5754 Marine Grade Aluminum Plate is an aluminum-magnesium alloy (containing 2.6-3.6% magnesium) with excellent corrosion resistance, weldability, and lightweight characteristics, widely used in maritime applications such as ship decks and yacht structures.

5754 aluminum plate belongs to rust-resistant aluminum, suitable for high-humidity environments. It is a non-heat-treatable alloy, and its strength can be slightly improved through cold working. Due to its excellent corrosion resistance, medium strength, good weldability, and formability, it is widely applied in shipbuilding.

5754 marine-grade aluminum plate comes in various tempers, such as H111 and H26. Different tempers affect the strength and hardness, with H26 having higher strength but lower formability compared to H111.

Why Do Shipbuilders Worldwide Trust Haomei 5754 Marine Aluminum Plate?

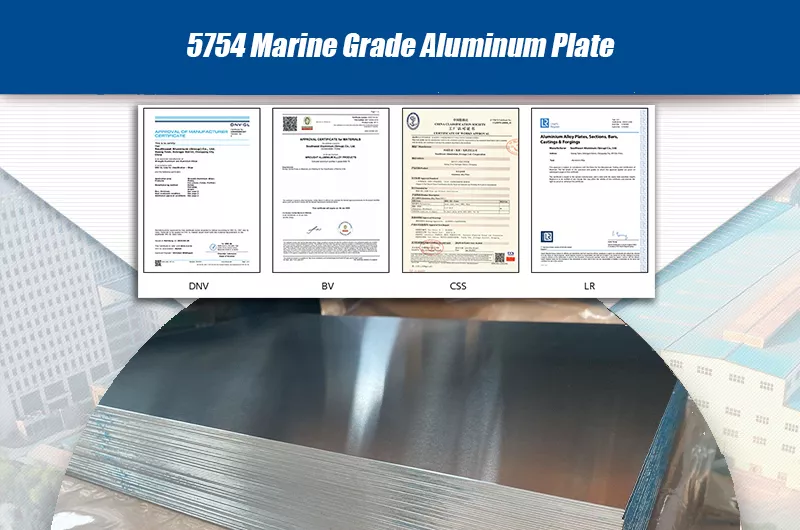

Our 5754 marine-grade aluminum plate has been certified by major international classification societies, including CCS, DNV, NK, ABS, BV, LR, KR, and other authoritative standards, ensuring the product's applicability and compliance in the global marine engineering field.

- Exceptional corrosion resistance: specially developed for marine environments, significantly extending the service life of vessels

- Excellent weldability: ensures strong and reliable hull welds, improving construction efficiency

- Outstanding impact toughness: maintains structural integrity and safety even in harsh sea conditions

We consistently uphold quality through certification and earn trust through performance, providing reliable aluminum solutions for your shipbuilding projects.

5754 Marine Grade Aluminum Plate Features (Why Suitable for Shipbuilding?)

Exceptional Corrosion Resistance:

Especially resistant to seawater corrosion. Its magnesium content (2.6-3.6%) allows the formation of a dense oxide layer in marine, humid, and salt spray environments, giving it far superior corrosion resistance compared to many other alloys.

Excellent resistance to stress corrosion cracking.

Good Weldability:

Can be welded using various methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, with high joint efficiency and low tendency for weld cracks.

Welded joint strength retention is good, making it an ideal choice for welded structural components in shipbuilding.

Medium Strength and Excellent Plasticity:

Strength is higher than pure aluminum and 1xxx series alloys. Although not as strong as 5xxx series 5083, it is sufficient for most structures such as hulls and superstructures.

Possesses high plasticity and toughness, easy for cold stamping, bending, rolling, etc., facilitating the manufacture of complex ship surfaces.

Low Density and Lightweight:

Density is approximately 2.7 g/cm³, only one-third of steel. Using 5754 aluminum plate can significantly reduce vessel weight, thereby improving speed, increasing payload, and lowering fuel consumption.

Non-Magnetic:

This property is crucial for specialized vessels such as minehunters and research ships (where magnetic interference must be avoided).

5754 Marine Grade Aluminum Plate Specifications

Common Tempers of 5754 Marine Aluminum

- O temper (annealed): the softest condition, with extremely high plasticity, suitable for deep drawing and other processes with large deformation.

