8011 Aluminum Foil

8011 aluminum foil, as an important aluminum alloy foil material, features excellent comprehensive properties, broad application prospects, high cost-effectiveness, and sustainable characteristics. It achieves a good balance in strength, toughness, corrosion resistance, and processing performance, meeting the demands of various application fields.

8011 aluminum foil maintains excellent ductility and formability. It can be folded, bent, or embossed without cracking. Alloying and controlled annealing endow it with good processing performance. 8011 aluminum foil can be processed into extremely thin sheets while maintaining good tear resistance.

8011 aluminum foil is an aluminum alloy foil material with added Al-Fe-Si elements, belonging to the 8 series alloy aluminum plates. Its chemical composition mainly includes aluminum (Al), iron (Fe), and silicon (Si). The addition of these alloying elements effectively improves the properties of pure aluminum. Compared to pure aluminum foil, 8011 aluminum foil has higher strength, good corrosion resistance, excellent formability, and certain electrical conductivity.

- Clean surface: uniform color, no spots, flat and pinhole-free

- Strong mechanical properties: high burst resistance, strong puncture and tear resistance

- Excellent barrier performance: outstanding moisture resistance, light shielding, and high barrier capacity

- Safe and hygienic: non-toxic and odorless, compliant with food contact safety standards

- Good processability: easy for lamination, printing, gluing, and other processing operations

Haomei Aluminum is a trusted aluminum foil supplier serving customers in industrial manufacturing and food packaging industries. If you are looking for the best cost-effective packaging solution or need high-quality aluminum foil customized to your specific specifications, width, and temper, Haomei Aluminum can meet your needs.

8011 Aluminum Foil Temper

- O

- H14

- H16

- H18

- H19

- H22

- H24

Aluminum Alloy 8011 Foil Specification

| Products | Type | Temper | Thickness(mm) | Width(mm) | Shape |

| 8011 Household Foil | Bare, Mill Finish | H111 H12 H14 H16 H18 H22 H24 H26 H28 | 0.01-0.2 | 300-1100 | coil |

| 8011 Container Foil | H22 H24 | 0.01-0.2 | 200-1100 | coil | |

| 8011 Packaging Foil | O H22 H24 | 0.018-0.2 | 100-1600 | coil | |

| 8011 Pharmaceutical Foil | H14 H18 | 0.018-0.2 | 100-1600 | coil |

Thickness Range

Between 0.006mm and 0.5mm

Food packaging: 0.02-0.04mm; Heat-sealed yogurt lids: 0.04-0.09mm; Bottle cap materials: around 0.2mm

Width Range

Between 100mm and 1700mm

Standard widths for beverage caps and food/pharmaceutical packaging; Industrial use: 1200mm, 1500mm

Temper Specifications

F (As fabricated), O (Annealed), H14, H16, H18, H19, H22, H24, H26, H28, etc.

O temper: High ductility; H14/H16: Medium strength; H18/H19: High strength

In fact, foil can be made extremely thin.

- Specialized 8011 foil can be as thin as approximately 0.00018 inches (about 0.0046 millimeters), suitable for ultra-thin applications;

- And as thick as approximately 0.064 inches (about 1.63 millimeters), suitable for heavy-duty foil (non-foil grades can be even thicker).

- Widths range from a few centimeters to over 1.5 meters. Foil is typically sold in coils or master rolls; standard coil inner diameters are 75 millimeters or 150 millimeters.

- Temper (hardness) is selected according to the application: fully annealed (O) or lightly tempered states (H14, H18) are suitable for applications requiring maximum formability (such as pharmaceutical blister foil); harder tempers (H22–H26) are suitable for heavy-duty packaging or consumer foil, offering higher strength.

- Rolled (bright or matte) surface finishes are standard; we also offer special surface treatments (coated, pre-painted, or embossed).

Physical and Chemical Properties of 8011 Aluminum Foil

- Density: About 2.7g/cm³, close to pure aluminum, characterized by light weight

- Thermal conductivity: Good thermal conductivity, able to conduct heat quickly

- Electrical conductivity: While lower than pure aluminum, still has good conductivity

- Corrosion resistance: Good corrosion resistance due to the dense oxide film on the aluminum surface

- Temperature resistance: Can operate normally in the range of -20℃ to 150℃

- Barrier performance: Excellent barrier performance, effectively blocking light, oxygen, water vapor, and odors

- Surface quality: Clean surface, uniform color, no spots, flat and pinhole-free

Advantages of 8011 Aluminum Foil

8011 aluminum foil, with its excellent corrosion resistance, surface quality, safety and hygiene, versatility, durability, lightness, and cost-effectiveness, is widely used across various industries and is an ideal choice for packaging materials.

