1050 Aluminum Disc Circle

What is 1050 Aluminum Disc

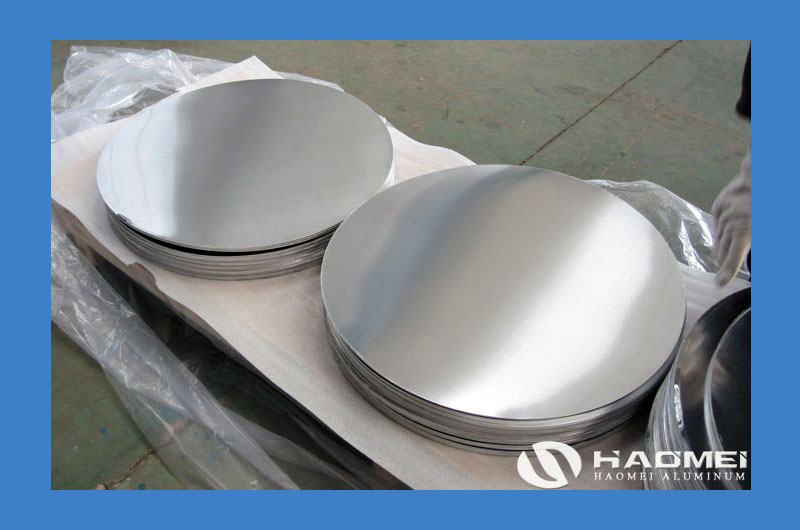

1050 aluminum disc is a circular sheet material made from 1050 aluminum alloy (commercially pure aluminum), known for its high purity, excellent processing performance, and wide range of applications.

With high purity, easy formability, and stable comprehensive performance, 1050 aluminum disc is a common material used in electronics, packaging, construction, and other fields. When selecting, it's important to match the temper (H12/H24, etc.) with the application scenario (conductivity/corrosion resistance/formability), and to consider 1060 alloy first for high-conductivity requirements.

- Bright and attractive surface, suitable for various surface treatments

- Low density, good plasticity, easy to process and form

- Excellent stamping and spinning performance in deep processing

- Outstanding corrosion resistance, naturally forming a dense aluminum oxide film on the surface

This alloy offers excellent corrosion resistance, high thermal and electrical conductivity, superior deep drawing ability, and good formability, making it suitable for various applications.

1050 aluminum disc is renowned for its extremely high aluminum content and strong market demand, making it one of the most widely used aluminum alloys. Additionally, its relatively affordable price makes it a cost-effective choice for many applications.

1050 aluminum disc also has excellent cold working formability, with an elongation rate of 35% to 38%, offering excellent stability and ductility. Due to their softness, these discs are especially suitable for applications requiring high plasticity, making them ideal materials for manufacturing various products.

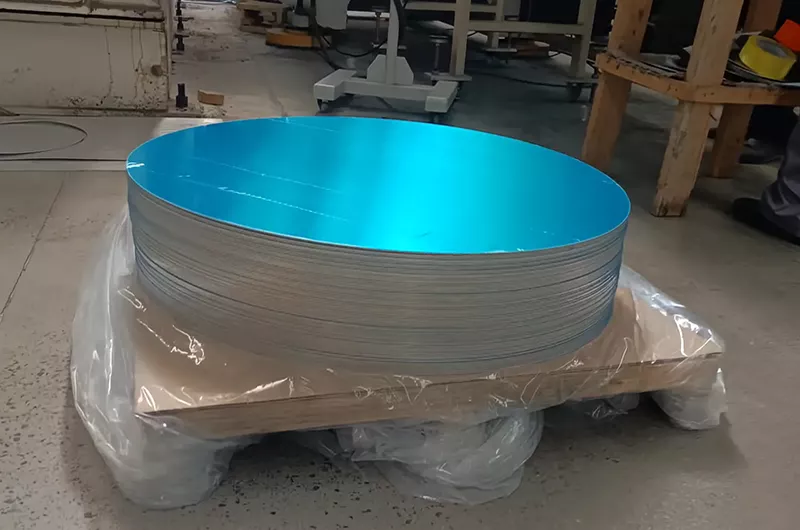

Haomei Aluminum is committed to providing the highest quality products. Our 1050 aluminum discs are subjected to strict quality control to ensure they meet the highest standards. We offer products in various sizes and thicknesses, ensuring the perfect circular product for your specific needs.

