Kitchenware Aluminum Circle Disc 1060 is a widely used aluminum alloy material in kitchenware, particularly suitable for the manufacturing of cookware, frying pans, and other cooking utensils. This aluminum disc is the material of choice in kitchenware manufacturing due to its high purity, excellent thermal conductivity, and outstanding corrosion resistance.

1060 Aluminum Circle Disc combines advantages such as lightweight, uniform heat dissipation, corrosion resistance, and safety, making it the preferred material for cookware components (such as pots, frying pans, and pressure cooker bases). It offers excellent formability and diverse processing options (deep drawing, stamping, painting, anodizing).

Thanks to its easy formability, thermal efficiency, and cost-effectiveness, 1060 Aluminum Circle Disc is an ideal choice for kitchenware. Its high purity ensures safety in food-contact applications, while customizable tempers (O, H12, H24) balance ductility and strength. For premium applications such as non-stick or pressure cookers, combining 1060 with protective coatings or alloy blends (such as 3003) can further enhance performance.

Why 1060 Aluminum Circles are Ideal for Kitchenware

| Feature | Benefit in Kitchenware |

| High purity and safety | Non-toxic, food-safe, no alloying contaminants |

| Excellent thermal conductivity | Even heating, rapid temperature response |

| Great formability | Easy to shape into complex cookware components |

| Strong corrosion resistance | Durability against cooking acids and moisture |

| Customizable strength | Temper options allow tailoring stiffness and rigidity |

| Non-toxic and recyclable | Environmentally-friendly and safe for food contact |

1060 Aluminum Circle Disc Technical Specifications

Dimensions:

- Thickness: 0.3–6.0 mm (common: 0.5–1.0 mm for cookware)

- Diameter: 100–1, 500 mm

Tolerances:

- Thickness: ±3%

- Diameter: ±0.5 mm for multiples of 5mm; ±3.0 mm otherwise

Mechanical Properties by Temper:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| O (Annealed) | 60–100 | ≥15 | ≥20–35 |

| H24 | 95–135 | ≥70 | ≥6–10 |

| H18 | ≥125 | ≥85 | ≥2–4 |

1060 Aluminum Circle Disc Characteristics

Formability

Excellent ductility and machinability; easily formed by deep drawing, stamping, and spinning without cracking—ideal for cookware parts such as pot bottoms and bodies.

Thermal Conductivity

High thermal conductivity enables fast and even heating—crucial for preventing hot spots on cooking surfaces.

Corrosion Resistance

Naturally forms a protective oxide layer that resists acids, salts, and moisture commonly encountered in cooking environments.

Strength Characteristics

Low strength in annealed O temper, but can be strengthened through cold working.

Other Properties

Lightweight, recyclable, non-toxic, and safe for direct contact with food.

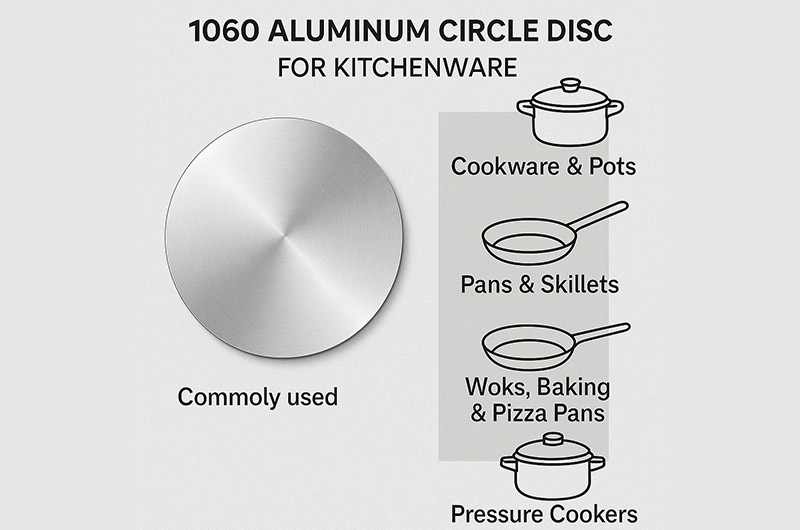

Kitchenware Aluminum Circle Disc 1060 Applications

1060 aluminum alloy circle discs (Aluminum Circle Disc 1060) are widely used in the manufacturing of kitchenware due to their excellent physical properties, such as superior thermal conductivity, corrosion resistance, and good machinability.