Excellent Corrosion Resistance

- Exceptional resistance to corrosion, resisting a variety of chemicals.

- Energy-saving and mildew-resistant: Prevents mold growth and conserves energy.

- Odorless: Does not release any odors, preserving the original taste of the product.

Superior Surface Quality

- Clean and uniform: Smooth surface with no blemishes, pinholes, or color variations.

- Moisture-proof and light-blocking: Excellent moisture resistance and light-blocking properties, with strong barrier capabilities.

Good Mechanical Properties

Strong resistance to puncturing and tearing, with good mechanical performance.

Safety and Hygiene

Non-toxic and odorless: Free from harmful chemicals, suitable for food and pharmaceutical packaging.

Versatility

- Packaging Material: Suitable for various uses such as lamination, printing, and coating.

- Industry Applications: Widely used in packaging for food, beverages, pharmaceuticals, and other fields.

Strong Environmental Adaptability

Environmental adaptability: Withstands humidity, light, and temperature changes, keeping the contents fresh.

Lightness

Lightweight Material: Easy to handle and transport, suitable for long-distance transportation, especially in the food, beverage, and pharmaceutical industries.

Cost-Effective

High cost-performance ratio: Affordable pricing and high value for money, suitable for businesses of all sizes.

8011 Aluminum Foil Surface Treatments

- Two sides bright

- single side bright

- bright dull

- embossed ( embossing )

- colored printed

- color coated

- lacquered

- Hydrophilic

- 8011 Plain Aluminum Foil: 8011 plain aluminum foil has a smooth, shiny surface without additional processing. It provides reliable barrier properties against moisture, light, and gases, making it widely used in food packaging, household foil, and pharmaceutical packaging.

- 8011 Embossed Aluminum Foil: 8011 embossed aluminum foil has textured patterns pressed onto its surface. The embossing enhances appearance, increases friction, and improves heat transfer. It is commonly applied in household foil, decorative wrapping, and insulation.

- 8011 Coated Aluminum Foil: 8011 coated aluminum foil is covered with a protective or functional coating such as resin, lacquer, or polymer film. This enhances corrosion resistance, printing quality, and overall performance for packaging and industrial applications.

- 8011 Laminated Aluminum Foil: 8011 laminated aluminum foil is bonded with paper, plastic, or film. The multi-layer structure offers better strength, sealing, and barrier properties, making it ideal for flexible packaging, food pouches, and beverage cartons.

- 8011 Lacquered Aluminum Foil: 8011 lacquered aluminum foil is coated with food-grade lacquer, providing excellent adhesion, heat-sealing ability, and resistance to acid, grease, and high temperatures. It is widely used in yogurt lids, beverage caps, and pharmaceutical packaging.

- 8011 Color Coated Aluminum Foil: 8011 color coated aluminum foil is painted in various colors, combining decorative appeal with protective performance. It is suitable for packaging, decorative wrapping, and insulation applications.

- 8011 Hydrophilic Aluminum Foil: 8011 hydrophilic aluminum foil has a coating that makes water spread evenly across its surface instead of forming droplets. This improves heat exchange efficiency and is widely used in air conditioners and heat exchangers.

- 8011 Hydrophobic Aluminum Foil: 8011 hydrophobic aluminum foil has a water-repellent surface treatment that prevents water adhesion. It reduces frost formation, improves durability, and is used in refrigeration and HVAC systems.

- 8011 Composite Aluminum Foil: 8011 composite aluminum foil is combined with other materials like plastics, paper, or non-woven fabrics to create a multifunctional barrier. It is used in food, pharmaceutical, and industrial packaging.

- 8011 Double-Sided Bright Aluminum Foil: 8011 double-sided bright aluminum foil has both surfaces polished to a shiny finish. It is commonly applied in decorative packaging, insulation, and reflective materials where high reflectivity is required.

- 8011 One-Side Bright / One-Side Matte Aluminum Foil: 8011 aluminum foil with one bright side and one matte side is produced by rolling. The dual finish allows different functional or aesthetic uses in packaging, cooking, and wrapping applications.

