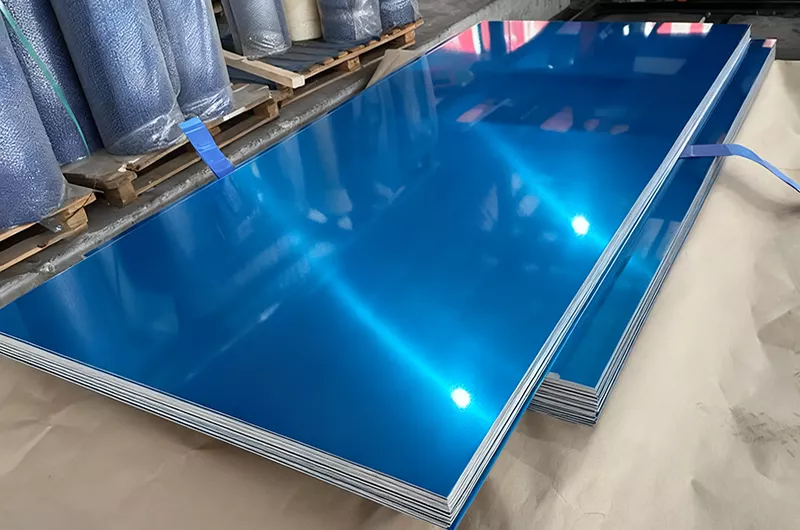

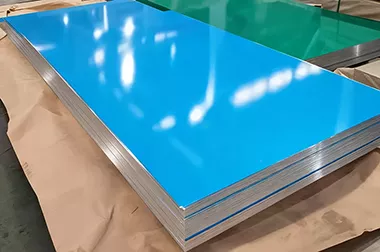

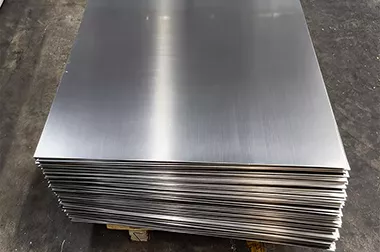

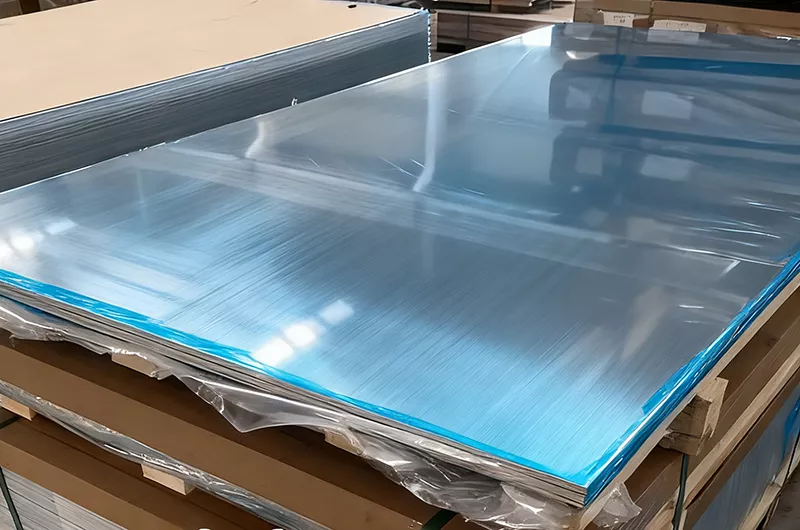

5052 Aluminum Plate Sheet

5052 aluminum sheet is an AL-Mg series anti-rust aluminum alloy plate, with magnesium as the main alloying element (content 2.2%~2.8%), featuring medium strength, excellent corrosion resistance, and welding performance. It cannot be strengthened by heat treatment but has outstanding cold working properties.

If you need an aluminum alloy sheet with good corrosion resistance, easy machinability, and medium strength, 5052 (especially in H32 temper) is a very ideal and reliable choice.