1050 Aluminum Disc Specifications

| Product | 1050 Aluminum Discs |

| Alloy | 1050 |

| Temper | O, H12, H14, H18, and H24 |

| Thickness | 0.5 mm to 6.0 mm |

| Diameter | 100 mm to 1200 mm |

| Delivery Time | Within 30-45 days after receiving the deposit |

| Packaging | Standard export wooden pallets or as per customer requirements |

| Material | Made using high-tech machinery and quality aluminum coils. Customizable according to customer requirements and specifications, offering different technical standards. |

| Surface | Bright and smooth surface, free from white rust, oil stains, edge damage, and other defects. |

| Application | Aluminum discs are used for reflective signs, road facilities, cookware, saucepan bases, kitchen utensils, non-stick pans, and more. |

Diameter Specifications of 1050 Aluminum Circle

The diameter range of 1050 aluminum discs is very wide and mainly determined by the requirements of different applications:

- Small Diameter 1050 Aluminum Circle : 10mm to 160mm, mainly used for small electronic components, precision instruments, etc.

- Medium Diameter 1050 Aluminum Circle : 100mm to 1250mm, widely used in cookware, lighting, traffic signs, etc.

- Large Diameter 1050 Aluminum Circle : Up to 1500mm, mainly used for special industrial purposes

Thickness Specifications of 1050 Aluminum Circle

The thickness specifications of 1050 aluminum discs are also diversified:

- Thin Sheet : 0.2mm to 2.0mm, mainly used in electronics, decoration, and other fields

- Medium Plate : 2.0mm to 6.0mm, widely used in cookware, home appliances, and other industries

- Thick Plate : 6.0mm to 10.0mm, suitable for applications with higher strength requirements

1050 Aluminum Disc Circle Different Tempers

| Temper | Main Characteristics |

| O Temper | Softest, best plasticity |

| H12 Temper | Slightly hardened, moderate plasticity |

| H14 Temper | Semi-hard, good overall performance |

| H18 Temper | Hardest, highest strength |

The hardness of 1050 aluminum disc mainly depends on its temper, ranging from O temper to H18 temper, with increasing hardness:

Low Hardness (O Temper)

Suitable for processing techniques that require large deformation, such as deep drawing and spinning

Medium Hardness (H14 Temper)

Suitable for general stamping, bending, and other forming processes

High Hardness (H18 Temper)

Suitable for applications requiring high dimensional stability, but more difficult to process

1050 Aluminum Disc Circle Surface Treatments

Various surface treatments can be applied, such as anodizing, spraying, electroplating, etc., to enhance decorative effects and corrosion resistance.

| Product Name | Description |

| 1050 Anodized Aluminum Discs | 1050 anodized aluminum discs form a durable oxide film through electrochemical treatment, enhancing surface hardness and corrosion resistance. At the same time, they offer a variety of color options, making them not only highly durable but also suitable for decorative and aesthetic needs. They are widely used in electronics, decoration, and mechanical component fields. |

| 1050 Color Coated Aluminum Discs | 1050 color coated aluminum discs are covered with a high-quality colored coating on the surface, providing a variety of colors along with excellent UV resistance and weather durability. They are suitable for outdoor and decorative applications, effectively preventing oxidation and corrosion, thereby extending the product’s service life. |

| Mill Finish 1050 Aluminum Discs | 1050 mill finish aluminum discs retain the original natural metallic luster of the aluminum material, with no additional surface treatment. They have good electrical conductivity and thermal conductivity, suitable for industrial uses that require further processing or surface treatment. Additionally, they are relatively cost-effective and widely used in manufacturing and processing industries. |

Features of 1050 Aluminum Discs

Spinning Quality

Due to its excellent spinning performance, 1050 aluminum discs show outstanding results in processing and are suitable for producing products that require spinning, such as cookware and tableware.

Flexibility and Corrosion Resistance

1050 aluminum discs exhibit excellent flexibility and corrosion resistance, ensuring long-lasting durability in various environments.

Electrical and Thermal Conductivity

This aluminum alloy has good electrical and thermal conductivity, making it suitable for applications requiring high electrical conductivity or heat dissipation.