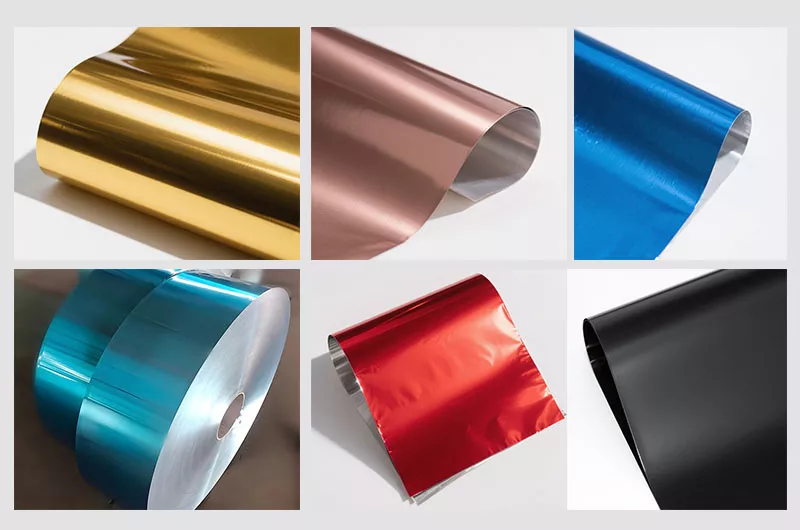

8011 Aluminum Foil Color Options

Color: rose gold, blue, black, red, golden, etc

-

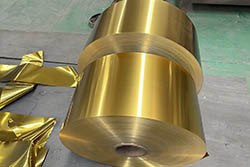

gold 8011 aluminum foil

-

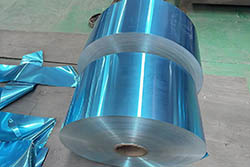

blue 8011 aluminum foil

-

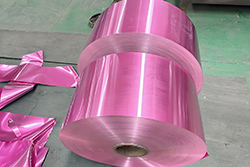

pink 8011 aluminum foil

-

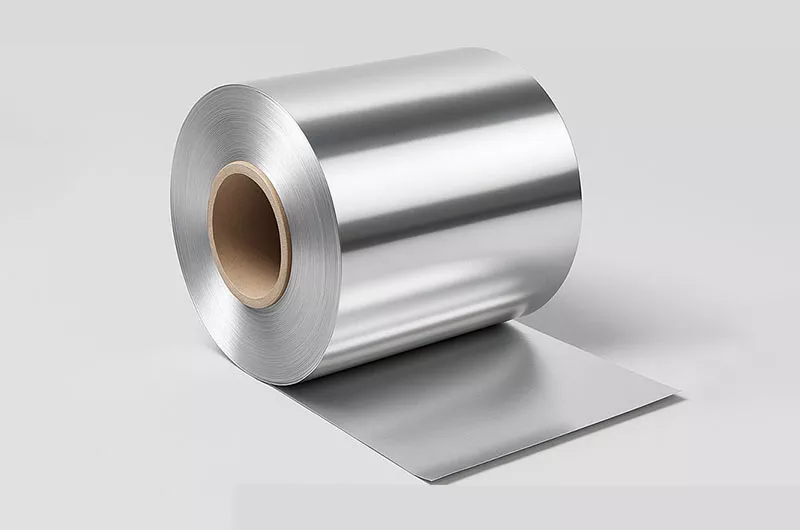

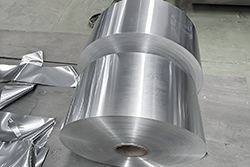

silver 8011 aluminum foil

-

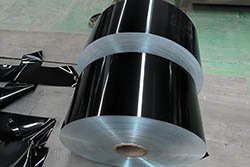

black 8011 aluminum foil

-

bronze 8011 aluminum foil

-

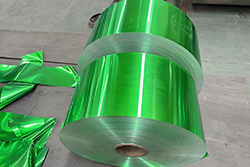

green 8011 aluminum foil

-

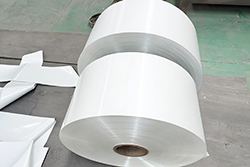

white 8011 aluminum foil

Classification of 8011 Aluminum Foil

Classification of 8011 Aluminum Foil by Shape

- 8011 Aluminum Roll Foil: Supplied in roll form, suitable for large-scale production and processing.

- 8011 Aluminum Sheet Foil: Provided in flat sheet form, suitable for applications requiring specific dimensions.

Classification of 8011 Aluminum Foil by Surface Finish

- Single-Sided Glossy 8011 Aluminum Foil: One side is smooth, and the other side is relatively rough, suitable for applications requiring reflective surfaces or a smooth finish on one side.

- Double-Sided Glossy 8011 Aluminum Foil: Both sides are smooth, suitable for applications requiring uniformity on both sides.

Classification of 8011 Aluminum Foil by Post-Processing

- Plain Aluminum Foil 8011: Unprocessed aluminum foil in its original state.

- Embossed Aluminum Foil 8011: Features a textured surface with embossed patterns for added aesthetics or functionality.

- Composite Aluminum Foil 8011: Laminated with other materials (such as plastic or paper) to enhance performance and application versatility.

- Coated Aluminum Foil 8011: Coated with protective or functional layers, such as water-resistant or corrosion-resistant coatings.

- Colored Aluminum Foil 8011: Treated with dyes to provide a range of color options for decorative packaging.

