1050 Aluminum Plate Sheet

1050 aluminum plate is a soft-textured, high-purity aluminum alloy sheet, belonging to the 1xxx series of commercially pure aluminum. With an aluminum content of no less than 99.5%, it exhibits outstanding corrosion resistance, electrical and thermal conductivity, as well as excellent ductility, making it highly favored in both industrial and decorative applications.

Thanks to its high-purity characteristics, 1050 aluminum plate offers good plasticity, making it easy to bend, stamp, and form. It is suitable for applications with high requirements for processing performance. At the same time, its surface has high reflectivity and a clean appearance, often used in products where both aesthetics and functionality are important. However, compared with other aluminum alloys, 1050 aluminum plate has relatively low mechanical strength and is therefore not suitable for load-bearing or structural applications, making it more appropriate for non-structural uses.

In terms of manufacturing process, 1050 aluminum alloy is a wrought alloy, typically processed into sheets through rolling or extrusion rather than casting. Its production process is mature and relatively simple, with a lower overall cost, making it one of the most widely used aluminum alloys in traditional industries. Its chemical composition and performance are similar to those of 1060 aluminum plate, and it is often considered a cost-effective choice in practical selection.

Due to its combination of excellent corrosion resistance, electrical conductivity, and formability, 1050 aluminum plate is widely used in chemical equipment, architectural decorative components, electrical conductors, and various products that require high purity and stability. Although this alloy cannot be strengthened through heat treatment, its strength can be moderately improved through cold working to meet diverse application requirements.

Aluminium 1050 Data Sheet

| Property | Value |

| Purity | ≥ 99.5% Al |

| Density | 2.71 g/cm³ |

| Tensile Strength | 100–145 MPa (H14) |

| Proof Stress | ≥ 85 MPa (H14) |

| Elongation | ≥ 12% |

| Conductivity | High (Thermal & Electrical) |

| Workability | Excellent (cold) |

| Machinability | Poor |

| Weldability | Excellent |

| Cost | Relatively low vs alloyed grades |

1050 Aluminum Plate Temper

1050 Aluminum Popular Tempers

1050 O Aluminum

- Temper: O indicates fully annealed (soft state), with the lowest hardness and excellent ductility.

- Features: Excellent plasticity and toughness, suitable for deep drawing, bending, and complex forming processes.

- Applications: Commonly used for products requiring complex forming, such as containers, utensils, signage, and deep-drawn parts.

1050 H14 Aluminum

- Temper: H14 indicates strain-hardened to a half-hard state.

- Features: Higher hardness than O temper, moderate strength while retaining good ductility.

- Applications: Suitable for applications requiring certain strength and partial formability, such as building decoration, appliance panels, signage, and automotive body panels.

1050 H24 Aluminum

- Temper: H24 indicates strain-hardened followed by low-temperature annealing, with hardness between H14 and H18.

- Features: Higher strength than H14, slightly lower formability, while still offering good plasticity and surface treatment performance.

1050 Aluminum Material Temper Options

1050 O Temper

- Features: Fully annealed, lowest strength, best plasticity

- Applications: Situations requiring deep drawing, stretching, and other complex processing

- Thickness range: 0.1-500mm

1050 H Temper

- H12/H22: Light strain hardening, relatively low strength

- H14/H24: Moderate strain hardening, medium strength

- H18/H19: Full strain hardening, high strength

- Applications: Situations requiring certain strength and hardness, such as structural and decorative components

1050 H32/H34 Temper

- Features: Strain hardened followed by low-temperature annealing, providing good strength and toughness

- Applications: Situations requiring high strength and certain toughness

1050 H112 Temper

- Features: Suitable for hot-worked products with specific mechanical property requirements

- Applications: Hot-rolled plates or products formed by thermal processing

1050 Aluminium Standards and Equivalent

1050 Aluminum complies with the following standards:

- ASTM: B209 (plate), B491 (tube).

- EN: 485-2 (mechanical properties), 573-3 (chemical composition).

1050 aluminum plate performs excellently in applications that require formability, corrosion resistance, and conductivity rather than strength. Its cost-effectiveness and versatility make it an ideal choice for sheet metal fabrication, reflectors, and containers. However, engineers must verify the choice of temper (e.g., H14 for medium strength, O for deep drawing) and consider protective coatings for use in abrasive environments.

Other names: AA1050A, Al99.5, A91050, UNS A91050, Aluminium 1050, AA1050, Al1050

1050 Aluminum Plate Sheet Surface Treatment Options

1050 Color Coated Aluminum Sheet

- Manufactured from high-purity 1050 aluminum, this color coated aluminum sheet features a durable organic paint finish that enhances appearance, color stability, and corrosion resistance.

- Building facades, signage, decorative panels, furniture, and interior decoration.

