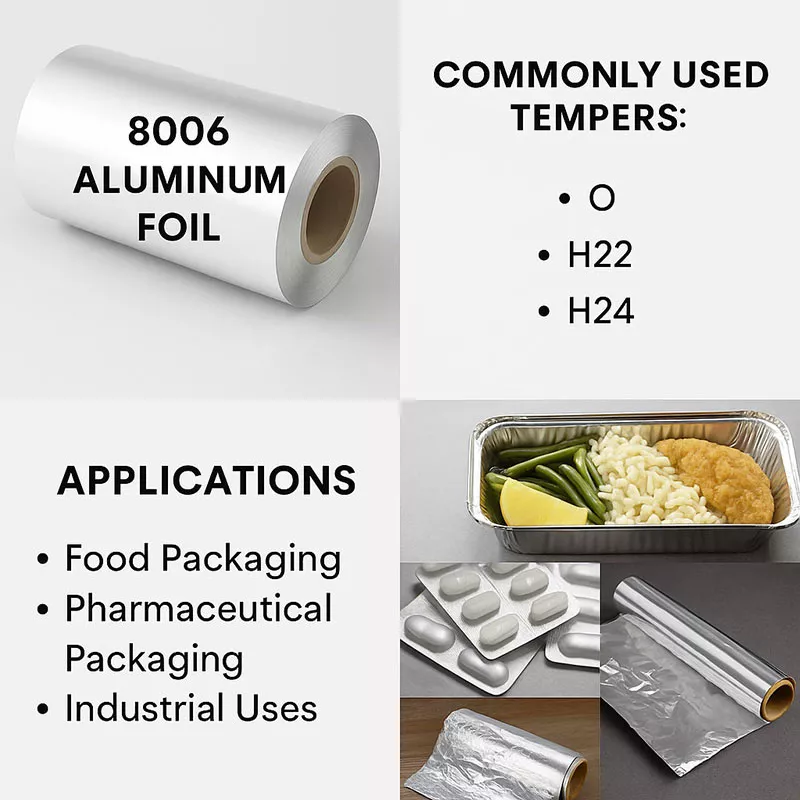

8006 Aluminum Foil

8006 aluminum foil is optimized for applications requiring excellent formability and barrier performance. Its unique iron-manganese composition makes it versatile, ranging from aerospace meal trays to heat exchangers. Its strength is higher than 8011 and its ductility is superior to 3003. Haomei Aluminum's 8006 aluminum foil complies with global standards (ASTM B373/B479), ensuring consistent quality.

As a high-performance 8-series aluminum alloy material, 8006 aluminum foil features high strength, good elongation, and excellent surface quality, performing particularly well in aerospace meal trays and high-end food packaging. Compared with other 8-series aluminum foils, 8006 shows significant advantages in strength, elongation, and formability, making it an ideal choice for high-end applications.

8006 aluminum foil cannot be strengthened by heat treatment. Compared with 8011 and 3003 aluminum foils, 8006 aluminum foil has higher elongation and cup height, with tensile strength superior to 8011. The core advantage of 8006 aluminum foil lies in its excellent deep-drawing formability and rigidity after forming, making it very suitable for manufacturing rigid containers that require certain support and deformation resistance.

- When selecting aluminum foil for containers, 8006 is a very good choice.

- For flexible packaging bags or pill blisters, 8011 or 1235 may be more suitable.

- The specific choice should be determined based on actual application requirements for strength, formability, and cost.

8006 aluminum foil is produced using hot-rolling technology, achieving A-grade brushed finish to ensure smooth, clean, and oil-free surfaces. The reason 8006 aluminum foil is used in aerospace anti-wrinkle food containers is that after stamping, the edges are wrinkle-free, the appearance is smooth and flat, and it exhibits excellent barrier and durability performance, performing well in packaging applications.

8006 Aluminum Foil Temper and Specifications

8006 Aluminum Foil Tempers

8006 aluminum foil is typically supplied in H18 (hard) or H19 (extra hard) temper to provide maximum strength and hardness. Sometimes, it is also available in O temper (soft) for deep-drawing processing, which hardens after forming.