5052 aluminum has excellent corrosion resistance. The magnesium element forms a dense oxide film, giving it outstanding performance in marine environments, chemical media, and humid conditions. It is particularly suitable for ship sheet metal, oil tanks, and coastal building facades. Its salt spray corrosion resistance is significantly better than that of 3003 and 6061 alloys.

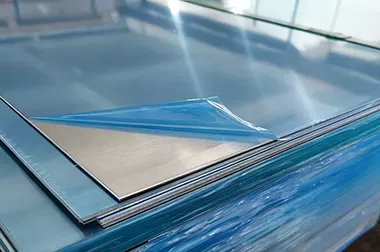

The surface of 5052 aluminum sheet is suitable for anodizing. After oxidation, the surface texture is uniform, making it commonly used in scenarios with high appearance requirements, such as electronic device enclosures and decorative panels.

5052 Aluminum Plate Standards

- ASTM B209-10

- AMSQQA250/8

5052 aluminum sheet specifications

| Category | Specification |

| Temper (Supply Condition) | O, H12 / H14 / H16 / H18, H32, H112, etc. |

| Thickness | 0.15–600 mm |

| Width | 20–2600 mm |

| Length | 500–16000 mm |

| Custom options | available for extra-wide (2600 mm) or extra-thick (600 mm) plates |

| Surface Treatment | Anodized, Mirror finish, Polished, Color coated, Embossed |

5052 Aluminum Plate Temper Options

5052 O (Annealed / Soft)

- Characteristics: Softest temper with excellent ductility and formability.

- Applications: Ideal for bending, stamping, or deep drawing, e.g., fuel tanks, shipbuilding, architectural panels.

- Mechanical Properties: Lowest strength but very easy to work.

5052 H14 (Half Hard)

- Characteristics: Moderate strength and hardness, good ductility.

- Applications: Light structural parts, automotive panels, kitchenware.

- Mechanical Properties: Easier to stamp than harder tempers, moderate strength.

5052 H32 (Medium Hard + Stabilized)

- Characteristics: Harder than H14 with moderate ductility; stabilized to prevent softening.

- Applications: Common in shipbuilding, fuel tanks, pressure vessels; balances formability and strength.

- Mechanical Properties: Widely used temper; medium strength and excellent corrosion resistance.

5052 H34 (Medium Hard)

- Characteristics: Slightly harder than H32; strength higher, ductility lower.

- Applications: Parts needing higher strength but still formable.

- Mechanical Properties: Suitable for thinner structural panels.

5052 H36 (Medium Hard to Hard)

- Characteristics: Harder than H34; high strength, lower ductility.

- Applications: Structural parts requiring higher load-bearing capacity.

- Mechanical Properties: Good strength and corrosion resistance; reduced formability.

5052 H38 (Hard)

- Characteristics: High hardness and strength; low ductility.

- Applications: Parts exposed to higher stress or wear.

- Mechanical Properties: Highest strength among common H-series, forming is more difficult.

5052 H39 (Extra Hard)

- Characteristics: Near maximum hardness; very low ductility.

- Applications: Structural supports or mechanical parts requiring high strength.

- Mechanical Properties: Can handle heavy loads but difficult to form or bend.

5052 H111 (Soft / Lightly Strain-Hardened)

- Characteristics: Slightly stronger than O temper but still highly formable.

- Applications: Deep drawing parts, stamping, light-load structures.

- Mechanical Properties: Easy to form, excellent corrosion resistance.

Haomei 5052 aluminum sheet for sale

5052 Aluminum Sheet

- Material: 5052 aluminum alloy

- Characteristics: Lightweight, excellent corrosion resistance, good ductility

- Applications: Marine panels, fuel tanks, architectural cladding, general fabrication

5052 Aluminum Plate

- Material: 5052 alloy, thicker gauge than sheet

- Characteristics: Stronger than sheet, good corrosion resistance, weldable

- Applications: Structural components, ship decks, industrial machinery

5052 H32 Aluminum Sheet

- Material: 5052 alloy, H32 temper (medium hard + stabilized)

- Characteristics: Balanced strength and formability, excellent corrosion resistance

