1050 O Aluminum

1050-O aluminum is a commercially pure, non-heat-treatable forged alloy in the annealed ("O") temper. It belongs to the 1xxx series, with a high aluminum purity (≥99.5%) and excellent formability, making it well-suited for applications where ductility and corrosion resistance are prioritized over strength.

1050 O aluminum is a commercially pure aluminum alloy with an aluminum content of at least 99.5%. It is known for its outstanding corrosion resistance, high ductility, and good thermal and electrical conductivity. The "O" temper designation indicates that the material is in a fully annealed (softened) state, enhancing its formability.

1050 aluminum 1050-O is a versatile material ideally suited for applications requiring high corrosion resistance, excellent formability, and good thermal and electrical conductivity, although it has relatively low mechanical strength.

1050-O aluminum alloy belongs to the 1050 series of aluminum alloys. The "O" indicates that the alloy is in an annealed state, which provides the lowest strength but the highest ductility, offering significant advantages in forming and shaping processes.

1050-O aluminum is the annealed version of 1050 aluminum. Compared with other forms of 1050 aluminum, it has the lowest strength but the highest ductility.

1050 O Aluminum Properties

| Property Category | Description |

| High Formability | 1050 O Aluminum exhibits extremely high formability, suitable for deep drawing, spinning, and other plastic deformation processes, and is not prone to cracking during stretching. |

| Corrosion Resistance | 1050 O Aluminum demonstrates excellent corrosion resistance in typical environments, making it suitable for various indoor and outdoor applications. |

| Electrical/Thermal Conductivity | 1050 O Aluminum has outstanding electrical and thermal conductivity, making it widely used in electronic and electrical industries. |

| Low Strength | 1050 O Aluminum is a low-strength material and cannot be strengthened through heat treatment. |

| High Ductility | 1050 O Aluminum has excellent ductility, performing well in cold forming processes such as deep drawing, spinning, and bending. |

| Weldability | 1050 O Aluminum possesses good weldability and can be welded using TIG, MIG, or resistance welding methods. It is recommended to use 1100 filler wire for same-series alloys or 5356/4043 filler wire when welding with other series alloys. |

| Surface Treatment | 1050 O Aluminum has high reflectivity and is suitable for decorative products and lighting reflectors that require good light reflection performance. |

| Limitations | Compared with heat-treatable alloys, 1050 O Aluminum has limitations due to its softness and lower strength, resulting in inferior machining performance. |

| Machinability | Due to its softness, 1050 O Aluminum presents some challenges during mechanical processing, and its machinability is relatively poor. |

| Cold Working Performance | 1050 O Aluminum shows good cold working performance and can meet various manufacturing needs through cold rolling, stamping, and other methods. |

| High Reflectivity | 1050 O Aluminum features high reflectivity, making it ideal for lighting reflectors and optical decorative applications requiring strong reflective performance. |

1050 O Aluminum is available in the following product forms

| Product Name | Description |

| 1050-O Aluminum Plate | 1050-O aluminum plate is a type of aluminum alloy material with good ductility and formability, mainly used for manufacturing various structural components and equipment casings. Its lightweight and corrosion-resistant properties make it widely used in fields such as construction, transportation (e.g., automobiles and ships), and industrial equipment (e.g., machine housings). Due to its excellent thermal and electrical conductivity, 1050-O aluminum plate is also commonly used in the manufacturing of electrical equipment and heat exchangers. |

| 1050-O Aluminum Coil | 1050-O aluminum coil is aluminum material formed through cold rolling or hot rolling, typically used for processing into other aluminum products. Due to its excellent workability and surface treatment properties, aluminum coil is widely used in construction (e.g., roofing, wall panels), decorative materials (e.g., aluminum alloy doors and windows), and electrical insulation materials. The lightweight characteristics of aluminum coil make it an ideal material choice in modern construction. |

| 1050-O Aluminum Foil | 1050-O aluminum foil is a thin and flexible aluminum material with good moisture-proof and oxidation-resistant properties. It is widely used in food packaging (e.g., aluminum foil bags, aluminum foil paper), pharmaceutical packaging (e.g., pharmaceutical aluminum blisters), and insulation materials (e.g., building insulation layers). The excellent barrier properties of aluminum foil can effectively extend the shelf life of food and pharmaceuticals. |

| 1050-O Aluminum Tube | 1050-O aluminum tube is a lightweight aluminum pipe with good corrosion resistance, suitable for structural applications, chemical equipment, and transmission pipelines. Due to its good mechanical properties and processability, aluminum tubes are widely used in aerospace, automotive manufacturing, and construction fields. |

| 1050-O Aluminum Profile | 1050-O aluminum profile is an aluminum frame made through the extrusion process, widely used in construction, furniture, and transportation. Its lightweight and corrosion-resistant properties make it an ideal material for manufacturing window frames, door frames, curtain walls, and furniture frames. Aluminum profiles can also be customized according to design requirements to meet different engineering needs. |