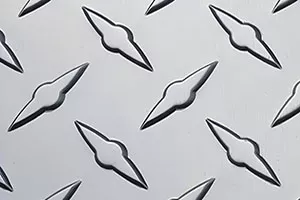

1050 Embossed Aluminum Plate

- 1050 embossed aluminum plate is processed with patterned or textured surfaces, improving surface strength, slip resistance, and visual appeal while maintaining lightweight properties.

- Flooring panels, elevator interiors, decorative walls, packaging, and protective applications.

Brushed 1050 Aluminum Plate

- Brushed 1050 aluminum plate is treated with fine abrasive brushing to create uniform linear textures, offering a clean, matte finish with a modern and refined look.

- Home appliance panels, elevator panels, furniture, and interior decorative projects.

Anodized 1050 Aluminum Plate

- Anodized 1050 aluminum plate undergoes an electrochemical oxidation process to form a dense protective oxide layer, enhancing corrosion resistance, surface hardness, and wear performance.

- Architectural panels, electronic enclosures, transportation components, and decorative aluminum products.

Polished 1050 Aluminum Plate

- Polished 1050 aluminum plate is finished through multi-step polishing to achieve a smooth and glossy surface, delivering strong visual appeal and easy maintenance.

- Decorative panels, signage, kitchenware, and selected automotive trim parts.

1050 Aluminum Mirror Sheet

- 1050 aluminum mirror sheet features a highly reflective, mirror-like surface produced through precision polishing, combining excellent aesthetics with lightweight aluminum performance.

- Interior decoration, signage, reflectors, commercial displays, and premium design elements.

Punched 1050 Aluminum Plate

- Punched 1050 aluminum plate is perforated with customized hole patterns to meet functional and decorative requirements, offering good airflow, weight reduction, and structural stability.

- Ventilation panels, decorative facades, filtration systems, and industrial components.

1050 Aluminum Plate Standard Size Range

Thickness Range

0.1-500mm

Covers a wide range from ultra-thin to extra-thick applications

Width Range

20-2650mm

Accommodates applications from narrow to wide formats

Length Range

500-16000mm

Extra-long sizes can be provided to meet special requirements

Common Thickness Specifications

| Type | Thickness Range | Application Fields | Common Stock Specifications |

| Thin Plate | 0.1-2.0mm | Packaging, decoration, electronics, etc. | 0.3mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm |

| Regular Plate | 2.0-6.0mm | General structural parts, signage, lighting, etc. | 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm |

| Medium Plate | 6.0-25.0mm | Structural parts requiring certain strength | 8.0mm, 10.0mm, 12.0mm, 15.0mm, 20.0mm |

| Thick Plate | 25-200mm | Special industrial applications | 25mm, 30mm, 40mm, 50mm, 100mm, 150mm |

| Extra Thick Plate | Over 200mm | Special engineering requirements | Custom production available |

1050 Aluminum Plate Dimensional Tolerance Standards

1050 Aluminum Plate Thickness Tolerance Standard (General Grade, Width ≤ 1000mm)

| Thickness Range (mm) | Permissible Tolerance (±mm) |

| ≤ 0.4 | ±0.02 |

| 0.4 < t ≤ 0.6 | ±0.03 |

| 0.6 < t ≤ 1.0 | ±0.04 |

| 1.0 < t ≤ 1.5 | ±0.05 |

Width Tolerance Standard (General Grade)

| Width Range (mm) | Permissible Tolerance (+mm) |

| ≤ 2000 | +6.0 |

| > 2000 | +12.0 |

Length Tolerance Standard (General Grade)

| Length Range (mm) | Permissible Tolerance (+mm or %) |

| ≤ 2000 | +6.0 |

| 2000 < L ≤ 3000 | +12.0 |

| > 3000 | +0.15% × L |

Flatness Tolerance Standard

| Thickness Range (mm) | Max Flatness Deviation (mm/m) |

| 0.2 – 0.5 | ≤ 15 |

| 0.5 – 3.0 | ≤ 10 |

| 3.0 – 6.0 | ≤ 8 |

1050 Aluminum Plate Sheet Color Options

Haomei 1050 Aluminum Alloy Product Forms

1050 Aluminum Sheet / Strip / Coil

1050 Aluminum Sheet

1050 Aluminum Sheet is lightweight and corrosion-resistant, with excellent formability and flexible processing. It is easy to cut, bend, and stamp. Widely used in building curtain walls, signage, lighting panels, and household appliance casings.

