5454 aluminum combines medium to high strength, excellent corrosion resistance, and good weldability—these properties are very useful for fuel, chemical, and other tanker trucks. It is not a heat-treatable alloy; its strengthening is achieved through cold working/strain hardening (i.e., different "H" tempers).

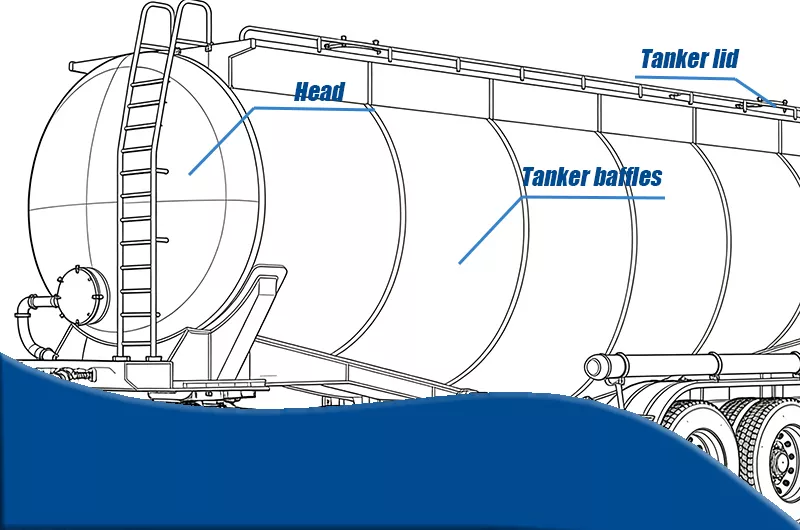

5454 tanker aluminum plate is a medium-strength, corrosion-resistant, and well-weldable aluminum alloy material, commonly used for the manufacture of anti-slosh baffles and tanks of tankers.

For 5454 tanker aluminum plates, 5454-H111 is preferred because it offers high formability suitable for tank bodies, or 5454-H32/O because it provides excellent corrosion resistance in tankers. This alloy features high strength, good weldability, and outstanding corrosion resistance, making it an ideal choice for tankers.

- 5454-H111 temper provides a good balance of strength and formability for tanker bodies.

- 5454 O temper (annealed) is used for applications requiring maximum formability.

The main trade-off is between the formability of the O temper and the added strength of the H111 temper.

Specifications of 5454 Aluminum Sheet Plate for Tanker

| Alloy | 5454 |

| Temper | 5454-H111, 5454-O |

| Thickness range | 3.0–12.0 mm (common: 5 / 6 / 8 mm) |

| Common widths | 1000–2600 mm (max 2600 mm helps reduce longitudinal seams) |

| Common lengths | 2000–12000 mm |

| Available surfaces | Mill, Mirror |

| Standards | EN 14286, ASTM B209 |

5454 Aluminum Alloy Applications and Advantages in Tankers

When used in tankers, 5454 aluminum can generally resist corrosion from various fluids, including certain petroleum products, as well as environmental exposure.

This alloy maintains stable performance at moderate to high temperatures (rather than extremely low temperatures). 5454 aluminum plates with mirror or polished surface treatments can reflect solar radiation, thereby reducing the temperature rise of the tank under sunlight.

5454 aluminum plates are used for the body of tankers (side walls, shell plates), and sometimes for the cab, baffles, bulkheads, and other parts.

However, for extremely low temperature (cryogenic) applications, alloys such as 5083 may be preferred because they have better toughness at low temperatures.

- Tank body main structure: commonly used in H111 temper, combined with 5083 aluminum alloy to form the tank body.

- Anti-slosh baffles / oil baffles: O temper or H111 treatment is applied to meet different mechanical requirements and reduce fluid sloshing during transportation.

- Wheel components: some models use 5454 aluminum plates to manufacture wheels, balancing lightweight and strength.

- Auxiliary tank structures: used together with grades like 5083 (tank main body) and 5182 (end caps) to create a lightweight, high-strength overall structure.

