Aluminum Foil

Aluminum foil is an extremely thin sheet material made from high-purity aluminum through a rolling process, typically ranging in thickness from 0.006 mm to 0.2 mm. As a versatile material, aluminum foil plays an irreplaceable role in various fields such as packaging, construction, electronics, and healthcare due to its unique physical and chemical properties.

The most notable feature of aluminum foil is its excellent barrier properties. It can completely block light, oxygen, moisture, and bacteria, making it an ideal choice for food and pharmaceutical packaging.

When aluminum foil is combined with plastic and paper, the shielding properties of the aluminum foil are integrated with the strength of the paper and the heat sealing properties of the plastic, further improving the shielding performance against water vapor, air, ultraviolet rays and bacteria required as a packaging material. This feature greatly broadens the application market of aluminum foil.

Items packaged in aluminum foil composite packaging are fully isolated from external light, moisture, etc., and thus are completely protected. Especially for the packaging of steamed food, the use of composite aluminum foil materials can ensure that the food does not deteriorate for at least one year. In addition, this packaging material is very convenient to heat and open, making it very popular among consumers.

Aluminum foil parameters

- Aluminum alloy: 1xxx, 3xxx, 8xxx series, etc.

- Aluminum status: O-H112, etc.

- Thickness: 0.006mm - 0.20mm

- Width: 50mm - 1500mm

Advantages of aluminum foil

- Cheap, reusable and recyclable, it is a popular environmentally friendly material in the world today.

- Beautiful aluminum foil containers are leak-proof, sturdy, easy to clean and keep food fresh. Aluminum has good electrical conductivity and can speed up baking and freezing. Aluminum foil containers can restore their original appearance faster and better than other packaging materials.

- Using environmentally friendly aluminum foil containers will not have any impact on the environment. Safe and convenient to use. Using aluminum foil containers instead of plastic products to package fast food can protect the environment and reduce white pollution.

Aluminum Foil Alloys

- 8011 Aluminum Foil: 8011 possesses multiple excellent properties, including outstanding barrier ability against oxygen, moisture, and light. It is commonly used for pharmaceutical packaging, food packaging, aluminum foil tape, cable wraps, aluminum bottle caps, and more.

- 8021 Aluminum Foil: 8021 is known for its exceptional barrier properties, safety, and good processing performance. It effectively blocks moisture and oxygen, is non-toxic and odorless, and is suitable for cold-formed pharmaceutical foil packaging, aluminum foil for lithium battery pouches, etc.

- 8006 Aluminum Foil: With a bright surface, higher strength, and excellent anti-wrinkle performance, 8006 foil resists edge wrinkling during stamping and maintains a flat appearance. It is ideal for producing wrinkle-free food containers, airline meal boxes, and wrinkle-free pastry cups—scenarios requiring high standards in appearance and performance.

- 8079 Aluminum Foil: Known for high strength and superior barrier properties, 8079 foil also has good elongation and pressability. It is widely used in food container materials, pharmaceutical capsules, food packaging, and battery pouch foil, offering reliable protection and enhanced visual appeal of packaging.

- 1235 Aluminum Foil: With an aluminum content of no less than 99.35%, 1235 foil features excellent rust resistance, formability, and weldability. It is widely used in cable wraps, tape foil, and aluminum foil for lithium battery cathodes.

- 1060 Aluminum Foil: 1060 aluminum foil belongs to the pure aluminum category (aluminum content ≥99.6%) and boasts excellent ductility and formability, along with good thermal conductivity and corrosion resistance. It is widely used in aluminum gaskets, electrolytic capacitors, and automotive heat shields.

- 1100 Aluminum Foil: 1100 foil has slightly higher strength among pure aluminum foils and can be stamped, bent, and processed. It is commonly used in kitchenware (such as baking tray liners and foil sheets), insulation materials, and isolation layers of electronic components.

- 1070 Aluminum Foil: Due to its high purity, 1070 aluminum foil offers superior electrical conductivity. It is suitable for applications such as capacitor electrode foil, precision electronic component packaging, high-end food packaging, and materials used in scientific research.

