Aluminium 1050 h24

What is 1050 H24 Material?

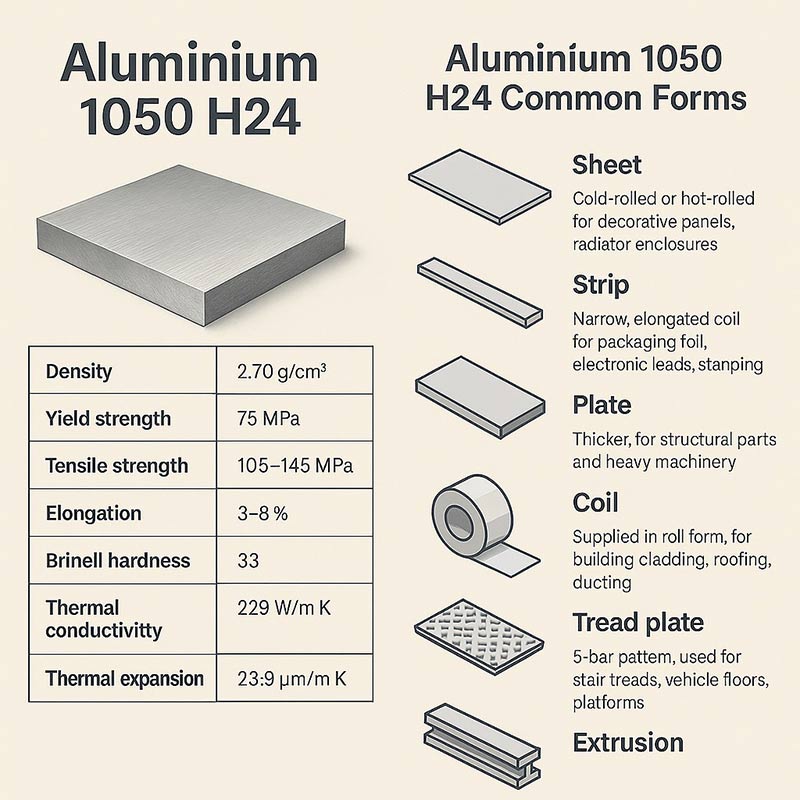

1050 H24 aluminum alloy is an industrial pure aluminum material, belonging to the 1000 series aluminum alloy family, with extremely high aluminum purity (≥99.5%). Its designation follows the international aluminum alloy grade standard, in which "1050" indicates that the minimum aluminum content of the alloy is 99.5%, while "H24" represents its temper.

- High Purity Aluminum content ≥99.5%, with very low impurity levels

- Good Corrosion Resistance Forms a dense aluminum oxide film on the surface to prevent further oxidation

- Excellent Workability Supports various processing methods, easy to form into complex structures

- High Electrical and Thermal Conductivity Electrical conductivity up to 57%-58% IACS, thermal conductivity 222-237 W/(m·K)

- Moderate Strength Tensile strength of 105-145 MPa in H24 temper

- Low Cost Contains no expensive alloying elements, cost-effective

Haomei Aluminum 1050 H24 Aluminium Product Specifications

| Typical alloy | 1050 h24 Aluminium |

| Alloy Types | Sheet, Plate, Coil, etc |

| Available Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114, F |

| Thickness(mm) | 0.2-600 |

| Width(mm) | 100-2650 |

| Length(mm) | Customized |

Aluminium 1050 H24 Standards and Equivalents

- EN: EN AW-1050A.

- ASTM: AA 1050.

- DIN: Al99.5.

1050 H24 aluminum is a versatile material that combines good mechanical properties with ease of processing, making it an ideal choice for many industrial and manufacturing applications.

