1050 h14 aluminium sheet plate

1050 H14 aluminum alloy belongs to the 1000 series commercial pure aluminum, with an aluminum content of approximately 99.5%. This alloy cannot be strengthened through heat treatment; instead, its mechanical properties are mainly achieved through strain hardening generated by cold working. Among them, the H14 temper indicates a half-hard condition, representing a relatively ideal balance between strength and processability.

In the H14 temper, 1050 aluminum is typically formed by cold rolling without subsequent annealing. This process allows the material to maintain good ductility while achieving higher strength than the annealed (O temper) condition. Compared with the fully hardened H18 temper, H14 offers slightly lower strength but more favorable formability, enabling it to meet most conventional processing requirements.

Benefiting from the characteristics of high-purity aluminum, 1050 H14 aluminum alloy exhibits excellent corrosion resistance, good ductility, and high reflectivity, along with outstanding weldability. It is suitable for bending, stamping, and various forming processes. As a result, this material is widely used in chemical equipment, lighting systems, decorative components, and a variety of general industrial applications, making it a practical material that balances performance and cost.

In terms of product supply, 1050 H14 aluminum plate generally refers to industrial pure aluminum plates with a thickness of less than 6 mm. It can be supplied as cut-to-length sheets, coils, flat sheets, or embossed (stucco) sheets according to requirements, and can also be provided with protective film or surface coating treatments to meet the demands of different application environments.

1050 H14 Aluminium Product Specifications

- Thickness: 0.5–6.0 mm (common range).

- Sheet size: Up to 4000 x 2000 mm.

- Coating: PVC coating or stucco finish available to enhance durability.

- Certification: Ensures compliance with standards such as BS EN 485-2 or ASTM B491.

- Customization: Some suppliers offer custom sizes and coatings.

- Packaging: Typically packaged in pallets or shrink wrap for protection.

Characteristics of 1050 H14 Aluminum Sheet

Excellent Processing Adaptability

1050 H14 aluminum alloy sheet is a non-heat-treatable aluminum alloy that achieves its required properties through cold working. During actual processing, the material demonstrates stable performance and good controllability, whether in cutting, stamping, or various forming operations, allowing it to be flexibly applied in a wide range of manufacturing and fabrication scenarios.

Superior Anodizing Performance

After anodizing, the surface of 1050 H14 aluminum sheet exhibits uniform color, high smoothness, and a fine, high-quality appearance. The resulting oxide film not only provides good corrosion resistance but also offers high reflectivity, making it particularly suitable for applications with high requirements for surface quality and decorative effects.

High-Quality Reflective Properties

The alloy features high surface flatness and smoothness, giving it a clear advantage in reflective applications. For example, when used in lighting reflectors, it can effectively improve light reflection efficiency, thereby enhancing overall lighting performance and reducing energy consumption.

Reliable Weldability

1050 H14 aluminum alloy has good weldability and is suitable for gas welding, arc welding, brazing, and soldering. Under proper process conditions, the welded joints are strong and stable, meeting the requirements of different engineering structures and assembly applications.

Good Ductility and Formability

The material offers excellent ductility and is not prone to cracking during deep drawing, bending, and other forming processes. This characteristic ensures high processing efficiency and reliable performance across a wide range of industrial manufacturing environments.