- 1050 Aluminum Foil: With an aluminum content ≥99.5%, 1050 aluminum foil has balanced overall properties and is commonly used in capacitors, cable wraps, aluminum foil gaskets, and heat sinks. It is a widely used general-purpose pure aluminum foil material.

- 3003 Aluminum Foil: Compared to pure aluminum foil, 3003 foil offers higher strength while maintaining good ductility and corrosion resistance. It is widely used in food containers (such as meal boxes and easy-open can lids), building soundproofing materials, HVAC ducts, and packaging materials.

- 3004 Aluminum Foil: 3004 aluminum foil has greater strength and hardness than 3003, with good formability, suitable for deep-drawing processing. It is mainly used for meal box materials, aluminum honeycomb cores, beverage can bodies, and beverage packaging—meeting the industrial and packaging needs for high strength and formability.

- 5052 Aluminum Foil: 5052 aluminum foil is a medium-strength alloy foil commonly used in scenarios requiring relatively high strength and corrosion resistance, such as honeycomb materials, door panel materials, meal box materials, and corrosion-resistant containers in the chemical industry. It is a medium- to high-end aluminum foil alloy with well-balanced comprehensive performance.

Aluminum Foil Thickness, Shape, and Popular Sizes

The dimensions of aluminum foil are usually represented by three parameters: thickness, width, and length. Thickness is the key parameter of aluminum foil and is typically measured in millimeters (mm) or microns (μm), with 1 millimeter equal to 1000 microns. Different application scenarios have different preferences for aluminum foil dimensions.

Aluminum Foil Thickness

- Double Zero Foil: ≤0.01mm (e.g., 0.006mm), mainstream in the packaging field, used for chocolate, pharmaceutical blister packs.

- Single Zero Foil: 0.01–0.1mm (e.g., 0.016mm cigarette foil).

- Thick Aluminum Foil: 0.1–0.2mm (e.g., air conditioning foil 0.08–0.2mm).

Aluminum Foil Shapes

- Hard Aluminum Foil: Aluminum foil that has not been softened (annealed) after rolling. If not degreased, its surface contains residual oil. Therefore, hard foil must be degreased before printing, lamination, and coating. It can be used directly for forming processes.

- Semi-Hard Aluminum Foil: Aluminum foil with hardness (or strength) between hard foil and soft foil, commonly used for forming processes.

- Soft Aluminum Foil: Aluminum foil that has been fully annealed and softened after rolling. The material is soft and the surface is free of residual oil. Most applications such as packaging, lamination, and electrical materials use soft foil.

Popular Aluminum Foil Sizes

- 18 micron aluminium foil

- 24 inch wide aluminum foil

- 18 inch aluminum foil

- 36 inch wide aluminum foil

- aluminum foil 1000 ft

- 500 ft aluminum foil

- aluminum foil 200 sq ft

- aluminum foil 250 sq ft

- aluminum foil 75 sq ft

- aluminium foil 20x20

Popular Aluminum Foil Thicknesses in Various Fields

Food Packaging Field

- Household Use: Thickness 0.01–0.02 mm

- Commercial Use: Thickness 0.01–0.03 mm

- Baking: Pre-formed containers with thickness 0.03–0.1 mm

Pharmaceutical Packaging Field

- Blister Packaging: Thickness 0.02–0.03 mm

- Cold Form Foil: Thickness approx. 0.15 mm

- Tropical Aluminum Foil: Thickness 0.02–0.03 mm

Construction Field

- Insulation Materials: Thickness 0.02–0.05 mm

- Waterproof and Moisture-Proof: Thickness 0.03–0.08 mm

- Decorative Applications: Customized to various sizes according to design requirements

