1060 aluminum sheet coil is used for pipe insulation treatment, which effectively prevents heat loss and improves energy efficiency. This aluminum sheet has excellent corrosion resistance and high-temperature resistance, making it suitable for various industrial pipe systems, ensuring its reliability in harsh environments.

Choosing 1060 aluminum sheet coil for pipeline insulation is a common option. It is essentially an industrial pure aluminum with an aluminum content of over 99.6%, thus possessing many characteristics suitable for insulation outer cladding.

1060 aluminum coil, with its corrosion resistance, ease of processing, and cost-effectiveness, has become the preferred material for pipeline insulation. When selecting, it is necessary to consider temperature, environment, and budget to reasonably choose thickness and surface treatment processes.

1060 insulation aluminum coil serves as the protective outer layer of insulation systems. This aluminum cladding material is commonly used in industrial and building applications, such as HVAC systems, pipe insulation, and building envelope insulation, to reduce heat loss and protect the underlying insulation layer.

Due to its excellent ductility, light weight, and relatively economical price, 1060 aluminum coil has become the preferred outer protective material for many pipeline insulation projects, especially suitable for most conventional indoor environments.

If your project is in a highly corrosive environment or requires higher strength for the outer material, you might consider 3003 aluminum coil.

1060 Insulation Aluminum Coil Specifications

| Item | Specification / Description |

| Thickness | Typically 0.3–1.5 mm, selection should consider pipe diameter and environment |

| Width | Commonly 1000–1200 mm, customizable up to 2650 mm |

| Standard | ASTM, B209, EN573-1 |

| Common Tempers | H14, H16, H24, H26, etc. |

| Common Thickness | 0.3 mm, 0.5 mm, 0.6 mm, 0.8 mm, 1.0 mm |

| Surface Treatment | PE/PVDF coating for enhanced corrosion resistance, Polysurlyn moisture barrier, Stucco embossed (orange peel), anodizing, film coating, corrugated, polyurethane moisture-proof aluminum jacket, kraft paper composite, ripple finish, etc. |

| Delivery Form | Mainly in coil form, can be slit into aluminum strips of different widths or flattened into sheets |

Surface Treatment Options for 1060 Insulation Aluminum Coil

Mill Finish 1060 Aluminum Insulation Coil

Provides a natural, uncoated aluminum surface with silver luster. Offers good baseline corrosion resistance and excellent thermal conductivity, cost-effective for indoor and general pipeline insulation where decorative or extra weather protection is not required.

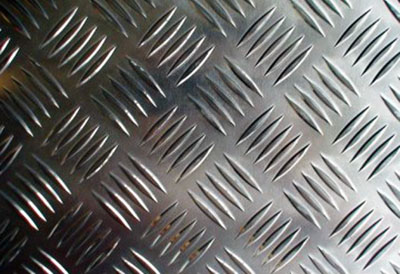

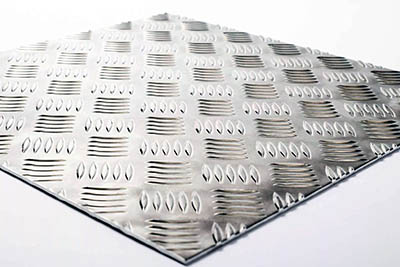

1060 Aluminum Embossed Insulation Roll

Surface stamped with a stucco (orange-peel) or other textured pattern. The embossing improves scratch resistance, hides minor surface imperfections, enhances grip during handling, and gives a neater appearance for exposed insulation jackets on pipes and ducts.

Color Coated 1060 Aluminum Insulation Coil

Factory-applied colored paint finish (various RAL/standard colors). Combines improved aesthetics with added weather and corrosion protection; commonly used for visible HVAC ducts, building facades, and projects that require a specified color or branding.

(PE) Coated 1060 Aluminum Insulation Coil

Coated with a polyethylene (PE) paint or film layer. Delivers bright color options, economical corrosion resistance and easy cleaning. Suitable for indoor use and mild outdoor conditions where cost effectiveness is important.

Fluorocarbon (PVDF) Coated 1060 Aluminum Insulation Coil

Coated with high-performance PVDF (fluorocarbon) paint. Provides outstanding UV stability, long-term color retention, and superior resistance to weathering and chemical attack — ideal for coastal, industrial, and high-end architectural applications.

Anodized 1060 Aluminum Insulation Coil

Electrochemically treated to form a hard, decorative oxide layer. Anodizing increases surface hardness, improves corrosion resistance and yields a metallic decorative finish that resists wear — a good choice when both durability and a premium metallic look are desired.

1060 Corrugated Aluminum Insulation Coil

Formed into corrugated (wave) profiles to increase stiffness and impact resistance compared with flat sheets. Commonly used where extra rigidity is required for cladding, jacketing, or temporary mechanical protection of insulated pipes and tanks.