- H32: 1/4 hard temper. Based on O temper, it has undergone appropriate cold working and stabilization, balancing strength and plasticity, making it the most commonly used temper in shipbuilding.

- H112: heat-treated temper. Suitable for hot-rolled thick plates, maintaining good mechanical properties.

Common Specifications of 5754 Marine Aluminum

- Thickness: typically ranges from 0.5mm to 150mm or even thicker, selected according to different parts of the vessel.

- Width: 1000mm, 1200mm, 1500mm, 2000mm, 2500mm, etc.

- Length: customizable, commonly 2000mm, 2500mm, 3000mm, 6000mm, etc.

Chemical composition of 5754 alloy

| Element | Composition(%) |

| Manganese (Mn) | ≤0.50 |

| Iron (Fe) | ≤0.40 |

| Magnesium (Mg) | 2.60-3.60 |

| Silicon (Si) | ≤0.40 |

| Copper (Cu) | ≤0.10 |

| Chromium (Cr) | ≤0.30 |

| Zinc (Zn) | ≤0.20 |

| Titanium (Ti) | ≤0.15 |

| Mangenese + Chromium (Mn + Cr) | 0.10-0.60 |

| Aluminium (Al) | Remainder |

Property of 5754 marine grade aluminum plate

| Alloy | Temper | Thickness mm | Tension strength RmMPa | Specified non-proportional elongation strength Rp0.2 Mpa | Elongation % | |

| A50 mm | A | |||||

| 5754 | O | 3.00-50.00 | 190-240 | ≥80 | ≥18 | ≥17 |

| H111 | 3.00-50.00 | 190-240 | ≥80 | ≥18 | ≥17 | |

| H22, H32 | 3.00-6.00 | 220-270 | ≥130 | ≥11 | - | |

| H112 | 6.00-12.50 | ≥190 | ≥100 | ≥12 | - | |

| >12.50-25.00 | ≥190 | ≥90 | - | ≥10 | ||

| >25.00-50.00 | ≥190 | ≥80 | - | ≥12 | ||

Specific Applications of 5754 Aluminum in Shipbuilding

5754 aluminum is commonly used in non-load-bearing or secondary load-bearing components of the hull structure, such as decks, bulkheads, and side panels. It can also be used in ship superstructures, such as wheelhouses and cabin walls. Additionally, it finds applications in ship piping, fuel tanks, and interior fittings, such as handrails and furniture.

Specific Applications of 5754 Aluminum in Shipbuilding

- Hull structure: hull plates, decks, bulkheads, keel, etc.

- Superstructure: wheelhouses, crew cabins, radar masts, etc. Reducing the weight of the superstructure helps improve vessel stability.

- Interior components and facilities: cabin walls, floors, stairs, doors and windows, furniture, etc.

- Other components: fuel tanks, piping systems, fender materials, etc.

Main Hull Structure

Application components: hull plates, decks, bulkheads, keel, and other core structures.

5754 aluminum alloy provides the main hull structure with excellent seawater corrosion resistance, significantly extending the vessel's lifespan. Its high-strength properties ensure the structural integrity of critical parts such as hull plates and the keel, effectively resisting impacts and pressures from the marine environment. Decks and bulkheads made of 5754 aluminum ensure safety while achieving a lightweight hull.

Superstructure

Application components: wheelhouses, crew cabins, radar masts, etc.

Using 5754 aluminum plates in the superstructure is a key strategy for improving vessel stability. By reducing the weight of the wheelhouse, crew cabins, and radar masts at the top, the vessel’s center of gravity is lowered, significantly enhancing navigation stability and fuel efficiency. This scientific lightweight design provides more usable space on the vessel without increasing displacement.

Interior Components and Facilities

Application components: internal cabin walls, floors, stairs, doors and windows, and ship furniture.

The excellent formability of 5754 aluminum alloy makes it easy to shape into various complex interior components. Stairs, floors, and bulkheads made from it are not only aesthetically pleasing and durable but also offer superior fire resistance and corrosion resistance, ensuring the safety and cleanliness of interior spaces. Meanwhile, aluminum ship furniture further reduces internal loads.

Functional and Auxiliary Components

Application components: fuel tanks, piping systems, fender materials, etc.

For key functional components such as fuel tanks and piping systems, the corrosion resistance of 5754 aluminum ensures fuel purity and long-term system sealing. As fender material, its strong impact toughness effectively absorbs collision energy, protecting the hull structure from damage during docking or mooring.