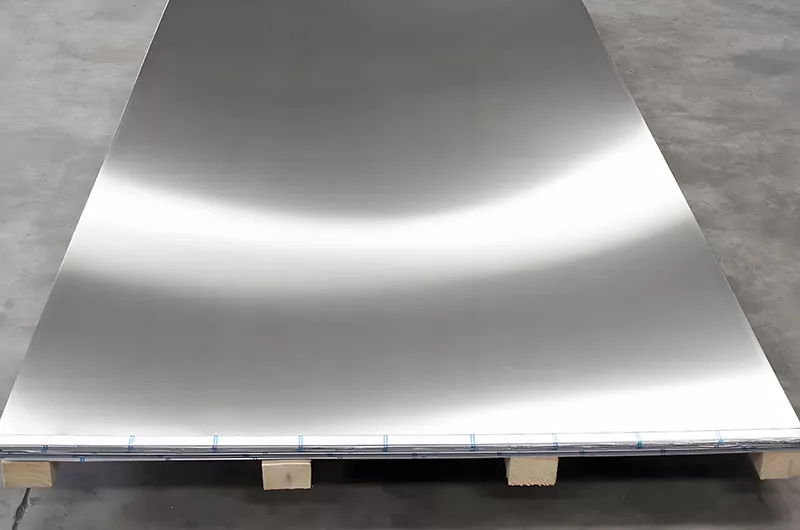

1050 Aluminum Plate

1050 Aluminum Plate features solid and durable thickness along with excellent corrosion resistance, suitable for bearing certain structural loads. Commonly used for industrial equipment enclosures, structural panels, and decorative guard plates, making it an ideal choice combining functionality and aesthetics.

1050 Aluminum Coil

1050 Aluminum Coil is available in O, H14, and H18 tempers, offering good rolling, stamping, and deep drawing performance. It is widely applied in roofing, exterior wall decoration, lighting panels, and household appliance components, providing both flexibility and durability.

1050 Aluminum Foil

1050 Aluminum Foil is made from high-purity aluminum, lightweight and corrosion-resistant, with excellent thermal conductivity and ductility. Suitable for various general industrial applications such as transformers, capacitors, insulation materials, and industrial packaging.

1050 Transformer Aluminum Foil

1050 Transformer Aluminum Foil has excellent electrical conductivity and stable mechanical strength, making it ideal for transformer windings. It ensures efficient energy transmission and maintains long-term reliability in both dry-type and oil-immersed transformers, making it a top choice for high-performance power equipment.

1050 Aluminum Foil for Insulation

1050 Aluminum Foil for Insulation features outstanding heat and reflective performance, while effectively blocking moisture and air. It is widely used in building insulation, pipe wrapping, and HVAC systems. Its high flexibility allows easy cutting and installation, closely fitting various surfaces to achieve efficient thermal and sound insulation.

1050 Industrial Aluminum Foil

1050 Industrial Aluminum Foil is designed for heavy-duty industrial applications, suitable for industrial packaging, protective linings, and component processing. It combines strength, corrosion resistance, and good machinability, meeting high manufacturing standards and providing reliable support for industrial production.

1050 Aluminum Circle Disc / Stamping Blanks

1050 Aluminum Circle Disc is lightweight, corrosion-resistant, with a smooth surface that is easy to cut and process. Suitable for various stamping and drawing processes, providing a reliable material base for cookware, lighting, reflectors, signage, and decorative parts.

1050 Aluminum Round Disc

1050 Aluminum Round Disc is made from high-purity aluminum with uniform thickness, ensuring stable performance during deep drawing and spinning processes. Widely used in cookware, lamp reflectors, signage, and various decorative parts, providing a reliable material for manufacturing high-quality components.

1050 Deep Drawing Aluminum Disc

1050 Deep Drawing Aluminum Disc has excellent ductility and stretchability, making it very suitable for deep drawing processes. Commonly used in the production of cookware, frying pans, lamp housings, and other precision-formed components, meeting high requirements for shape and accuracy.

1050 Mirror Aluminum Circle Disc

1050 Mirror Aluminum Circle Disc has a high-gloss polished surface, combining aesthetics with excellent reflectivity. Perfect for high-end lighting equipment, reflectors, cookware, signage, and decorative parts, enhancing product texture and visual appeal.

1050 Aluminum Strip and Busbar

1050 Aluminum Strip and Busbar combine high conductivity with good flexibility, suitable for conductive connections in electrical equipment. Whether used as busbars or aluminum strips, they ensure stable current transmission and long-term reliability.

1050 Aluminum Strip for Transformer Winding

1050 Aluminum Strip for Transformer Winding features high conductivity along with excellent ductility and flexibility. Perfect for dry-type and oil-immersed transformer winding processes, ensuring efficient energy transmission while maintaining long-term stable performance.

1050 Aluminum Busbar / Bus Bar

1050 Aluminum Busbar has excellent electrical conductivity and mechanical strength, widely used in distribution cabinets, switchgear, and various power connection systems. Its high flexibility and corrosion resistance ensure safe and reliable operation over time.

1050 Electrical Aluminum Strip

1050 Electrical Aluminum Strip features high conductivity and good formability, suitable for various electrical devices, transformers, capacitors, and industrial power transmission systems. Easy to process and stable in performance, making it an ideal choice for electrical applications.