Haomei Aluminum 1050 H24 Aluminium Product Specifications

Forms available: Sheets, strips, plates, coils, tread plates (especially 5-bar pattern), extrusions

| Product Form | Description |

| Aluminium 1050 H24 Sheet | 1050 H24 sheets are produced by cold or hot rolling, typically with thicknesses from 0.2 mm to several millimeters. They can be cut to standard sizes (e.g., 1500 × 3020 mm) as per EN 485 or ASTM B209. With high purity (≥ 99.5%), moderate strength, excellent workability, and reflectivity, they are commonly used in decorative panels, radiator housings, cookware, nameplates, and traffic signs. |

| Aluminium 1050 H24 Strip | 1050 H24 strip refers to narrower and longer sheet coils, with flexible thickness ranges, commonly used in packaging foil, electronic leads, precision stamping parts, and LED tape conductors. Achieved via cold rolling, it offers high plasticity, excellent corrosion resistance, and superior electrical and thermal conductivity, ideal for continuous and high-volume stamping applications. |

| Aluminium 1050 H24 Plate | 1050 H24 plate is a thicker form (generally over 6 mm, even up to several tens of millimeters), used in structural components, heavy machinery, mold bases, electrical brackets, and non-load-bearing aerospace structures. It retains aluminum's corrosion resistance and workability, well-suited for thickness-critical but moderately strength-demanding applications. |

| Aluminium 1050 H24 Coil | 1050 H24 coil is supplied in roll form as continuous strip, with a thickness range of approx. 0.3–8 mm and width up to 2650 mm. With excellent ductility and ease of processing and transport, it is widely used in building cladding, roofing materials, HVAC ducting, cable shielding, and other large-area fabrication scenarios. Also suitable as base material for color-coated aluminum. |

| Aluminium 1050 H24 Tread Plate (5-bar pattern) | 1050 H24 tread plate typically features a 5-bar pattern with embossed or raised surface, and is commonly 0.8–3 mm thick. Combining light weight, anti-slip properties, and aesthetic appeal, it has excellent corrosion and oxidation resistance. It is widely used for stair treads, elevator floors, truck/van flooring, industrial platforms, and ship decks, ideal for safety and anti-slip applications. |

| Aluminium 1050 H24 Extrusion | 1050 H24 extrusions are formed by hot extruding aluminum into shapes such as profile tubes, channels, rails, and frames. With high plasticity and corrosion resistance of pure aluminum, they are suitable for lightweight, precision, and smooth-surface industrial components like sliding rail systems, heat sink fins, trim strips, lamp frames, and furniture structural profiles. Suitable for anodizing and mechanical surface polishing. |

Main Properties and Characteristics of Aluminium 1050 H24

- High Purity: The high purity of 1050 aluminum gives it excellent corrosion resistance.

- Good Weldability: The high purity of this alloy makes it easy to weld using common techniques such as gas welding and arc welding.

- Excellent Formability: The H24 temper achieves a good balance between strength and formability, allowing bending, plasticity, and other forming processes.

- Good Electrical Conductivity: 1050 aluminum is a good electrical conductor.

- Anodizing: It is very suitable for anodizing, a process that enhances corrosion resistance and provides a decorative surface.

- Machinability: The 1050 alloy is well known for its good machinability.

Aluminium 1050 h24 alloy composition

| Element | Content (%) |

| Aluminum (Al) | 99.5 to 100 |

| Iron (Fe) | 0 to 0.4 |

| Silicon (Si) | 0 to 0.25 |

| Manganese (Mn) | 0 to 0.050 |

| Zinc (Zn) | 0 to 0.050 |

| Copper (Cu) | 0 to 0.050 |

| Magnesium (Mg) | 0 to 0.050 |

| Vanadium (V) | 0 to 0.050 |

| Titanium (Ti) | 0 to 0.030 |

Aluminium 1050 h24 mechanical property

| Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | ||||

| Min | Max | Min | Max | ||

| 0.008 - 0.020 | 15.2 | 21 | 10.9 | - | 3 |

| 0.020 - 0.059 | 15.2 | 21 | 10.9 | - | 4 |

| 0.059 - 0.118 | 15.2 | 21 | 10.9 | - | 5 |

| 0.118 - 0.236 | 15.2 | 21 | 10.9 | - | 8 |

Physical Properties of 1050 H24 Aluminum Alloy

1050 H24 aluminum alloy has the following excellent physical properties:

Density and Weight

- Density is about 2.71 g/cm³, making it a lightweight material

- Light weight, with high specific strength

Thermal Properties

- High thermal conductivity, about 222-237 W/(m·K)