5754 Aluminum Plate Common Stock Dimensions

| Description | Thickness (mm) | Width (mm) | Length (mm) | Temper | Unit Weight (kg) |

| 1x1000x2000 5754 O Marine Aluminum Sheet | 1 | 1000 | 2000 | O | 5.32 |

| 1x1000x2000 5754 H111 Marine Aluminum Sheet | 1 | 1000 | 2000 | H111 | 5.32 |

| 1x1000x2000 5754 H22 Marine Aluminum Sheet | 1 | 1000 | 2000 | H22 | 5.32 |

| 1x1000x2500 5754 O Marine Aluminum Sheet | 1 | 1000 | 2500 | O | 6.65 |

| 1x1000x2500 5754 H111 Marine Aluminum Sheet | 1 | 1000 | 2500 | H111 | 6.65 |

| 1x1000x2500 5754 H22 Marine Aluminum Sheet | 1 | 1000 | 2500 | H22 | 6.65 |

| 1x1200x2500 5754 O Marine Aluminum Sheet | 1 | 1200 | 2500 | O | 7.98 |

| 1x1200x2500 5754 H111 Marine Aluminum Sheet | 1 | 1200 | 2500 | H111 | 7.98 |

| 1x1200x2500 5754 H22 Marine Aluminum Sheet | 1 | 1200 | 2500 | H22 | 7.98 |

| 1x1200x3000 5754 O Marine Aluminum Sheet | 1 | 1200 | 3000 | O | 9.58 |

| 1x1200x3000 5754 H111 Marine Aluminum Sheet | 1 | 1200 | 3000 | H111 | 9.58 |

| 1x1200x3000 5754 H22 Marine Aluminum Sheet | 1 | 1200 | 3000 | H22 | 9.58 |

| 1x1500x3000 5754 O Marine Aluminum Sheet | 1 | 1500 | 3000 | O | 11.97 |

| 1x1500x3000 5754 H111 Marine Aluminum Sheet | 1 | 1500 | 3000 | H111 | 11.97 |

| 1x1500x3000 5754 H22 Marine Aluminum Sheet | 1 | 1500 | 3000 | H22 | 11.97 |

| 2x1000x2000 5754 O Marine Aluminum Sheet | 2 | 1000 | 2000 | O | 10.64 |

| 2x1000x2000 5754 H111 Marine Aluminum Sheet | 2 | 1000 | 2000 | H111 | 10.64 |

| 2x1000x2000 5754 H22 Marine Aluminum Sheet | 2 | 1000 | 2000 | H22 | 10.64 |

| 2x1000x2500 5754 O Marine Aluminum Sheet | 2 | 1000 | 2500 | O | 13.3 |

| 2x1000x2500 5754 H111 Marine Aluminum Sheet | 2 | 1000 | 2500 | H111 | 13.3 |

| 2x1000x2500 5754 H22 Marine Aluminum Sheet | 2 | 1000 | 2500 | H22 | 13.3 |

| 2x1200x2500 5754 O Marine Aluminum Sheet | 2 | 1200 | 2500 | O | 15.96 |

| 2x1200x2500 5754 H111 Marine Aluminum Sheet | 2 | 1200 | 2500 | H111 | 15.96 |

| 2x1200x2500 5754 H22 Marine Aluminum Sheet | 2 | 1200 | 2500 | H22 | 15.96 |

| 2x1200x3000 5754 O Marine Aluminum Sheet | 2 | 1200 | 3000 | O | 19.15 |

| 2x1200x3000 5754 H111 Marine Aluminum Sheet | 2 | 1200 | 3000 | H111 | 19.15 |

| 2x1200x3000 5754 H22 Marine Aluminum Sheet | 2 | 1200 | 3000 | H22 | 19.15 |

| 2x1500x3000 5754 O Marine Aluminum Sheet | 2 | 1500 | 3000 | O | 23.94 |

| 2x1500x3000 5754 H111 Marine Aluminum Sheet | 2 | 1500 | 3000 | H111 | 23.94 |

| 2x1500x3000 5754 H22 Marine Aluminum Sheet | 2 | 1500 | 3000 | H22 | 23.94 |

| 3x1000x2000 5754 O Marine Aluminum Sheet | 3 | 1000 | 2000 | O | 15.96 |