1050 Aluminum Conductive Strip

1050 Aluminum Conductive Strip is characterized by high conductivity and excellent flexibility, adaptable to bending and complex wiring requirements. Widely used in power equipment, electrical connectors, and precision conductive applications, ensuring stable current transmission and long service life.

1050 Aluminum Deep-Processing & Custom Products

1050 Aluminum deep-processing and custom products are mostly manufactured according to customer drawings or specifications, meeting various industrial and manufacturing needs, combining precision, processability, and reliability.

1050 Aluminum Slitting Strip

1050 Aluminum Slitting Strip is precisely slit, with width and thickness customizable according to customer requirements. Suitable for industrial parts production, packaging materials, and electronic component manufacturing, ensuring accurate dimensions and easy subsequent processing and assembly.

1050 Aluminum Blanks

1050 Aluminum Blanks can be cut according to customer drawings or specifications, with uniform thickness and smooth surface. Widely used in stamping, drawing, and spinning processes, providing a reliable base material for cookware, lighting, and decorative parts production.

1050 Aluminum Stamping Parts

1050 Aluminum Stamping Parts can be customized according to customer design drawings, featuring good ductility and formability. Suitable for electronic device housings, appliance panels, and precision industrial parts production, meeting high-precision processing requirements.

1050 Aluminum Cutting Sheets

1050 Aluminum Cutting Sheets can be cut according to size and shape, with uniform thickness and easy processing. Commonly used in industrial manufacturing, building decoration, and electronics processing, ensuring efficient production and stable product quality.

1050 Aluminum Advantages

| Advantage | Description |

| Excellent Processing Performance | 1050 aluminum alloy features a soft texture and excellent ductility, providing stable performance during forming. It is particularly suitable for cold working processes such as spinning, bending, and drawing, while also allowing easy welding and ensuring high product consistency. |

| Outstanding Corrosion Resistance | With a high aluminum content, the material naturally forms a dense oxide film on the surface, offering strong resistance to oxidation and corrosion in atmospheric and freshwater environments. This results in a long service life and low maintenance costs. |

| Superior Electrical & Thermal Conductivity | Among aluminum alloy series, 1050 alloy ranks high in both electrical and thermal conductivity, making it ideal for applications that require efficient electrical conduction or heat dissipation. |

| Strong Weldability | Suitable for various common welding methods, including gas welding, atomic hydrogen welding, and resistance welding. The welds are stable and less prone to cracking, making the material well-suited for continuous and mass production. |

1050 Aluminum Plate Fabrication

- High plasticity, easy for stamping, bending, deep drawing, and other forming processes

- Not heat-treatable for strengthening; properties can only be adjusted through cold working or annealing

- Cold workability: Excellent

- Weldability: Excellent (gas, arc, resistance welding)

- Brazability/Weldability: Excellent

- Machinability: Poor (due to softness)

Welding Tips:

- Welding similar/alloy group: Use filler material 1100

- Welding 5083/5086/7xxx series: Use 5356

- Others: 4043 is recommended

Its simple production process and excellent formability make 1050 aluminum plate a cost-effective solution across a wide range of industries.

- Cold workability: Excellent, suitable for deep drawing, spinning, and bending.

- Mechanical machinability: Poor due to softness, but can be improved through cold working.

| Process | Rating |

| Workability - Cold | Excellent |

| Machinability | Poor |

| Weldability - Gas | Excellent |

| Weldability - Arc | Excellent |

| Weldability - Resistance | Excellent |

| Brazability | Excellent |

| Solderability | Excellent |

1050 Aluminum Plate Features

- High Purity: 1050 aluminum contains 99.5% aluminum, making it one of the purest forms of aluminum available.

- Corrosion Resistance: This alloy has excellent corrosion resistance, making it ideal for use in harsh environments, particularly in marine and chemical industries.

- Formability: 1050 aluminum is easy to manufacture, weld, and process, suitable for various manufacturing processes such as extrusion, forming, and stamping.

- Thermal and Electrical Conductivity: It has good thermal and electrical conductivity, suitable for applications such as conductors and heat exchangers.

- Not Heat Treatable: 1050 aluminum cannot be heat-treated to increase strength but can be hardened through work hardening processes.

- Strength: 1050 aluminum has moderate tensile strength, lower than alloys like 7075 or 2024, but still sufficient for many applications.

Haomei 1050 Aluminum Plate Sheet Popular Products

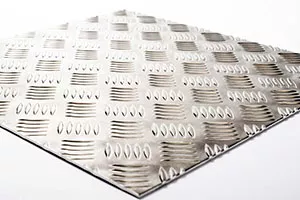

1050 Aluminum Tread Checkered Plate

The 1050 aluminum tread checkered plate is used in flooring, stair treads, and as a protective covering for surfaces.