Anodizing Performance

After anodizing, 1050 aluminum discs rarely discolor, which not only enhances their durability but also increases their aesthetic appeal.

Excellent Reflectivity

The surface of this material has excellent reflectivity, making it especially suitable for polishing, and thus an ideal choice for producing high-gloss products.

Pearlescent Anodizing Effect

After anodizing, 1050 aluminum discs can achieve an outstanding pearlescent effect, enhancing the visual appeal of the product.

1050 Aluminum Disc Circle CC/DC

1050 aluminum circles are usually supplied in either “CC” (Continuous Casting) or “DC” (Direct Chill Casting) form. The choice between CC and DC is crucial, as they differ significantly in physical properties and price.

Comparison of CC vs. DC 1050 Aluminum Circles

| Performance Index | 1050 CC | 1050 DC | Impact |

| Deep Drawing Performance | Relatively poor, not suitable for deep drawing | Excellent, suitable for complex deep drawing | DC can be used for deep-drawn cookware, while CC is mostly used for standard cookware |

| Surface Quality | Average | Good, no color difference after anodizing | DC is suitable for products requiring high surface quality |

| Elongation | Lower | Higher, better plasticity | DC has stronger fracture resistance and a wider processing range |

| Mechanical Strength | Relatively lower | Higher and more stable performance | DC products have a longer service life and are less prone to deformation |

| Anodizing Effect | Average | Excellent, with a uniform oxide film | DC is suitable for anodizing and other surface treatment processes |

1050 Aluminum Circle CC / DC Price and Application Scenarios

Price: 1050 CC aluminum circles are usually cheaper than 1050 DC aluminum circles, as the production process is simpler and the cost is lower.

Application Scenarios:

- 1050 CC: Suitable for standard cookware (such as shallow-drawn pots and baking trays), decorative parts, and simple stamped components where deep drawing performance and surface quality requirements are not high.

- 1050 DC: Suitable for deep-drawn cookware (such as pressure cookers and deep pots), spun parts, high-quality anodized products, and components requiring higher strength and durability.

1050 Aluminum Circle CC / DC: Which One Should You Choose?

- If deep drawing, spinning, or high-quality surface treatment is required: prioritize 1050 DC aluminum circles.

- If the budget is limited and processing performance requirements are not high: 1050 CC aluminum circles are a more cost-effective choice.

Both types are based on 1050 aluminum alloy (aluminum content ≥99.5%), featuring good corrosion resistance, electrical conductivity, thermal conductivity, and workability. The main supply temper is O temper (soft), which is convenient for subsequent processing.

- If cost is your primary concern, such as for making flat lids, shallow trays, or basic lighting reflectors, choose CC.

- If you produce high-quality cookware, kettles, or any products requiring “deep drawing” (depth greater than 10–15 cm) or a premium polished/anodized appearance, choose DC.

1050 Aluminum Disc Circle CC/DC Diameter Tolerance

"CC/DC diameter tolerance" refers to the allowable deviation between the actual diameter and the nominal diameter of the disc:

CC (Continuous Casting)

Diameter tolerance of aluminum discs produced by continuous casting is generally controlled within ±0.5mm to ±1.0mm

DC (Hot Rolling)

Diameter tolerance of aluminum discs produced by hot rolling is relatively larger, generally within ±1.0mm to ±2.0mm

1050 Aluminum Disc Key Specifications Table (Inches)

| Thickness (in) | Diameter (in) | Common Tempers | Surface Finish | Primary Applications |

| 0.020–0.040 | 4–12 | O, H12, H14 | Mill finish | Small cookware, lids, reflectors |

| 0.050–0.063 | 12–18 | H12, H14, H22 | Mill finish, anodized | Cookware pots, lighting fixtures |

| 0.080–0.100 | 18–24 | H14, H24 | Anodized, coated | Traffic signs, large cookware bases |

| 0.125–0.188 | 24–36 | H24, H18 | Coated, mill finish | Industrial parts, architectural elements |

| 0.250–0.750 | 30–60 | H18, H22 | Mill finish | Heavy-duty components, machinery |

