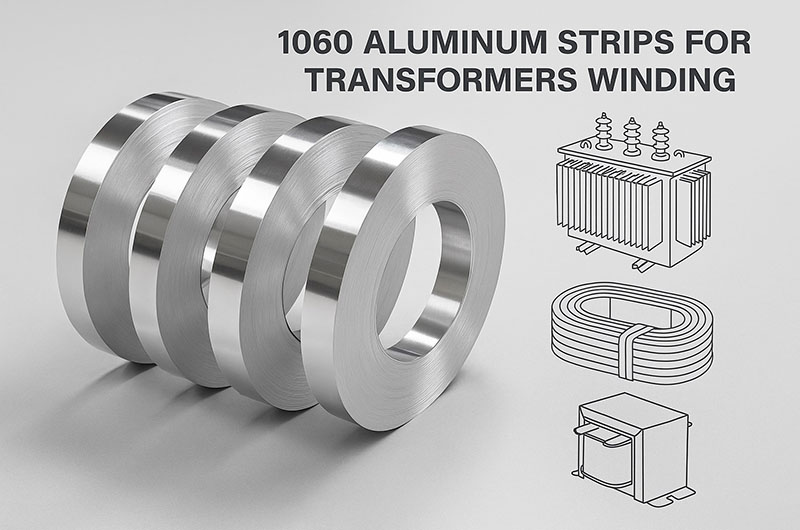

1060-O aluminum strip is widely used in transformer windings due to its excellent conductivity and cost-effectiveness. With an aluminum content of at least 99.6%, the 1060 alloy offers high electrical conductivity, typically around 61.5% IACS (International Annealed Copper Standard), making it highly suitable for transformer applications.

1060 O aluminum strip is a specialty material that is widely applied in transformer windings due to its high conductivity, cost efficiency, and adaptability to manufacturing processes.

1060-O aluminum strip provides an optimal solution for modern transformers, balancing electrical performance, weight reduction, and cost. Its high purity, customizable dimensions, and compatibility with various transformer types make it an indispensable material in power distribution networks.

1060 aluminum strip is extensively used in transformer production, especially in areas with strict electrical and mechanical performance requirements. Annealed or O temper 1060 aluminum strip offers greater flexibility and ductility, making it easier to form and process in transformer windings.

1060 aluminum strip offers conductivity second only to copper but at a significantly lower cost. The material is typically in O temper (soft state), making it suitable for stamping, stretching, and other forming processes.

1060 aluminum strip is an essential conductive material in transformer manufacturing, particularly suitable for dry-type and resin-cast transformers. Known for its high purity, it achieves a balance between cost, performance, and reliability.

Characteristics of 1060 O Transformer Winding Aluminum Strip

The 1060(O) aluminum strip is primarily used for high and low voltage windings of dry-type transformers. It has high electrical conductivity, a soft texture, a smooth surface, and no burrs, making it an ideal material for producing dry-type transformers and a key raw material for manufacturing transformer windings.

1060 aluminum strip has high ductility, corrosion resistance, and is easy to process, though it has relatively low strength and cannot be strengthened by heat treatment.

- Excellent electrical conductivity: 1060 aluminum strip's electrical conductivity exceeds 61.5% IACS (International Annealed Copper Standard), enabling efficient current conduction and reducing energy loss in transformer windings.

- Good formability: 1060 aluminum strip exhibits excellent formability during processing, allowing precise cutting and shaping to meet various transformer design requirements.

- Good weldability: 1060 aluminum strip has good weldability and can be firmly joined with other materials using various welding methods, meeting the strict connection quality requirements in transformer manufacturing.

- Economic efficiency: Compared with copper, it maintains good conductivity while significantly reducing costs—can cut costs by 40–50% compared to copper.

- Lightweight: Density is only 30% of copper, reducing equipment weight.

- Corrosion resistance: The natural oxide film resists atmospheric corrosion.

- Excellent edge control: Smooth, burr-free edges benefit coil winding and reduce insulation layer wear.

- Heat dissipation: Foil-wound design exposes coil edges to air, reducing operating temperature by 20–30% compared to wire-wound transformers.

- Space efficiency: Allows compact windings, reducing transformer size by 15–25%.

- Voltage stress management: Minimal voltage difference between adjacent foil turns (e.g., 5V/turn), compared to several hundred volts/turn in wire-wound transformers, thus reducing corona discharge.

Specifications of 1060 Transformer Aluminum Strip

| Item | Specification/Parameter Description |

| Alloy & Temper | 1060-O |

| Thickness | 0.2 mm to 3.5 mm |

| Width | 10 mm to 1600 mm |

| Conductivity | ≥ 61.5% IACS |

| Inner Diameter Options | 300 mm, 400 mm, 500 mm |

| Thickness Tolerance Range | Thin strip (0.2–0.4 mm): ±0.01 mm Thicker strip (1.8–2.5 mm): ±0.01 mm |

| Edge Quality | Slit or round edges, burr height ≤ 0.03 mm, minimizing insulation issues during winding |

| Surface Finish | Smooth, scratch-free surface with oxidation resistance to ensure consistent performance |

| Surface Quality | Mill finish, smooth, burr-free edges |

| Packaging | Wooden pallets or boxes with protective paper |

Surface and Structural Quality

- Surface treatment: Smooth, scratch-free, atomized finish to minimize oxidation.