| 3x1000x2000 5754 H111 Marine Aluminum Sheet | 3 | 1000 | 2000 | H111 | 15.96 |

| 3x1000x2000 5754 H22 Marine Aluminum Sheet | 3 | 1000 | 2000 | H22 | 15.96 |

| 3x1000x2500 5754 O Marine Aluminum Sheet | 3 | 1000 | 2500 | O | 19.95 |

| 3x1000x2500 5754 H111 Marine Aluminum Sheet | 3 | 1000 | 2500 | H111 | 19.95 |

| 3x1000x2500 5754 H22 Marine Aluminum Sheet | 3 | 1000 | 2500 | H22 | 19.95 |

| 3x1200x2500 5754 O Marine Aluminum Sheet | 3 | 1200 | 2500 | O | 23.94 |

| 3x1200x2500 5754 H111 Marine Aluminum Sheet | 3 | 1200 | 2500 | H111 | 23.94 |

| 3x1200x2500 5754 H22 Marine Aluminum Sheet | 3 | 1200 | 2500 | H22 | 23.94 |

| 3x1200x3000 5754 O Marine Aluminum Sheet | 3 | 1200 | 3000 | O | 28.73 |

| 3x1200x3000 5754 H111 Marine Aluminum Sheet | 3 | 1200 | 3000 | H111 | 28.73 |

| 3x1200x3000 5754 H22 Marine Aluminum Sheet | 3 | 1200 | 3000 | H22 | 28.73 |

| 3x1500x3000 5754 O Marine Aluminum Sheet | 3 | 1500 | 3000 | O | 35.91 |

| 3x1500x3000 5754 H111 Marine Aluminum Sheet | 3 | 1500 | 3000 | H111 | 35.91 |

| 3x1500x3000 5754 H22 Marine Aluminum Sheet | 3 | 1500 | 3000 | H22 | 35.91 |

| 5x1000x2000 5754 O Marine Aluminum Sheet | 5 | 1000 | 2000 | O | 26.6 |

| 5x1000x2000 5754 H111 Marine Aluminum Sheet | 5 | 1000 | 2000 | H111 | 26.6 |

| 5x1000x2000 5754 H22 Marine Aluminum Sheet | 5 | 1000 | 2000 | H22 | 26.6 |

| 5x1000x2500 5754 O Marine Aluminum Sheet | 5 | 1000 | 2500 | O | 33.25 |

| 5x1000x2500 5754 H111 Marine Aluminum Sheet | 5 | 1000 | 2500 | H111 | 33.25 |

| 5x1000x2500 5754 H22 Marine Aluminum Sheet | 5 | 1000 | 2500 | H22 | 33.25 |

| 5x1200x2500 5754 O Marine Aluminum Sheet | 5 | 1200 | 2500 | O | 39.9 |

| 5x1200x2500 5754 H111 Marine Aluminum Sheet | 5 | 1200 | 2500 | H111 | 39.9 |

| 5x1200x2500 5754 H22 Marine Aluminum Sheet | 5 | 1200 | 2500 | H22 | 39.9 |

| 5x1200x3000 5754 O Marine Aluminum Sheet | 5 | 1200 | 3000 | O | 47.88 |

| 5x1200x3000 5754 H111 Marine Aluminum Sheet | 5 | 1200 | 3000 | H111 | 47.88 |

| 5x1200x3000 5754 H22 Marine Aluminum Sheet | 5 | 1200 | 3000 | H22 | 47.88 |

| 5x1500x3000 5754 O Marine Aluminum Sheet | 5 | 1500 | 3000 | O | 59.85 |

| 5x1500x3000 5754 H111 Marine Aluminum Sheet | 5 | 1500 | 3000 | H111 | 59.85 |

| 5x1500x3000 5754 H22 Marine Aluminum Sheet | 5 | 1500 | 3000 | H22 | 59.85 |

| 6x1000x2000 5754 O Marine Aluminum Sheet | 6 | 1000 | 2000 | O | 31.92 |

| 6x1000x2000 5754 H111 Marine Aluminum Sheet | 6 | 1000 | 2000 | H111 | 31.92 |

| 6x1000x2000 5754 H22 Marine Aluminum Sheet | 6 | 1000 | 2000 | H22 | 31.92 |