- Applications: Shipbuilding, automotive fuel tanks, pressure vessels

5052 H32 Aluminum Plate

- Material: 5052 alloy, H32 temper, plate thickness

- Characteristics: Medium-hard, stabilized, corrosion-resistant

- Applications: Marine structures, industrial equipment, heavy-duty panels

5052 H34 Sheet

- Material: 5052 alloy, H34 temper (slightly harder than H32)

- Characteristics: Higher strength, slightly reduced ductility

- Applications: Structural panels, parts requiring moderate strength

5052 O Aluminum Sheet

- Material: 5052 alloy, O temper (annealed/soft)

- Characteristics: Softest temper, excellent ductility, very easy to form

- Applications: Deep drawing parts, bending, stamping, architectural applications

1/8" 5052 Aluminum Sheet

- Material: 5052 alloy, 1/8 inch thick

- Characteristics: Standard sheet thickness, corrosion-resistant, formable

- Applications: Medium-duty panels, fabrication, automotive and marine parts

3/16" Aluminum Plate 5052

- Material: 5052 alloy, 3/16 inch thick plate

- Characteristics: Moderate strength, corrosion-resistant, weldable

- Applications: Machinery panels, structural supports, ship components

1/4" 5052 Aluminum Plate

- Material: 5052 alloy, 1/4 inch thick

- Characteristics: High strength among common 5052 plates, good corrosion resistance

- Applications: Heavy-duty structural parts, industrial equipment, marine applications

0.100" Aluminum Sheet 5052

- Material: 5052 alloy, 0.100 inch (≈2.54 mm) thick

- Characteristics: Lightweight, corrosion-resistant, good ductility and formability

- Applications: Medium-duty panels, automotive parts, marine structures, general fabrication

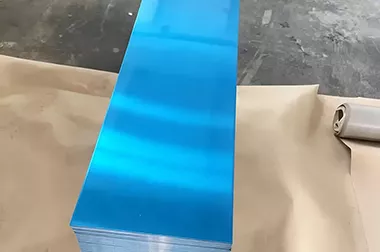

5052 Mirror Aluminum Plate

- Material: 5052 alloy, polished/mirror finish

- Characteristics: Highly reflective surface, corrosion-resistant

- Applications: Decorative panels, interior design, signage, appliances

5052 Anodized Aluminum Sheet

- Material: 5052 alloy, anodized surface

- Characteristics: Enhanced corrosion resistance, surface hardness, color options

- Applications: Architectural cladding, marine trim, decorative or functional surfaces

Haomei Aluminum also offers the following 5052 aluminum products, with complete specifications and competitive prices.

5052 Aluminum Tube

- Material: 5052 aluminum alloy

- Characteristics: Lightweight, corrosion-resistant, good formability, can be welded

- Applications: Automotive fuel lines, marine tubing, structural supports, industrial piping

5052 Aluminum Pipe

- Material: 5052 alloy, round or cylindrical form

- Characteristics: High corrosion resistance, strong and durable, suitable for pressure applications

- Applications: Plumbing, marine applications, pressure vessels, HVAC systems

5052 Aluminum Angle

- Material: 5052 alloy, L-shaped profile

- Characteristics: Good strength-to-weight ratio, corrosion-resistant, easy to fabricate and weld

- Applications: Structural framing, construction supports, marine and automotive reinforcement

5052 Aluminum Strip

- Material: 5052 alloy, narrow flat form

- Characteristics: Lightweight, corrosion-resistant, highly formable, can be anodized or coated

- Applications: Decorative trim, electrical components, automotive parts, industrial fabrication

5052 Aluminum Plate Features

- High strength, especially fatigue resistance

- Corrosion Resistance: Excellent

- Formability/Machinability: Good

- Heat Treatment: Poor

- Machining: Fair

- Weldability: Good

- Excellent corrosion resistance: Especially in marine and chemical environments, it has strong salt spray corrosion resistance, making it a typical "rust-proof aluminum".

- Medium strength: 5052 has higher strength than pure aluminum (such as 1060, 1100) and 3003 aluminum alloy, but lower than heat-treatable alloys like 6061.