1050 Sublimation Aluminum Sheet

The 1050 sublimation aluminum sheet is used in customized signage, photo panels, and other printed decorative elements.

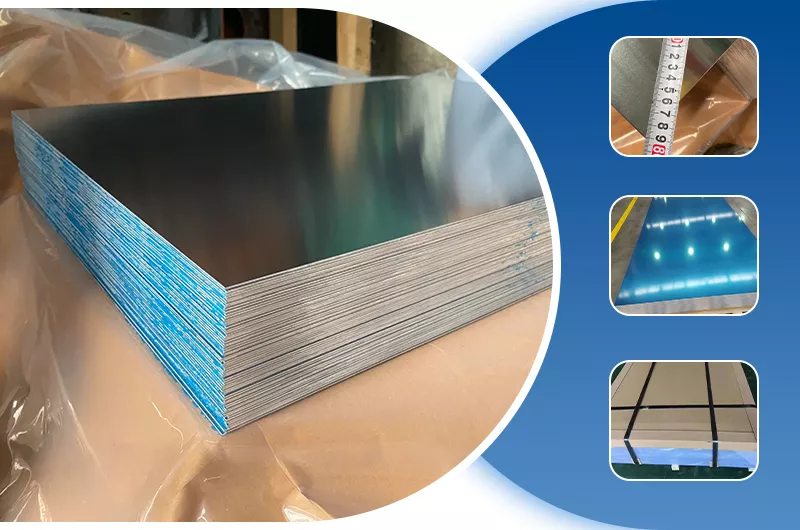

1050 Plain Aluminum Sheets

1050 aluminum sheets are widely used in industrial fields due to their excellent weldability and good machinability.

1050 Aluminum Diamond Plate

The 1050 aluminum diamond plate has anti-slip properties and is widely used on floors and the surfaces of vehicles.

Orange Peel 1050 Aluminum Plate

The 1050 orange peel aluminum plate has a texture similar to orange peel on the surface, creating a unique visual effect, suitable for decorative applications and high-end products.

1050 Aluminum Plate for Curtain Wall

Specifically designed for curtain wall decoration, featuring lightweight, high strength, corrosion resistance, and excellent surface finish options such as coating, anodizing, brushing, or color finishing. Suitable for large building facades and interior decoration.

1050 Anti-Slip Aluminum Plate

Surface treated with embossing, raised patterns, or anti-slip textures to increase friction. Ideal for stairs, ramps, industrial platforms, or flooring. Wear-resistant, corrosion-resistant, and highly safe.

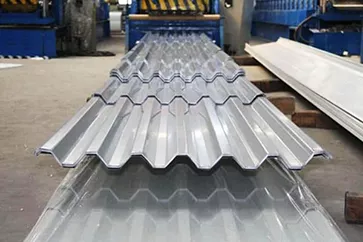

1050 Corrugated Aluminum Plate

Corrugated processing improves rigidity and load-bearing capacity. Commonly used for roofing, wall cladding, or transportation equipment. Lightweight, durable, and corrosion-resistant.

1050 Anti-corrosion Insulation Aluminum Coil

Used in electrical, air conditioning, and refrigeration systems for insulation and corrosion protection. Typically anodized or coated to enhance corrosion resistance and insulation performance. Coil form allows easy processing and installation.

1050 PCB Aluminum Entry Sheet

Used as a thermal conductive substrate or base for printed circuit boards (PCB) and electronic products. Offers excellent thermal conductivity, dimensional stability, and processability. Suitable for LED heat sinks, power modules, and other electronics applications.

1050 Aluminum Sheet for Power Battery Shell

Specifically used for power battery shells or battery pack frames. Features high strength, lightweight, corrosion resistance, and excellent formability. Suitable for electric vehicles and energy storage system battery packs.

1050 Automotive Insulation Aluminum Sheet Coil

Used for automotive insulation, soundproofing, and heat dissipation. Coil form facilitates processing into interior components or car body insulation layers. Lightweight, corrosion-resistant, with good thermal or insulating performance.

1050 Aluminum Plate Chemical Composition

| Element | % Present |

| Manganese (Mn) | 0.0 - 0.05 |

| Iron (Fe) | 0.0 - 0.40 |

| Copper (Cu) | 0.0 - 0.05 |

| Magnesium (Mg) | 0.0 - 0.05 |

| Silicon (Si) | 0.0 - 0.25 |

| Zinc (Zn) | 0.0 - 0.07 |

| Titanium (Ti) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

Mechanical Properties of 1050 Aluminum Sheet

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation |

| Thickness(mm) | (MPa) | (MPa) | (%) | |

| 1050-O/ 1050-H111 | 0.2-0.5 | 65-95 | Min20 | Min20 |

| 0.5-1.5 | Min22 | |||

| 1.5-3.0 | Min26 | |||

| 3.0-6.0 | Min29 | |||

| 6.0-12.5 | Min35 | |||

| 12.5-80.0 | ||||

| 1050-H112 | 6.0-12.5 | Min75 | Min30 | Min20 |

| 12.5-80.0 | Min70 | Min25 | ||

| 1050-H12 | 0.2-0.5 | 85-125 | Min65 | Min2 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min7 | |||