- Corrosion-resistant components: suitable for transporting mildly corrosive media (such as fuel or chemical raw materials); its corrosion resistance can extend tank service life and reduce maintenance costs.

| Component | Recommended Temper | Thickness | Notes |

| Tank Body | 5454-H111 / 5454-H32 | 5–8 mm | H111 for standard service; H32 for high-temp or heavy load |

| Heads / Covers | 5454-O | Same or thicker than body | Soft temper, easy for spinning and forming |

| Baffles / Partitions | 5454-O | ≈1 mm thinner | Reduce weight, keep impact resistance |

| Bulkheads | 5454-O | 5–8 mm | Separate compartments, ensure independent transport |

5454-H111 Aluminum for Tank Body Fabrication

Advantages:

High formability for tank body manufacturing.

Meets high engineering requirements for strength and performance.

Disadvantages:

Requires specific tempering temperatures; please consult the manufacturer for detailed specifications.

5454-H32/O Aluminum for Pressure Vessels and Tankers

Advantages:

Excellent corrosion resistance, especially in marine and chemical environments.

Medium to high strength, suitable for welded structures such as pressure vessels.

Disadvantages:

Depending on the market, cost may be higher than other options.

Other Considerations

5182 Tanker Aluminum Plate

- Advantages: Developed specifically for the storage and transport of hazardous materials, compliant with the latest ADR regulations. High strength and corrosion resistance.

- Disadvantages: Since it is specifically designed for hazardous material transport, the price may be higher than other alloys.

5083 Tanker Aluminum Plate

- Advantages: Frequently used for tankers due to its high strength and weldability.

- Disadvantages: In some environments, corrosion resistance may be slightly lower than 5454.

5454 Tanker Aluminum Plate Material Characteristics

- Corrosion Resistance: As a typical rust-resistant aluminum, 5454 alloy performs excellently in humid and chemical environments, making it particularly suitable for fuel transport applications.

- Strength and Toughness: Tensile strength is approximately 20% higher than 5052 aluminum plates, while maintaining good plasticity and formability, making it easy to process into tank structures.

- Fabrication Performance: Supports cutting, bending, welding, and other processes, accommodating customized requirements for tanker anti-slosh baffles, oil baffles, and other components.

5454 Aluminum Plate Temper Selection for Tankers

For the best combination of tanker body strength and formability, choose the following material:

5454-H111 Aluminum Plate

Advantages:

High strength and good corrosion resistance.

Excellent weldability.

Good machinability and formability.

More corrosion-resistant than 5052.

Disadvantages:

Formability is lower than -O temper.

For maximum formability when the highest strength is not required, choose the following material:

5454-O Aluminum Plate:

Advantages:

Excellent formability and plasticity.

High corrosion resistance.

Good weldability.

Disadvantages:

Lower strength than H111 temper.

Durability may be lower under high-pressure applications.

Which 5454 Aluminum Plate is Right for You?

If your main focus is on the strength and durability of the tank body, especially for transporting hazardous or high-pressure liquids, choose 5454-H111.

If your design requires complex shapes or you prioritize the ease of forming the metal sheet, choose 5454-O, but note that compared to H111, the final tank may be less robust.

5454 Aluminum Mill Finish and Mirror Finish Differences for Tanker Use

For cost-effectiveness and simplicity, choose "Mill Finish": the cheapest, fastest to produce, and easy to paint. Suitable for transporting ordinary diesel or gasoline.

For high-end applications and sun protection, choose "Mirror Finish": suitable for regions with strong sunlight such as the Middle East; it can lower tank temperatures, reduce gasoline evaporation, and gives a premium appearance.

Choose Mill Finish:

- Cost-effective, fast for mass production

- Surface requires painting

- Suitable for transporting ordinary oils, in non-harsh environments

Choose Mirror Finish:

- Handles high temperatures and strong sunlight

- Reduces evaporation when transporting volatile media

- Achieves a high-end appearance

| Requirement Dimension | Mill Finish | Mirror Finish |

| Cost & Efficiency | Good – Low cost, suitable for large-scale production | Poor – Polishing process increases cost |

| Temperature Control | Weak – Absorbs more heat, tank temperature rises easily | Strong – High reflectivity, effectively reduces tank temperature |

| Suitable Media | Suitable for ambient temperature, non-corrosive media | Suitable for volatile media (e.g., liquefied gas) |

| Appearance | Standard industrial look | Good – Premium and aesthetically pleasing |

| Post-Processing | Surface is easy to paint and perform secondary processing | Mirror finish serves as the final treatment |