- Flatness: Deviation <1/1000 to ensure uniform winding.

- Burr height: ≤0.01 mm (critical for high-voltage applications).

1060 Transformer Aluminum Strip Surface and Formability

- Surface treatment: Rolled (natural) finish, clean and burr-free surface to ensure optimal electrical contact and prevent coil damage.

- Ductility: Soft-annealed "O" grade material offers excellent elongation and formability, ideal for fine winding applications.

Advantages of Haomei 1060 O Transformer Aluminum Strip

- High Cost Performance: The production process is mature, and the price is significantly lower than that of copper and other alloy materials.

- Easy Processing: Suitable for various processes such as stamping, stretching, and welding, meeting the needs of complex structures.

- Excellent Elongation: 1060 O-temper aluminum strip has high elongation, performing well in stretching and forming processes, better meeting deformation requirements in transformer manufacturing.

- Good Workability: 1060 O-temper aluminum strip has excellent workability under normal conditions, ensuring consistency and stability in the production process and improving the overall product quality.

- Superior Oxidation Performance: 1060 aluminum strip performs better than other alloys in oxidation treatment, enhancing product appearance, prolonging service life, and reducing maintenance frequency.

- High Flatness: The 1060 O-temper aluminum strip produced by Haomei Aluminum has extremely high flatness, with flatness error less than 1/1000. High-precision flatness ensures stability and consistency during subsequent processing and application, enhancing overall product quality.

1060 Aluminium Strip Chemical Composition

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.6 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.0200 | 0.0022 | 0.0039 |

Transformer Aluminum Strip 1060 Tolerance

| Major brand | A1060(O)/A1050(O) | ||||

| Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 |

| Tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 |

| Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 |

| Tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 |

Transformer Aluminum Strip 1060 Burr and Collapse

| The width of aluminum belt | Burr’s height | Collapsed side’s height |

| <0.2 | 0.01 | ≥0.05-0.1 |

| 0.2-1.0 | 0.015 | |

| 1.1-1.5 | 0.02 | |

| >1.6 | 0.03 |

Electrical and Mechanical Properties of 1060 Aluminum Strip

- High electrical conductivity: Typically ≥61.5% IACS (International Annealed Copper Standard).

- Mechanical strength: Tensile strength ranges between 60–95 N/mm²; elongation exceeds 25%, ensuring flexibility and durability.

Density and Resistivity of 1060 Aluminum Strip

- Density: ~2.703 g/cm³.

- Maximum resistivity at 20°C: ≤0.02825 Ω·mm²/m.

Applications of 1060 Transformer Aluminum Strip

- Transformer Windings: 1060 aluminum strip is mainly used for manufacturing transformer windings. Its excellent conductivity and processability make it an ideal material for windings. The aluminum strip can be used both as a conductor and mechanical support in the windings.

- Conductor Material: In various conductor components of transformers, 1060 aluminum strip provides stable conductivity and durability, ensuring safe operation of transformers under high load and harsh environments.

- Electrical Insulation: The high corrosion resistance and excellent weldability of 1060 aluminum strip make it a suitable material for electrical insulation components, helping protect internal parts of transformers from external environmental factors.

It is important to note that although aluminum strips like 1060-O have advantages in terms of cost and conductivity, they may not match the electrical performance of copper strips, especially in ultra-high voltage and high-power transformer applications.

| Application Field | Description |

| Transformer Windings | Mainly used as conductive material for high and low voltage windings of dry-type transformers, replacing copper to reduce cost |

| Dry-type Transformers | Preferred for low/medium voltage windings due to its lightweight and easy handling |

| Oil-immersed Transformers | Used for high-power applications (up to 4 MVA), suitable for cost-effective coil production |

| Other Industrial Uses | Includes architectural decoration, electronic components, heat exchangers, cookware, and deep-drawing products, etc. |

Typical Application Scenarios

Due to its combination of conductivity, ductility, and economic value, it has become the standard for windings in dry-type transformers (both high and low voltage). Used in regulator windings and other electrical components requiring copper alternatives.

Mainly used for high and low voltage windings in dry-type transformers, especially suitable for:

- Solar power station combiner systems

- Conductive materials for power transformers

- Components in new energy vehicle charging stations

1060 Transformer Aluminum Strip Manufacturing and Processing

| Item | Description |

| Production Process | 1060 transformer aluminum strip is manufactured through a series of strictly controlled processes, including cold rolling and hot rolling, to ensure mechanical properties and dimensional stability. It is then annealed to improve flexibility and ductility, making it more suitable for transformer winding applications. Finally, it undergoes precise slitting (slit edge) processing to ensure uniform thickness and neat edges, providing a good processing basis for subsequent winding operations. |

| Edge Treatment | 1060 transformer aluminum strip adopts advanced edge processing technology, with a burr-free process that ensures smooth and clean edges, greatly reducing the risk of damage to insulating materials during winding. In addition, the edge processing technology ensures high compatibility with modern automatic winding machines, improving production efficiency and product consistency. |

| Packaging Method | At the finished product stage, the 1060 transformer aluminum strip is wound on a sturdy paper core with an inner diameter ranging from 150 mm to 500 mm, flexibly configured according to customer equipment requirements. The entire coil is then placed in a reinforced wooden pallet or box to protect the product during transportation and handling, preventing edge deformation or surface scratches, ensuring that each roll of aluminum strip received by the customer is in optimal condition. |