1050 Aluminum Circle Typical Popular Sizes

Diameters: 4 ″, 6 ″, 8 ″, 10 ″, 12 ″, up to 38.5 ″

Thicknesses: 0.014 ″, 0.020 ″, 0.039 ″, 0.118 ″, 0.196 ″, 0.394 ″ Listed one by one in a table

| Description | Thickness (in) | Diameter (in) | Thickness (in) | Common Tempers | Typical Applications |

| 0.014" x 4" 1050 aluminum circle | 0.014 | 4 | 0.014 | O, H14 | Electronics, foil packaging |

| 0.02" x 4" 1050 aluminum circle | 0.02 | 4 | 0.02 | O, H18 | Light reflectors, capacitors |

| 0.02" x 6" 1050 aluminum circle | 0.02 | 6 | 0.02 | H14, H24 | HVAC components, lighting |

| 0.039" x 6" 1050 aluminum circle | 0.039 | 6 | 0.039 | H18, H22 | Decorative trims, signage |

| 0.02" x 8" 1050 aluminum circle | 0.02 | 8 | 0.02 | H12, H14 | Cookware, industrial fins |

| 0.039" x 8" 1050 aluminum circle | 0.039 | 8 | 0.039 | H16, H24 | Chemical tanks, roofing |

| 0.039" x 10" 1050 aluminum circle | 0.039 | 10 | 0.039 | H14, H22 | Food containers, heat sinks |

| 0.118" x 10" 1050 aluminum circle | 0.118 | 10 | 0.118 | H18, H24 | Machinery parts, structural |

| 0.039" x 12" 1050 aluminum circle | 0.039 | 12 | 0.039 | H12, H18 | Automotive panels, ducts |

| 0.118" x 12" 1050 aluminum circle | 0.118 | 12 | 0.118 | H24, H26 | Marine fittings, heavy fabrications |

| 0.196" x 38.5" 1050 aluminum circle | 0.196 | 38.5 | 0.196 | H22, H32 | Aerospace, pressure vessels |

| 0.394" x 38.5" 1050 aluminum circle | 0.394 | 38.5 | 0.394 | H18, H28 | Shipbuilding, industrial frames |

1050 Aluminium Circle Equivalent Name

A1050, 1050a, aa1050, 1050aa, al1050, al1050a, 1050 aa, aa 1050, jis a1050p, al1050 class, aw1050, en1050 grade etc

1050 Aluminium Circle Chemical Compositon

| Chemical composition(%) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | —— | 0.05 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | —— | 0.05 | 0.03 | 99.6 |

| 3003 | 0.6 | 0.7 | 0.05~0.2 | 1.0~1.5 | —— | —— | 0.10 | —— | Margin |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | —— | Margin |

| 8011 | 0.50~0.9 | 0.6~1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | 0.08 | Margin |

1050 Aluminum Disc Circle Applications

Due to their excellent ductility, 1050 aluminum discs are particularly suitable for deep drawing processes. They can be processed into hard-anodized quality aluminum discs, making them ideal for high-demand surface treatment applications.

Due to its excellent formability and electrical conductivity, 1050 aluminum discs are widely used in:

- Cookware: Due to its good thermal conductivity and deep-drawing capabilities, it is ideal for making pots, frying pans, and woks.

- Lighting: Used for making lampshades and reflectors, offering high reflectivity and ease of forming.

- Traffic Signs: Due to its durability and resistance to environmental factors, it is used for manufacturing road signs.

- Electrical Components: Suitable for applications requiring electrical conductivity, such as capacitor housings and electrical enclosures.

- Chemical Containers: Due to its corrosion resistance, it is used to manufacture tanks and other chemical containers.

- Electronic and Electrical Products: Used for heat sinks, capacitors, etc., leveraging its electrical and thermal conductivity advantages.

- Industrial Components: Stamped into gaskets, nameplates, and other components suitable for traffic and chemical equipment fields.

1050 Aluminum Discs for Cookware Production

1050 aluminum discs are highly suitable for manufacturing various types of cookware, especially products requiring deep drawing processes. This aluminum alloy excels in cookware production due to its outstanding forming ability and high aluminum purity, ensuring that the final products have exceptional durability and consistent quality.

- Deep-drawn Cooking Pots: Suitable for the production of cooking pots using deep drawing techniques.

- Kitchen Utensil Spun Parts: Can be used to make spun parts for kitchen utensils.