- Thermal expansion coefficient is 23.6 μm/m·K

- Melting point range between 646-657℃

Electrical Properties

- Electrical conductivity up to 57%-58% IACS

- Electrical resistivity of 0.0281 Ω·mm²/m (at 20℃)

Aluminium 1050 H24 Fabrication and Surface Characteristics

Aluminium 1050 H24 Corrosion Resistance

- Forms a dense aluminum oxide film on the surface to prevent further oxidation and corrosion

- Exhibits excellent corrosion resistance in fresh water, atmosphere, and many chemicals

- Can replace certain stainless steels in scenarios such as hydrochloric acid storage tanks and reactor linings

Aluminium 1050 H24 Workability

1050 H24 aluminum alloy has excellent workability:

Formability

- Supports various plastic forming processes such as stamping, bending, and stretching

- Retains certain ductility even in H24 temper

Weldability

- Excellent weldability, compatible with multiple welding methods

- No special heat treatment required after welding

Machinability

- Machinability is average, requiring sharp cutting tools

- Machinability can be improved by adding small amounts of alloying elements

Aluminium 1050 H24 Workability

1050 H24 aluminum alloy has excellent workability:

Formability

- Supports various plastic forming processes such as stamping, bending, and stretching

- Retains certain ductility even in H24 temper

Weldability

- Excellent weldability, compatible with multiple welding methods

- No special heat treatment required after welding

Machinability

- Machinability is average, requiring sharp cutting tools

- Machinability can be improved by adding small amounts of alloying elements

Aluminium 1050 H24 Surface Treatment Performance

- Good anodizing performance, forming a transparent and bright oxide film

- Suitable for painting, spraying, electroplating, and various other surface treatments

Applications of 1050 H24 Aluminum Alloy

Applications in the Electronics and Electrical Field

1050 H24 aluminum alloy has wide applications in the electronics and electrical industry:

Conductive Materials

- Used for wires, cables, and conductive connectors

- Manufacturing transformer strips, busbars, and conductive stranded wires

Electronic Heat Dissipation Applications

- Ideal material for electronic device heat sinks

- Used to manufacture computer CPU coolers and LED lighting heat dissipation components

Electronic Components

- Used in manufacturing capacitor foils and electronic shielding materials

- Printing circuit board substrates and PS plates

Applications in the Construction and Decoration Field

1050 H24 aluminum alloy also plays an important role in construction and decoration:

- Building structural components: used in roofs, walls, and partitions for non-load-bearing structural parts

- Decorative applications: after anodizing, the surface has high gloss, suitable for decorative panels

- Building accessories: making frames and trims for doors and windows, as well as signs and nameplates

Applications in the Chemical and Food Industry

1050 H24 aluminum alloy has unique advantages in the chemical and food industries:

- Chemical equipment: manufacturing hydrochloric acid storage tanks, reactor linings, and chemical pipelines

- Food and beverage industry: meets food hygiene standards, used for food packaging materials

- Pharmaceutical industry: used in pharmaceutical packaging and medical equipment, with no harmful substance leaching

Other Application Fields

Packaging Industry

- Aluminum foil products widely used in food, pharmaceutical, and cigarette packaging

- Used in the production of cans, bottle caps, and tubes as packaging containers

Daily Goods and Consumer Products

- Manufacturing cookware, tableware, and decorative items

- Lighting fixtures, signs, nameplates, and other functional products

Transportation Field

- Non-load-bearing components of automobiles, ships, and aircraft

- Heat exchangers and radiators for automobiles and ships

Advantages and Limitations of 1050 H24 Aluminum

Advantages of 1050 H24 Aluminum

- High purity, excellent electrical and thermal conductivity

- Good corrosion resistance

- Excellent workability

- Good weldability

- Low density and good specific strength

- Relatively low cost

Limitations of 1050 H24 Aluminum

- Relatively low strength

- Low hardness, limited wear resistance

- Limited high-temperature performance

- Average machinability

- Corrosion resistance in special environments is not as good as other alloys

Comparison of Aluminium 1050 H24 with Other Tempers

- H14 (semi-hard): Higher strength but lower ductility.