Electronics Field

- Capacitors: Thickness 0.01–0.05 mm

- Lithium Batteries: Thickness 0.005–0.02 mm

- Electromagnetic Shielding: Thickness 0.01–0.03 mm

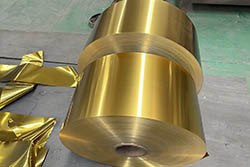

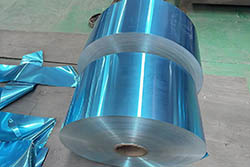

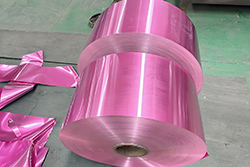

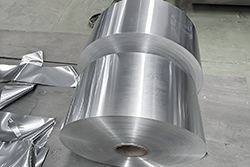

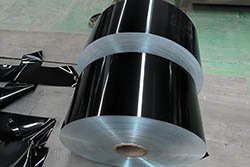

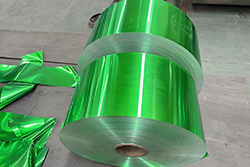

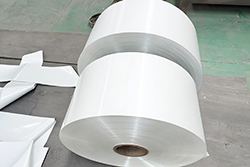

Aluminum Foil Colors

The natural color of aluminum foil is silver-white, which is determined by the optical properties of aluminum metal. The surface of pure aluminum foil displays a metallic luster with high reflectivity, effectively reflecting light and heat. Through different surface treatment processes, aluminum foil can present a variety of colors to meet the needs of different application scenarios.

-

gold aluminum foil

-

blue aluminum foil

-

pink aluminum foil

-

silver aluminum foil

-

black aluminum foil

-

bronze aluminum foil

-

green aluminum foil

-

white aluminum foil

- Golden Aluminum Foil: One of the most common colored aluminum foils on the market, widely used in food packaging, pharmaceutical packaging, and decoration fields. It is usually achieved by applying specific organic coatings or special anodizing treatments on the aluminum foil surface.

- Blue Aluminum Foil: Commonly used in hydrophilic aluminum foil for air conditioners and refrigeration equipment, such as 8011H22 blue hydrophilic aluminum foil. The blue coating typically has hydrophilic properties, helping discharge condensate and improve heat exchange efficiency.

- Black Aluminum Foil: Typically used in special decorative applications or scenarios requiring heat absorption, such as solar collectors. The black coating can enhance the aluminum foil's solar energy absorption rate.

- Bronze Aluminum Foil: Featuring a vintage-style appearance, it is often used in high-end packaging and decorative fields. Usually produced through special anodizing or multi-layer coating processes.

- Color Printed Aluminum Foil: By printing colors and patterns on the surface of aluminum foil, a variety of pattern and color combinations can be achieved. It is widely used in food packaging, pharmaceutical packaging, and gift packaging.

Effect of Color on Aluminum Foil Performance

- Optical Properties: Aluminum foils of different colors have different light reflection and absorption characteristics. For example, white and silver foils have high reflectivity, while black foil has high absorption.

- Thermal Properties: Color affects the foil’s ability to absorb and emit heat. Dark-colored foil typically absorbs more heat than light-colored foil, which is particularly important in solar applications.

- Corrosion Resistance: Some color treatment processes, such as anodizing, can form a protective film on the aluminum foil surface to improve its corrosion resistance. Different colored coatings may also offer varying degrees of anti-corrosion performance.

- Decorative Effect: Color is an important component of aluminum foil's decorative properties and can significantly impact a product’s visual appeal and market attractiveness.

Aluminum Foil Surface Treatments

- Plain aluminum foil (plain foil): Plain foil is aluminum foil without any subsequent processing, retaining the original silver-white metallic luster and natural texture of aluminum. Its surface is clean and smooth, with soft texture and excellent ductility.

- Composite aluminum foil: Composite aluminum foil is a functional material made by combining aluminum foil with other materials, offering properties such as oxidation resistance, heat resistance, corrosion resistance, and thermal insulation. It is widely used in industries like construction and food packaging.

- Embossed aluminum foil: Embossed foil is aluminum foil processed with patterns using molds, enhancing the tactile texture and decorative appeal while also improving stiffness to a certain extent.

