3004 Corrugated Aluminum Plate is an aluminum-magnesium-manganese alloy material, commonly used in building roofing, wall cladding, and other fields. It features lightweight, corrosion resistance, and high strength.

3004 corrugated aluminum plate is made from 3004 aluminum alloy as the base material, formed into a corrugated cross-section through cold bending or rolling processes. This material combines the corrosion resistance of 3004 alloy with the mechanical advantages of the corrugated structure.

3004 corrugated aluminum plate is a corrosion-resistant, non-heat-treatable aluminum alloy sheet. Similar to 3003, it contains an additional 1% magnesium to enhance strength. This lightweight material is widely used for its durability, especially suitable for roofing and wall panels. The corrugated design enhances structural integrity and aesthetic appeal of roofs, while its formability, coating, and customization options further extend its versatility.

3004 Corrugated Aluminum Plate Materials and Properties

3004 aluminum alloy is an aluminum-manganese alloy, containing a higher amount of manganese, which enhances its corrosion resistance and strength, making it suitable for long-term use in harsh environments.

- Composition: Manganese aluminum alloy with a small amount of magnesium, offering higher strength compared to 3003 alloy.

- Durability: Highly resistant to rust and corrosion.

- Non-heat-treatable: Cannot be strengthened through heat treatment.

- Strength: Compared to regular aluminum plates, 3004 aluminum alloy has a higher tensile strength, capable of withstanding greater mechanical stress and wind pressure, making it suitable for building structures with high strength requirements.

- Corrosion Resistance: 3004 aluminum alloy demonstrates excellent corrosion resistance, especially in humid, marine, and acidic or alkaline environments, maintaining its structural stability and appearance over extended periods.

- Formability: 3004 aluminum alloy has excellent workability and formability. It can be manufactured into various shapes of corrugated aluminum plates using methods such as hot pressing and stamping to meet different design needs.

- Lightweight: Due to its corrugated structure, the 3004 corrugated aluminum plate provides high strength while effectively reducing weight, making it easier to transport and install.

- Impact Resistance and Shock Absorption: Due to its unique structure, the corrugated aluminum plate has strong impact resistance and can absorb external vibrations and shocks, thus extending its service life.

3004 Corrugated Aluminum Plate Specifications

| Alloy | 3004 |

| Temper | H14 |

| Thickness | 0.2-6.0mm |

| Width | 200-2650mm |

| Length | 1-10mm |

| Wave height | 17-18 mm |

| Coating | Galvanized, color coated |

| Standard | GB/T 3880-2005, B209-2020, JC/T 1074-2012, ASTM A1196-2020, ISO 9001, CE, SGS |

| Remark | Specifications can be customized |

Popular 3004 Aluminum Corrugated Panels for Roofing and Cladding

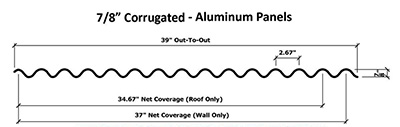

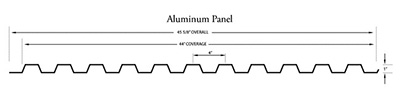

7/8" 3004 Corrugated Aluminum Sheet

Rib Height: 7/8"Rib Distance (Pitch): 2.67"

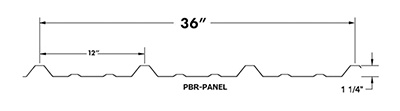

PBR 3004 Aluminum Wall Panels

Rib Height: 1.25 inchesRib Distance (Pitch): 12"

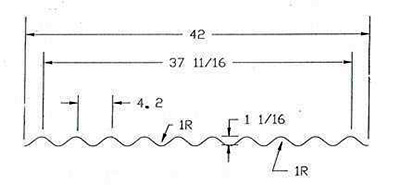

4.2 Inch 3004 Corrugated Aluminum Sheet

Rib Height: 1/16"Rib Distance (Pitch): 4.2"

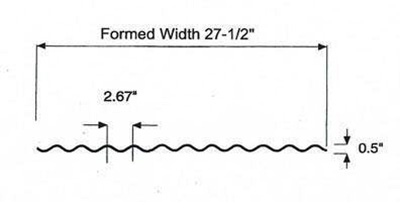

2.5" x 0.5" 3004 Corrugated Aluminum Panel

Rib Height: 1/2"Rib Distance (Pitch): 2.67"

1.25 inch x 0.25 inch 3004 Corrugated Aluminum Panel

Rib Height: 1/4"Rib Distance (Pitch): 1 1/4"

3004 Aluminum Stucco Embossed Mill Finish 4" Rib

Rib Height: 1"Rib Distance (Pitch): 4"

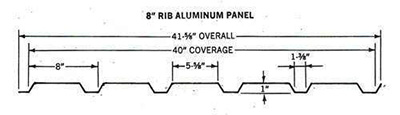

3004 Aluminum Stucco Embossed Mill Finish (8" Rib)

Rib Height: 1"Rib Distance (Pitch): 8"