| 6.0-12.5 | Min9 | |||

| 12.5-40.0 | ||||

| 1050-H14 | 0.2-1.5 | 105-145 | Min85 | Min2 |

| 1.5-3.0 | Min4 | |||

| 3.0-6.0 | Min5 | |||

| 6.0-12.5 | Min6 | |||

| 12.5-25 | ||||

| 1050-H16 | 0.2-0.5 | 120-160 | Min100 | Min1 |

| 0.5-1.5 | Min2 | |||

| 1.5-4.0 | Min3 | |||

| 1050-H18 | 0.2-0.5 | Min135 | Min120 | Min1 |

| 0.5-1.5 | Min140 | Min2 | ||

| 1.5-3.0 | Min2 | |||

| 1050-H19 | 0.2-0.5 | Min155 | Min140 | Min1 |

| 0.5-1.5 | Min150 | Min130 | ||

| 1.5-3.0 | ||||

| 1050-H22 | 0.2-0.5 | 85-125 | Min55 | Min4 |

| 0.5-1.5 | Min5 | |||

| 1.5-3.0 | Min6 | |||

| 3.0-6.0 | Min11 | |||

| 6.0-12.5 | Min12 | |||

| 1050-H24 | 0.2-0.5 | 105-145 | Min75 | Min3 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min8 | |||

| 6.0-12.5 | ||||

| 1050-H26 | 0.2-0.5 | 120-160 | Min90 | Min2 |

| 0.5-1.5 | Min3 | |||

| 1.5-4.0 | Min4 | |||

| 1050-H28 | 0.2-0.5 | Min140 | Min110 | Min2 |

| 0.5-1.5 | ||||

| 1.5-3.0 | Min3 |

1050 Aluminum Plate General Physical Properties

| Physical Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x 10-6/K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 222 W/m.K |

| Electrical Resistivity | 0.0282 x 10-6 Ω .m |

1050 Aluminum Weldability

When welding 1050 to itself or to alloys from the same subgroup, 1100 filler wire is recommended. For welding alloys 5083 and 5086 or alloys from the 7XXX series, 5356 filler wire is recommended. For other alloys, use 4043 filler wire.

1050 Aluminum Plate Applications

Main Applications of 1050 Aluminum Plate

Due to its excellent corrosion resistance, ductility, reflectivity, and conductivity (but limited strength), this alloy is widely used in:

| Industry | Typical Applications |

| Electronics/Electrical | Heat sinks, capacitor housings, conductive components, LED substrates |

| Chemical Equipment | Corrosion-resistant containers, storage tanks, pipelines, heat exchangers |

| Consumer Goods/Architecture | Lamp reflectors, cookware, decorative panels, signage, anti-slip tread plates |

| Packaging | Food containers, foil materials (requires surface treatment) |

These diverse applications highlight the alloy's versatility and reliability in both industrial and decorative environments.

| Application | Description |

| 1050 Aluminum Plate for Electric Heater Enclosures | 1050 aluminum plate, with its lightweight and corrosion-resistant properties, is an ideal choice for manufacturing electric heater enclosures. Its excellent mechanical properties ensure long-lasting use of the electric heater enclosures, while being able to withstand high-temperature environments, effectively enhancing the durability and efficiency of the equipment. |

| 1050 H24 Aluminum Plate for Ducts | 1050 H24 aluminum plate, with its outstanding thermal conductivity, effectively transfers heat and facilitates air circulation in air duct systems. It is widely used in ventilation and air conditioning systems, ensuring efficient heat exchange during the operation of the equipment. |

| 1050 H12 Aluminum Plate for License Plates | 1050 H12 aluminum plate, known for its high durability and wear resistance, is an ideal material for making license plates. Its corrosion resistance ensures long-term use in various weather conditions, while providing sufficient toughness and durability, ensuring the stability of the license plate after prolonged use. |

| 1050 Insulation Aluminum Plate | 1050 insulation aluminum plate provides excellent thermal insulation due to its high reflectivity and low thermal conductivity. This makes it an ideal material for thermal insulation applications, widely used in construction, equipment, and transportation fields to reduce energy loss and improve energy efficiency. |

| 1050 CTP Plate/Printing Plate Aluminum | 1050 CTP plate aluminum features a smooth surface and excellent machinability, making it highly suitable for the production of computer-to-plate (CTP) printing plates. It ensures the stability and high precision of the printing quality, making it an indispensable material in the printing industry. |