Polysurlyn Moisture Barrier 1060 Aluminum Coils

Laminated with a Polysurlyn moisture barrier (multi-layer polyethylene/aluminum composite). Provides excellent vapor barrier performance, strong adhesion, and enhanced protection against moisture ingress and delamination — suited for humid, coastal, or chemically aggressive environments.

PolyKraft Paper 1060 Aluminum Insulation Coils

Backed with Kraft paper laminated to a polyethylene film (PolyKraft). Offers an economical vapor-resistant backing that improves handling and resists basic moisture; appropriate for general insulation jobs where heavy-duty moisture barriers are not required.

Mill Finish 1060 Aluminum Sheet Coil for Pipeline Insulation

Mill Finish 1060 Aluminum Sheet Coil is an aluminum coil that retains its original surface from the production process without further processing. Its surface is smooth but not polished or treated with additional coatings. This aluminum coil has excellent corrosion resistance and good formability, making it suitable for applications that require direct attachment of insulation materials to pipe surfaces.

Features: The coil surface is smooth but not highly polished. It has excellent corrosion resistance and good formability, making it ideal for applications where insulation materials need to be applied directly to pipes without requiring high aesthetic quality.

Application: Mill Finish 1060 aluminum coil is used as the base material for pipe insulation. It serves as a substrate for adding insulation materials (such as fiberglass or mineral wool), and the smooth surface helps in easily attaching the insulation layer.

1060 Aluminum Embossed Sheet Coil for Pipeline Insulation

1060 Aluminum Embossed Sheet Coil has an embossed surface that creates a raised pattern or texture. This treatment not only enhances the mechanical strength of the aluminum but also increases the bonding strength between the aluminum surface and the insulation material. The embossed aluminum coil has advantages in abrasion resistance and slip resistance, making it very suitable for pipeline insulation applications that require extra durability.

Features: The embossed surface enhances mechanical strength and abrasion resistance while maintaining excellent corrosion resistance and thermal conductivity. The pattern helps increase the surface area, thereby improving the bonding of the insulation.

Application: This aluminum coil is commonly used in pipeline insulation applications that require additional durability. The raised patterns help maintain the integrity of the insulation and reduce the risk of moisture or debris accumulating between the insulation layer and the aluminum surface.

1060 Corrugated Aluminum Sheet Coil for Pipeline Insulation

1060 Corrugated Aluminum Sheet Coil features a corrugated shape on its surface, which increases the rigidity and strength of the aluminum. The corrugated design not only enhances the aluminum's resistance to bending but also provides a larger surface area for insulation material adhesion. This type of aluminum coil is particularly suitable for pipeline insulation applications that require additional protection against physical impact or are used in harsh environments.

Features: The corrugated design increases the bending strength of the aluminum, making it more resistant to physical impacts. It also increases the surface area, improving the adhesion of the insulation layer. This type of aluminum still retains the typical excellent corrosion resistance of 1060 aluminum.

Application: This coil is typically used in areas where pipelines need extra protection against mechanical stress, or where the insulation layer needs to remain in place under various environmental conditions.

Polysurlyn Moisture Barrier 1060 Aluminum Coil for Pipeline Insulation

Polysurlyn Moisture Barrier 1060 Aluminum Coil is coated with a layer of Polysurlyn moisture barrier film on the aluminum surface. Polysurlyn is a polymer coating that effectively blocks moisture, preventing aluminum corrosion while helping to maintain the long-term stability of the insulation layer. This product is highly suitable for environments with high humidity, such as marine or industrial pipelines, ensuring that the aluminum material is protected from moisture and extending the lifespan of both the pipeline and the insulation materials.

Features: The Polysurlyn layer provides excellent moisture resistance, ensuring that the aluminum does not come into contact with water, which could lead to corrosion and insulation failure. The aluminum itself retains the typical properties of 1060, including lightweight and thermal conductivity.

Application: This is typically used for pipeline insulation in high-humidity or water-exposed environments, such as in marine or industrial applications. The moisture barrier ensures that the aluminum will not deteriorate over time, thus maintaining the performance of both the insulation layer and the pipeline.

PolyKraft Paper Aluminum Coils for Pipeline Insulation

PolyKraft Paper Aluminum Coils are made of aluminum coils with a layer of PolyKraft paper composite. The PolyKraft paper provides additional moisture protection for the aluminum and enhances the aluminum coil's resistance to damage. This composite material helps prevent moisture infiltration, ensures the insulation materials are securely attached, and effectively reduces heat conduction. This aluminum coil is suitable for pipeline insulation applications that require high moisture resistance and mechanical protection.

