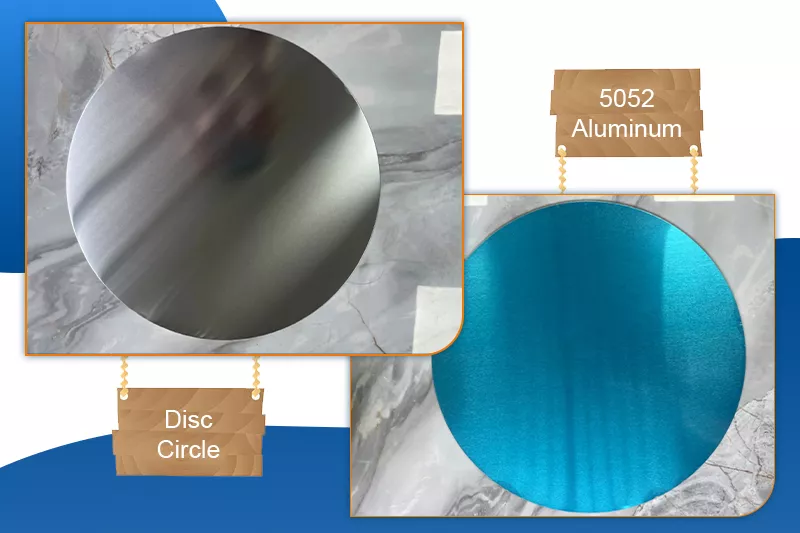

5052 Aluminum Disc Circle

5052 aluminum disc circle refers to circular sheet material made from 5052 aluminum alloy. 5052 aluminum alloy belongs to the Al-Mg series alloys. It inherits the core advantages of 5052 aluminum alloy, such as excellent corrosion resistance, good machinability, and relatively high strength, making it highly suitable for manufacturing processes that require subsequent processing such as stamping and deep drawing.

5052 aluminum alloy circles are well known for their higher strength compared with 1xxx series aluminum alloys. They are especially suitable for applications that need to maintain durability in humid, marine, or chemically corrosive environments.

Although 1000 series and 3000 series aluminum alloys are commonly used to manufacture general cookware, when products need to withstand saltwater exposure, vibration, or higher mechanical stress, 5052 aluminum alloy becomes the ideal “industrial-grade” choice.

5052 aluminum disc circle is a versatile and corrosion-resistant aluminum disc. This aluminum circle is available in a wide range of diameters and thicknesses. Due to its smooth surface, neat edges, and the ability to be painted, engraved, or polished, it is also widely used in DIY, industrial, and decorative projects.

Features of 5052 Aluminum Disc Circle

- Alloy composition: Mainly alloyed with magnesium and chromium, enhancing strength and corrosion resistance.

- Processing performance: Good formability (spinning, stamping, deep drawing), excellent machinability, and weldability.

- Corrosion resistance: Outstanding, especially in marine environments, making it suitable for outdoor and maritime applications.

- Formability: Due to its good ductility, it is highly suitable for deep drawing and stamping.

- Weldability: Excellent, making it an ideal choice for joining different components.

- Surface treatment: Smooth surface, suitable for painting, powder coating, or engraving.

- Strength: Medium to high strength, higher than 1050 / 1060 / 1100 series.

- Heat treatment: Not heat-treatable.

- High fatigue strength: Maintains integrity under vibration conditions, therefore widely used in automotive and aerospace components.

Specification of 5052 Aluminum Circle

| Item | Specification |

| Alloy | 5052 |

| Temper | O, H32, H34, H111 |

| Thickness | 0.2 – 6.0 mm |

| Diameter | 100 – 1600 mm, customizable |

| Surface | Bright, Matte, Brushed, Anodized, Mill Finish, PE / PVC film protection, etc. |

| MOQ | 1 – 3 tons |

| Edge | Smooth deburred edge, suitable for deep processing |

| Common Standards | ASTM B209, AMS 4016 (H32), AMS 4015 (O) |

5052 Aluminum Circle Thickness tolerance

| Thickness tolerance | mm |

| diameter<455mm | +/- 0.05 mm |

455|

+/- 0.1 mm

|

|

| Diameter >1000 mm | +/- 0.2 mm |

5052 Aluminum Circle Available Temper

O – Annealed temper, most suitable for forming and spinning.