- H18

- O

- H22

- H24

8006 H18 Aluminum Foil

8006 H18 aluminum foil is in a fully hard state with high strength and excellent barrier properties. It is widely used where durability and puncture resistance are required.

- Electronic cable shielding

- High-strength industrial packaging

- Roof waterproofing materials

- Pharmaceutical outer packaging

- Construction and decoration materials

8006 H19 Aluminum Foil

8006 H19 aluminum foil has an extra hard temper, stronger than H18, with almost no ductility. It is ideal for applications requiring maximum strength and barrier performance.

- High-end food and medicine blister packaging

- Battery shell and insulation shielding

- Industrial laminated foils

- Retort-resistant packaging

- Protective covering materials

8006 O Aluminum Foil

8006 O aluminum foil is in a soft annealed state, offering excellent ductility and formability. It is easy to emboss, stretch, and fold, making it suitable for daily and food-related applications.

- Household aluminum foil

- Aviation food containers

- Baking trays and cake cups

- Chocolate and confectionery wrapping

- Yogurt lids and easy-peel seals

- Flexible foil pouches

O temper (annealed): Fully annealed state, with the highest plasticity.

H14 temper: Work-hardened without annealing, medium hardness.

H16 temper: A higher degree of work hardening.

H18 temper: Full hard state, with the highest strength and hardness.

H19 temper: Extra hard state, with strength higher than H18.

H22 temper: Work-hardened and then partially annealed.

H24 temper: Work-hardened followed by partial annealing.

H26 temper: Work-hardened followed by near-full annealing.

H28 temper: Work-hardened followed by light annealing.

Among these, O temper is mainly used in scenarios requiring deep drawing or complex forming; H18 is suitable for applications requiring high strength and hardness; H22, H24, etc., balance strength and formability and are suitable for most meal box forming applications.

| Temper | Thickness (mm) | Tensile Strength (MPa) | Elongation (%) |

| O | 0.04–0.09 | 90–140 | ≥4 |

| O | 0.09–0.14 | 110–120 | ≥15 |

| H24 | 0.035–0.090 | 125–155 | ≥5.0 |

8006 Aluminum Foil Specifications

- Thickness: Aluminum foil for containers is relatively thick, commonly ranging from 0.05mm to 0.20mm (i.e., 50–200 microns). Foils used for sealing caps are thinner.

- Surface: Can be one side bright (contact side with rollers, shiny) and one side dull (double-rolled contact side, matte). Coating, printing, and other post-processing are also possible.

| Alloy Type | 8006 aluminium foil |

| Alloy State | O, H14, H16, H18, H19, H22, H24, H26, H28 |

| Thickness (mm) | 0.014-0.2 |

| Width (mm) | 100-1500 |

| Length | Jumbo roll |

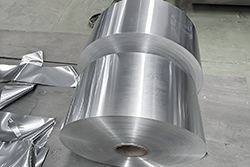

8006 Aluminum Foil Surface Treatments

- 8006 Plain Aluminum Foil (Plain Foil): 8006 plain aluminum foil has a smooth surface without additional processing. It is commonly used in food packaging, household foil, and industrial applications where basic barrier and forming properties are required.

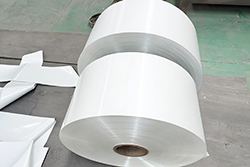

- 8006 Composite Aluminum Foil: This type combines 8006 aluminum foil with other materials (such as paper, plastic, or film) through lamination. It enhances strength, moisture resistance, and insulation, making it suitable for flexible packaging and insulation materials.

- 8006 Embossed Aluminum Foil: Embossed 8006 foil has textured patterns on its surface. The embossing improves strength, prevents slipping, and adds decorative effects. It is widely used in food containers, wrapping, and architectural applications.

- 8006 Laminated Aluminum Foil: Laminated foil is produced by bonding layers of 8006 foil with adhesives or other substrates. It offers excellent barrier properties, durability, and heat resistance, often used in pharmaceutical packaging and high-performance insulation.