- Printed Aluminum Foil 8011: Printed with patterns or text for branding and informational purposes.

Features of 8011 Aluminum Foil

- Corrosion Resistance and Barrier Properties: Like other aluminum materials, 8011 aluminum foil offers excellent corrosion resistance. In foil form, it forms a tight barrier against moisture, oxygen, light, and grease, extending the shelf life of packaged products. Its surface is non-porous and inert (odorless), making it safe for food and pharmaceutical use.

- Thermal/Electrical Performance: 8011 aluminum foil exhibits excellent thermal and electrical conductivity. It can withstand moderate heating without softening, making it suitable for baking packaging and heat-sealing containers.

- Formability: The fine-grain microstructure of 8011 aluminum foil provides outstanding ductility. It can be processed through high-speed embossing, stamping, creasing, or curling without cracking or work hardening. The combination of high strength and ductility allows 8011 foil to be made very thin (saving material) while still maintaining puncture resistance during use.

These characteristics—lightweight, corrosion-resistant, high barrier efficiency, and easy formability—make 8011 the preferred choice for commercial aluminum foil.

Major Application Fields and Specification Requirements of 8011 Aluminum Foil

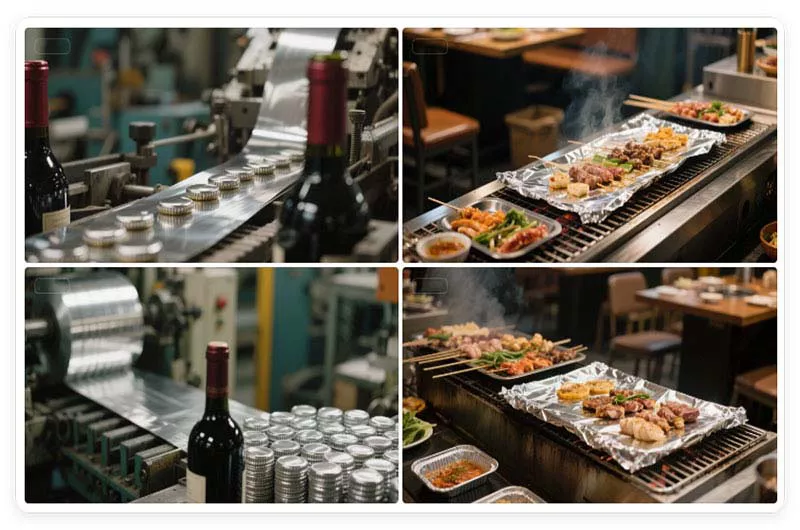

Applications in Food Packaging

Advantages of 8011 aluminum foil for food packaging:

Clean surface without foreign matter, hygienic and safe; excellent moisture resistance and high barrier capacity, light-shielding; non-toxic and odorless, food safe; effectively preserves freshness and quality of food, extending shelf life

Food packaging foil: 8011 aluminum foil is widely used for packaging various foods such as chocolate, candy, bread, and pastries. In these applications, the typical thickness is 0.02–0.04mm, and the material temper is mostly O or H14. These foil specifications offer good flexibility and barrier performance to maintain food freshness and quality.

Heat seal foil: In food packaging, 8011 aluminum foil is often used as a heat sealing material for making various food bags and containers. Typically, thickness ranges from 0.04–0.09mm, and the temper is H16 or H18 to ensure adequate strength and heat sealing performance.

Lunch box material: 8011 aluminum foil is an ideal material for making aluminum lunch boxes due to its good deep-drawing and forming properties. Common thickness is 0.093–0.2mm, with O or H14 temper, which ensures strength, formability, and food hygiene.

Container foil: 8011 aluminum foil is widely used for various food containers such as cake cups and egg tart trays. Common thickness is 0.02–0.07mm, temper is H16 or H18, to ensure the container’s strength and stability.

Applications in Pharmaceutical Packaging

Advantages of 8011 aluminum foil for pharmaceutical packaging:

High cup convex value, high foil strength, excellent sealing performance; excellent moisture resistance, light-shielding, and high barrier ability; tested for bacteria and mold, non-toxic and odorless, safe and hygienic; strictly compliant with industry standards, heavy metals ≤ 0.25 ppm

PTP pharmaceutical foil: 8011 aluminum foil is the main material for making PTP (Press Through Packaging) aluminum foil used in packaging tablets and capsules. Typical thickness is 0.02–0.03mm, with H18 temper to ensure sufficient strength and barrier performance.

Cold-formed pharmaceutical foil: 8011 aluminum foil is also used for cold-forming pharmaceutical packaging for special medications. Thickness is usually 0.025–0.05mm, with H16 or H18 temper, to meet cold forming requirements.