| 6x1000x2500 5754 O Marine Aluminum Sheet | 6 | 1000 | 2500 | O | 39.9 |

| 6x1000x2500 5754 H111 Marine Aluminum Sheet | 6 | 1000 | 2500 | H111 | 39.9 |

| 6x1000x2500 5754 H22 Marine Aluminum Sheet | 6 | 1000 | 2500 | H22 | 39.9 |

| 6x1200x2500 5754 O Marine Aluminum Sheet | 6 | 1200 | 2500 | O | 47.88 |

| 6x1200x2500 5754 H111 Marine Aluminum Sheet | 6 | 1200 | 2500 | H111 | 47.88 |

| 6x1200x2500 5754 H22 Marine Aluminum Sheet | 6 | 1200 | 2500 | H22 | 47.88 |

| 6x1200x3000 5754 O Marine Aluminum Sheet | 6 | 1200 | 3000 | O | 57.46 |

| 6x1200x3000 5754 H111 Marine Aluminum Sheet | 6 | 1200 | 3000 | H111 | 57.46 |

| 6x1200x3000 5754 H22 Marine Aluminum Sheet | 6 | 1200 | 3000 | H22 | 57.46 |

| 6x1500x3000 5754 O Marine Aluminum Sheet | 6 | 1500 | 3000 | O | 71.82 |

| 6x1500x3000 5754 H111 Marine Aluminum Sheet | 6 | 1500 | 3000 | H111 | 71.82 |

| 6x1500x3000 5754 H22 Marine Aluminum Sheet | 6 | 1500 | 3000 | H22 | 71.82 |

| 8x1000x2000 5754 O Marine Aluminum Plate | 8 | 1000 | 2000 | O | 42.56 |

| 8x1000x2000 5754 H111 Marine Aluminum Plate | 8 | 1000 | 2000 | H111 | 42.56 |

| 8x1000x2000 5754 H22 Marine Aluminum Plate | 8 | 1000 | 2000 | H22 | 42.56 |

| 8x1000x2500 5754 O Marine Aluminum Plate | 8 | 1000 | 2500 | O | 53.2 |

| 8x1000x2500 5754 H111 Marine Aluminum Plate | 8 | 1000 | 2500 | H111 | 53.2 |

| 8x1000x2500 5754 H22 Marine Aluminum Plate | 8 | 1000 | 2500 | H22 | 53.2 |

| 8x1200x2500 5754 O Marine Aluminum Plate | 8 | 1200 | 2500 | O | 63.84 |

| 8x1200x2500 5754 H111 Marine Aluminum Plate | 8 | 1200 | 2500 | H111 | 63.84 |

| 8x1200x2500 5754 H22 Marine Aluminum Plate | 8 | 1200 | 2500 | H22 | 63.84 |

| 8x1200x3000 5754 O Marine Aluminum Plate | 8 | 1200 | 3000 | O | 76.61 |

| 8x1200x3000 5754 H111 Marine Aluminum Plate | 8 | 1200 | 3000 | H111 | 76.61 |

| 8x1200x3000 5754 H22 Marine Aluminum Plate | 8 | 1200 | 3000 | H22 | 76.61 |

| 8x1500x3000 5754 O Marine Aluminum Plate | 8 | 1500 | 3000 | O | 95.76 |

| 8x1500x3000 5754 H111 Marine Aluminum Plate | 8 | 1500 | 3000 | H111 | 95.76 |

| 8x1500x3000 5754 H22 Marine Aluminum Plate | 8 | 1500 | 3000 | H22 | 95.76 |

| 10x1000x2000 5754 O Marine Aluminum Plate | 10 | 1000 | 2000 | O | 53.2 |

| 10x1000x2000 5754 H111 Marine Aluminum Plate | 10 | 1000 | 2000 | H111 | 53.2 |

| 10x1000x2000 5754 H22 Marine Aluminum Plate | 10 | 1000 | 2000 | H22 | 53.2 |

| 10x1000x2500 5754 O Marine Aluminum Plate | 10 | 1000 | 2500 | O | 66.5 |

| 10x1000x2500 5754 H111 Marine Aluminum Plate | 10 | 1000 | 2500 | H111 | 66.5 |