- Non-stick Aluminum Cookware: Ideal for producing non-stick aluminum cookware, ensuring the durability of the finished product.

- Cookware Bottoms: Used for processing cookware bottoms, providing excellent thermal conductivity and durability.

- Cookware Sets and Containers: Widely used for forming cookware sets and other containers, meeting diverse kitchen needs.

1050 Aluminum Discs for Reflective Traffic Signs

Due to the high reflectivity and durability of 1050 aluminum discs, this material not only provides excellent reflective performance but also ensures the signs’ longevity and stability under various weather conditions.

1050 aluminum discs can also be used in lighting equipment, offering good reflective performance for manufacturing lighting fixtures.

Haomei Aluminum Discs for Multi-Industry Applications

Kitchenware & Household Appliances

This is the most traditional and largest-demand application field for aluminum circles.

- Aluminum Circle for Cookware: Used to manufacture non-stick pans, pressure cookers, woks, stock pots, and pizza pans. High thermal conductivity ensures even heating.

- Aluminum Circle for Rice Cooker Inner Pot: Base material for rice cooker inner pots, usually using the 3003 series alloy to improve strength and corrosion resistance.

- Aluminum Circle for Kettle Bottom: Base material for the heating plate at the bottom of electric kettles, requiring excellent flatness and thermal conductivity.

- Aluminum Circle for Coffee Pot: Used to manufacture the water chamber and filter cup of moka pots or espresso machines.

Lighting & Lampshades

Utilizing aluminum’s reflectivity and ease of spinning.

- Aluminum Circle for Lamp Shades: Formed into various lamp shade shapes through spinning, such as industrial pendant lamps and commercial lighting covers.

- Aluminum Circle for Recessed Lighting: Inner reflector rings for recessed downlights, often anodized to increase reflectivity.

- Aluminum Circle for LED Light Base: Heat dissipation substrates or reflective backing plates for high-power LED lamps.

Packaging & Containers

Leveraging aluminum’s non-toxicity, barrier properties, and deep drawing performance.

- Aluminum Circle for Aerosol Cans: Primary blanks for aerosol cans (such as sprays, fire extinguishers, and air fresheners), formed by cold extrusion.

- Aluminum Circle for Cosmetic Jars: Used to produce high-end cream jars, powder cases, and lipstick tube caps, often combined with anodizing, printing, or hot stamping.

- Aluminum Circle for Aluminum Bottles: Bottle bottoms or fully drawn blanks for premium beverage bottles, sports bottles, or pesticide containers.

- Aluminum Circle for Caps & Closures: Stamping material for pharmaceutical caps and anti-counterfeit closures for alcoholic beverages.

Transportation & Infrastructure

Mainly utilizing its weather resistance and lightweight advantages.

- Aluminum Circle for Traffic Signs: Substrates for road signs, speed limit signs, and warning signs, requiring a flat surface and easy application of reflective films.

- Aluminum Circle for License Plates: Base material for round or oval special license plates in certain countries or regions.

- Aluminum Circle for Automotive Heat Shields: Heat shields around engine compartments or exhaust systems, using aluminum’s thermal reflectivity to protect components.

- Aluminum Circle for Wheel Hub Caps: Decorative plates for automotive wheel center caps.

Industrial & Electronics

- Aluminum Circle for Capacitors: Housings for electrolytic capacitors, requiring extremely high material purity (usually 1070 series) and dimensional accuracy.

- Aluminum Circle for Pressure Vessels: End caps or shells for small pressure vessels, such as protective covers for hydraulic pumps.

- Aluminum Circle for Heat Sinks: Circular fin heat sinks used in electronic components.

Construction & Decoration

- Aluminum Circle for Column Covers: Decorative cladding panels or top/bottom finishing rings for architectural columns.

- Aluminum Circle for Decorative Trays: Craft trays, medal bases, or circular embossed decorative elements for building facades.

| Application Type | Recommended Alloy | Processing Method | Key Performance Requirements |

| Deep Drawing (e.g. pressure cookers) | 3003, 5052 | Deep Drawing | Fine grain size, avoidance of “orange peel” effect |

| Spinning (e.g. lamp shades) | 1050, 1100, 1070 | Spinning | Excellent ductility, no cracking during forming |

| Stamping (e.g. signs) | 1060, 3003 | Stamping | Surface flatness, burr-free edges |

Other Common Aluminum Circles and Their Application Fields

- 1060 Aluminum Disc Circle: With aluminum content above 99.6%, it has higher purity than 1050 and offers better corrosion resistance, electrical and thermal conductivity. Mainly used in electronics, chemical industry, food packaging, and other fields requiring high purity.