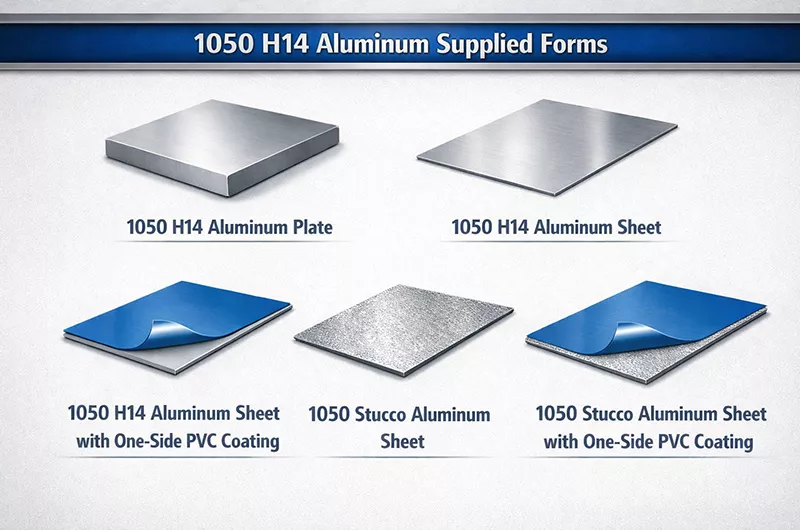

1050 H14 Aluminum Supplied Forms

1050 H14 Aluminum Plate

This form refers to thicker aluminum plates designed for applications where higher rigidity and durability are required. They are available in a wide range of thicknesses and dimensions to suit different industrial and structural needs.

1050 H14 Aluminum Sheet

1050 H14 aluminum sheets are flat-rolled products offering excellent formability and surface quality. They are commonly used across manufacturing, construction, and general industrial applications due to their versatility and ease of processing.

1050 H14 Aluminum Sheet with One-Side PVC Coating

These sheets feature a protective PVC film applied to one side of the surface. The coating helps prevent scratches and surface damage during handling, fabrication, and transportation, while also offering additional resistance to corrosion and environmental exposure.

1050 Stucco Aluminum Sheet

Stucco aluminum sheets are characterized by their embossed, textured surface. This pattern enhances impact resistance and visual appeal, making the material suitable for decorative applications as well as functional uses where surface durability is important.

1050 Stucco Aluminum Sheet with One-Side PVC Coating

Combining an embossed stucco finish with a one-side PVC protective film, this product offers both improved surface strength and enhanced protection. It is particularly well suited for applications that demand durability, surface protection, and a refined appearance.

1050 H14 Aluminum Sheet Hot Selling Size Table

| Thickness (in) | Width (in) | Length (in) | Notes |

| 0.080" 1050 H14 aluminum sheet | 12" | 24" | Standard sheet size |

| 0.100" 1050 H14 aluminum sheet | 24" | 48" | Standard sheet size |

| 0.125" 1050 H14 aluminum sheet | 48" | 144" | Standard sheet/plate |

| 0.160" 1050 H14 aluminum sheet | 12" | 24" | Standard sheet/plate |

| 0.190" 1050 H14 aluminum sheet | 24" | 48" | Standard sheet/plate |

| 0.250" 1050 H14 aluminum sheet | 48" | 144" | Standard plate |

| 0.313" 1050 H14 aluminum sheet | 12" | 24" | Standard plate |

| 0.375" 1050 H14 aluminum sheet | 24" | 48" | Standard plate |

| 0.500" 1050 H14 aluminum sheet | 24" | 48" | Standard plate |

| 0.625" 1050 H14 aluminum sheet | 12" | 24" | Standard plate |

| 0.750" 1050 H14 aluminum sheet | 24" | 48" | Standard plate |

1050 H14 Aluminium Alloy Designations

Aluminium 1050-H14; UNS A91050; NF A5 (France); DIN Al99.5; AA1050-H14, ASTM B491; BS 1B (UK); CSA 9950 (Canada); ASTM B491; Al1050-H14

1050 H14 Aluminium Chemical Composition

| Element | % Present |

| Cu | 0-0.05 |

| Mg | 0-0.05% |

| Si | 0-0.25% |

| Fe | 0-0.4% |

| Mn | 0-0.05% |

| Zn | 0-0.07% |

| Ti | 0-0.05% |

| Al | Balance |

1050 H14 Aluminium Mechanical Properties

(for sheet thicknesses from 0.2 mm to 6.00 mm)

| Property | Value |

| Tensile Strength | 105–145 MPa |

| Proof (Yield) Strength | Minimum 85 MPa |

| Elongation | Minimum 12% |

| Hardness | Approximately 34 HB |

Note: These values indicate moderate strength, suitable for general-purpose applications.