Types of Kitchenware Suitable for 1060 Aluminum Circle

- Main Products: Non-stick pans, pressure cookers, kitchen sinks, cooking containers, tableware (such as pot lids, serving plates)

- Special Uses: Baking molds, food packaging cans (concave utensils requiring deep drawing or spinning)

| Kitchenware | Application Description | Advantages |

| Cookware and Pots | Aluminum Circle Disc 1060 is used in the bottom or entire body of pots, providing quick and even heating. | Fast Heating |

| Even heat distribution, preventing localized overheating | ||

| Improved cooking efficiency | ||

| Prolongs the lifespan of cookware | ||

| Frying Pans | Aluminum Circle Disc 1060 is used as the base material for frying pans, ensuring uniform heat distribution and preventing food from burning. | Even heating, preventing localized overheating |

| Lightweight and easy to handle | ||

| High temperature resistance, suitable for high-temperature cooking | ||

| Woks | Aluminum Circle Disc 1060 is used at the bottom of woks, ensuring uniform heat transfer and enhancing high-temperature heating during stir-frying. | Efficient heat transfer, reducing food sticking to the pan |

| Rapid heating, saving cooking time | ||

| Excellent even heat distribution | ||

| Baking Pans | Aluminum Circle Disc 1060 is used at the bottom of baking pans, ensuring uniform heat distribution to prevent uneven cooking or burning. | Even heating, preventing localized charring |

| Increased cooking efficiency, reducing the risk of food burning | ||

| Skillets | Aluminum Circle Disc 1060 is used at the bottom of skillets, ensuring even heat distribution during frying, preventing food from burning or being unevenly cooked. | Quick response to temperature changes |

| Even heat distribution | ||

| Improves frying results, preventing localized burning or uneven cooking |

Cookware and Pots

Due to the high thermal conductivity and low thermal expansion coefficient of 1060 aluminum alloy, it can quickly and evenly transfer heat, preventing localized overheating or burning of food. This makes it an ideal material for cookware and pots.

- Bottom Material: In traditional cookware manufacturing, the heat transfer performance of the bottom of the pot is crucial. The 1060 aluminum circle disc ensures that heat is evenly distributed across the bottom of the pot, preventing heat accumulation and improving cooking efficiency. Its strong thermal conductivity helps shorten heating times, saving energy.

- Entire Pot Body: Not just for the bottom, 1060 aluminum alloy discs can also be used to make the entire pot body. Due to its low density and high strength, aluminum pots are lighter, making them easier to handle, and also have better corrosion resistance, extending the pot's lifespan.

Frying Pans

Frying pans typically require even heat distribution to prevent food from burning due to localized overheating during cooking. The 1060 aluminum alloy circle disc, with its excellent thermal conductivity, is the ideal material for the bottom of frying pans.

- Even Heating: The aluminum alloy circle disc quickly transfers heat evenly to every part of the frying pan, ensuring uniform heat distribution for the food and preventing hot and cold spots, thus reducing the risk of food burning or uneven cooking.

- High-Temperature Resistance: 1060 aluminum alloy has good high-temperature resistance and can withstand high temperatures during everyday cooking, such as frying and high-temperature sautéing. Even with prolonged high-temperature use, it maintains stable performance.

- Lightweight: Compared to other metal materials, 1060 aluminum alloy has a lower density, making frying pans not only lightweight but also easy to handle, ideal for daily cooking use.

Other Kitchenware (Woks, Baking Pans, Skillets, etc.)

In addition to traditional cookware, 1060 aluminum circle discs are also widely used in the manufacture of other kitchen utensils, such as woks, baking pans, skillets, etc. These utensils all have high demands for heat transfer performance.

- Woks: Woks require rapid heating and the ability to maintain even heat distribution at high temperatures to prevent food from sticking or overheating. The 1060 aluminum alloy circle disc, with its high thermal conductivity, ensures that woks heat quickly and evenly, improving cooking efficiency.