- Laminated Aluminum Foil: Also known as composite aluminum foil, this multi-layer material is made by laminating aluminum foil with one or more functional materials (such as PET film, PE foam, kraft paper, bubble wrap, fiberglass cloth, etc.) via thermal lamination or hot pressing.

- Color Coated Aluminum Foil: A surface-painted or coated aluminum foil. The coating (e.g., polyester, epoxy) can maintain color for years without fading. It combines aluminum foil's barrier properties, ductility, and weather resistance. Commonly used in food packaging, architectural decoration, and household products.

- Coated aluminum foil: Coated foil is aluminum foil with a specific functional coating (such as anti-corrosion or hydrophilic layers, typical in air conditioner hydrophilic foil). The coating bonds tightly with the foil substrate, significantly enhancing targeted performance.

Aluminum Foil Coating Technologies

- Hydrophilic Coating: Mainly used in air conditioning and refrigeration heat exchange fins, such as 8011 H22 blue hydrophilic aluminum foil and 8011-O golden hydrophilic aluminum foil. The hydrophilic coating allows condensed water to form a water film instead of droplets, avoiding liquid bridges and improving heat exchange efficiency.

- Hydrophobic Coating: Opposite of hydrophilic foil, hydrophobic coatings give the aluminum foil water-repelling properties, causing condensate to form fine, easily sliding droplets. Usually achieved with low surface energy materials like PTFE, offering self-cleaning and anti-corrosion characteristics.

- Anti-Corrosion Coating: Achieved by applying organic or inorganic anti-corrosion materials to the aluminum foil surface, enhancing corrosion resistance and lifespan. Widely used in construction, automotive, and marine engineering.

- Carbon Coated Aluminum Foil: Designed specifically for high-performance battery systems as advanced anode current collectors. A uniform conductive carbon layer is applied to high-purity aluminum foil, effectively preventing corrosion and enhancing adhesion between electrode materials and the collector, ensuring battery stability and reliability.

- Conductive Coating: By coating the aluminum foil surface with conductive materials like carbon nanotubes or graphene, interface resistance is reduced by 15–20%, and electrode sheet processing performance is improved. This coating is mainly used in lithium batteries and other electronic applications.

- Color Coating: Applying various colored organic coatings to the aluminum foil surface gives it different colors and decorative effects. Color coating is widely used in packaging, decoration, and construction.

Aluminum Foil Embossing and Printing Technologies

Embossing Process: A technique that forms various patterns on the aluminum foil surface using embossing equipment. Embossing enhances the decorative appearance of aluminum foil and also improves its mechanical and anti-slip performance.

Functions of Embossed Aluminum Foil:

- Increases surface area and improves heat exchange efficiency

- Enhances mechanical strength and rigidity

- Improves anti-slip performance

- Enhances decorative effect

Printing Technology: Various printing methods can be applied to the aluminum foil surface, including offset printing, gravure printing, and flexographic printing. Printing allows the addition of logos, patterns, and usage instructions, increasing product market appeal.

Hot Stamping Process: A special printing technique in which metallic foil is transferred to the aluminum foil surface via heat pressing, forming shiny patterns or text. Hot stamping is widely used in high-end packaging and decorative fields.

Applications of Aluminum Foil

Food Packaging

Aluminum foil is widely used in the field of food packaging, including baking, grilling, preservation, and ready-to-eat food packaging. Its excellent barrier properties effectively prevent oxidation, moisture, and spoilage of food, thus extending shelf life.

- Kitchen aluminum foil

- Food container aluminum foil

- Baking and grilling containers

- Chocolate and candy packaging

- Aluminum foil for yogurt lids

- Retort packaging

- Aluminum foil pouches

Pharmaceutical Packaging

Aluminum foil is a key material in pharmaceutical packaging, providing excellent barrier properties to prevent moisture, oxidation, and degradation of medicines, ensuring their quality and stability while meeting strict hygiene standards.

- Blister packaging

- Cold-forming composite hard film

- Tropical blister aluminum foil

- Medical sterilization packaging

- Moisture-proof pharmaceutical packaging

Air Conditioner Aluminum Foil

8011, 1100, 1200, 3102, 8006 and other aluminum alloys for air conditioning. Products include hydrophilic aluminum foil, hydrophobic aluminum foil, coated aluminum foil, fin materials, aluminum foil tubes, and insulation tapes for HVAC systems.