H32 / H34 – Strain-hardened temper, with improved strength and surface stability.

| 5052 Aluminum Circle | Features | Typical Applications |

| 5052 O Aluminum Circle | Fully annealed, the softest condition with extremely high ductility. | Deep drawing, spinning processes. For example: deep cookware, high-difficulty irregular-shaped containers, pressure vessel heads. |

| 5052 H32 Aluminum Circle | Stabilized temper, balancing strength with a certain level of formability. | General bending, shallow drawing. For example: general cookware, traffic sign blanks, enclosure panels, condenser housings. |

| 5052 H34 Aluminum Circle | Higher hardness than H32, providing more stable structural strength. | Flat support components, high-strength signage, structural parts that do not require significant deformation. |

5052 Aluminum Circle Temper Selection Guide

- If you require “spinning” or “deep drawing”: be sure to choose the O temper. 5052-O offers excellent ductility and can withstand multiple drawing operations without cracking, making it the preferred choice for manufacturing deep pots, tall containers, fuel tanks, and other complex shapes.

- If you require “bending” or “shallow drawing”: H32 is the most versatile and well-balanced option. It has better surface hardness than the O temper, improved resistance to impact and dents, while still maintaining good bending performance (R-angles are less prone to cracking).

- If you prioritize “surface flatness” and “load-bearing capacity”: H34 or higher hardness tempers (such as H36 / H38) are more suitable. Aluminum circles in these tempers are very hard and resistant to deformation under load, making them ideal for architectural decorative discs, large road signs, or electronic product back panels.

5052 Aluminum Circle Shapes and Surface Treatments

Shapes: Pre-cut discs or plates in various diameters and thicknesses are available (for example, 1/8 inch, 1/4 inch).

Surface treatments: Smooth surface, usually with clean, burr-free laser-cut edges, suitable for powder coating, anodizing, painting, or polishing.

Common Diameters of 5052 Aluminum Circle

| Size Category | Diameter Range (inch) | Diameter Range (mm) | Typical Applications |

| Small Diameter | 2" - 8" | 50mm - 200mm | Spice jar lids, flashlight housings, small spotlight covers. |

| Medium Diameter | 8" - 20" | 200mm - 500mm | Household boiling pots, flat-bottom frying pans, traffic signs. |

| Large Diameter | 20" - 47" | 500mm - 1200mm | Large industrial drum bottoms, high-mast lighting fixtures, large traffic roundabout signs. |

5052 Aluminum Disc Circle Surface Treatments

- 5052 Mill Finish Aluminum Disc Circle: Retains the original processed surface, most cost-effective, suitable for industrial base components where appearance is not critical.

- 5052 Brushed Aluminum Disc Circle: Surface has uniform hairline texture, giving a metallic feel and fingerprint resistance, commonly used in mid-to-high-end appliance panels.

- 5052 Polished Aluminum Disc Circle: Mechanically polished to a mirror-like high gloss, often used for lamp reflectors or decorative accessories.

- 5052 Anodized Aluminum Disc Circle: Forms a hard oxide layer on the surface, providing corrosion and wear resistance while offering various vibrant metallic colors.

- 5052 PE/PVDF Coated Aluminum Disc Circle: Surface coated with fluorocarbon or polyester paint, offering excellent weather resistance, widely used for building facades and colored ceilings.

- 5052 Non-stick Coated Aluminum Disc Circle: Surface coated with Teflon or ceramic layer, providing excellent water and oil repellency, the preferred choice for high-quality flat-bottom pans.

Comparison of 5052 Aluminum Circle Finishes

| Finish Type | Durability | Aesthetics | Primary Benefit |

| Mill | Moderate | Low | Most cost-effective |

| Brushed | High | High | Hides wear and tear |

| Polished | Moderate | Very High | Maximum reflectivity |

| Anodized | Very High | High | Corrosion & scratch resistance |

| Coated | High | High | Color variety & weather resistance |

| Non-stick | Moderate | Functional | Food release properties |

5052 Aluminum Circle Mechanical properties

| Alloy | 5052 |

| Tensile strength(MPa) | 170-305 |

| Conditional yield strength (Mpa) | ≥70 |

| Elastic modulus(Gpa) | 69.3-70.7 |

5052 Aluminum Circle Chemical Composition (%)

| Alloy | 5052 |

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.4 |

| Mn | 0.1 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Ni | - |

| Zn | 0.1 |

| Ti | - |

| Zr | - |

| Al | Remainder |

5052 Aluminum Disc Circle Applications

- Crafts and DIY: jewelry, custom signage, model parts, decorative items.