| 1050 Patterned Aluminum Plate | 1050 patterned aluminum plate, with its anti-slip surface and exceptional durability, is commonly used for flooring and other applications that require a robust tread pattern. Its anti-slip properties enhance safety and it is widely used in transportation, industrial equipment, and construction projects. |

| 1050 Busbar Aluminum Plate | 1050 busbar aluminum plate, with its excellent electrical conductivity and corrosion resistance, is an ideal material for busbar systems. It maintains stable performance in high-current transmission environments while effectively resisting corrosion from external conditions, thereby extending the lifespan of the power system. |

| 1050 Aluminum Plate for Hoses | 1050 aluminum plate, due to its lightweight and flexibility, is suitable for manufacturing durable and high-performance hoses. This aluminum plate is particularly important in industrial and automotive applications, offering strength while maintaining good flexibility and durability. |

Common Specifications in 1050 Aluminum Applications

Application in the Electronics and Electrical Field

1050 aluminum plate is widely used in electronics and electrical fields due to its excellent conductivity and corrosion resistance:

Lithium Battery Components

Soft connection aluminum plate: Thickness 0.2-0.5mm

Tab material: Thickness 0.1-0.3mm

Explosion-proof valve: Thickness 0.3-1.0mm

Material temper: O or H14

Electrical Equipment

Busbar: Thickness 3.0-10.0mm, Width 20-200mm

Transformer aluminum strip: Thickness 0.2-3.0mm, Width 20-1650mm

Cable tray: Thickness 1.0-3.0mm

Electronic Components

Heat sinks: Thickness 1.0-3.0mm

PCB substrate: Thickness 0.5-2.0mm

PS/CTP plate base: Thickness 0.14-0.4mm

Application in the Construction and Decoration Field

1050 aluminum plate is mainly used in this field for its aesthetic, corrosion resistance, and formability:

Curtain Wall Projects

Solid aluminum panels: Thickness 1.5-5.0mm, Common sizes 600×600mm, 600×1200mm

Aluminum composite panels: Skin thickness 0.12-0.50mm (total thickness 3-4mm)

Decorative strips: Thickness 1.0-3.0mm

Roof and Wall Applications

Corrugated aluminum plate: Thickness 0.3-1.5mm, Models YX35-125-750, YX23-210-840, etc.

Aluminum tiles: Thickness 0.3-1.5mm

Insulation aluminum coil: Thickness 0.3-3.0mm, Width 600-2000mm

Interior Decoration

Ceiling panels: Thickness 0.8-1.5mm, Common sizes 600×600mm, 600×1200mm

Decorative panels: Thickness 1.0-3.0mm, can be carved, embossed, etc.

Screens and partitions: Thickness 1.5-3.0mm

Application in the Packaging Field

The application of 1050 aluminum plate in the packaging field mainly utilizes its corrosion resistance, workability, and lightweight characteristics:

Food Packaging

Aluminum foil: Thickness 0.009-0.23mm, Width 3-1800mm

Bottle cap material: Thickness 0.2-0.5mm

Tube packaging: Thickness 0.1-0.3mm

Industrial Product Packaging

Aluminum coil: Thickness 0.2-1.0mm, Width 600-1500mm

Transport packaging: Thickness 0.5-2.0mm

Equipment protection cover: Thickness 1.0-3.0mm

Pharmaceutical Packaging

Pharmaceutical aluminum foil: Thickness 0.02-0.05mm

Medicine boxes: Thickness 0.1-0.3mm

Medical device packaging: Thickness 0.2-0.5mm

Application in the Transportation Field

The application of 1050 aluminum plate in transportation mainly focuses on its lightweight and corrosion resistance:

Automobile Manufacturing

Car body panels: Thickness 0.8-1.5mm

Engine heat shields: Thickness 0.5-1.5mm

Interior decorative parts: Thickness 0.5-2.0mm

Shipbuilding

Interior ship fittings: Thickness 1.0-3.0mm

Ship hull: Thickness 2.0-5.0mm

Ship accessories: Thickness 1.0-5.0mm

Railway Vehicles

Interior car decorations: Thickness 0.8-1.5mm

Structural vehicle parts: Thickness 1.5-3.0mm

Train nameplates: Thickness 0.5-1.0mm

Application in Daily Use and Other Fields

Daily Necessities

Tableware: Thickness 0.5-1.5mm

Cookware: Thickness 0.8-3.0mm

Decorative items: Thickness 0.3-2.0mm

Lighting Equipment

Lamp reflectors: Thickness 0.3-1.0mm

Lampshades: Thickness 0.5-2.0mm

Lightboxes: Thickness 1.0-3.0mm

Advertising Signage

Signs: Thickness 0.5-3.0mm

Nameplates: Thickness 0.3-1.0mm

Display racks: Thickness 1.0-3.0mm

Factors Affecting 1050 Aluminum Price

Raw Material Cost

Fluctuations in aluminum ingot prices are a major influencing factor

The price of 1050 aluminum plate is usually 2000-5000 CNY/ton higher than pure aluminum ingots