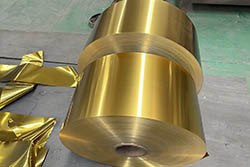

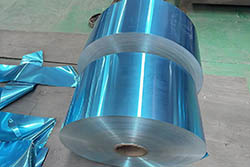

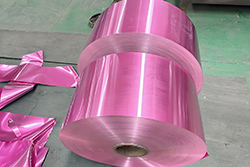

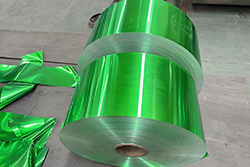

- 8006 Color Coated Aluminum Foil: This foil is coated with different colors using high-quality paint or resin. It provides an attractive appearance, corrosion resistance, and design flexibility, making it suitable for packaging, decoration, and labeling.

- 8006 Coated Aluminum Foil: General coated 8006 foil is treated with protective or functional coatings (such as anti-corrosion, heat-sealing, or non-stick coatings). It enhances performance in food packaging, heat exchanger fins, and industrial uses.

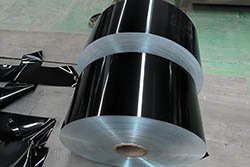

8006 Aluminum Foil Color Options

-

gold 8006 aluminum foil

-

blue 8006 aluminum foil

-

pink 8006 aluminum foil

-

silver 8006 aluminum foil

-

black 8006 aluminum foil

-

bronze 8006 aluminum foil

-

green 8006 aluminum foil

-

white 8006 aluminum foil

Outstanding Mechanical Properties of 8006 Aluminum Foil

- The tensile strength of 8006 aluminum foil is significantly higher than 8011 aluminum foil and slightly lower than 3003 aluminum foil.

- The elongation and cup height (deep-drawing forming indicator) surpass 8011 and 3003 aluminum foils, e.g., cup height can reach 6.35mm, ensuring wrinkle-free edges after stamping and a smooth appearance.

- The hot-rolling process (different from 8011's cast-rolled process) results in uniform internal structure, surface quality achieving "A-grade brushing, " clean and oil-free, meeting food-grade hygiene standards.

8006 is similar to 8011 but with a different focus: 8011 is the most widely used aluminum foil with balanced performance. 8006 generally has higher strength and hardness than 8011, especially maintaining better shape after deep drawing, making it more advantageous in rigid container applications.

Basic Properties and Parameters of 8006 Aluminum Foil

- Thickness range: 0.006–0.5 mm (commonly 0.02–0.2 mm)

- Width range: 10–1600 mm (typically 100–1600 mm), length can be customized according to requirements

- Temper: includes soft (O), semi-hard (H14, H16, H18, H19), and hard (H22, H24, H26, H28) tempers, suitable for different forming processes

- Tensile strength: 123–135 MPa, with high elongation and cupping value to ensure a flat, wrinkle-free surface and smooth edges after stamping

Advantages of 8006 Aluminum Foil

- High tensile strength: 8006 aluminum foil has significantly higher tensile strength than 8011 foil, making it less likely to tear or puncture during use.

- Excellent cupping formability and elongation: Compared to 8011 aluminum foil, 8006 foil offers higher cupping formability and elongation. This means it better adapts to complex shapes and size requirements during manufacturing, making it suitable for applications with high formability demands.

- Produced by hot rolling process: 8006 aluminum foil is manufactured using a hot rolling process, which improves foil uniformity and thickness control, while enhancing its physical properties and surface smoothness.

- Refined appearance: After stamping, 8006 aluminum foil has smooth, wrinkle-free edges and a neat appearance, offering superior visual and user experience compared to other aluminum foil materials.

- Extended shelf life: 8006 aluminum foil provides excellent barrier performance, effectively blocking moisture, light, and air, thereby helping preserve the freshness of packaged contents and extend their shelf life.

- Cost-effective: 8006 aluminum foil is economical and ideal for both large and small packaging applications. Its high cost-performance ratio meets diverse packaging needs.

- Eco-friendly and recyclable: 8006 aluminum foil is a recyclable, environmentally friendly material that meets modern sustainability standards, providing a high-quality choice for eco-friendly packaging.

- Protective performance: Smooth surface, oil-free, meets Brush Water Grade A standard, offering excellent moisture resistance, freshness preservation, and temperature resistance (can be directly heated), compliant with food safety requirements.