- Good fatigue strength: Performs stably under cyclic loads.

- Outstanding formability: 5052 can undergo deep drawing, bending, and other cold working processes with good machinability.

- Weldability: Has good welding performance and is suitable for commonly used welding methods.

- Good surface treatment properties: 5052 aluminum is easy to anodize, paint, and perform other surface treatments to achieve an attractive and durable finish.

- Non-magnetic: This is a common feature of aluminum alloys, suitable for applications requiring magnetic interference resistance.

5052 aluminum density

Density: 2.68 g/cm³ (or 2680 kg/m³)

This is typical for 5000-series (Al-Mg) alloys — slightly lower than pure aluminum (2.70 g/cm³) due to magnesium content.

Lightweight yet strong, ideal for applications needing both strength and corrosion resistance (e.g. marine, automotive).

5052 aluminum hardness

| Temper | Type | Brinell Hardness (HB) | Typical Use |

| 5052 O | Annealed (soft) | ~47 HB | Deep drawing, forming |

| 5052 H32 | Strain hardened + stabilized | ~60 HB | Common sheet temper |

| 5052 H34 | Strain hardened more than H32 | ~65 HB | Panels, enclosures |

| 5052 H36 | Strain hardened further | ~70 HB | High strength needs |

| 5052 H38 | Full hard | ~75 HB | Maximum hardness applications |

5052 aluminum processing properties

- Cold stamping performance: Best in annealed (O) condition, followed by H32/H34, while H36/H38 is relatively poor.

- Weldability: Good for gas welding, arc welding, and other processes, with weld strength reaching 90%~95% of the base metal.

- Surface requirements: Local defect depth ≤ 8% of the thickness, total area <5%.

5052 aluminum chemical properties

| Element | Content (% by weight) |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Copper (Cu) | ≤ 0.10 |

| Iron (Fe) | ≤ 0.40 |

| Manganese (Mn) | ≤ 0.10 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.10 |

| Aluminium (Al) | Remainder |

5052 aluminum mechanical properties

| Tensile Strengths | ||||

| Hardening | Ultimate MPa (PSI) | Yield MPa (PSI) | Tensile Strength acc. ASTM B209 [KSI] | Yield Strength acc. ASTM B209 [KSI] |

| O | 195 (28000) | 89.6 (13000) | ||

| H32 | 228 (33000) | 193 (28000) | 31.0 - 38.0 | >23.0 |

| H34 | 262 (38000) | 214 (31000) | 34.0 - 41.0 | >26.0 |

| H36 | 276 (40000) | 241 (35000) | 37.0 - 44.0 | >29.0 |

| H38 | 290 (42000) | 255 (37000) | >39.0 | >32.0 |

5052 aluminum thermal properties

| Property | Value |

| Melting temperature (Tm) | 607 °C (1, 125 °F) |

| Thermal conductivity (k) | 138 W/m·K |

| Linear thermal expansion coefficient (α) | 2.38 × 10⁻⁵ K⁻¹ |

| Specific heat capacity (c) | 880 J/kg·K |

Heat Treatment of 5052 Aluminum Plate

5052 Aluminum Plate products are a non-heat treatable aluminum alloy that offers excellent finishing qualities. Among the non-heat treatable alloys, 5052 is considered one of the strongest options.

Although not heat treatable, Aluminum 50502 can be strengthened through a work hardening process (5052-H32). 5052 does not contain copper, so it is less susceptible to saltwater corrosion than copper-containing alloys.

Welding of 5052 Aluminum Plate

Aluminum 5052 can be easily welded using a variety of techniques, and it offers the best welding characteristics of all aluminum alloys.

What is 5052 aluminium used for?

- Shipbuilding and marine engineering: ship plates, cabins, oil tanks, pipelines, etc. This is its classic application area, thanks to its excellent seawater corrosion resistance.

- Vehicle manufacturing: body panels, oil tanks, and components of trucks and tankers. Reduces weight and resists road salt corrosion.

- Architectural decoration: ceilings, curtain wall panels, interior wall decoration, shutters, etc. Easy to form and surface treat.