- O (annealed): Softer but with higher ductility.

| Comparison Items | Aluminium 1050 H24 | Aluminium 1050 H14 (semi-hard) | Aluminium 1050 O (annealed) |

| Processing Method | Cold-work hardened and partially annealed to balance strength and ductility. | Cold-work hardened but not annealed, leading to higher strength and lower ductility. | Fully annealed to achieve the softest state, providing maximum ductility. |

| Strength | Moderate; strength is between H14 and O temper, suitable for applications requiring both strength and workability. | Higher strength than H24; ideal for applications needing greater resistance to deformation. | Lowest strength but excellent flexibility, ideal for highly plastic forming processes. |

| Ductility | Good ductility, though slightly lower than O temper, allowing for bending and forming. | Lower ductility than H24, making it less suitable for large bends or deep drawing. | Highest ductility, ideal for complex stamping, bending, and deep drawing. |

| Suitable Applications | Suitable for applications requiring both moderate strength and good formability, such as architectural decoration, signage, and industrial uses. | Ideal for applications needing higher rigidity but not extreme forming properties, such as structural components and mechanical parts. | Best for applications requiring extreme plasticity, such as deep-drawn products and extrusion forming. |

| Typical Products | Aluminum sheets, coils, signs, architectural decorations, automotive interiors, etc. | Traffic signs, electronic device casings, architectural decorations, etc. | Deep-drawn products, aluminum foil, kitchenware, chemical storage tanks, etc. |

Comparison of Aluminium 1050 H24 with Related Alloys

- Compared with 1050A-H24: Nearly identical composition; slight differences in impurity limits (e.g., Zn ≤0.07% in 1050A).

- Compared with 1060: Similar performance; 1060 often substitutes 1050 in cost-sensitive applications.

- Strength Limitation: Lower than alloy grades (e.g., 6xxx/7xxx); not suitable for high-stress applications.

Standards and Certifications of Aluminium 1050 H24

- Mechanical Properties: ASTM B491, EN 485-2, ISO 6361-2.

- Dimensions: Thickness 0.2–8.0 mm; Width 100–2650 mm.

Processing and Forming Characteristics of Aluminium 1050 H24

- Formability: Excellent; H24 retains high ductility and bendability without cracking.

- Machinability: Poor — best suited for sheet/tread plate; use appropriate high-speed steel tools when cutting to avoid chip buildup.

- Bending Radius: Minimum approx. 1t (thickness) for 180° bend.

- Weldability: Excellent for TIG/MIG/gas-shielded/arc welding; use 1100 filler for same-series welding, Al4043/5356 for dissimilar alloys. Weld strength approx. 65 MPa. Avoid preheating above 110°C.

- Annealing: Not required; H24 is partially annealed. Full annealing can restore it to the softer O temper. No heat treatment required for hardening.

Aluminium 1050-H24 strikes a unique balance of formability, conductivity, and corrosion resistance, making it an ideal choice for electrical, construction, and consumer electronics applications.

Aluminium 1050 H24 combines the inherent advantages of high-purity aluminium alloys – excellent conductivity, corrosion resistance, and aesthetic appeal – with a temper that offers a balanced combination of strength and formability. Its predictable chemical composition and mechanical properties make it an ideal choice for industrial and decorative applications.

Products you may be interested in

- 1050 Aluminum Plate Sheet

- 1050 h14 aluminium sheet plate

- 1050 H18 Aluminium

- 1050 O Aluminum

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

Further reading

Users viewing this material also viewed the following

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

Recommended Content