1060 Transformer Aluminum Strip vs. Alternatives

| Item | Description |

| Cost Efficiency | 1060 transformer aluminum strip stands out in the industry due to its extremely high cost performance. Compared to traditional copper materials, 1060 aluminum strip is more affordable, significantly reducing raw material costs in large-scale transformer production. At the same time, it still provides approximately 61.5% IACS conductivity, meeting electrical performance requirements while effectively optimizing the overall budget, making it a cost-effective alternative to copper. |

| Thermal Performance | 1060 transformer aluminum strip possesses excellent thermal conductivity, enabling rapid heat dissipation during current transmission and effectively suppressing heat accumulation. This thermal property not only helps transformers operate within a safe temperature range but also greatly reduces the risk of insulation material aging caused by overheating, thereby extending the overall service life of the equipment. |

| Corrosion Resistance | 1060 transformer aluminum strip naturally forms a dense layer of aluminum oxide in the air, providing good corrosion resistance. This natural protective layer remains highly stable even in humid, high-salt, or industrial gas environments, allowing it to maintain structural integrity and conductivity under various harsh conditions, thus enhancing the product's long-term durability. |

1060 O aluminum strips are the cornerstone of modern transformer manufacturing, balancing performance, affordability, and adaptability. Their high conductivity, precision engineering, and robust packaging make them highly suitable for both dry-type and oil-immersed transformers.

1060 Aluminum Comparison with Alternative Materials

1060 vs. Other Aluminum Alloys

| Alloy | Conductivity (% IACS) | Key Application |

| 1050 | ≥60% | General-purpose power transformers |

| 1060 | ≥61.5% | Standard dry-type transformers (optimal cost-performance) |

| 1070 | ≥62.7% | High-efficiency transformers |

| 1350 | ≥62% | Distribution transformers |

1060 Aluminum vs. Copper

- Weight Savings: Aluminum windings weigh 42% less than copper for equivalent conductivity .

- Cost Efficiency: Aluminum reduces material costs by 30–50% .

- Trade-offs: Aluminum requires 40% larger volume to match copper’s conductivity but remains lighter .

1060 Transformer Aluminum Strip Packaging

- Winding details: Uses hard paper cores (Ø150–500mm) for internal winding; customized iron cores are available upon request.

- Coils are secured with interleaving paper and fiber tape.

- Shipped using pallets or wooden crates (in “eye to wall” or “eye to sky” orientation) to ensure protection during transportation.

- Delivery: Standard minimum order quantity is around 5 tons; delivery time is approximately 7–15 days depending on specifications.

Pre-Purchase Recommendations

- Please confirm your exact thickness, width, and edge type requirements.

- Specify packaging and coil ID preferences based on your winding configuration.

1060 Transformer Aluminum Strip Procurement and Quality Control

Procurement Specifications

- Temper: O grade (fully annealed) for optimal softness and formability.

- Certification: Complies with ASTM, RoHS, and ISO9001 standards.

- Packaging: Moisture-proof wooden pallets/boxes; coil inner diameter: 150–505 mm.

Quality Assurance

Testing Protocols:

- Conductivity: Verified through resistivity testing.

- Mechanical Properties: Tensile strength and elongation checked.

- Surface Inspection: Free from scratches, burrs, or impurities.

Advantages of 1060 Transformer Aluminum Strip Over Traditional Designs

- Thermal Management: Even heat distribution extends transformer lifespan.

- Reliability: Solid foil construction resists vibration damage, reducing failure rates.

- Sustainability: Lower carbon footprint in production and recycling compared to copper.

Limitations and Mitigation Measures

- Lower conductivity compared to copper: Can be compensated through design optimization (e.g., increasing cross-sectional area).

- Softness: Annealing reduces hardness but enhances winding adaptability.

With its high purity, electrical efficiency, mechanical flexibility, and superior cost advantage over copper, 1060 O aluminum strip is the preferred choice for transformer windings—ideal for both mass production and customized coil designs.

Haomei Other Alloy Transformer Aluminium Strips

-

1050 Transformer Aluminium Strips

1050 aluminum strip has a conductivity better than 60% IACS. It is widely used in transformer windings. Its main applications include windings of dry and oil-immersed transformers.

-

1070 Transformer Aluminium Strips

1070 aluminum strip has a conductivity of more than 62.7% IACS, and its thickness is generally 0.1mm to 3.5mm, which can adapt to the design requirements of different transformer windings and provide flexible options.

-

1350 Transformer Aluminium Strips

1350 aluminum foil strip has a conductivity better than 62% IACS. It is widely used in transformer windings, especially oil-immersed and dry transformers. Its high conductivity ensures the high efficiency and stability of the transformer.