- Electrical enclosures: housings, chassis, and control boxes for various instruments. Attractive, rust-proof, and non-magnetic.

- Sheet metal fabrication: used to manufacture enclosures, cabinets, and covers that require certain strength and good corrosion resistance.

- Pressure vessels: used for tanks and containers that do not bear high pressure.

- Lighting industry: lamp housings and reflectors.

Transportation

- Automotive fuel tanks, body panels (such as doors and hoods), bus luggage racks, and motorcycle side cases, taking advantage of its lightweight (1/3 the density of steel) and corrosion resistance.

- Ship decks and cabin structural parts, suitable for marine salt spray environments.

Electronics and electrical

- Computer cases, power supply enclosures, charging pile cabinets, combining electromagnetic shielding with ease of processing.

- Electrical components (such as transformer housings), balancing conductivity and corrosion resistance.

Architectural decoration

- High-end curtain wall panels, suspended ceilings, signs; after anodizing, a variety of colors and textures can be achieved.

- Interior door handles and panels, corrosion-resistant and easy to clean.

Industrial equipment

- Tank truck bodies, air storage cylinders, chemical containers, meeting corrosion resistance requirements in liquid/gas media.

- Mold manufacturing (such as mask machine parts), taking advantage of its good formability and weldability.

Typical applications

- Cooking Utensils

- Food Processing Equipment

- Storage Tanks

- Truck/Trailer components

- Mail Boxes

- Ladders

- Railing

- Frames

- Home appliances

- Kitchen cabinets

- Boats

- Home freezers

- Airline pipes

5052 Aluminum Plate Applications

- 5052 aluminum plate for automobile fuel tank

- 5052A aluminum plate for distribution box

- LCD back sheet material 5052 aluminum plate

- 5052 aluminum plate for car engine cover

- 5052 aluminum plate for car trunk lid

- 5052 aluminum plate for LED backplane

- 5052 mold aluminum plate

- 5052-H18 aluminum plate for lifting platform

- 5052-h32 aluminum plate for automobiles

- 5052 aluminum plate for hood/car bottom

- 5052 H32 aluminum plate for fuel tank plate

- 5052 aluminum plate aluminum trolley case

- Gearbox housing material 5052 aluminum plate

- Auto parts 5052-H24 aluminum plate

- 5052 H32 aluminum plate for automobile skin

- 5052 H19 aluminum plate can lid material

- Car roof 5052 aluminum plate

- 5052A aluminum plate for decoration

- 5052 h24 aluminum plate for new energy vehicles

- Car engine cover material 5052 aluminum plate

- 5052 aluminum plate for keyboard shell

- 5052 aluminum plate for chassis cabinets

- 4mm thick 5052 aluminum plate for water tank

- 5052 aluminum plate for automobile chimney

- Shutters 5052 aluminum sheet roll

- 5052 h38 alloy aluminum plate

- 5052 aluminum plate for truck fuel tank

- 5052 mold aluminum plate

- 5052-O aluminum plate for air conditioning

- 5052 stretched aluminum plate

- Laptop shell material 5052 aluminum plate

- 5052 marine aluminum plate

- 5052 O H32 H34 Aerospace Aluminum Sheet

- 5052 Aluminum Marine Grade Sheet Plate

- 5052 aluminum plate for aluminum alloy flange

- Stamped 5052A aluminum plate for door handles

- 5052 Oil Tanker Aluminum Tread Checkered Plate

- 5052 H19 H48 Aluminum Sheet Coil for Cans End

- 5052 H32 H34 3C Digital Shell Aluminum Sheet Strip

- Electrical casing 5052-H32 stamping aluminum plate

- Spin bike brake pads use 7 thick 5052 aluminum plates

- 5052 aluminum plate for electrical appliance housing

- The tank truck body is made of 5083 aluminum plate

- 5052 H18 H19 Aluminum Sheet for EOE and Ring Pull

- 3105 5052 5182 H19 H48 Aluminum Sheet Strips for Shutters

- 5052 O/H32/H26/H34 Aluminum Automotive Body Sheet

- 5052 aluminum plate for new energy vehicle compartments

- Sheet metal parts use 2.0/3.0 thick 5052 aluminum plate

- GIS high voltage switch housing material 5052 aluminum plate

- 5052 aluminum plate for automobile engine outer panels

- The fan blades are made of 5052-H32 aluminum plate

- 5052-o tempered aluminum plate for automobile fenders

- 5052-H114 pattern aluminum plate for anti-slip use in passenger car compartments