8006 Aluminum Foil Standards

- ASTM B479

- QQA-1876

- ASTM Standards: B373 (Container Foil) and B479 (General Foil)

- Surface Certification: Grade A wettability (clean and oil-free surface)

- Quality Indicators: Trace impurity content ≤ 0.15%, controllable pinhole density

Performance of 8006 Aluminum Foil

- High strength: 8006 aluminum foil possesses excellent mechanical strength.

- Excellent ductility: 8006 foil can stretch without breaking.

- Good corrosion resistance: Resistant to various chemical corrosion.

- Superior barrier properties: 8006 aluminum foil offers excellent barrier properties, effectively preventing moisture, oxygen, and light from penetrating, thus maintaining the freshness and quality of packaged contents. This feature is especially crucial for food and pharmaceutical packaging.

- Good heat resistance: 8006 aluminum foil withstands high temperatures without melting or deforming, suitable for various high-temperature environments. During heat treatment or heating, it maintains outstanding performance and stability.

- Easy to form: This aluminum foil has good formability and can be easily processed into various shapes and sizes. Whether for complex geometries or specific packaging needs, 8006 foil meets the requirements for a wide range of applications.

- Lightweight: 8006 aluminum foil is light in weight, making it easy to handle and transport. This lightweight characteristic not only reduces transportation costs but also improves the convenience of packaging and handling.

8006 Aluminum Foil Chemical Composition

| Ingredient | Cu | Mg | Mn | Fe | Si | Zn | Cr | Other | Al |

| Content | ≤0.30 | ≤0.10 | 0.30~1.0 | 1.2~2.0 | ≤0.40 | ≤0.10 | – | 0.15 | Margin |

8006 Aluminum Foil Mechanical Properties

| Alloy Temper | Thickness(mm) | ≥Tensile Strength (N/mm2) | ≥Elongation (%) |

| 8006 O | >0.04-0.09 | ≥90-140 Mpa | ≥4 |

| >0.09-0.14 | ≥110-120 Mpa | ≥15 | |

| >0.14-0.20 | ≥110-120 Mpa | ≥20 | |

| 8006 H22 | 0.035-0.090 | ≥120-150 Mpa | ≥5.0 |

| >0.09-0.140 | ≥120-150 Mpa | ≥15 | |

| >0.14-0.20 | ≥120-150 Mpa | ≥20 | |

| 8066 H24 | 0.035-0.090 | ≥125-150 Mpa | ≥5.0 |

| >0.09-0.14 | ≥125-155Mpa | ≥15 | |

| >0.14-0.20 | ≥125-155 Mpa | ≥18 |

8006 Aluminum Foil Physical Properties

| Properties | Metric | Imperial |

| Density | 2.74 g/cm³ | 0.098 lb/in³ |

8006 Aluminum Foil Thermal Properties

| Properties | Metric | Imperial |

| Thermal conductivity | 190-210 W/mK | 1317- 1456 BTU in/hr.ft².°F |

Applications of 8006 Aluminum Foil

8006 aluminum foil is widely used in various fields, mainly including:

Food packaging: Especially for aerospace meal boxes, wrinkle-free containers, pastry cups, and other high-end food packaging.

Pharmaceutical packaging: As a barrier layer material for blister packs.

Container manufacturing: Semi-rigid container aluminum foil material.

Industrial applications: Electronics, electrical appliances, and other industrial uses.

| Application | Material | Temper | Thickness | Use |

| Wrinkle-free lunch box material | 8006 aluminum foil | O | 0.03-0.20mm | 8006 aluminum foil is used to create wrinkle-free lunch box materials, providing a smooth and sturdy surface. |

| Airline lunch box material | 8006 aluminum foil | O/H22/H24 | 0.05-0.20mm | 8006 aluminum foil is ideal for making airline lunch boxes due to its high strength and durability. |

| 8006 aluminum foil for lunch box containers | 8006 aluminum foil | O/H22/H24 | 0.04-0.20mm | 8006 aluminum foil is used to manufacture lunch box containers, ensuring they are robust and maintain their shape. |

Food Packaging and Containers

- Meal Trays

- Takeout Containers, Airline Meal Trays, Pre-packaged Meal Packaging

- Features: Wrinkle-free edges after stamping, high strength, not easily deformed