| 10x1000x2500 5754 H22 Marine Aluminum Plate | 10 | 1000 | 2500 | H22 | 66.5 |

| 10x1200x2500 5754 O Marine Aluminum Plate | 10 | 1200 | 2500 | O | 79.8 |

| 10x1200x2500 5754 H111 Marine Aluminum Plate | 10 | 1200 | 2500 | H111 | 79.8 |

| 10x1200x2500 5754 H22 Marine Aluminum Plate | 10 | 1200 | 2500 | H22 | 79.8 |

| 10x1200x3000 5754 O Marine Aluminum Plate | 10 | 1200 | 3000 | O | 95.76 |

| 10x1200x3000 5754 H111 Marine Aluminum Plate | 10 | 1200 | 3000 | H111 | 95.76 |

| 10x1200x3000 5754 H22 Marine Aluminum Plate | 10 | 1200 | 3000 | H22 | 95.76 |

| 10x1500x3000 5754 O Marine Aluminum Plate | 10 | 1500 | 3000 | O | 119.7 |

| 10x1500x3000 5754 H111 Marine Aluminum Plate | 10 | 1500 | 3000 | H111 | 119.7 |

| 10x1500x3000 5754 H22 Marine Aluminum Plate | 10 | 1500 | 3000 | H22 | 119.7 |

| 12x1000x2000 5754 O Marine Aluminum Plate | 12 | 1000 | 2000 | O | 63.84 |

| 12x1000x2000 5754 H111 Marine Aluminum Plate | 12 | 1000 | 2000 | H111 | 63.84 |

| 12x1000x2000 5754 H22 Marine Aluminum Plate | 12 | 1000 | 2000 | H22 | 63.84 |

| 12x1000x2500 5754 O Marine Aluminum Plate | 12 | 1000 | 2500 | O | 79.8 |

| 12x1000x2500 5754 H111 Marine Aluminum Plate | 12 | 1000 | 2500 | H111 | 79.8 |

| 12x1000x2500 5754 H22 Marine Aluminum Plate | 12 | 1000 | 2500 | H22 | 79.8 |

| 12x1200x2500 5754 O Marine Aluminum Plate | 12 | 1200 | 2500 | O | 95.76 |

| 12x1200x2500 5754 H111 Marine Aluminum Plate | 12 | 1200 | 2500 | H111 | 95.76 |

| 12x1200x2500 5754 H22 Marine Aluminum Plate | 12 | 1200 | 2500 | H22 | 95.76 |

| 12x1200x3000 5754 O Marine Aluminum Plate | 12 | 1200 | 3000 | O | 114.91 |

| 12x1200x3000 5754 H111 Marine Aluminum Plate | 12 | 1200 | 3000 | H111 | 114.91 |

| 12x1200x3000 5754 H22 Marine Aluminum Plate | 12 | 1200 | 3000 | H22 | 114.91 |

| 12x1500x3000 5754 O Marine Aluminum Plate | 12 | 1500 | 3000 | O | 143.64 |

| 12x1500x3000 5754 H111 Marine Aluminum Plate | 12 | 1500 | 3000 | H111 | 143.64 |

| 12x1500x3000 5754 H22 Marine Aluminum Plate | 12 | 1500 | 3000 | H22 | 143.64 |

| 15x1000x2000 5754 O Marine Aluminum Plate | 15 | 1000 | 2000 | O | 79.8 |

| 15x1000x2000 5754 H111 Marine Aluminum Plate | 15 | 1000 | 2000 | H111 | 79.8 |

| 15x1000x2000 5754 H22 Marine Aluminum Plate | 15 | 1000 | 2000 | H22 | 79.8 |

| 15x1000x2500 5754 O Marine Aluminum Plate | 15 | 1000 | 2500 | O | 99.75 |

| 15x1000x2500 5754 H111 Marine Aluminum Plate | 15 | 1000 | 2500 | H111 | 99.75 |

| 15x1000x2500 5754 H22 Marine Aluminum Plate | 15 | 1000 | 2500 | H22 | 99.75 |

| 15x1200x2500 5754 O Marine Aluminum Plate | 15 | 1200 | 2500 | O | 119.7 |

| 15x1200x2500 5754 H111 Marine Aluminum Plate | 15 | 1200 | 2500 | H111 | 119.7 |