- 1070 Aluminum Disc Circle: With aluminum content above 99.7%, it is one of the highest purity commercially available aluminum grades. Excellent corrosion resistance and formability, mainly used in special chemical industry, electronics, and decorative applications.

- 1100 Aluminum Disc Circle: Contains 0.12-0.20% iron and silicon, slightly higher strength than 1050 and 1060. Mainly used in cookware, decorative materials, nameplates, etc.

- 3003 Aluminum Disc Circle: The main alloying element is manganese. It has significantly higher strength than pure aluminum, good corrosion resistance, and processability. Mainly used in cookware, architectural decoration, traffic signs, etc.

- 5052 Aluminum Disc Circle: The main alloying element is magnesium. It features higher strength and excellent corrosion resistance, especially to marine climate corrosion. Mainly used in automotive, marine, and pressure vessel applications.

- 6061 Aluminum Disc Circle: The main alloying elements are magnesium and silicon. It can be strengthened by heat treatment, offering high strength, good corrosion resistance, and processability. Mainly used in machinery manufacturing, aerospace, and building structures.

Aluminum Circle Application Selection Guide

Cookware and Home Appliances

Aluminum discs are widely used in the cookware and home appliance industries:

- Cooking Pots: 1050 and 3003 aluminum discs with a thickness of 0.3-6.0mm are the main materials for various cookware, offering good thermal conductivity and formability

- Small Appliances: Such as rice cooker inner pots, electric kettle heating bases, etc., typically use 1050 or 3003 aluminum discs with thicknesses of 0.5-3.0mm

- Kitchen Utensils: Such as bowls, plates, basins, etc., commonly use 1050 and 1060 aluminum discs, which are lightweight, corrosion-resistant, and easy to clean

- When selecting aluminum discs for cookware, thermal conductivity, corrosion resistance, and formability should be considered. 1050 and 3003 are the most commonly used choices.

Architecture and Decoration

Applications of aluminum discs in the architectural and decorative fields include:

- Architectural Decoration: Such as ceilings, decorative panels, etc., usually use 1050 and 1060 aluminum discs with surface treatment for enhanced appearance

- Building Signage: Such as traffic signs, billboards, etc., usually use 3003 aluminum discs for higher strength and weather resistance

- Structural Components: Such as lightweight components, connectors, etc., can use 6061 and other high-strength aluminum alloy discs

- When choosing aluminum discs for construction, factors like strength, weather resistance, and decorative effects should be considered, and the appropriate alloy and temper selected.

Electronics and Electrical Applications

Aluminum discs are used in electronics and electrical applications including:

- Electronic Components: Such as capacitor shells, electronic heat sinks, etc., usually made of 1050 and 1060 aluminum discs for good conductivity and heat dissipation

- Electrical Equipment: Such as parts for transformers and distribution boxes, can use 1050 and 3003 aluminum discs

- Communication Equipment: Such as antennas, shielding covers, etc., usually made of high-purity aluminum discs to ensure good electrical performance

- When selecting aluminum discs for electronics and electrical use, conductivity, thermal conductivity, and corrosion resistance are key factors. 1050 and 1060 pure aluminum discs are common choices.

Transportation Field

Applications of aluminum discs in transportation include:

- Automotive Manufacturing: Such as decorative parts, radiators, mufflers, etc., can use 1050, 3003, and 5052 aluminum discs

- Shipbuilding: Such as interior panels, equipment housings, etc., usually use 5052 and 5083 aluminum discs for corrosion resistance in marine environments

- Aerospace: Such as aircraft interior parts, structural components, etc., can use high-strength aluminum discs such as 6061 and 7075

- When choosing aluminum discs in the transportation field, strength, corrosion resistance, and lightweight requirements should be considered to select the right alloy and temper for the application.