Features: The PolyKraft paper coating enhances moisture resistance and provides an additional protective layer against damage. The paper also helps reduce thermal conductivity, making it an ideal choice for insulation applications where protecting the aluminum from corrosion and maintaining insulation performance are critical.

Application: This is typically used for pipeline insulation in areas where high moisture resistance and protection against mechanical damage are required. The PolyKraft paper helps maintain the integrity of the insulation layer while providing an additional protective layer for the aluminum surface.

1060 Insulation Aluminum Coil Features

| Feature Dimension | Description | Application in Pipeline Insulation |

| Material and Composition | 1060 is industrial pure aluminum, aluminum content ≥99.6%, iron content ≤0.35%, other elements in trace amounts | Relatively soft texture, easy to process and form. |

| Physical and Mechanical Properties | Low strength (tensile strength 110-136MPa), excellent plasticity and ductility (elongation 3-5%), good corrosion resistance | Easy to bend and wrap around pipes, can withstand a certain degree of bending without cracking, forms a dense oxide film, resistant to environmental corrosion. |

| Thermal Conductivity | Excellent (thermal conductivity 167 W/m°C, electrical conductivity 43% IACS, similar reference to alloy 6063) | Not an insulating material itself, but as a protective layer, it does not accelerate heat loss. |

| Appearance | Silvery metallic luster, surface can be treated (e.g., matte) | Aesthetic and neat, suitable for outdoor or visually demanding applications. |

| Density | Approximately 2.71 g/cm³ | Lightweight, reduces overall weight of the insulation system, convenient for transportation and installation. |

Advantages and Limitations of 1060 Insulation Aluminum Coil

Advantages of 1060 Insulation Aluminum Coil

- Corrosion Resistance: Aluminum forms a dense oxide film in the air, with significantly better resistance to acid rain, salt spray, and other corrosion compared to galvanized steel, making it especially suitable for chemical plants, coastal areas, and other high-corrosion environments.

- Durability and Long Service Life: With its strength and corrosion resistance, the aluminum cladding provides a durable protective layer for insulation systems, generally with a service life exceeding 20 years.

- Ease of Processing: Aluminum has excellent ductility and malleability, making it easy to bend, form, and wrap, thereby improving installation efficiency.

- Aesthetic Appearance: The bright surface of aluminum provides a good visual effect, especially suitable for large-scale construction projects.

- Moisture and Environmental Barrier: Aluminum effectively blocks moisture, oxygen, and other environmental factors, helping to maintain the integrity of the insulation layer.

- Recyclability: Aluminum has high recycling value. After its service life ends, a large portion of the material can be recycled, making it a more economical choice.

- Cost-Effectiveness: 1060 aluminum coil produced by casting and rolling processes is less expensive than hot-rolled materials, and its service life is 3–5 times that of steel sheets, resulting in lower long-term maintenance costs.

- Lightweight and Easy to Handle: Aluminum weighs about one-third of iron or steel, making transportation, handling, and installation more convenient and safer.

Limitations of 1060 Insulation Aluminum Coil

Temperature Range: For O temper (annealed state), the recommended long-term usage temperature is ≤150℃. It softens at high temperatures. H14/H16 tempers can withstand slightly higher temperatures, but usually not exceeding 200℃. For higher temperature resistance (e.g., above 350℃), alloys such as 3003 should be selected.

Comparison Between 1060 Insulation Aluminum Coil and 3003 Aluminum Coil

| Feature | 1060 Aluminum Coil (Pure Aluminum) | 3003 Aluminum Coil (Aluminum-Manganese Alloy) |

| Alloy Type | Series 1, pure aluminum | Series 3, aluminum-manganese alloy |

| Main Characteristics | Good plasticity, easy to process, low cost, moderate corrosion resistance | Higher strength, better corrosion resistance (especially suitable for chemical plants, coastal and high-corrosion environments) |

| Typical Applications | Pipeline insulation and building insulation under common environments | Projects with high corrosion risk, such as desulfurization insulation in chemical plants or coastal pipeline insulation |

| Approximate Cost | Lower | Relatively higher |

Applications of 1060 Insulation Aluminum Coil

- Industrial Insulation: Used to protect insulation layers of pipelines, tanks, and equipment in chemical plants, refineries, and power stations.

- Building: Used for insulation jackets in large buildings such as warehouses, shopping centers, and high-rise buildings.

- HVAC Systems: Used to wrap and protect insulated pipes and ducts.

- Food Processing and Storage: Used in refrigeration systems for cold storage facilities and food processing plants.

-

Advantages Scenarios of 1060 Insulation Aluminum Coil:

- For most common indoor pipeline insulation (such as residential buildings, general industrial plants' hot water pipes, low-pressure steam pipes), 1060 aluminum sheet provides excellent overall cost-performance ratio.

- For projects with strict cost control, it is a highly economical choice.