- 8011 O H22 H24 air conditioner foil

- 8006 O H22 air conditioner foil

- Hydrophilic aluminum foil for air conditioners

- Hydrophobic aluminum foil for air conditioners

- Coated aluminum foil for air conditioners

Construction Aluminum Foil

In the construction field, aluminum foil is used for insulation, waterproofing, moisture-proofing, and decoration. Its high reflectivity effectively reflects heat, improving thermal insulation of buildings and reducing energy consumption.

- Thermal insulation aluminum foil

- Waterproof and moisture-proof layers

- Building decorative materials

- Roof reflective layers

- Curtain wall systems

Industrial Aluminum Foil

Industrial aluminum foil typically has a larger thickness (0.05–0.2mm), high strength, and durability. It is widely used in various industrial manufacturing processes, meeting the demands of harsh environments.

- Insulation layers for industrial pipelines

- Corrosion-resistant liners for chemical equipment

- Materials for industrial filters

- Carriers for metalworking lubricants

- Industrial tapes and composite materials

Electronic Aluminum Foil

In the electronics field, aluminum foil is used in capacitors, lithium battery current collectors, electromagnetic shielding, and heat dissipation. Its excellent conductivity and processability make it an ideal material for electronic components.

- Capacitor aluminum foil

- Aluminum foil for cable wrapping

- Aluminum foil for transformers

- Lithium battery current collectors

- Electromagnetic shielding materials

- Flexible circuit boards

- Heat dissipation for electronic equipment

Automotive Aluminum Foil

Aluminum foil is used in the automotive industry for heat exchangers, thermal and acoustic insulation, and automotive electronics. With the development of new energy vehicles, the demand for high-performance aluminum foil continues to grow.

- Automotive heat exchangers

- Thermal and acoustic insulation materials

- Automotive electronic components

- New energy vehicle batteries

- On-board equipment shielding

- Other automotive aluminum foil applications

Other Applications

Aluminum foil is also widely used in other fields such as household items, cable shielding, and aerospace. Its multifunctionality allows it to play an important role in many industries.

- Aluminum foil for bottle caps

- Honeycomb aluminum foil

- Sealing gasket aluminum foil

- Aluminum foil for hairdressing

- Cigarette packaging aluminum foil

- Aluminum foil for windows

- Aluminum foil tapes

- Aluminum foil with parchment paper backing

- Cathode foil

Other Aluminum Foil

- heavy duty aluminum foil

- aluminum foil sheets

- wide aluminum foil

- Heat-Sealed Aluminum Foil

- aluminum foil packaging

- aluminum foil lids

- nonstick aluminum foil

- aluminium spout pouch

- plastik aluminium foil

- aluminum foil pouch

- clear aluminum foil

heavy duty aluminum foil

Heavy duty aluminum foil is a type of aluminum foil with greater thickness and higher strength, typically over 0.02 mm thick. It has significantly better toughness and tear resistance compared to regular foil. Capable of withstanding higher temperatures and heavier weights without tearing easily, it is suitable for repeated use. It is widely used in oven cooking, grilling, wrapping large food containers, and heavy-duty industrial packaging, meeting the needs for load-bearing and durability.

aluminum foil sheets

Aluminum foil sheets are pre-cut aluminum foil products in fixed sizes, usually square or rectangular, individually packed or stacked in bundles. They are convenient to use without the need for cutting. Available in various thicknesses and specifications, they are suitable for food wrapping and baking in home kitchens, as well as for disposable food packaging in restaurants and the takeaway industry, offering both practicality and convenience.

wide aluminum foil

Wide aluminum foil refers to foil rolls with a large width, generally over 1 meter and sometimes several meters wide. It offers excellent ductility and coverage. Due to its wide format, it is ideal for continuous processing in large-scale industrial production, such as insulation layering in construction, packaging of large equipment, printing substrates, and battery tab materials. It reduces splicing steps and improves operational efficiency.