1050 H14 Aluminium Physical Properties

| Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | Approximately 650 °C |

| Modulus of Elasticity | About 71 GPa |

| Thermal Conductivity | Around 222 W/m·K |

| Thermal Expansion | 24 × 10⁻⁶ /K |

Note: High thermal conductivity and low density make it suitable for heat transfer and lightweight construction applications.

1050 H14 Aluminium Manufacture and Weldability

- Formability: Excellent cold working properties, suitable for deep drawing, bending, and shaping.

- Weldability: Rated excellent for gas welding, arc welding, and resistance welding; typical filler rods include 1100 for self-welding and 5356 or 4043 for welding other alloys.

- Brazing and Soldering: Also excellent.

- Machinability: Considered poor due to its softness, so forming is typically used instead of machining.

- Cold Working: Excellent formability for bending, rolling, and stamping.

- Welding: Suitable for TIG, MIG, and resistance welding. Recommended filler rods:

- 1100: For welding to similar alloys.

- 5356: For connecting 5xxx or 7xxx series alloys.

- Machining: Poor machinability due to softness; requires sharp tools and lubrication.

1050 H14 Aluminium Advantages and Limitations

1050 H14 Aluminium Advantages

| Advantages | Description |

| High corrosion resistance (ideal for marine/outdoor use) | 1050 H14 aluminum alloy has excellent corrosion resistance, making it perform well in marine and outdoor environments. Its natural aluminum oxide layer effectively resists saltwater and harsh weather conditions, widely used in the marine industry, shipbuilding, and outdoor equipment, ensuring stability and reliability over long-term use. |

| Reflective surface for decorative or functional purposes | The reflective surface characteristics of 1050 H14 aluminum alloy make it highly suitable for applications requiring high gloss and reflective effects. Its surface can reflect a significant amount of light, making it widely used in traffic signs, lighting fixtures, decorative panels, etc., providing both functionality and enhancing visual appeal. |

| Lightweight and durable | 1050 H14 aluminum alloy is lightweight but highly durable. Due to the low density of aluminum and its high strength, 1050 H14 maintains a lightweight while withstanding wear from daily use. It is suitable for applications that require weight control without compromising on durability, such as transportation equipment, structural frames, and electronic product enclosures. |

1050 H14 Aluminium Disadvantages

- Lower strength compared to heat-treatable alloys (e.g., 6082T6).

- Poor machinability, limiting precision applications.

1050 H14 Aluminium Applications

1050 H14 is suitable for various industries due to its reflective surface, weldability, and corrosion resistance:

- Construction: Roofing, cladding, waterproofing sheets, and decorative panels.

- Electrical: Light reflectors, heat exchangers, and conductive components.

- Consumer goods: Kitchenware, signage, and packaging materials.

- Industrial: Chemical equipment containers, heat sinks, signage, cable sheaths, etc.

- Civil applications: Household goods, decorative materials, electronic component enclosures, etc.

1050 H14 aluminum sheet is an economical and versatile material, ideal for applications requiring moderate strength, excellent corrosion resistance, and high formability. Although it is not heat treatable, its performance can be enhanced through cold working. The balance of its performance and cost makes it highly popular across industries, from chemical processing to construction.

1050 H14 aluminum sheet is the preferred material for applications where corrosion resistance, formability, and cost-effectiveness are prioritized. Its balance of mechanical properties and ease of fabrication makes it suitable for construction, industrial, and electrical uses.

Typical Applications of 1050 H14 Aluminum Sheet

- PS Aluminum CTP Printing Plates: In the printing industry, 1050 H14 aluminum alloy is used to produce PS (photosensitive) aluminum plates and CTP (computer-to-plate) printing plates. Its excellent surface finish and high reflective quality ensure superior print quality.