| 1050-O Aluminum Powder | 1050-O aluminum powder is a fine aluminum particle widely used in fireworks, coatings, and chemical industries. Its excellent combustion characteristics and luster make it a common pigment and filler in coatings, while it serves as fuel and an oxidizer in fireworks. The applications of aluminum powder also include anti-corrosive coatings and plastic reinforcement materials. |

| 1050-O Aluminum Strip | 1050-O aluminum strip is a thin and long aluminum material, typically used for cable sheathing and conductive connectors. Due to its good electrical conductivity and corrosion resistance, aluminum strip is widely used in electronic devices and power systems. The lightweight characteristics and ease of processing of aluminum strip make it an important material for cables and connectors. |

| 1050-O Aluminum Disc | 1050-O aluminum disc is a round aluminum material widely used for manufacturing cookware, lamp reflectors, and electronic product casings. Its good thermal conductivity makes it widely applicable in cooking utensils, while in lighting, it can enhance light reflection. The lightweight and corrosion-resistant properties of aluminum discs also give them potential applications in automotive and aerospace fields. |

| 1050-O Aluminum Sheet | 1050-O aluminum sheet is a flat aluminum material widely used in various sheet metal processing and decorative materials. Its good processing performance and surface treatment capabilities make it broadly applied in automotive, construction, home appliances, and electronic product casings. The lightweight and corrosion-resistant properties of aluminum sheets make them important materials in modern manufacturing and construction industries. |

Applications of 1050 O Aluminum

- Daily Use Products: Cookware, decorative items, signage, etc.

- Industrial Components: Chemical containers, heat sinks, reflectors, lighting accessories.

- Electronics & Electrical: Conductive components, cable protective sleeves, transformer aluminum strips.

- Deep Drawn Products: Bottle caps, spun vessels, stamped parts.

- Construction: Flashing, reflectors, and cladding.

- Chemical/Food Processing: Storage tanks, containers, and equipment linings.

- Electrical: Cable sheaths and heat sinks.

| Application Field | Description | Product Forms |

| Chemical Process Equipment | 1050-O aluminum alloy is widely used in the manufacturing of chemical process equipment due to its excellent corrosion resistance and good workability. These devices often come into contact with various chemicals, including strong acids and bases. Equipment components made from 1050-O aluminum alloy (such as reactors, pipelines, and tanks) can effectively resist corrosion and extend the lifespan of the equipment. Additionally, the weldability of this aluminum alloy facilitates the production of complex structures, ensuring the sealing and safety of the equipment. | 1050-O aluminum plate, 1050-O aluminum tube |

| Food Industry Containers | Due to its excellent corrosion resistance and good hygiene properties, 1050-O aluminum alloy is widely used in the food industry for manufacturing containers and packaging materials. Its smooth surface is easy to clean and does not easily react chemically with food, making it very suitable for food packaging and storage. These containers can be used for refrigeration, transportation, and storage of various foods, ensuring their safety and freshness. | 1050-O aluminum coil, 1050-O aluminum foil |

| Fireworks Powder | 1050-O aluminum alloy also has significant applications in the manufacturing of fireworks products. Aluminum powder is one of the key components in fireworks and pyrotechnics, providing necessary combustion characteristics and brightness. The high purity and good workability of 1050-O aluminum alloy make it an ideal choice for producing high-quality fireworks powder, ensuring that fireworks produce beautiful sparks and colors when ignited. | 1050-O aluminum powder |

| Architectural Decoration | In the construction industry, 1050-O aluminum alloy is commonly used in various decorative flashing materials. Its good ductility and processability allow designers to easily create complex decorative elements, such as exterior wall decorations, eaves panels, and window frames. Additionally, the corrosion resistance and high reflectivity of this aluminum alloy enable buildings to effectively withstand external environmental impacts while maintaining aesthetic appeal and long-lasting performance. | 1050-O aluminum plate, 1050-O aluminum profile |

| Lighting Reflectors | 1050-O aluminum alloy is widely used in lamp reflectors due to its high reflectivity. The primary function of the reflector is to effectively reflect light back to the desired area, thereby enhancing lighting efficiency. Reflectors made from 1050-O aluminum alloy can provide stronger light reflection, improving the efficiency of lighting equipment, especially in commercial and industrial lighting applications. | 1050-O aluminum sheet, 1050-O aluminum disc |

| Cable Sheathing | 1050-O aluminum alloy provides excellent protective performance in cable sheathing applications. The lightweight characteristics and good conductivity of aluminum alloy make it an ideal material for cable sheathing. It effectively prevents external environmental factors (such as moisture, chemicals, and mechanical damage) from affecting the cables, ensuring their safety and stable operation. Additionally, the weldability and processability of aluminum alloy facilitate the manufacturing process, allowing for various specifications and designs of cable sheathing. | 1050-O aluminum foil, 1050-O aluminum tube |

| General Sheet Metal Processing | 1050-O aluminum alloy is widely applied in various sheet metal processing fields due to its good workability. Its high ductility allows it to be processed through cold rolling, shearing, and stamping, making it suitable for manufacturing various metal parts and structures. Whether in the automotive, aerospace, or construction industries, 1050-O aluminum alloy can provide high-quality sheet metal products to meet diverse application needs. | 1050-O aluminum plate, 1050-O aluminum coil |