Heat-Sealed Aluminum Foil

Heat-Sealed Aluminum Foil is specially treated (e.g., coated with heat-sealing adhesive) to allow sealing by heating. It provides excellent sealing performance and effectively blocks air, moisture, and odors. It is widely used in the sealed packaging of food and pharmaceuticals, such as yogurt cup lids, can seals, and pharmaceutical aluminum foil seals. It ensures the freshness and safety of contents and allows for easy opening.

aluminum foil packaging

Aluminum foil packaging uses aluminum foil as the main or auxiliary material. It leverages the foil’s barrier properties, light-blocking ability, and corrosion resistance to protect contents from environmental impact. Available in various forms such as foil bags, foil boxes, and foil rolls, it is used across food (e.g., snacks, meat), pharmaceuticals, cosmetics, and industrial parts packaging, combining protection with attractive presentation.

aluminum foil lids

Aluminum foil lids are specially designed covers made of aluminum foil for containers. They often feature easy-peel edges or sealing layers and fit tightly on the openings of plastic cups, glass jars, metal cans, etc. With excellent sealing and preservation properties, they prevent liquid leakage and spoilage. Commonly used for takeaway containers, sauce bottles, yogurt cups, etc., they are easy to peel after use, offering convenience and practicality.

nonstick aluminum foil

Nonstick aluminum foil is aluminum foil coated with a non-stick layer (e.g., silicone) that effectively prevents food from sticking. It is particularly suitable for baking and grilling, avoiding food adhesion that can cause tearing or waste. It is easy to clean after use and does not require additional oil, maintaining the high-temperature resistance of aluminum foil while enhancing cooking convenience. It is favored by both home kitchens and the food service industry.

aluminium spout pouch

Aluminium spout pouch is a soft packaging bag made of aluminum foil and plastic composite, equipped with a spout for convenient dispensing. It can stand upright and is suitable for storing liquids or semi-liquids (such as juice, sauces, cosmetic lotions, etc.). Once sealed, it resists leakage and is lightweight and portable. It is widely used in the packaging of portable foods and daily-use products.

plastik aluminium foil

Plastik aluminium foil is a composite material made by combining aluminum foil with plastic film through a lamination process. It integrates the barrier and light-blocking properties of aluminum foil with the flexibility and sealing capabilities of plastic. This composite material offers higher strength and is less prone to rupture, commonly used for food pouches, vacuum packaging, and industrial moisture-proof packaging. It is suitable for complex packaging and transportation environments, helping to extend product shelf life.

aluminum foil pouch

An aluminum foil pouch is a bag-shaped packaging made entirely of aluminum foil or laminated with other materials. It offers excellent barrier properties, resistance to high and low temperatures, and airtightness. Available in various styles, such as vacuum bags, stand-up pouches, and zipper bags, it is widely used for packaging snacks, ready-to-eat foods, and electronic products. It prevents oxidation and spoilage while enhancing product visibility through printing.

clear aluminum foil

Clear aluminum foil is specially processed (e.g., made ultra-thin or laminated with transparent film) to combine the basic properties of aluminum foil with a certain level of transparency, breaking the traditional opacity of aluminum foil. It is often used in packaging scenarios where product visibility is desired, such as premium candies and health supplements. It protects the contents while allowing consumers to see the product inside, balancing functionality and presentation.

Aluminum foil characteristics

Aluminum foil has a clean, hygienic and shiny appearance. It can be made into integrated packaging materials with many other packaging materials, and the surface printing effect of aluminum foil is better than other materials. In addition, aluminum foil has the following characteristics:

- The surface of aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can grow on its surface.

- Aluminum foil is a non-toxic packaging material that can be in direct contact with food without any danger to human health.

- Aluminum foil is a tasteless and odorless packaging material that will not cause any odor to the packaged food.

- If the aluminum foil itself is not volatile, it and the packaged food will never dry or shrink.

- No matter whether it is at high temperature or low temperature, there will be no grease penetration in the aluminum foil.