Chemical Composition of 5454 Aluminum Sheet Plate for Tanker

| Element | Composition % |

| Si | 0.25 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.5-1.0 |

| Mg | 2.4-3.0 |

| Cr | 0.05-0.20 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.20 |

| Al | Remainder |

Mechanical Properties of 5454 Aluminum Sheet Plate for Tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| O, H111 | 3.00-6.00 | 215-285 | ≥85 | ≥19 | - | 1.0t |

| >6.00-12.00 | 215-285 | ≥85 | ≥19 | - | 2.0t |

5454 vs 5083 Aluminum Plates for Tanker Applications

| Item | 5454 Aluminum Plate | 5083 Aluminum Plate |

| Alloy Series | Al-Mg (medium magnesium content) | Al-Mg (high magnesium content) |

| Typical Tensile Strength | ≥215 MPa (H32 temper) | ≥275 MPa (H32 temper) |

| Typical Yield Strength | ≥85 MPa (H32 temper) | ≥125 MPa (H32 temper) |

| Corrosion Resistance | Excellent, especially resistant to stress corrosion cracking | Outstanding, especially resistant to seawater corrosion |

| Weldability | Excellent, very low tendency for weld cracking | Good, but requires tighter control of heat input |

| Formability | Good | Good (but higher strength causes slightly more springback) |

| Maximum Service Temperature | ~150°C | ~65°C |

| Main Application Focus | Ttanker bodies, pressure vessels, chemical equipment | Shipbuilding, maritime equipment, special tanks, military vehicles |

Strength vs. Corrosion Resistance:

5083 has higher strength (approximately 20-30% higher than 5454), which means that for the same load requirements, wall thickness could potentially be reduced, achieving lightweight design.

5454 has medium strength but outstanding resistance to stress corrosion cracking. Stress corrosion cracking (SCC) occurs when tensile stress and specific corrosive media act together to cause brittle fracture; this is a critical consideration for tanker bodies subjected to liquid sloshing and road vibrations.

High-Temperature Performance – Decisive Advantage:

This is a key feature of 5454 in tanker applications. Its maximum continuous service temperature can reach 150°C, whereas 5083's SCC resistance significantly decreases above 65°C.

Tank temperatures may rise when transporting certain chemicals or under prolonged sun exposure in hot regions. Additionally, during welding, the heat-affected zone experiences high temperatures, and 5454 maintains more stable performance in such conditions.

Weldability and Regional Preferences:

5454 has very stable weldability, maintaining high post-weld strength, low crack sensitivity, a wider process window, and easier quality assurance.

5083 also has good weldability, but due to its higher magnesium content, improper heat input control can cause welding issues.

This partly explains regional preferences: in North America (e.g., Mexico's tanker manufacturing centers), the focus is on balanced overall performance, process stability, and high-temperature adaptability, so 5454 is commonly used. In Europe and other regions, where higher strength, lightweight design, and moderate environmental temperatures are prioritized, 5083 is more frequently used.

5454 Aluminum Plate Selection and Procurement Guide

Material Selection and Fabrication Considerations

When selecting and using 5454 aluminum plates for tanker manufacturing, the following points should also be considered:

- Regional preferences and selection: Different regions have different choices for tanker aluminum. For example, 5454 aluminum plates are more common in North America (e.g., Mexico), whereas 5083 alloy is more prevalent in Europe, South America, and Asia. Decisions should be based on target market requirements or specific customer specifications.

- Professional welding process to ensure quality: Tanker body weld quality is critical. Professional automated welding processes can effectively control heat input and, using special techniques such as backfilling-free self-fusion, significantly reduce back-side porosity defects, improving weld quality and pass rates.

- Confirm material certification and standards: When purchasing, ensure the supplier provides material certifications and test reports that meet tanker manufacturing standards.

How to choose the right aluminum plate for your tanker project?

