wall decorations. Its lightness also makes it easier to handle and install, reducing labor and transportation costs during installation. Furthermore, in applications where structural efficiency and cost savings are important, reducing weight is a very beneficial characteristic. |

| Anti-slip | The corrugated surface of the 1100 aluminum sheet increases friction, improving its anti-slip properties. This feature makes the corrugated aluminum sheet particularly suitable for areas that require anti-slip treatments, such as driveways, walkways, stair platforms, and ship decks. The corrugated structure helps increase the friction coefficient of the contact surface, reducing the risk of slipping accidents. In environments that are wet, greasy, or otherwise slippery, 1100 corrugated aluminum sheet provides additional safety. Therefore, it offers superior safety performance over smooth aluminum sheets in certain applications, such as industrial workshops, warehouses, and outdoor platforms. |

1100 Corrugated Aluminum Sheet Applications

1100 corrugated aluminum sheet is suitable for applications that require good corrosion resistance and weldability, commonly used in containers, storage tanks, and building decorations in the chemical and food industries.

Construction Industry:

- Roofs and Walls: Lightweight and strong, suitable for industrial plants, warehouses, and commercial buildings.

- Facades and Decoration: Extra-wide sheets (up to 2650mm) allow seamless joining, commonly used in modern architectural design.

- Photovoltaic Roofs: Integrated with PV modules, leveraging aluminum’s thermal conductivity to improve power generation efficiency.

Industrial & Transportation:

- Ventilation Ducts: Corrosion resistance suitable for exhaust systems in chemical and food processing industries.

- Automotive Parts: Bus doors, engine panels, etc., benefiting from lightweight and impact resistance.

Other Fields:

- Electronic Equipment Enclosures: Balances electromagnetic shielding with easy machinability.

- Packaging Materials: Food-grade corrosion resistance meets packaging requirements.

| Industry | Application | Description |

| Construction Industry | Decorative applications | Due to its excellent corrosion resistance and lightweight properties, 1100 corrugated aluminum sheet is widely used in exterior walls, roofs, and curtain wall decorations. It is especially suitable for decorative elements in modern architectural styles, such as walls, ceilings, and sunshades. |

| Decorative applications | Interior and exterior decoration | 1100 corrugated aluminum sheet, with its unique corrugated structure and aesthetic appeal, is often used for interior and exterior decoration applications, such as walls, ceilings, and partitions, especially suitable for modern and industrial-style designs. |

| Lightweight structures | Lightweight sunshades, partitions, protective covers, etc. | Suitable for lightweight structural applications that do not bear heavy loads, such as sunshades, partitions, and decorative protective covers, meeting the needs for lightness and corrosion resistance. |

| Transportation | Ship, car, transportation vehicle exteriors | Due to its good corrosion resistance, 1100 corrugated aluminum sheet is widely used for exterior parts of ships, cars, and other transportation vehicles, offering both protection and an aesthetic appearance. |

| Containers and packaging | Food, chemical, pharmaceutical container packaging | 1100 corrugated aluminum sheet is used in the container and packaging industry for manufacturing lightweight containers, especially for food, chemicals, and pharmaceuticals. Its excellent corrosion resistance and weldability ensure the safety of the contents. |

| Chemical industry | Corrosion-resistant equipment casings | In the chemical industry, 1100 corrugated aluminum sheet is commonly used to make equipment casings that require corrosion resistance, suitable for environments with lower strength requirements but higher demands for corrosion resistance. |

1100 Corrugated Aluminum Sheet Processing Methods

- Stamping and Molding: Due to the excellent formability of 1100 aluminum alloy, it is commonly formed into corrugated aluminum sheets through stamping or molding.

- Welding: 1100 corrugated aluminum sheet has good weldability and is often used in connection through aluminum welding techniques.

- Shearing and Bending: Due to its lower hardness, 1100 aluminum alloy can easily be processed through shearing, bending, and other methods to meet different size and shape requirements.

Comparison of Corrugated Aluminum Sheet 1100 with Other Alloys

| Feature | 1100 Corrugated Aluminum Sheet | 3003 Corrugated Aluminum Sheet |

| Strength | Lower (approx. 131MPa in H24 temper) | Higher (approx. 165MPa in H24 temper) |

| Corrosion Resistance | Excellent (suitable for outdoor / humid environments) | Good (slightly lower due to manganese content) |

| Workability | Excellent (suitable for deep drawing, welding) | Good (requires higher forming force) |

| Cost | Lower (simple processing of pure aluminum) | Medium (alloying elements increase cost) |

Suitable Scenarios: 1100 is better suited for applications emphasizing corrosion resistance and formability (e.g., building facades), while 3003 is used for structural parts requiring medium strength (e.g., automotive frames).

How to Choose 1100 Corrugated Aluminum Sheets

- Clarify Requirements: Understand your application scenario (roofing, anti-corrosion, decoration), load requirements, corrosion resistance needs, budget, etc.

- Check Material and Temper: Confirm it is 1100 alloy and the required temper (O for soft, H24 for semi-hard).

- Verify Specifications: Determine the required corrugation type, thickness (considering load and wind), length, and width based on design or use.

- Surface Treatment: For weather resistance or decorative purposes, inquire about surface treatment options (e.g., color coating, fluorocarbon coating, anodizing).

1100 corrugated aluminum sheets, due to their corrosion resistance, light weight, ease of processing, and cost-effectiveness, have become an ideal choice in many industrial and construction applications.

1100 corrugated aluminum sheet, with its excellent corrosion resistance, outstanding machinability, and formability, is an ideal choice for many applications that do not require high strength but demand high corrosion resistance. Its lightweight and aesthetically pleasing corrugated effect make it widely used in fields such as construction, decoration, and transportation. Although its strength is lower, for many lightweight structures and decorative applications, 1100 corrugated aluminum sheet is undoubtedly an ideal material choice.