- Due to its superior ductility, it is ideal for wrapping pipes with complex shapes or requiring precise bending.

-

Limitations of 1060 Insulation Aluminum Coil

- Low Strength: In areas requiring high impact or compressive resistance (e.g., where people might step or equipment may collide), 1060 aluminum sheet may be too soft and easily deformed.

- Corrosion resistance is good but not top-tier: In extreme corrosive environments with strong acids, alkalis, or high salinity (e.g., coastal areas, near desulfurization systems in chemical plants), the durability of 1060 may not match the superior rust resistance of 3003 aluminum coil (aluminum-manganese alloy with 1.0-1.5% manganese).

1060 aluminum coil is widely used in industries such as chemical processing, oil and gas, and HVAC systems due to its high thermal conductivity, corrosion resistance, lightweight, and ease of fabrication.

It not only helps reduce energy loss in pipelines but also provides reliable protection in harsh environments, making it a key material for efficient operations and cost savings.

Chemical Processing Industry

Application:

In chemical processing, pipelines are often exposed to corrosive chemicals and high-humidity environments.

1060 aluminum coil, with its excellent corrosion resistance and moisture-proof properties, protects pipelines from external chemical corrosion and moisture damage.

It helps maintain a stable temperature inside the pipeline, ensuring the efficiency of chemical reactions and product quality.

Effect:

Enhances the safety and efficiency of chemical plant operations.

Reduces pipeline maintenance costs and extends service life.

Oil and Gas Industry

Application:

Oil and gas pipelines operate under extreme temperature variations and high-humidity conditions. 1060 aluminum coil is used for pipeline insulation to reduce heat loss and ensure energy efficiency during the transportation process.

At the same time, its corrosion resistance allows it to perform reliably in saline environments or harsh climates, such as offshore platforms or cold regions.

Effect:

Reduces energy loss and improves economic efficiency.

Provides long-term, stable protection in harsh environments.

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Application:

In HVAC systems, 1060 aluminum coil is used as the outer insulation layer for pipelines to prevent condensation and heat loss.

Its lightweight and ease of fabrication make it an ideal choice for insulating pipes and duct systems.

Effect:

Improves the temperature regulation efficiency of indoor environments.

Reduces energy consumption and operating costs, improving the performance of air conditioning and heating systems.

1060 aluminum sheet coil is a cost-effective and durable pipeline insulation solution with excellent thermal insulation, corrosion resistance, and strength, while also helping to improve the efficiency and service life of pipeline systems.

1060 Aluminum Chemical Composition for Aluminum Coil for Pipeline Insulation

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | single |

| 99.60 | 0.25 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.05 | 0..35 | 0.05 |

Typical Application Cases

- Industrial Pipelines: Power plant steam pipes using 0.8mm thick 1060 aluminum coil with alumina fiber insulation, service life over 15 years.

- Chemical Equipment: Chemical plant pipelines wrapped with 1.0mm aluminum coil, surface coated with PVDF to resist strong acid corrosion.

- Building HVAC: Central air conditioning condensate pipes using 0.5mm aluminum coil, seams fixed with self-tapping screws, smooth appearance with excellent waterproof performance.

Selection and Usage Considerations for 1060 Insulation Aluminum Coil

Purchasing Guide

Environmental Adaptation

For corrosive environments, it is recommended to choose thickness ≥0.6mm or coated with anti-corrosion layers (e.g., epoxy resin).

In areas at risk of mechanical impact (e.g., maintenance corridors), use aluminum coil ≥0.8mm thick and add stiffening ribs.

Installation Prohibitions

Do not step on the aluminum sheet or stack heavy objects on it to avoid deformation.

When in contact with different metals (e.g., aluminum and carbon steel supports), use insulating pads to prevent galvanic corrosion.

Alternative Solutions

For high-temperature scenarios (>200℃), consider 3003-H14 aluminum coil (temperature resistance up to 250℃) or stainless steel cladding.

For locations with extremely high fire protection requirements (e.g., nuclear power plants), fire-resistant aluminum coils with composite rock wool or glass wool should be selected.

Precautions

- Pay attention to thickness: Common thicknesses for 1060 aluminum sheet coil in pipeline insulation range from 0.3mm to 1.0mm, typically around 0.5mm. Selection should consider pipe size, insulation thickness, and external environment (e.g., wind exposure, need for mechanical protection).

- Understand temper: Aluminum coils have different tempers (e.g., O, H12, H14, H18). O temper (annealed state) is the softest with excellent ductility, ideal for deep drawing or complex bending. H tempers (work-hardened state) have higher strength but increased hardness.

- Surface Treatment: Different finishes such as matte or bright can be selected. Matte surfaces are less likely to show fingerprints and stains, offering aesthetic appeal and easier maintenance.