- Industrial: cookware, electrical enclosures, automotive components, building panels, yacht hatches.

- Signage: road signs (curved discs), traffic signs.

- Kitchenware: lighting fixtures, tableware.

- Marine hardware: hull components, oil-tight hatches, and marine accessories.

- Industrial signage: high-quality road signs and traffic indicators requiring long-term weather resistance.

- Transportation: truck and trailer enclosures, fuel tanks, and pressure vessels.

- High-end cookware: professional-grade pots or specialized containers requiring greater durability than standard aluminum.

- Lighting: reflectors and lampshades requiring high-quality anodized surface treatment.

Why Choose 5052 Aluminum Disc Circle?

5052 Aluminum Disc Circle combines strength, corrosion resistance, and ease of processing, making it an ideal material for both creative and practical metal products.

Compared to pure aluminum circles, 5052 aluminum alloy offers higher mechanical strength and superior corrosion resistance, making it an ideal choice for long-term use in harsh environments, while still maintaining excellent machinability.

Comparison of 5052 Aluminum Disc Circle with Other Common Aluminum Alloys

| Comparison Item | 5052 Aluminum Alloy | 3003 Aluminum Alloy | 6061 Aluminum Alloy |

| Main Features | Excellent corrosion resistance, medium strength, good formability and weldability. | Excellent formability, average strength, good corrosion resistance. | High strength, heat-treatable, good machinability. |

| Typical Applications | Marine components, vehicle panels, stampable cookware/lighting. | Daily stamping parts, cans, building materials. | High-strength structural parts, bicycle frames, precision mechanical components. |

| Heat-treatable | No | No | Yes |

In summary, if your product will be used in humid or salt-spray environments (such as marine or outdoor applications), or requires medium stamping and drawing (such as cookware or lighting), 5052 aluminum circles provide a balanced and reliable performance choice.

5052 Aluminum Disc Circle Purchasing & Selection Guide

When purchasing 5052 aluminum circles, Haomei Aluminum recommends confirming the following key aspects to ensure that the material properties match your final application requirements.

Define Application Requirements

Before placing an order, clearly specify the product’s requirements for corrosion resistance, mechanical strength, and formability. Also inform us of the subsequent processing methods, such as stamping depth, spinning process, or whether welding will be involved. This information will help us recommend the most suitable material solution for you.

Confirm Material Temper

Different tempers significantly affect processing performance. We can provide O temper, H32, and other options.

If your product involves complex or deep drawing processes, we generally recommend selecting O temper (annealed) for optimal formability.

Verify Key Technical Parameters

To ensure product consistency and processing stability, please confirm the following parameters when purchasing:

- Alloy grade: 5052 aluminum alloy

- Thickness and diameter range

- Dimensional tolerance requirements

- Surface quality standards (e.g., allowance for minor scratches or dents)

Haomei Aluminum can strictly control and customize production according to your requirements.

Understand Minimum Order Quantity (MOQ)

Aluminum circles usually have a minimum order quantity, commonly calculated by weight (tons) or minimum order size/area. We support flexible MOQ options and encourage early communication with our sales and technical teams.

Surface Treatment Selection

Depending on different application scenarios, Haomei Aluminum can provide various 5052 aluminum circle surface treatment options, including:

- Anodizing

- Surface coating

- Brushed finish

To meet your diverse needs for appearance, corrosion resistance, and functionality.

Further reading

- 5052 Aluminum Coil

- 5052 Aluminum Plate Sheet

- 5052 h32 aluminum sheet

- 5052 0 aluminum sheet

- 5052 h34 aluminum sheet

Users viewing this material also viewed the following

- Aluminium circle 5052 H32 for Tank Cover

- 5052 Diamond Tread Aluminum Plate

- 5052 Stucco Embossed Aluminum Sheet

Recommended Content