Baking Supplies

Cake pans, baking trays, pie pans. Features: strong load-bearing capacity, even heat conduction

Caps Sealing and Flexible Packaging

- Yogurt, jelly, canned food sealing films

- Features: good tear performance, reliable sealing

High-Strength Flexible Packaging Composites

- Pharmaceutical Packaging

- Replaces 8011 aluminum foil, high surface cleanliness, excellent strength

Industrial and Electronic Fields

Heat Exchangers

- Hydrophilic coating used for air conditioning evaporators and condensers

- Improves heat dissipation efficiency, reduces energy consumption

Electronic Components and Capacitors

- Used as conductive material and shielding layer

- Processed using ductility and toughness

Construction and Decoration

Insulation Materials

- Polyurethane insulation boards, ventilation ducts, hollow walls

- Reflects thermal radiation, moisture-proof

Honeycomb Core and Soundproof Materials

Enhances the lightweight, structural stability, and soundproof performance of building materials

Comparison of 8006 Aluminum Foil with Other 8-Series Foils

Comparison between 8006 and 8011 Aluminum Foil

8006 aluminum foil differs from 8011 aluminum foil in several aspects:

Production Process: 8006 foil is mainly hot-rolled, while 8011 foil can be cast-rolled or hot-rolled.

Mechanical Properties: 8006 foil has about 10 MPa higher tensile strength than 8011 foil.

Elongation and Erichsen Value: 8006 foil has significantly better elongation and Erichsen values than 8011 foil.

Surface Quality: 8006 foil has superior surface quality, especially in pinhole control.

Price: Due to higher process requirements, 8006 foil is usually 5-10% more expensive than 8011 foil.

Comparison between 8006 and 8079 Aluminum Foil

8079 aluminum foil is another common 8-series foil. Compared with 8006:

Strength: 8079 foil has higher strength than 8006 foil.

Elongation: 8006 foil has better elongation than 8079 foil.

Rolling Performance: 8079 foil has good rolling performance, but 8006 foil offers better formability.

Application Fields: 8079 foil is mainly used in pharmaceutical packaging and battery pouches, while 8006 foil is better suited for high-end meal box applications.

Comprehensive Comparison of 8006 with Other 8-Series Aluminum Foils

| Characteristic | 8006 Foil | 8011 Foil | 8079 Foil | 8021 Foil |

| Tensile Strength (MPa) | 123–135 | 110–125 | 130–145 | 115–125 |

| Elongation (%) | ≥15 | ≥12 | ≥10 | ≥12 |

| Erichsen Value (mm) | ≥6.2 | ≥5.5 | ≥5.0 | ≥5.5 |

| Production Process | Mainly hot-rolled | Cast-rolled or hot-rolled | Cast-rolled or hot-rolled | Cast-rolled or hot-rolled |

| Main Applications | High-end meal boxes, aerospace meal boxes | Regular meal boxes, bottle cap materials | Pharmaceutical packaging, battery pouches | Medical packaging, battery pouches |

| Price Index | 105–110 | 100 | 110–115 | 105–110 |

8006 Aluminum Foil Production Process

Melting and Casting

The production of 8006 aluminum foil begins with the melting and casting process:

Raw Material Preparation: Using aluminum ingots with purity ≥99.45% and appropriate alloying elements

Melting: Raw materials are loaded into the melting furnace and heated to 720–750°C until fully melted

Refining: Degassing and inclusion removal are carried out by gas stirring and adding refining agents

Filtration: Ceramic filter plates are used to ensure melt cleanliness

Casting: The melt is cast into ingots or directly cast-rolled into slabs

Rolling Processing

Rolling is the core process in 8006 aluminum foil production:

Hot Rolling: The ingot is heated to 400–450°C and hot rolled through multiple passes to reduce thickness from 600–700 mm to 3–5 mm

Cold Rolling: Carried out at room temperature to further reduce the thickness to 0.2–0.24 mm

Foil Rolling: Specialized foil rolling mills reduce the strip to final thickness, typically 0.006–0.2 mm

Heat Treatment

Heat treatment greatly influences the final properties of 8006 aluminum foil:

Homogenization Annealing: Eliminates internal stress generated during rolling and improves the material’s microstructure

Intermediate Annealing: Conducted during multi-pass rolling to enhance plasticity

Final Annealing: Determines the final temper and performance of the aluminum foil

Surface Treatment

Surface treatment processes include cleaning, oiling, passivation, etc., which are critical to the final application performance of the foil.