- Aluminum foil is an opaque packaging material, so it is a good packaging material for products exposed to sunlight, such as margarine.

- Aluminum foil has good plasticity, so it can be used to package products of various shapes. Containers of various shapes can also be made at will.

- Aluminum foil has high hardness and high tensile strength, but its tear strength is low, so it is easy to tear.

- Aluminum foil itself cannot be heat-sealed. It must be coated with a heatable material, such as PE, on its surface to achieve heat sealing.

- Adverse reactions may occur when aluminum foil comes into contact with other heavy metals or heavy metals.

Aluminum foil anti-corrosion measures

Corrosion mainly results from the aluminum foil becoming damp or exposed to water during production and transportation. In order to control the generation of corrosion waste, the following anti-corrosion measures need to be taken:

- Ensure there is no moisture in the compressed air and strengthen the management of air dryers.

- Control the water content of rolling oil below 400×0.000001, and strengthen the management of rolling oil.

- Use sealed packaging and put an appropriate amount of desiccant in each roll of aluminum foil.

- Ensure that the humidity of the wooden shaft and board of the packaging box does not exceed 18%, and the temperature of the packaging aluminum coil does not exceed 45 degrees Celsius.

- When transporting from a low temperature area to a high temperature and high humidity area, do not open the sealed package immediately.

- Do not place aluminum foil rolls in places where there is leakage of rain or snow on the roof of the workshop or warehouse.

- When transporting aluminum foil to high temperature areas, strengthen the sealing of the packaging and add desiccant if necessary.

- When packaging aluminum foil products in the rainy season, strengthen the sealing packaging and increase the use of desiccant.

Aluminum foil related topic search

- Aluminum foil for wine bottle caps

- Battery aluminum foil

- Aluminum foil for lithium battery soft packaging aluminum plastic film

- tape foil

- Aluminum foil substrate for beverage lids

- Insulation aluminum foil (phenolic aluminum foil for air ducts)

- Aluminum foil for disposable takeaway packaging boxes

- Aluminum foil for aluminum lunch boxes

- Aluminum foil for filter

- Aluminum foil for egg tarts

- Aluminum foil for oral liquid bottle caps

- cable foil

- Cigarette packaging foil

- decorative foil

- Aluminum foil for electrolytic capacitors

- Aluminum foil for pole tab material

- Aluminum foil for electronic labels

- Aluminum foil for anti-theft bottle cap materials

- lunch box aluminum foil

- 8011-h18 Aluminum foil for pharmaceutical packaging

- Aluminum foil for RFID etched electronic tag antenna

- capacitor aluminum foil

- Aluminum foil gasket

- Aluminum foil for beer sealing

- Aluminum foil for honeycomb core

- Aluminum foil for packaging

- Sealing gasket aluminum foil

- Insulated aluminum foil

- Yogurt covered with aluminum foil

- Easy-open lid aluminum foil

- Aluminum foil for transformer

- Aluminum for bottle caps

- Capsule aluminum foil board base material

- Honeycomb aluminum foil

- Aluminum foil for cosmetic bottle caps

- Aluminum foil base material for tape

- Aluminum foil for cable tape

- PTP medicinal aluminum foil substrate

- electronic foil

- Aluminum foil for grill pan

- container foil

- household foil

- Medicinal aluminum foil

- Food grade aluminum foil

- 8011 aluminum foil lunch box base material

- Aluminum foil substrate for baked lunch boxes

- Tropical type blister aluminum foil

- Aluminum foil for mask nose strip

- 8011-O aluminum foil substrate for yogurt lid

- Pharmaceutical aluminum foil substrate

- Aluminum foil for battery explosion-proof valve

- Aluminum foil substrate for barbecue

- Aluminum foil for packaging aluminum foil bags

- heat seal foil

- Aluminum foil for milk powder cover

- Aluminum foil for tin foil bags

- air conditioner foil

- Hairdressing aluminum foil

- Chocolate packaging aluminum foil

- baking foil

- kitchen aluminum foil