5052 Aluminum Plate and Sheet Stock

| Description | Thickness (IN) | Width (IN) | Length (IN) |

| ASTM B209 AMS-QQ-A-250/8 5052 H32 Aluminum Sheet 0.02" x 48" x 96" | 0.02" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.025" x 36" x 96" | 0.025" | 36" | 96" |

| AMS4015 ASTM B209 5052 O Aluminum Sheet 0.025" x 48" x 144" | 0.025" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.025" x 48" x 120" | 0.025" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.032" x 48" x 96" | 0.032" | 48" | 96" |

| ASTM B209 AMS-QQ-A-250/8 5052 H32 Aluminum Sheet 0.032" x 48" x 120" | 0.032" | 48" | 120" |

| AMS-QQA-250/8 151-002-02B032 5052 H34 Aluminum Sheet 0.032" x 48" x 144" | 0.032" | 48" | 144" |

| AMS-QQA-250/8 ASTM B209 5052 O Aluminum Sheet 0.032" x 48" x 96" | 0.032" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.04" x 48" x 144" | 0.04" | 48" | 144" |

| ASTM B209 AMS4015 5052O Aluminum Sheet 0.04" x 48" x 144" | 0.04" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.04" x 48" x 120" | 0.04" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.04" x 48" x 96" | 0.04" | 48" | 96" |

| AMS-QQA-250/8 ASTM B209 5052 O Aluminum Sheet 0.04" x 48" x 144" | 0.04" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.05" x 48" x 144" | 0.05" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.05" x 48" x 120" | 0.05" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.05" x 60" x 120" | 0.05" | 60" | 120" |

| AMS-QQA-250/8 ASTM B209 5052 O Aluminum Sheet 0.05" x 48" x 144" | 0.05" | 48" | 144" |

| AMS4015 ASTM B209 5052O Aluminum Sheet 0.063" x 48" x 144" | 0.063" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.063" x 36" x 96" | 0.063" | 36" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.063" x 60" x 120" | 0.063" | 60" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.063" x 48" x 96" | 0.063" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.063" x 48" x 144" | 0.063" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.063" x 48" x 120" | 0.063" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.063" x 36" x 96" | 0.063" | 36" | 96" |

| AMS4017 ASTM B209 5052 H34 Aluminum Sheet 0.063" x 48" x 144" | 0.063" | 48" | 144" |

| ASTM B209 AMS-QQ-A-250/8 5052 H32 Aluminum Sheet 0.063" x 48" x 144" | 0.063" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.08" x 48" x 120" | 0.08" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.08" x 60" x 120" | 0.08" | 60" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.08" x 48" x 144" | 0.08" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.08" x 48" x 96" | 0.08" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.08" x 60" x 120" | 0.08" | 60" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.09" x 48" x 144" | 0.09" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.09" x 48" x 120" | 0.09" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.09" x 60" x 144" | 0.09" | 60" | 144" |

| AMS4015 ASTM B209 5052 O Aluminum Sheet 0.09" x 48" x 144" | 0.09" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.1" x 48" x 120" | 0.1" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.1" x 48" x 144" | 0.1" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.1" x 48" x 96" | 0.1" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 48" x 144" | 0.125" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 48" x 96" | 0.125" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 36" x 96" | 0.125" | 36" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 48" x 120" | 0.125" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 60" x 144" | 0.125" | 60" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 60" x 120" | 0.125" | 60" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 60" x 120" | 0.125" | 60" | 120" |

| ASTM B209 505SH32 Aluminum Sheet 0.125" x 48" x 96" | 0.125" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.125" x 72" x 144" | 0.125" | 72" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.16" x 48" x 144" | 0.16" | 48" | 144" |