- Baking Pans: During baking, even heat distribution is crucial for proper food cooking. The 1060 aluminum circle disc provides uniform heat at the bottom of the baking pan, ensuring the food cooks evenly and prevents some areas from becoming overcooked or undercooked.

- Skillets: Skillets require precise temperature control during cooking to avoid food burning. The 1060 aluminum alloy circle disc, used as the base material for skillets, ensures quick temperature response, allowing for rapid temperature adjustments to suit different cooking needs.

The 1060 aluminum alloy circle disc is widely used in cookware and other kitchen utensils due to its excellent thermal conductivity, lightweight, and corrosion resistance. Whether for the bottom of pots, frying pans, woks, baking pans, or skillets, using 1060 aluminum discs significantly enhances heat transfer, improves cooking efficiency and food quality, and extends the lifespan of kitchenware. This makes it an essential material choice in kitchenware manufacturing.

The 1060 aluminum circle discs are typically processed through cutting, stamping, annealing, and other processes to achieve uniform thickness and smooth surfaces. Their excellent thermal conductivity and stability allow them to be used at high temperatures for extended periods without deforming or discoloring.

Kitchenware Aluminum Circle Disc 1060 Advantages

Excellent Thermal Conductivity: The good thermal conductivity of 1060 aluminum alloy enables kitchenware to heat up quickly and evenly, preventing localized overheating and helping to improve cooking efficiency. Durability: The high-purity aluminum alloy provides higher high-temperature resistance, allowing it to withstand prolonged high-temperature use and reduce deformation and damage. Easy to Clean and Maintain: Due to its smooth surface, 1060 aluminum circle discs are easy to clean after use, with food residue not easily sticking to it. Its strong corrosion resistance also prevents rusting due to prolonged exposure to moisture. Lightweight: Compared to other materials, aluminum alloy is lighter in weight, reducing the overall weight of utensils, making them more convenient to use.

The 1060 aluminum circle disc is an ideal material for kitchenware. With its high purity, excellent thermal conductivity, corrosion resistance, and formability, it is widely used in the manufacturing of cookware, frying pans, and other cooking utensils. Its high-temperature resistance, even heating, and easy-to-clean features make it advantageous for long-term use in the kitchen environment, offering efficient and durable solutions for both home and commercial kitchens.

Chemical Compositions of 1060 Aluminium Circle

| Alloy | Min. AL | Si | Fe | Cu | Mn | Mg | Ni | Zn | V | Other |

| 1060 | 99.6% | 0.25% | 0.35% | 0.05% | 0.03% | 0.03% | - | 0.05% | 0.05% | 0.03% |

Mechenical Property of Kitchenware Aluminum Circle Disc 1060

| Alloy | Temper | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 1060 | 0 | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 |

Manufacturing Characteristics of 1060 Kitchenware Aluminum Circles

Production Process of 1060 Kitchenware Aluminum Circle

Stamped from coil, then annealed to achieve desired temper; can be pre-coated via roller coating to ensure environmental protection and finishing quality.

Production Process:

- Casting: Molten aluminum ingots are rolled into coils through hot/cold rolling

- Stamping: Precision molds punch coils into circular blanks

- Annealing: O-temper discs are heat-treated to improve formability

Surface Treatment:

- Finishes: Standard mill finish, polishing, or anodizing to enhance appearance/durability

- Suitable for non-stick coatings on cookware surfaces

- Quality Control: Strict inspection for defects (scratches, oil stains, burrs) according to ASTM/EN standards

Processing Techniques

- Stamping Forming: Blank material is cut by press and punched into discs with burr-free edges

- Temper Selection: Soft temper (O) or semi-hard (H24, H26) enhances stretchability and reduces cracking risk

- Heat Treatment: Non-heat treatable; strength improved via cold working

Comparison of 1060 Kitchenware Circles with Competing Alloys

Compared with 3003 Aluminum:

- 1060: Superior formability and lower cost; ideal for simple shapes

- 3003: Higher strength (due to manganese content), suitable for pressure cooker bodies

Compared with 5052 Aluminum:

- 1060: Better thermal conductivity

- 5052: Superior corrosion resistance (due to magnesium content), suitable for marine environments

Precautions

- Strength Limitation: Not suitable for load-bearing or high-strength components

- Surface Protection: Long-term contact with acidic foods may require protective coatings (e.g., Teflon)