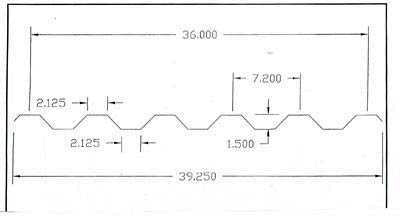

7.2 3004 Corrugated Aluminum Sheet

Rib Height: 1.5"Rib Distance (Pitch): 7.2"

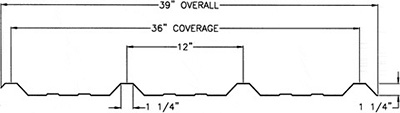

12" rib (R Panel) 3004 Corrugated Aluminum Sheet

Rib Height: 1 1/4"Rib Distance (Pitch):12"

3004 Corrugated Aluminum Plate Surface Treatments

PVDF 3004 Corrugated Aluminum Plate

After PVDF coating, the 3004 corrugated aluminum plate surface forms a highly weather-resistant layer that can withstand UV rays, rain, acid rain, and other environmental corrosion. The coating is vibrant, durable, and fade-resistant, suitable for exterior wall decoration, roof covering, and industrial buildings. PVDF-coated plates combine lightweight and corrosion-resistant properties, reducing maintenance costs while maintaining the strength advantage of aluminum.

Key Advantages:

- High weather resistance, long-lasting color

- Corrosion and oxidation resistance

- Aesthetic appeal, customizable in multiple colors

- Easy to clean and maintain

Anodized 3004 Corrugated Aluminum Plate

The anodized 3004 corrugated aluminum plate forms a hard and dense oxide film on the surface, which not only enhances corrosion resistance but also improves wear resistance. The oxide film bonds tightly with the aluminum substrate, preventing oxidation and environmental erosion, and provides a natural metallic luster or colored finish. Anodized plates are widely used in building decoration, curtain walls, roofing, and industrial facilities, offering both aesthetic appeal and durability.

Improves corrosion and wear resistance High surface hardness, extends service life Can achieve natural metal color or dyed effect Environmentally friendly and easy to maintain

Color Coated 3004 Corrugated Aluminum Plate

Color-coated 3004 corrugated aluminum plate is coated with multiple layers of organic coatings on the substrate and baked to form a uniform, durable colored surface. This treatment not only provides a wide range of color options but also improves the corrosion resistance and decorative effect of the plate. Color-coated aluminum plates are widely used in commercial buildings, industrial plants, roofs, walls, and decorative panels, combining aesthetics with long-term stability.

Key Advantages:

- Rich colors, customizable

- Enhanced corrosion resistance

- Uniform coating, smooth surface

- Aesthetic and durable, suitable for building decoration

Advantages of Corrugation

Key Advantages:

- Structural Integrity: Corrugated pattern enhances aluminum plate strength and stiffness.

- Aesthetic Appeal: Provides classic visual attraction for roof and wall applications.

- Functionality: Wave design helps with waterproofing and facilitates construction.

3004 Corrugated Aluminum Plate Applications

Construction Industry

- Roofs and Walls: The 3004 corrugated aluminum plate is widely used for exterior wall decoration and roofing in buildings, especially in areas that require windproof, waterproof, and corrosion-resistant properties. Its corrugated shape is not only aesthetically pleasing but also effectively enhances the rigidity of the structure, ensuring long-term use without deformation.

- Exterior Decoration: In modern architectural exteriors, the appearance and durability of 3004 corrugated aluminum plates make them ideal materials for commercial buildings, factories, warehouses, and other large structures.

Transportation Industry

- Containers and Vehicles: Due to its lightweight and corrosion resistance, 3004 corrugated aluminum plate is commonly used in containers, vehicle exteriors, and other structural components of transportation vehicles, capable of withstanding various environmental challenges encountered during transportation.

- Soundproofing and Shock Absorption: In transportation vehicles and containers, the shock resistance of 3004 corrugated aluminum plates makes them an ideal choice for soundproofing and vibration-damping materials.

Other Applications

- Fireproof and Thermal Insulation: The structure of 3004 corrugated aluminum plates helps improve thermal insulation and fire resistance, making them suitable for various applications that require heat insulation.

- Environmental Applications: This material is non-toxic, non-polluting, and meets modern environmental requirements, making it widely used in green building and environmental projects.

3004 Corrugated Aluminum Plate Chemical Composition Limits

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al Min |

| 3004 | 0.30 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | – | 0.25 | 0.25 | 0.05 | 0.15 | Remainder |

Typical Mechanical Properties Data Of Aluminum 3004

| Alloy-Temper |

Tensile Strength (ksi) |

Yield Strength (ksi) |

Elongation (%) |

| 3004-O | 26 | 10 | 19 |

| 3004-H34 | 39 | 29 | 5 |

| 3004-H38 | 41 | 36 | 4 |

The 3004 corrugated aluminum plate, with its outstanding performance, especially in strength, corrosion resistance, formability, and lightweight advantages, is widely used in construction, transportation, industry, and other fields. It not only withstands various complex external environments but also effectively reduces maintenance costs, making it an ideal material choice for modern construction and engineering.