Prefer 5454 if:

The transported medium is corrosive or chemically complex.

The vehicle operates mainly in hot climates, with large day-night temperature differences, or under prolonged sun exposure.

Welding process stability and pass rate are top priorities.

Following North American market or related customer technical standards.

Consider 5083 if:

Pursuing extreme lightweight and higher strength (allowing thinner walls under regulations).

Transporting non-corrosive or very mildly corrosive media (e.g., certain refined oils).

Vehicle operating environment has moderate temperatures.

Following European or related market technical traditions.

Practical Procurement and Fabrication Tips

- Clarify standards: When requesting quotations and procuring, clearly specify the required material standards (e.g., ASTM B209, EN 485), alloy grade (5454), temper (H32), thickness tolerance, and dimensional requirements in the contract.

- Supplier qualifications: Choose suppliers capable of providing authoritative third-party test reports (e.g., SGS), and verify their track record of supplying reputable tanker manufacturers.

- Welding procedure qualification: Before mass production, perform welding procedure tests using the specific batch of 5454 aluminum plate you purchased. Determine optimal welding wire type (e.g., ER5356), shielding gas, current, and voltage parameters to verify weldability.

5454 Aluminum Tanker Plates FAQ

Why is 5454 aluminum alloy particularly suitable for tanker manufacturing?

- Excellent corrosion resistance: Can resist corrosion from various chemicals, petroleum products, food, and other liquids, ensuring the purity of transported media and long service life of the tank itself.

- Good resistance to stress corrosion cracking: SCC is a critical failure mode under pressure, transport vibration, and residual welding stresses. 5454 alloy performs exceptionally in this regard, offering high safety.

- Medium to high strength: Stronger than commonly used 5052 alloy, capable of withstanding internal tank pressure and various mechanical loads during transport, enabling lightweight tank design.

- Excellent weldability: Weld joints have high strength, are less prone to cracking, and the welding process is mature and reliable.

- Good formability: Easily processed into complex tank shapes through stamping, rolling, and other methods.

What are the common tempers of 5454 aluminum tanker plates?

- H32: Strain-hardened temper, 1/4 hard. This is the most commonly used temper, achieving a good balance between strength and formability.

- H34: Strain-hardened temper, 1/2 hard. Higher strength than H32, suitable for areas requiring greater strength.

- H111: Suitable for products with lower work hardening than H11. Retains good formability.

- O temper: Annealed, softest texture, best formability. Typically used for components requiring deep drawing or severe deformation.

What are the differences between 5454 and the common 5052 and 5083 aluminum alloys?

| Property | 5454 | 5052 | 5083 |

| Magnesium Content | Medium (2.4-3.0%) | Low (2.2-2.8%) | High (4.0-4.9%) |

| Strength | Medium-high | Medium | Very high |

| Corrosion Resistance | Excellent, good SCC resistance | Good | Excellent, but SCC sensitivity higher than 5454 in certain environments |

| Weldability | Excellent | Good | Excellent, but slightly higher susceptibility to hot cracking than 5454 |

| Applications | Road tankers, chemical tanker bodies | Interior parts, non-pressure components, construction | Ships, marine facilities, pressure vessels |

- 5454 is the "gold standard" for road tankers, achieving the best balance of strength, corrosion resistance, and weldability.

- 5052 has lower strength and is often used in less demanding applications or non-pressure parts of tankers.

- 5083 has the highest strength, but cost and SCC sensitivity are relatively higher, making it more suitable for ships and low-temperature pressure vessels.

What should be noted when welding 5454 aluminum plates?

Welding wire selection: Typically recommended to use 5356 or 5183 wire.

What media can 5454 aluminum tanker plates transport?

Due to its excellent corrosion resistance, 5454 aluminum plates are widely used for transporting:

- Petrochemical products (e.g., gasoline, diesel)

- Chemicals (e.g., certain alcohols, aldehydes)

- Food (e.g., cooking oil, juice, alcoholic beverages)

- Other non-strong acid or strong alkali liquids

Important note: Before transporting specific chemicals, the compatibility of the medium with the aluminum alloy must be confirmed to avoid corrosive reactions.