| 15x1200x2500 5754 H22 Marine Aluminum Plate | 15 | 1200 | 2500 | H22 | 119.7 |

| 15x1200x3000 5754 O Marine Aluminum Plate | 15 | 1200 | 3000 | O | 143.64 |

| 15x1200x3000 5754 H111 Marine Aluminum Plate | 15 | 1200 | 3000 | H111 | 143.64 |

| 15x1200x3000 5754 H22 Marine Aluminum Plate | 15 | 1200 | 3000 | H22 | 143.64 |

| 15x1500x3000 5754 O Marine Aluminum Plate | 15 | 1500 | 3000 | O | 179.55 |

| 15x1500x3000 5754 H111 Marine Aluminum Plate | 15 | 1500 | 3000 | H111 | 179.55 |

| 15x1500x3000 5754 H22 Marine Aluminum Plate | 15 | 1500 | 3000 | H22 | 179.55 |

| 20x1000x2000 5754 O Marine Aluminum Plate | 20 | 1000 | 2000 | O | 106.4 |

| 20x1000x2000 5754 H111 Marine Aluminum Plate | 20 | 1000 | 2000 | H111 | 106.4 |

| 20x1000x2000 5754 H22 Marine Aluminum Plate | 20 | 1000 | 2000 | H22 | 106.4 |

| 20x1000x2500 5754 O Marine Aluminum Plate | 20 | 1000 | 2500 | O | 133 |

| 20x1000x2500 5754 H111 Marine Aluminum Plate | 20 | 1000 | 2500 | H111 | 133 |

| 20x1000x2500 5754 H22 Marine Aluminum Plate | 20 | 1000 | 2500 | H22 | 133 |

| 20x1200x2500 5754 O Marine Aluminum Plate | 20 | 1200 | 2500 | O | 159.6 |

| 20x1200x2500 5754 H111 Marine Aluminum Plate | 20 | 1200 | 2500 | H111 | 159.6 |

| 20x1200x2500 5754 H22 Marine Aluminum Plate | 20 | 1200 | 2500 | H22 | 159.6 |

| 20x1200x3000 5754 O Marine Aluminum Plate | 20 | 1200 | 3000 | O | 191.52 |

| 20x1200x3000 5754 H111 Marine Aluminum Plate | 20 | 1200 | 3000 | H111 | 191.52 |

| 20x1200x3000 5754 H22 Marine Aluminum Plate | 20 | 1200 | 3000 | H22 | 191.52 |

| 20x1500x3000 5754 O Marine Aluminum Plate | 20 | 1500 | 3000 | O | 239.4 |

| 20x1500x3000 5754 H111 Marine Aluminum Plate | 20 | 1500 | 3000 | H111 | 239.4 |

| 20x1500x3000 5754 H22 Marine Aluminum Plate | 20 | 1500 | 3000 | H22 | 239.4 |

| 25x1000x2000 5754 O Marine Aluminum Plate | 25 | 1000 | 2000 | O | 133 |

| 25x1000x2000 5754 H111 Marine Aluminum Plate | 25 | 1000 | 2000 | H111 | 133 |

| 25x1000x2000 5754 H22 Marine Aluminum Plate | 25 | 1000 | 2000 | H22 | 133 |

| 25x1000x2500 5754 O Marine Aluminum Plate | 25 | 1000 | 2500 | O | 166.25 |

| 25x1000x2500 5754 H111 Marine Aluminum Plate | 25 | 1000 | 2500 | H111 | 166.25 |

| 25x1000x2500 5754 H22 Marine Aluminum Plate | 25 | 1000 | 2500 | H22 | 166.25 |

| 25x1200x2500 5754 O Marine Aluminum Plate | 25 | 1200 | 2500 | O | 199.5 |

| 25x1200x2500 5754 H111 Marine Aluminum Plate | 25 | 1200 | 2500 | H111 | 199.5 |

| 25x1200x2500 5754 H22 Marine Aluminum Plate | 25 | 1200 | 2500 | H22 | 199.5 |

| 25x1200x3000 5754 O Marine Aluminum Plate | 25 | 1200 | 3000 | O | 239.4 |

| 25x1200x3000 5754 H111 Marine Aluminum Plate | 25 | 1200 | 3000 | H111 | 239.4 |