Aluminum 1050 O Data Sheet

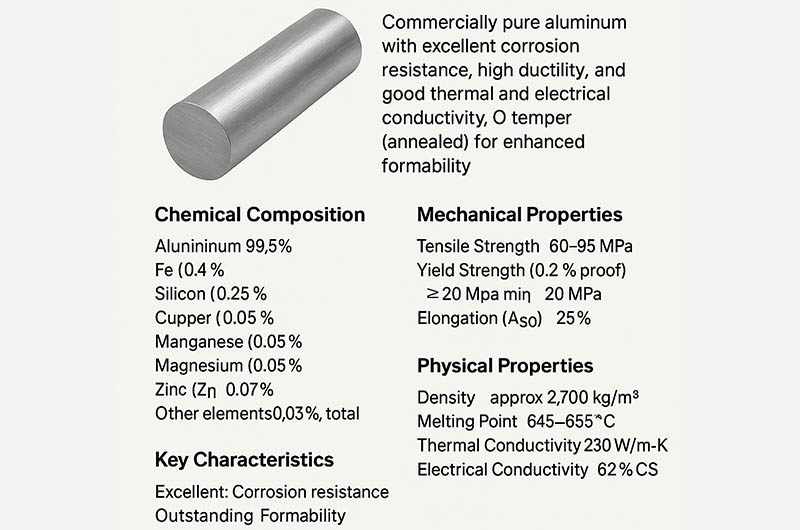

Alloy 1050 Chemical Composition

BS EN 573-3

| Chemical Element | % Present |

| Aluminium (Al) | 99.50 - 0.00 |

| Manganese (Mn) | 0.00 - 0.05 |

| Iron (Fe) | 0.00 - 0.40 |

| Copper (Cu) | 0.00 - 0.05 |

| Magnesium (Mg) | 0.00 - 0.05 |

| Silicon (Si) | 0.00 - 0.25 |

| Zinc (Zn) | 0.00 - 0.07 |

| Titanium (Ti) | 0.00 - 0.05 |

| Other (Each) | 0.00 - 0.03 |

Aluminum 1050 O Mechanical Properties

Sheet 0.2mm to 6.00mm

BS EN 485-2

| Mechanical Property | Value |

| Tensile Strength | 65 -95 MPa |

| Proof Stress | 20 Min MPa |

| Hardness Brinell | 20 HB |

Aluminum 1050 O General Physical Properties

| Physical Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x 10-6/K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 222 W/m.K |

| Electrical Resistivity | 0.0282 x 10-6 Ω .m |

1050 O Aluminum Processing and Heat Treatment

- Annealing Process: Heat to 350~430℃, hold and then cool slowly to enhance plasticity and relieve stress.

- Welding Performance: Supports gas welding, TIG welding, spot welding, etc.; post-weld annealing is recommended.

1050 O Aluminum Manufacturing Notes

- Cold Working: Very suitable for forming, but annealing is needed if processing is extensive to avoid cracking.

- Finishing: Suitable for anodizing, polishing, and chemical brightening.

- Heat Treatment: Not applicable (non-heat-treatable alloy).

1050 O Aluminum Comparison with Other Tempers

- H14 Temper (Semi-Hard): Increased tensile strength but reduced plasticity.

- Unannealed Temper: Strength is increased by cold deformation, but elongation is significantly reduced.

| Comparison Temper | Description |

| H14 Temper (Semi-Hard) | Compared to 1050 H14 temper (semi-hard), 1050 O Aluminum offers higher plasticity and ductility, making it more suitable for deep drawing, spinning, bending, and other cold working processes. The H14 temper undergoes a certain degree of cold work hardening, which increases tensile strength but significantly reduces plasticity, making it more appropriate for applications that require moderate strength but lower forming complexity. |

| Unannealed Temper | 1050 O Aluminum is in a fully annealed condition, offering excellent ductility and toughness, which is ideal for deep forming processes. In contrast, unannealed tempers (such as F temper or partially cold-worked states) rely on cold deformation to increase strength. However, this significantly lowers the material's elongation and forming adaptability, increasing the risk of cracks or fractures during processing. Thus, the O temper provides more stable and reliable performance in complex forming scenarios. |

1050-O aluminum is a widely used high-purity alloy, valued for its ductility, corrosion resistance, and ease of fabrication. Although its mechanical strength is limited, its application spans various industries from construction to electrical engineering.

Products you may be interested in

- 1050 Aluminum Plate Sheet

- 1050 h14 aluminium sheet plate

- Aluminium 1050 h24

- 1050 H18 Aluminium

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

Further reading

Users viewing this material also viewed the following

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

Recommended Content