| ASTM B209 ASME SB209 5083 O Aluminum Sheet 0.1875" x 72" x 240" | 0.1875" | 72" | 240" |

| ASTM B209 ASME SB209 5083 O Aluminum Sheet 0.1875" x 84" x 240" | 0.1875" | 84" | 240" |

| ASTM B209 5052 H32 Aluminum Sheet 0.19" x 48" x 144" | 0.19" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.19" x 60" x 120" | 0.19" | 60" | 120" |

| ASTM B209 5052 H32 Aluminum Sheet 0.19" x 60" x 144" | 0.19" | 60" | 144" |

| ASTM B209 5052 H32 Aluminum Sheet 0.19" x 36" x 96" | 0.19" | 36" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.19" x 48" x 96" | 0.19" | 48" | 96" |

| ASTM B209 5052 H32 Aluminum Sheet 0.19" x 48" x 120" | 0.19" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Plate 0.249" x 48" x 120" | 0.249" | 48" | 120" |

| ASTM B209 5052 H32 Aluminum Plate 0.249" x 48" x 144" | 0.249" | 48" | 144" |

| ASTM B209 5052 H32 Aluminum Plate 0.249" x 60" x 144" | 0.249" | 60" | 144" |

| ASTM B209 5052 H32 Aluminum Plate 0.249" x 48" x 96" | 0.249" | 48" | 96" |

Does 5052 aluminum bend easily?

Yes, 5052 aluminum has excellent formability, especially in softer conditions such as O (annealed) or H32.

- Good ductility — can be bent, rolled, or formed without cracking.

- Very suitable for deep drawing, curved panels, or complex shapes.

- Aluminum with higher hardness (H34, H36, H38) has poorer bendability but higher strength.

Tip: When bending harder aluminum, use a larger bending radius to prevent cracking.

For example: metal sheets for ship hulls, oil tanks, or car panels usually use 5052 aluminum because it can be easily formed into curves and angles.

Is 5052 marine grade aluminum?

Yes, 5052 aluminum is considered marine grade.

Reasons:

- Excellent corrosion resistance, especially in saltwater and marine environments.

- Resistant to pitting and stress corrosion.

- Commonly used in ships, decks, oil tanks, and marine structures.

Comparison: It belongs to the 5xxx series (aluminum-magnesium alloy). Due to its magnesium content, it is typically considered marine grade. 5052 has slightly lower strength than 5083 or 5086 but is easier to form.

Comparison of 5052 aluminum with common aluminum alloys

- Strength: 1100-O < 3003-H14 < 5052-H32 < 6061-T6

- Corrosion resistance: 5052-H32 > 6061-T6 > 3003-H14

Factors to consider when choosing 5052 aluminum

Temper selection:

- Requires deep drawing —> choose O temper.

- Requires bending with moderate strength —> choose H32 temper (most commonly used).

- Requires higher strength —> choose H34 or higher hardness tempers.

Surface quality:

- Standard surface: suitable for subsequent treatments such as painting.

- Bright/mirror surface: suitable for applications requiring reflection or direct decorative finish.

- Anodizing: 5052 is very suitable for anodizing, allowing various colors and enhancing surface hardness and wear resistance.

- Thickness tolerance: select the tolerance grade according to application requirements and industry standards.

5052 aluminum processing and usage recommendations

- Surface treatment: Ensure the sheet surface is free of scratches and grease before oxidation. Sheets produced by hot rolling are recommended to ensure uniform anodized texture.

- Welding process: Prefer ER5356 welding rods; after welding, clean the weld seam to prevent corrosion.

- Storage conditions: Avoid contact with acidic or alkaline substances, store in a dry and ventilated place, and prevent damage to the surface oxide film.

Products you may be interested in

Further reading

Users viewing this material also viewed the following

- 5052 Diamond Tread Aluminum Plate

- 5052 Stucco Embossed Aluminum Sheet

- Aluminium circle 5052 H32 for Tank Cover

Recommended Content