| 25x1200x3000 5754 H22 Marine Aluminum Plate | 25 | 1200 | 3000 | H22 | 239.4 |

| 25x1500x3000 5754 O Marine Aluminum Plate | 25 | 1500 | 3000 | O | 299.25 |

| 25x1500x3000 5754 H111 Marine Aluminum Plate | 25 | 1500 | 3000 | H111 | 299.25 |

| 25x1500x3000 5754 H22 Marine Aluminum Plate | 25 | 1500 | 3000 | H22 | 299.25 |

| 30x1000x2000 5754 O Marine Aluminum Plate | 30 | 1000 | 2000 | O | 159.6 |

| 30x1000x2000 5754 H111 Marine Aluminum Plate | 30 | 1000 | 2000 | H111 | 159.6 |

| 30x1000x2000 5754 H22 Marine Aluminum Plate | 30 | 1000 | 2000 | H22 | 159.6 |

| 30x1000x2500 5754 O Marine Aluminum Plate | 30 | 1000 | 2500 | O | 199.5 |

| 30x1000x2500 5754 H111 Marine Aluminum Plate | 30 | 1000 | 2500 | H111 | 199.5 |

| 30x1000x2500 5754 H22 Marine Aluminum Plate | 30 | 1000 | 2500 | H22 | 199.5 |

| 30x1200x2500 5754 O Marine Aluminum Plate | 30 | 1200 | 2500 | O | 239.4 |

| 30x1200x2500 5754 H111 Marine Aluminum Plate | 30 | 1200 | 2500 | H111 | 239.4 |

| 30x1200x2500 5754 H22 Marine Aluminum Plate | 30 | 1200 | 2500 | H22 | 239.4 |

| 30x1200x3000 5754 O Marine Aluminum Plate | 30 | 1200 | 3000 | O | 287.28 |

| 30x1200x3000 5754 H111 Marine Aluminum Plate | 30 | 1200 | 3000 | H111 | 287.28 |

| 30x1200x3000 5754 H22 Marine Aluminum Plate | 30 | 1200 | 3000 | H22 | 287.28 |

| 30x1500x3000 5754 O Marine Aluminum Plate | 30 | 1500 | 3000 | O | 359.1 |

| 30x1500x3000 5754 H111 Marine Aluminum Plate | 30 | 1500 | 3000 | H111 | 359.1 |

| 30x1500x3000 5754 H22 Marine Aluminum Plate | 30 | 1500 | 3000 | H22 | 359.1 |

Comparison Between 5754 Marine Aluminum and 5083 Aluminum

In the shipbuilding sector, 5083 aluminum alloy is another mainstay and is often compared with 5754:

| Feature | 5754 Aluminum Plate | 5083 Aluminum Plate |

| Magnesium Content | About 2.6-3.6% | About 4.0-4.9% |

| Strength | Medium strength | Higher strength, one of the strongest in the 5xxx series |

| Corrosion Resistance | Excellent, especially resistant to seawater corrosion | Outstanding, comparable or slightly superior to 5754 |

| Weldability | Excellent, stable performance after welding | Good, but strength in the heat-affected zone drops slightly more than 5754 |

| Workability | Excellent, easier to form | Good |

| Application Focus | Internal hull structures, superstructures, and skin where extreme strength is not required | Main hull structures, decks, high-strength components, and areas requiring higher strength |

If the structure needs to withstand higher loads (such as the main hull), 5083 with higher strength is usually selected.

If better formability and weldability are prioritized and the strength requirement is moderate (such as for superstructures), 5754 is a more economical and suitable choice.

Recommendations for Purchasing and Using 5754 Marine Aluminum

- Define Requirements: For medium and low load areas (bulkheads, deck sublayers, etc.), choose 5754. For high-strength areas (keel, outer side panels), choose 5083. Prefer H111 temper (easy forming) or H321 (fatigue-resistant), thickness according to design (2-12mm) to match installation needs.

- Material Certification: Must comply with ASTM B209 international standard, or have certification from classification societies such as DNV, ABS, CCS, and request a Material Test Certificate (MTC) to verify parameters.

- Specifications and Surface Treatment: Select plates close to the finished dimensions to reduce splicing. For underwater or high-humidity areas, apply passivation or coating; for exposed areas, anodizing can be applied to enhance corrosion resistance.

- Storage Requirements: Store in a dry, ventilated area; avoid direct contact with steel, copper, or other metals to prevent galvanic corrosion.