Finishing Operations

Finishing operations include:

Slitting: Cutting large coils into customer-specified widths

Inspection: Comprehensive inspection of dimensions, surface quality, and physical properties

Packaging: Packing according to customer requirements to ensure damage-free transportation and storage

Common Issues and Solutions in the Use of 8006 Aluminum Foil

Pinhole Issue

Pinholes are one of the most common issues in the use of 8006 aluminum foil:

Causes: Raw material impurities, improper rolling processes, die wear, etc.

Impact: Reduces barrier properties and shortens product shelf life

Solutions:

Strict control of raw material quality

Optimize rolling process parameters

Regular inspection and replacement of dies

Use electrolytic cleaning to reduce pinholes

Forming Cracks

Cracking during forming is also a common problem for 8006 aluminum foil:

Causes: Insufficient ductility of the material, improper forming processes, poor die design, etc.

Impact: Leads to product rejection and increases production costs

Solutions:

Select suitable temper materials (such as O temper or H24 temper)

Optimize forming parameters, such as reducing forming speed and increasing forming passes

Improve die design to reduce stress concentration

Apply appropriate preheating treatment to the material

Surface Oil Contamination

Surface oil contamination may affect further processing and product quality of 8006 aluminum foil:

Causes: Inadequate cleaning, improper oiling amount, environmental contaminants, etc.

Impact: Affects printing, coating, and welding performance

Solutions:

Optimize cleaning processes to ensure surface cleanliness

Accurately control oiling amount to avoid over- or under-lubrication

Improve production environment to reduce pollutants

Regular cleaning and maintenance of production equipment

Poor Heat Sealing

Poor heat sealing is a common problem in the packaging process of 8006 aluminum foil:

Causes: Improper heat sealing temperature, insufficient pressure, inadequate time, etc.

Impact: Reduces sealing performance and affects product shelf life

Solutions:

Optimize heat sealing parameters including temperature, pressure, and time

Ensure the heat sealing surface is clean, free of oil and dust

Select appropriate heat sealing materials and coatings

Regular inspection and maintenance of heat sealing equipment

Storage Corrosion

Corrosion during storage of 8006 aluminum foil also requires attention:

Causes: Excessive humidity, insufficient surface protection, contact with corrosive substances, etc.

Impact: Reduces material performance, affects product appearance and service life

Solutions:

Control storage humidity, avoid humid environments

Ensure intact packaging to prevent moisture intrusion

Apply special surface treatments for products used in harsh environments

Avoid contact with corrosive substances

Comparison of 8006 Aluminum Foil with Common Aluminum Foils (e.g., 1235, 3003)

8006 Aluminum Foil vs 1235 Aluminum Foil

8006 is harder and stronger than 1235: 1235 is very soft, commonly used in easily tearable packaging (such as pill blisters), whereas 8006 is used for containers requiring certain support.

| Characteristics | 8006 Aluminum Foil | 1235 Pure Aluminum Foil |

| Main Composition | Al-Fe-Mn | ≥99.35% Al |

| Strength/Hardness | High | Low (Soft) |

| Elongation | Medium | Excellent |

| Typical Applications | Food Containers, Rigid Packaging | Pharmaceutical Packaging, Flexible Packaging, Capacitors |

| Features | Harder, good stiffness, suitable for deep drawing | Extremely soft, highly ductile, easy to tear |

8006 Aluminum Foil vs 3003 Aluminum Foil

8006 aluminum foil, with its higher strength and excellent formability, performs well in applications requiring high strength and durability. In contrast, 3003 and 8011 aluminum foils perform well in applications with lower strength requirements, suitable for different packaging needs.