Industrial and Special Fields

Aluminum discs are used in industrial and special applications including:

- Chemical Equipment: Such as parts for reactors and storage tanks, typically use corrosion-resistant aluminum discs like 1050, 3003, and 5052

- Food Packaging: Such as food containers, easy-open cans, etc., usually use 1050 and 1060 aluminum discs that meet food safety standards

- Medical Devices: Such as casings for medical equipment and medical containers, can use high-purity aluminum discs for good biocompatibility

When selecting aluminum discs for industrial and special applications, corrosion resistance, hygiene, and special performance requirements should be considered, and the appropriate alloy and temper selected.

Mechanical Properties of 1050 Aluminium Circle

| Alloy Temper | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 1050 0 | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| >0.5-1.0 | ≥30 | ||||

| >1.0-4.0 | ≥35 | ||||

| 1050 H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 |

| >0.5-1.0 | ≥15 | ||||

| >1.0-4.0 | ≥18 | ||||

| 1050 H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 |

| >0.5-1.0 | ≥8 | ||||

| >1.0-4.0 | ≥10 | ||||

| 1050 H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.0 | ≥6 | ||||

| 1050 H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 |

| >0.5-1.0 | ≥3 | ||||

| >1.0-4.0 | ≥4 |

1050 Aluminum Disc Circle Comparison with 1060 Aluminum

| Property | 1050 | 1060 |

| Aluminum Content | ≥99.5% | ≥99.6% |

| Strength | Moderate | Slightly Higher |

| Cost | Lower | Higher |

Applications: Used for cookware and electrical components, but 1050 is more cost-effective.

Advantages of 1050 Aluminum Disc Circle

Excellent corrosion resistance: A dense aluminum oxide film forms on the surface to protect the interior from corrosion

Good processing performance: Excellent plasticity, suitable for stamping, spinning, stretching, and other processing

Superior physical properties: Good thermal and electrical conductivity, low density

Excellent surface quality: Can undergo various surface treatments to meet diverse application needs

Relatively low cost: Lower cost compared to alloyed aluminum

Deep drawing quality: 1050 aluminum disc exhibits low anisotropy, which helps avoid cracking during deep drawing processes

Mechanical properties: Strong mechanical performance suitable for various forming technologies

Heat dissipation: High and uniform thermal distribution makes it ideal for cookware applications

Reflectivity: The bright surface of 1050 aluminum disc provides high reflectivity, beneficial for lighting applications

Durability: Excellent corrosion resistance ensures long service life in various environments

Formability: Ideal for deep drawing and spinning processes

The main limitation of 1050 aluminum disc is its relatively low strength, making it unsuitable for applications requiring high strength. Additionally, pure aluminum has relatively low wear resistance and hardness.

1050 Aluminum Circle Processing Techniques

1050 aluminum discs have excellent processing properties. Common techniques include:

Stamping

1050 aluminum discs can be stamped at room temperature. O temper and H12 temper materials show excellent stamping performance.

Spinning

Suitable for forming various rotating parts such as bowls, plates, and lampshades. H14 temper shows good formability during spinning.

Drawing

Can be used to form containers of various depths. O temper material can be stretched to more than 1.5 times its diameter.

Bending

Can be bent at 90° or even smaller angles without cracking. The bending radius increases with material hardness.

Welding

1050 aluminum discs can be joined using various welding methods such as gas welding, TIG welding, spot welding, etc.

Haomei 1050 Aluminum Disc Quality Control System

As a professional aluminum circle manufacturer, Haomei always adheres to the principle of "quality first". From raw materials to finished products, every process is strictly controlled to ensure that each 1050 aluminum disc meets the high standards of our customers.

Chemical Composition Control: Ensuring Material Purity from the Source

We understand that chemical composition is fundamental to product performance. Therefore, strict full-process control is implemented for 1050 aluminum disc composition:

Raw Material Inspection: Each batch of aluminum ingots undergoes spectroscopic analysis to verify that the chemical composition complies with GB/T 3190 standards or customer-specified standards.

Smelting Process Monitoring: Sampling and analysis points are set during smelting to monitor the composition changes of molten aluminum in real time. The alloy ratio is adjusted according to the results to ensure precise and stable composition.

Finished Product Sampling: Before delivery, finished products are batch-sampled and tested with direct-reading spectrometers to ensure consistency and traceability of the final product's chemical composition.