Specification Factors

Thinner or thicker plates are priced higher

Wider widths result in higher prices

Special sizes (e.g., extra-wide, extra-long) are more expensive

Processing Technology

Surface treatments (anodizing, spraying, etc.) increase cost

Special processing (embossing, punching, etc.) increases cost

High precision requirements increase cost

Purchase Volume

Bulk purchasing generally results in better pricing

Small-batch purchasing tends to be more expensive

1050 Aluminum Plate Selection Guide

Electronics and Electrical Field

Prioritize high purity (above 99.7%) 1050 aluminum plates

Pay attention to conductivity and surface quality

Select appropriate thickness and temper based on specific application

Construction and Decoration Field

Focus on surface treatment quality and weather resistance

Choose suitable thickness based on usage environment

For outdoor applications, PVDF coated surfaces are recommended

Packaging Field

Pay attention to material cleanliness and surface quality

Choose proper thickness and temper according to packaging requirements

Food packaging must comply with relevant hygiene standards

Transportation Field

Focus on lightweight and corrosion resistance

Select appropriate thickness and temper according to structural needs

For automotive applications, consider composite use with other materials

1050 Aluminum Limitations

- Low mechanical strength — not suitable for load-bearing structural applications

- Poor machinability — tooling wears quickly; requires low-speed machining

1050 Aluminum vs. Other Pure Aluminum Grades

- 1050 vs 1060: Similar composition (1060 contains ≥99.6% aluminum), comparable performance; 1050 is more widely used due to cost advantage

- 1050 vs 1100: 1100 contains a small amount of copper, offering slightly higher strength but slightly lower corrosion resistance than 1050

1050 Aluminum Comparison with Similar Alloys

| Alloy | Strength (MPa) | Conductivity (% IACS) | Primary Use |

| 1050 | 75–110 | 61–63 | Forming, reflectors |

| 1060 | 70–105 | 61–62 | Electrical components |

| 1100 | 90–120 | 59–62 | General fabrication |

| 3003 | 110–145 | 40–50 | Cookware, pressure vessels. |

1050 Aluminum Plate Packaging and Transportation

- Packaging Handling: 1050 aluminum plates are coated to ensure the surface remains scratch-free.

- Transportation Packaging: The plates are packaged in plastic bags or kraft paper and placed with desiccants to keep them clean and dry.

- Transportation Conditions: During shipping, use enclosed containers, ship holds, or open vehicles, and cover with rain and snow-proof tarps to prevent water, rain, or snow from entering.

- Wooden Pallets and Reinforcement: Use wooden pallets and secure with steel bands to avoid collisions during transportation and maintain the geometric shape of the plates.

- Export Packaging: Export products are packed in wooden crates or racks, with fumigation marks and certification provided.

- Special Requirements: Packaging is done according to other customer requirements. During transport, if rain covers are added, ensure they prevent water ingress due to weather, and avoid jolting during loading and unloading to ensure the safe delivery of the aluminum plates to the user.

1050 Aluminum Anti-Oxidation Guide

Although 1050 aluminum coils are corrosion-resistant, when the aluminum coils are placed in water or rain, the surface is easily oxidized, resulting in spots on the surface, which affects the use of customers. Therefore, the storage environment of aluminum coils is very important. Here we give you the following suggestions:

- The storage environment of 1050 aluminum plates should be dry, bright, well-ventilated, and non-corrosive.

- Aluminum coils 1050 should be kept away from leakage in rainy and snowy weather as much as possible.

- Strengthen the management of rolling oil, and control its water content below 0.4%.

- Aluminum coils should be sealed, and an appropriate amount of desiccant should be placed in each coil.

- When transporting from a low-temperature area to a high-temperature and high-humidity area, do not open the sealed packaging of 1050 aluminum coils immediately.

- The humidity of the wooden shaft and wooden board of the packaging box shall not exceed 18%, and the temperature of the packaged color aluminum coil shall not exceed 45°C.

1050 Aluminum Related questions

What is a 1050 grade aluminum?

A 1050 grade aluminum refers to a specific alloy with aluminum as its primary component and 99.5% purity.

What is the difference between 1100 and 1050 aluminium?

The main difference between 1100 and 1050 aluminum lies in their chemical composition, with 1100 containing a small amount of copper, while 1050 is pure aluminum.

What is the difference between 1050 and 3003 aluminum?

The difference between 1050 and 3003 aluminum lies in their alloy composition, with 3003 containing manganese as an alloying element, imparting improved strength and corrosion resistance compared to 1050.

Products you may be interested in

- 1050 h14 aluminium sheet plate

- Aluminium 1050 h24

- 1050 H18 Aluminium

- 1050 O Aluminum

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

Further reading

Users viewing this material also viewed the following

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

Recommended Content