- Aluminum Composite Panels (ACP): 1050 H14 aluminum alloy is used as the outer layer material in aluminum composite panels. Its excellent machinability and corrosion resistance make it suitable for building facade decoration and other applications.

- Battery Soft Connectors: Due to its excellent conductivity and weldability, 1050 H14 aluminum alloy is widely used in battery soft connectors to ensure stable battery performance.

- Signage: The high reflective finish and excellent surface treatment of 1050 H14 aluminum alloy make it an ideal material for producing advertising signage.

- Lighting Reflectors: In the lighting industry, 1050 H14 aluminum alloy is commonly used to manufacture lighting reflectors, enhancing light reflection efficiency and lighting effects.

- Heat Exchangers: This aluminum alloy is used to manufacture heat exchanger components, utilizing its excellent thermal conductivity and corrosion resistance to improve heat dissipation.

- Cable Sheathing: Due to its excellent mechanical properties and corrosion resistance, 1050 H14 aluminum alloy is also used to produce cable sheathing, providing additional protection and durability.

Aluminium 1050 (EN AW-1050) H14 & H24

In practical applications, H14 and H24 are the two most common supply tempers for 1050 aluminum.

1050-H14

1050-H14 is a half-hard temper that obtains a certain level of strength through cold working.

In this temper, the material provides good rigidity and surface stability, but its formability is relatively limited, making it unsuitable for deep drawing or complex forming processes. It is commonly used in applications that require a certain degree of flatness and strength but involve relatively simple forming operations, such as decorative panels, signage, appliance housings, and light industrial components.

1050-H24

1050-H24 is a temper that has been strain-hardened and then partially annealed, achieving a better balance between strength and formability.

Compared with H14, H24 has slightly lower strength but greater flexibility, with improved bending and forming performance. It is more suitable for products that require a certain degree of deformation during processing. Typical applications include lighting reflectors, cable sheathing, decorative trims, and various enclosure-type products.

Comparison Between 1050 H14 and H24

| Item | 1050-H14 | 1050-H24 |

| Hardness | Higher | Medium |

| Strength | Higher | Medium |

| Formability | Average | Better |

| Deep Drawing Suitability | Limited | More Suitable |

Questions Related to 1050 H14 Aluminum

What is 1050A H14 grade aluminium?

1050A H14 is a specific type of aluminum alloy that combines the characteristics of 1050 aluminum with the H14 temper.

- 1050A: This alloy is a variation of 1050 aluminum, which is a commercially pure aluminum with a minimum of 99.5% aluminum content. The "A" indicates a slight modification in the alloy's composition, which can affect properties such as strength and workability.

- H14: This indicates the temper or hardness of the aluminum. H14 is a strain-hardened condition with a moderate increase in strength compared to the soft, annealed (O) state. The "14" signifies a specific level of hardness and strength in the H temper range.

What is H14 in aluminium?

H14 is a temper designation for aluminum. It refers to a strain-hardened condition where the aluminum has been cold worked to achieve a certain level of hardness and strength, but not as hard as H18 (fully hardened). H14 is used for applications requiring moderate strength and good formability.

What is aluminum 1050 grade?

Aluminum 1050 is a commercially pure aluminum grade with a minimum of 99.5% aluminum content. It is known for its excellent corrosion resistance, high thermal and electrical conductivity, and good workability. However, it has relatively low strength compared to other aluminum alloys.

What is the equivalent of Aluminium 1050?

- EN AW-1050 (European Standard)

- AA 1050 (American Society for Testing and Materials, ASTM)

- JIS A1050 (Japanese Industrial Standard)

Products you may be interested in

- 1050 Aluminum Plate Sheet

- Aluminium 1050 h24

- 1050 H18 Aluminium

- 1050 O Aluminum

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

Further reading

Users viewing this material also viewed the following

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

Recommended Content