Pharmaceutical bottle caps: 8011 aluminum foil is widely used in making pharmaceutical bottle caps, such as oral liquid bottle caps and capsule foil boards, due to its excellent sealing, corrosion resistance, and safety. Typical thickness is 0.15–0.2mm, with H14 or H16 temper for strength and sealing performance.

Applications in Industrial Fields

Advantages of 8011 aluminum foil for industrial use:

- Clean degreasing, flat profile

- Good electrical conductivity and shielding performance

- Excellent corrosion resistance and oxidation resistance

- Capable of withstanding various stresses and environmental conditions in industrial applications

Cable foil: 8011 aluminum foil is an ideal material for making cable shielding layers due to its good conductivity and shielding effect. Common thickness is 0.05–0.2mm, with H14 or H16 temper for strength and shielding.

Tape foil: 8011 aluminum foil is widely used in various aluminum foil tapes for electrical insulation, sealing, and shielding. Thickness is 0.014–0.05mm, temper is H18 or H19 to ensure strength and adhesion.

Air conditioning foil: 8011 aluminum foil is also used in making fins for air conditioner radiators, offering good thermal conductivity and corrosion resistance. Typical thickness is 0.08–0.2mm, temper is H22 or H24, meeting heat exchange and durability requirements.

Other Application Fields

Other application advantages:

- Clean surface, uniform color, no spots

- Low ear rate, suitable for deep drawing

- Good flexibility and heat resistance

- Easy to process and form, suitable for various design needs

Bottle cap material: 8011 aluminum foil is widely used for manufacturing various bottle caps, including liquor caps, wine caps, cosmetic caps, milk powder lids, pharmaceutical caps, beverage caps, yogurt lids, etc. Typical thickness is 0.15–0.2mm, temper is H14 or H16 for strength and sealing.

Sealing foil: 8011 aluminum foil is used as a sealing material for various packaging containers with good sealing and barrier performance. Common thickness is 0.02–0.05mm, temper is H16 or H18 to ensure sealing reliability.

Decorative foil: 8011 aluminum foil can be used for various decorative purposes such as interior decoration and gift wrapping. Thickness is 0.01–0.03mm, temper is O or H14 for flexibility and decorative effects.

Barbecue foil: 8011 aluminum foil is also widely used in households and the catering industry for barbecue purposes. Common thickness is 0.014–0.02mm, temper is O or H14 for flexibility and heat resistance.

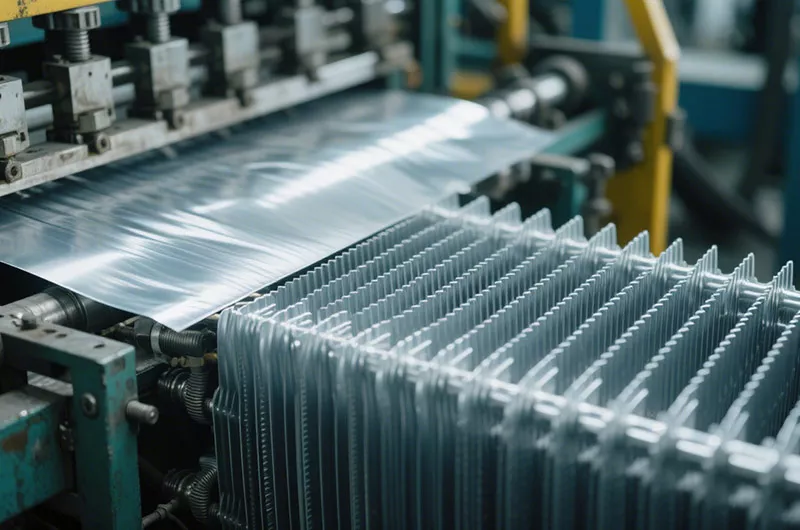

Production Process of 8011 Aluminum Foil

The production process of 8011 aluminum foil is complex and involves multiple precise processing steps:

Melting and Casting

High-purity aluminum ingots and appropriate amounts of Fe, Si, and other alloying elements are placed into a furnace and heated to 720–750°C to fully dissolve and mix the elements. The molten alloy is then cast into ingots.

Heating and Hot Rolling

The ingots are heated in a furnace to 400–450°C and then hot rolled in multiple passes to reduce the thickness from several hundred millimeters to 6–10mm.

Cold Rolling

The hot-rolled plates are cold rolled in multiple passes to reduce the thickness to the target range (0.1–0.5mm). Intermediate annealing is performed during cold rolling to eliminate work hardening.

Foil Rolling

The aluminum sheet after cold rolling and annealing is further processed into foil. For ultra-thin foil under 0.012mm, double-roll tandem rolling (stack rolling) is used to mass-produce 0.006mm–0.03mm single-side bright foil.