- Composition: 3003 contains manganese (1.0–1.5%) but lower Fe

- Performance: 3003 has higher rigidity; 8006 excels in elongation and deep drawing

- Uses: 3003 for rigid trays; 8006 for complex-shaped containers

| Characteristics | 8006 Aluminum Foil | 3003 Aluminum Foil |

| Tensile Strength | 123-135MPa | 140-160MPa |

| Elongation | High (≥3%) | Medium (≥2%) |

| Formability | Excellent (wrinkle-free stamping) | Medium |

| Production Process | Hot Rolling | Hot Rolling / Cast Rolling |

| Typical Applications | Aerospace Meal Trays, Heat Exchangers | Beverage Cans, Decorative Materials |

8006 Aluminum Foil Purchasing and Usage Recommendations

- Customization Requirements: Clearly specify thickness, width, surface treatment (e.g., coating type), and application. Suppliers can provide sample testing (e.g., cup height, corrosion resistance).

- Cost Optimization: Recycled aluminum products offer high cost-performance but require confirmation of supply stability; bulk purchases can reduce unit price (e.g., orders above 10 tons).

- Quality Control: Focus on brushed finish grade (A-grade is superior), tensile strength fluctuation range, and surface cleanliness, avoiding oil or scratch defects.

Haomei Aluminum Foil Product Range

- 8011 Aluminum Foil 8011 possesses multiple excellent properties, including outstanding barrier ability against oxygen, moisture, and light. It is commonly used for pharmaceutical packaging, food packaging, aluminum foil tape, cable wraps, aluminum bottle caps, and more.

- 8021 Aluminum Foil 8021 is known for its exceptional barrier properties, safety, and good processing performance. It effectively blocks moisture and oxygen, is non-toxic and odorless, and is suitable for cold-formed pharmaceutical foil packaging, aluminum foil for lithium battery pouches, etc.

- 8079 Aluminum Foil Known for high strength and superior barrier properties, 8079 foil also has good elongation and pressability. It is widely used in food container materials, pharmaceutical capsules, food packaging, and battery pouch foil, offering reliable protection and enhanced visual appeal of packaging.

- 1235 Aluminum Foil With an aluminum content of no less than 99.35%, 1235 foil features excellent rust resistance, formability, and weldability. It is widely used in cable wraps, tape foil, and aluminum foil for lithium battery cathodes.

- 1060 Aluminum Foil 1060 aluminum foil belongs to the pure aluminum category (aluminum content ≥99.6%) and boasts excellent ductility and formability, along with good thermal conductivity and corrosion resistance. It is widely used in aluminum gaskets, electrolytic capacitors, and automotive heat shields.

- 1100 Aluminum Foil 1100 foil has slightly higher strength among pure aluminum foils and can be stamped, bent, and processed. It is commonly used in kitchenware (such as baking tray liners and foil sheets), insulation materials, and isolation layers of electronic components.

- 1070 Aluminum Foil Due to its high purity, 1070 aluminum foil offers superior electrical conductivity. It is suitable for applications such as capacitor electrode foil, precision electronic component packaging, high-end food packaging, and materials used in scientific research.

- 1050 Aluminum Foil With an aluminum content ≥99.5%, 1050 aluminum foil has balanced overall properties and is commonly used in capacitors, cable wraps, aluminum foil gaskets, and heat sinks. It is a widely used general-purpose pure aluminum foil material.

- 3003 Aluminum Foil Compared to pure aluminum foil, 3003 foil offers higher strength while maintaining good ductility and corrosion resistance. It is widely used in food containers (such as meal boxes and easy-open can lids), building soundproofing materials, HVAC ducts, and packaging materials.

- 3004 Aluminum Foil 3004 aluminum foil has greater strength and hardness than 3003, with good formability, suitable for deep-drawing processing. It is mainly used for meal box materials, aluminum honeycomb cores, beverage can bodies, and beverage packaging—meeting the industrial and packaging needs for high strength and formability.

- 5052 Aluminum Foil 5052 aluminum foil is a medium-strength alloy foil commonly used in scenarios requiring relatively high strength and corrosion resistance, such as honeycomb materials, door panel materials, meal box materials, and corrosion-resistant containers in the chemical industry. It is a medium- to high-end aluminum foil alloy with well-balanced comprehensive performance.