Dimensional Accuracy Control: High-Precision Equipment Ensures Geometric Accuracy

Dimensional accuracy directly affects the quality of customers' subsequent processing. We ensure dimensional consistency through advanced equipment and rigorous inspection:

Advanced Equipment Support: We have introduced high-precision casting-rolling lines, cold rolling mills, and stamping machines to ensure that both the original coil and the aluminum discs meet extreme tolerance requirements in thickness and diameter.

Die Management System: A die maintenance plan is established, including regular calibration and replacement, to ensure consistent disc dimensions, free from burrs and eccentricity.

Online Inspection Technology: Key production stations are equipped with laser thickness gauges and CCD optical detectors for real-time data feedback and automatic warning.

Finished Product Dimensional Inspection: A professional quality inspection team uses micrometers, calipers, and other precision instruments to conduct sampling inspection, ensuring that diameter and thickness deviations meet customer standards (e.g., within ±0.05mm).

Mechanical Properties Control: Ensuring Processability and Performance

To meet customer requirements for stamping, drawing, and other subsequent processing, we focus on controlling the mechanical properties of 1050 aluminum discs:

Rolling Process Control: Multiple rolling passes and a well-designed reduction rate are used to adjust work hardening levels, ensuring material uniformity and ductility.

Heat Treatment Process Optimization: A continuous annealing furnace is used to precisely control temperature and holding time, ensuring the ideal soft O-temper microstructure.

Grain Refinement Control: Cooling rates are strictly controlled during aluminum casting and heat treatment to suppress coarse grain formation and enhance overall performance.

Mechanical Property Testing: Each batch of finished products undergoes tensile strength, yield strength, and elongation tests. Data is archived and available for customer traceability.

Surface Quality Control: Ensuring Appearance and Post-Processing Compatibility

We place great importance on the surface condition of 1050 aluminum discs, which affects not only aesthetics but also subsequent surface treatments and processing:

Substrate Surface Control: High-quality aluminum sheets with clean surfaces, free of indentations and bubbles, are selected as raw materials for stamping.

Clean Production Environment: We implement clean production throughout. Equipment is maintained daily, and oil stains, metal chips, and other contaminants are eliminated in the production area.

Pre-Treatment Process: According to customer requirements, surface cleaning, degreasing, and passivation are conducted to enhance adhesion and corrosion resistance.

Strict Visual Inspection: A combination of manual visual inspection and optical detection is used to identify defects such as oxidation spots, scratches, and surface unevenness, ensuring flawless appearance.

Every 1050 aluminum disc delivered by Haomei Aluminum is rigorously screened through our quality control system, meeting both industry standards and special customer requirements. We do not just deliver products—we deliver a commitment and responsibility to quality.

Haomei Aluminum is a professional aluminum product manufacturer, mainly producing 1xxx, 3xxx, 5xxx, 6xxx, and 8xxx series of pure aluminum and aluminum alloy sheets/plates/coils/strips/discs. We have been exporting aluminum discs to countries such as the United States, the United Kingdom, Italy, Germany, the Netherlands, Bulgaria, Brazil, Chile, Thailand, Vietnam, Ghana, Afghanistan, Iraq, Iran, Syria, Jordan, Lebanon, Israel, and Palestine.

1050 Aluminum Disc Circle Processing Characteristics

Mechanical Properties

After treatment in states such as H12 or H14, the material possesses a balance of strength and ductility, making it suitable for stamping, spinning, and other processing needs, and is resistant to cracking during processing.

Surface Treatment

Some products have a film coating or polished surface treatment, making them suitable for applications that require high surface smoothness, such as heat dissipation fans and traffic signs.

While 1050 aluminum discs offer many advantages, their mechanical strength is lower compared to other aluminum alloys. Therefore, for applications requiring higher strength, other alloys like 3003 or 5005 may be more suitable.

1050 aluminum discs are versatile components, widely used in multiple industries due to their excellent performance (including high purity, formability, and electrical conductivity).

Further reading

- 1050 Aluminum Plate Sheet

- 1050 Aluminum Strip

- 1050 h14 aluminium sheet plate

- Aluminium 1050 h24

- 1050 H18 Aluminium

- 1050 O Aluminum

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

- 1050 Aluminum Coil

- 1050 Aluminum Foil

Users viewing this material also viewed the following

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

Recommended Content