Slitting and Surface Treatment

According to customer needs, the foil is slit to the required width and length. Surface treatments such as oiling, painting, and coating can also be applied.

Price Influencing Factors of 8011 Aluminum Foil

- Raw material price: Fluctuations in aluminum ingot prices directly impact cost and selling price

- Alloy composition and processing: Proportion and purity of alloying elements affect performance and production cost

- Specification and temper requirements: Higher demands in thickness, width, and temper result in higher prices

- Surface treatment: Additional steps like oiling, painting, and coating increase cost

- Minimum order quantity and lead time: Larger orders result in lower unit prices; shorter lead times may incur rush fees

Chemical Composition of 8011 Alloy Metal Aluminum Foil

| Si | Cu | Mg | Zn | Mn | Cr | Fe | Ti | Other | Other total | Al |

| 0.50 ~ 0.90 | ≤ 0.1 | ≤ 0.05 | ≤ 0.1 | ≤ 0.2 | ≤ 0.05 | 0.60 ~ 1.0 | ≤ 0.08 | ≤ 0.05 | ≤ 0.15 | remainder |

Mechanical Properties of 8011 Aluminum Foil

| Alloy Temper | Thickness(mm) | Tensile Strength(Mpa) | Elongation(%)A50mm | Elongation(%)A100mm |

| 8011 O | 0.006-0.009 | 50-100 | – | 0.5 |

| 8011 O | >0.009-0.025 | 55-100 | – | 1 |

| 8011 O | >0.025-0.04 | 55-110 | – | 4 |

| 8011 O | >0.04-0.09 | 60-120 | – | 4 |

| 8011 O | >0.09-0.14 | 60-120 | 13 | – |

| 8011 O | >0.14-0.2 | 60-120 | 15 | – |

| 8011 H18 | 0.035-0.2 | ≥160 | – | – |

| 8011 H19 | 0.035-0.2 | ≥170 | – | – |

| 8011 H22 | 0.035-0.04 | 90-150 | – | 1 |

| 8011 H22 | >0.04-0.09 | 90-150 | – | 2 |

| 8011 H22 | >0.09-0.14 | 90-150 | 5 | – |

| 8011 H22 | >0.14-0.2 | 90-150 | 6 | – |

| 8011 H24 | 0.035-0.04 | 120-170 | 2 | – |

| 8011 H24 | >0.04-0.09 | 120-170 | 3 | – |

| 8011 H24 | >0.09-0.14 | 120-170 | 4 | – |

| 8011 H24 | >0.14-0.2 | 120-170 | 5 | – |

Differences Between 8011 and 8021 Aluminum Foil

- 8011 Aluminum Foil: Higher strength, wide applicability, but lower elongation and puncture resistance compared to 8021.

- 8021 Aluminum Foil: More balanced performance, especially in terms of elongation and puncture resistance, suitable for high-end applications.

| Characteristics | 8011 Aluminum Foil | 8021 Aluminum Foil |

| Chemical Composition | Contains manganese (Mn) and magnesium (Mg) elements | Does not contain manganese (Mn) and magnesium (Mg) elements |

| Strength and Corrosion Resistance | High strength and corrosion resistance | Relatively lower strength, but better elongation and puncture resistance |

| Elongation and Puncture Resistance | Lower elongation and puncture resistance | Higher elongation and puncture resistance |

| Application Fields | Pharmaceutical packaging, food packaging, lunch box materials, tape foil, cable foil, milk cap materials, bottle cap materials | Lithium battery soft-pack aluminum plastic film, blister pharmaceutical packaging |

| Features | Suitable for various uses with higher strength | Higher price, suitable for applications with strict requirements for heat sealability, elongation, etc. |

What is the Difference Between 8011 Aluminum Foil and 1235 Aluminum Foil?

- 1235 Aluminum Foil: Primarily used for flexible packaging, suitable for applications requiring thinness and flexibility.

- 8011 Aluminum Foil: Widely applicable, with higher strength and corrosion resistance, suitable for various packaging and industrial uses.

| Characteristics | 1235 Aluminum Foil | 8011 Aluminum Foil |

| Chemical Composition | Mainly contains 99.35% aluminum, with almost no other alloy elements | Contains manganese (Mn) and magnesium (Mg) elements, enhancing strength and corrosion resistance |

| Processing | Lower annealing temperature, with annealing time similar to 8011 aluminum foil | Higher annealing temperature, with higher tensile strength |

| Tensile Strength | Lower | Higher |

| Elongation | Relatively higher | Similar to 1235 aluminum foil |

| Uses | Mainly used for soft packaging, such as milk packaging, cigarette packaging, beverage packaging, food packaging bags, etc. Commonly used for snack bags, cigarette packaging, chocolate packaging, etc. | Widely used for food containers, food packaging, pharmaceutical packaging, industrial uses, etc. Commonly used for household purposes, pharmaceutical packaging (with good moisture-proof, light-blocking, and barrier properties), and industrial uses (waterproof materials, air conditioning foil, cable foil, ventilation ducts, insulation materials, etc.) |

| Features | Very thin (0.006mm-0.009mm), suitable for applications requiring flexibility | Suitable for various applications, environmentally friendly and recyclable, wide thickness range (up to 0.2mm, minimum thickness of 0.006mm), with higher strength and corrosion resistance |

How to Choose Between 1235 Aluminum Foil and 8011 Aluminum Foil?

| Attribute/Aspect | 1235 Aluminum Foil | 8011 Aluminum Foil |

| Alloy Composition | Pure aluminum foil (Al content not less than 99.35%) | Aluminum with iron and silicon as main alloy elements |

| Applications | Soft packaging, laminating, insulation | Food packaging, pharmaceutical packaging, household aluminum foil, etc. |

| Strength and Formability | Generally softer and more ductile | Good balance between strength and formability |

| Cost Consideration | Usually slightly higher in price due to high purity | Typically chosen as a cost-effective solution |

| Barrier Properties | Excellent moisture-proof and gas-proof properties | Good barrier properties; suitable for food and pharmaceutical packaging |

Comparative Analysis of 8011 Aluminum Foil and Other Alloy Foils

Comparison with Series 1 Pure Aluminum Foil

Series 1 pure aluminum foil (such as 1235, 1060, etc.) is the most basic aluminum foil product. Compared to 8011 aluminum foil, it offers higher ductility and deep-drawing performance, but has lower strength and rigidity. In contrast, 8011 aluminum foil maintains a certain degree of flexibility while delivering better strength and rigidity, making it more suitable for applications requiring higher strength.

Comparison with Series 3 Aluminum Foil (3003)

3003 aluminum foil primarily contains manganese (Mn). In the annealed condition, its tensile strength is slightly higher than that of 8011 aluminum foil, but in the work-hardened condition, their strengths are comparable. The elongation of 3003 aluminum foil is generally superior to that of 8011 aluminum foil, especially in medium-hardness temper conditions.

Comparison with Series 5 Aluminum Foil (5052)

5052 aluminum foil exhibits higher tensile strength and hardness, particularly in work-hardened conditions. In H32 temper, the tensile strength of 5052 aluminum foil can reach 210–240 MPa, significantly higher than that of 8011 aluminum foil in the same temper. Additionally, 5052 aluminum foil also offers better fatigue resistance and impact toughness.

Overall Performance Comparison

| Performance Indicator | 8011 Aluminum Foil | Series 1 Pure Aluminum Foil | 3003 Aluminum Foil | 5052 Aluminum Foil |

| Tensile Strength (MPa) | 80–200 | 70–170 | 90–200 | 170–240 |

| Elongation (%) | 2–10 | 5–20 | 3–15 | 2–12 |

| Hardness (HV) | 30–80 | 25–70 | 35–85 | 50–100 |

| Corrosion Resistance | Good | Good | Good | Excellent |

| Formability | Good | Excellent | Excellent | Moderate |

| Cost | Moderate | Low | Medium–High | High |

| Main Applications | Bottle caps, cable foil, AC foil, food packaging | Food packaging, pharmaceutical packaging, decorative foil | Food packaging, architectural decoration, electronic equipment | Aerospace, marine, pressure vessels |

Frequently Asked Questions about 8011 Aluminum Foil

Pinhole Problems

Causes: impurities in raw materials, contamination during rolling, poor quality rolling oil, etc.

Solutions: strictly control raw material quality, strengthen cleanliness in production, use high-quality rolling oil, regularly inspect and maintain equipment.

Bright Line Issues

Causes: damage to roller surfaces, frictional heat during rolling, uneven distribution of rolling oil, etc.

Solutions: regularly inspect and maintain rollers, ensure even oil distribution, control rolling speed and temperature, avoid excessive friction.

Deep‑draw Cracking

Causes: material hardness too high, improper deep‑draw mold design, insufficient lubrication, etc.

Solutions: choose suitable temper (O or H14), optimize mold design, use proper lubricants, control deep‑draw speed and passes.

Poor Printability

Causes: aluminum foil surface oxide film too thick or too thin, insufficient surface tension, incompatible printing inks, etc.

Solutions: control oxide film thickness, perform surface pretreatment (e.g., corona treatment), choose appropriate printing ink, adjust printing process parameters.

Oxidation Discoloration

Causes: high humidity or oxygen in storage environment, damage to surface protective layer, etc.

Solutions: control humidity and temperature in storage, avoid direct exposure to air, use moisture‑proof packaging, regularly inspect and maintain protective layer.

Deformation Issues

Causes: excessive stacking height, uneven pressure, vibration and impact during transportation, etc.

Solutions: design proper stacking method, control stacking height, use appropriate supports and fixtures, choose stable transportation to reduce vibration and impact.

Packaging of 8011 Aluminum Foil

Inner Packaging

Typically uses plastic film or aluminum foil bags to prevent exposure to air, oxidation, and contamination. For high‑precision or special‑requirement products, desiccants may be placed inside.

Outer Packaging

Wooden crates, cartons, or plastic boxes are used to provide adequate protection. For export products, fumigated wooden crates and pallets are used.

Protective and Reinforcement Measures

Paper or film is added to the surface of the foil coil to prevent scratches, plastic or kraft paper is used to protect against moisture and rain, desiccants are added, and steel straps are used to reinforce the packaging to avoid collisions during transportation.

Haomei Aluminum Foil Product Range

- 8011 Aluminum Foil: 8011 possesses multiple excellent properties, including outstanding barrier ability against oxygen, moisture, and light. It is commonly used for pharmaceutical packaging, food packaging, aluminum foil tape, cable wraps, aluminum bottle caps, and more.

- 8021 Aluminum Foil: 8021 is known for its exceptional barrier properties, safety, and good processing performance. It effectively blocks moisture and oxygen, is non-toxic and odorless, and is suitable for cold-formed pharmaceutical foil packaging, aluminum foil for lithium battery pouches, etc.

- 8006 Aluminum Foil: With a bright surface, higher strength, and excellent anti-wrinkle performance, 8006 foil resists edge wrinkling during stamping and maintains a flat appearance. It is ideal for producing wrinkle-free food containers, airline meal boxes, and wrinkle-free pastry cups—scenarios requiring high standards in appearance and performance.

- 8079 Aluminum Foil: Known for high strength and superior barrier properties, 8079 foil also has good elongation and pressability. It is widely used in food container materials, pharmaceutical capsules, food packaging, and battery pouch foil, offering reliable protection and enhanced visual appeal of packaging.

- 1235 Aluminum Foil: With an aluminum content of no less than 99.35%, 1235 foil features excellent rust resistance, formability, and weldability. It is widely used in cable wraps, tape foil, and aluminum foil for lithium battery cathodes.

- 1060 Aluminum Foil: 1060 aluminum foil belongs to the pure aluminum category (aluminum content ≥99.6%) and boasts excellent ductility and formability, along with good thermal conductivity and corrosion resistance. It is widely used in aluminum gaskets, electrolytic capacitors, and automotive heat shields.

- 1100 Aluminum Foil: 1100 foil has slightly higher strength among pure aluminum foils and can be stamped, bent, and processed. It is commonly used in kitchenware (such as baking tray liners and foil sheets), insulation materials, and isolation layers of electronic components.

- 1070 Aluminum Foil: Due to its high purity, 1070 aluminum foil offers superior electrical conductivity. It is suitable for applications such as capacitor electrode foil, precision electronic component packaging, high-end food packaging, and materials used in scientific research.

- 1050 Aluminum Foil: With an aluminum content ≥99.5%, 1050 aluminum foil has balanced overall properties and is commonly used in capacitors, cable wraps, aluminum foil gaskets, and heat sinks. It is a widely used general-purpose pure aluminum foil material.

- 3003 Aluminum Foil: Compared to pure aluminum foil, 3003 foil offers higher strength while maintaining good ductility and corrosion resistance. It is widely used in food containers (such as meal boxes and easy-open can lids), building soundproofing materials, HVAC ducts, and packaging materials.

- 3004 Aluminum Foil: 3004 aluminum foil has greater strength and hardness than 3003, with good formability, suitable for deep-drawing processing. It is mainly used for meal box materials, aluminum honeycomb cores, beverage can bodies, and beverage packaging—meeting the industrial and packaging needs for high strength and formability.

- 5052 Aluminum Foil: 5052 aluminum foil is a medium-strength alloy foil commonly used in scenarios requiring relatively high strength and corrosion resistance, such as honeycomb materials, door panel materials, meal box materials, and corrosion-resistant containers in the chemical industry. It is a medium- to high-end aluminum foil alloy with well-balanced comprehensive performance.

Users viewing this material also viewed the following

- 8011 1235 aluminum foil gaskets for container sealing

- 8011 8079 1235 Aluminum foil for yogurt packaging

- Hot sealing aluminum foil 8011 1235

- 8011 Aluminium foil for beer bottle neck label

- Blister Aluminium Foil 8011 8021 8079

- Pharmaceutical Aluminum Foil 8011 8021 8079

Recommended Content